Guide Contents

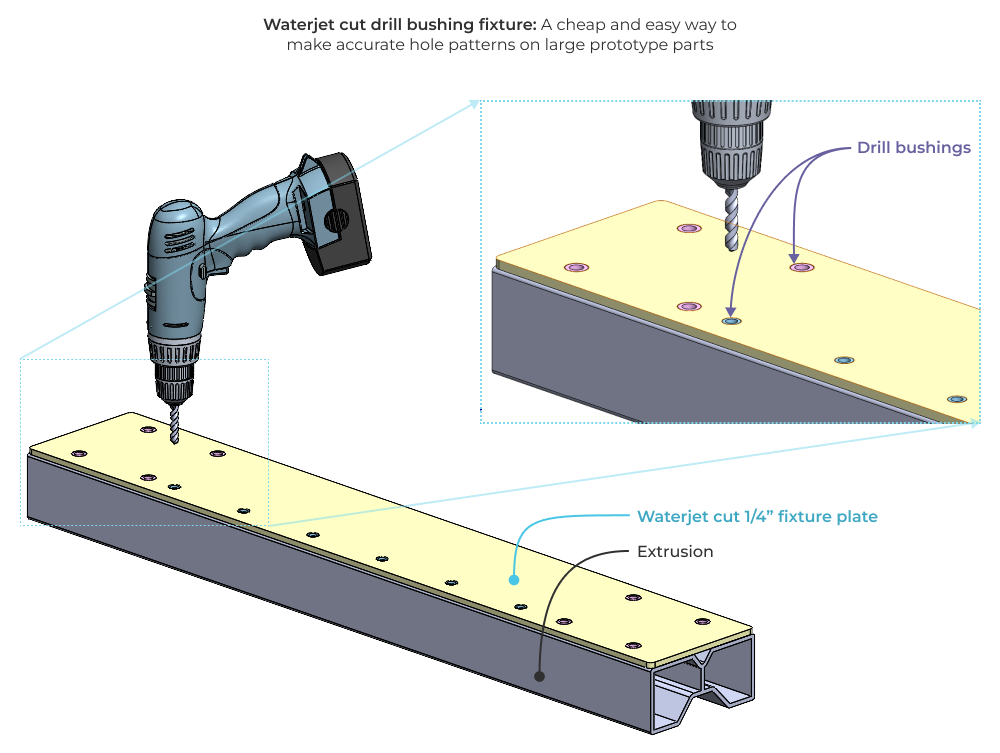

Project Insight: Accurate Waterjet Cutting Services

Why Speed & Precision Matter in Product Development

Rapid iteration requires parts that are both accurate and quickly produced to avoid bottlenecks in design cycles.

Sub-millimeter precision ensures seamless assembly, eliminating costly rework and delays in prototyping or production.

For hardware startups, balancing cost and quality is critical—every day counts in capturing market opportunities and scaling efficiently.

How Honyo Prototype Delivers Next-Gen Waterjet Cutting

Online Instant Quote: Our AI-powered platform delivers real-time pricing and lead times—no more waiting for manual quotes. Upload your design, get an instant cost breakdown, and proceed in seconds.

Precision Engineering: Advanced waterjet technology with sub-millimeter accuracy ensures complex geometries cut flawlessly, even for tight-tolerance enclosures, brackets, and chassis.

Fast Turnaround: Streamlined workflow from design to delivery—prototypes in 24-48 hours, production runs accelerated through optimized cutting paths and automated quality checks.

Cost-Effective Solutions: Tailored for sheet metal enclosures, brackets, and chassis, we maximize material utilization and minimize waste, delivering premium quality at competitive rates.

As your digital manufacturing partner, Honyo Prototype turns your designs into reality—faster, smarter, and with unparalleled precision.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

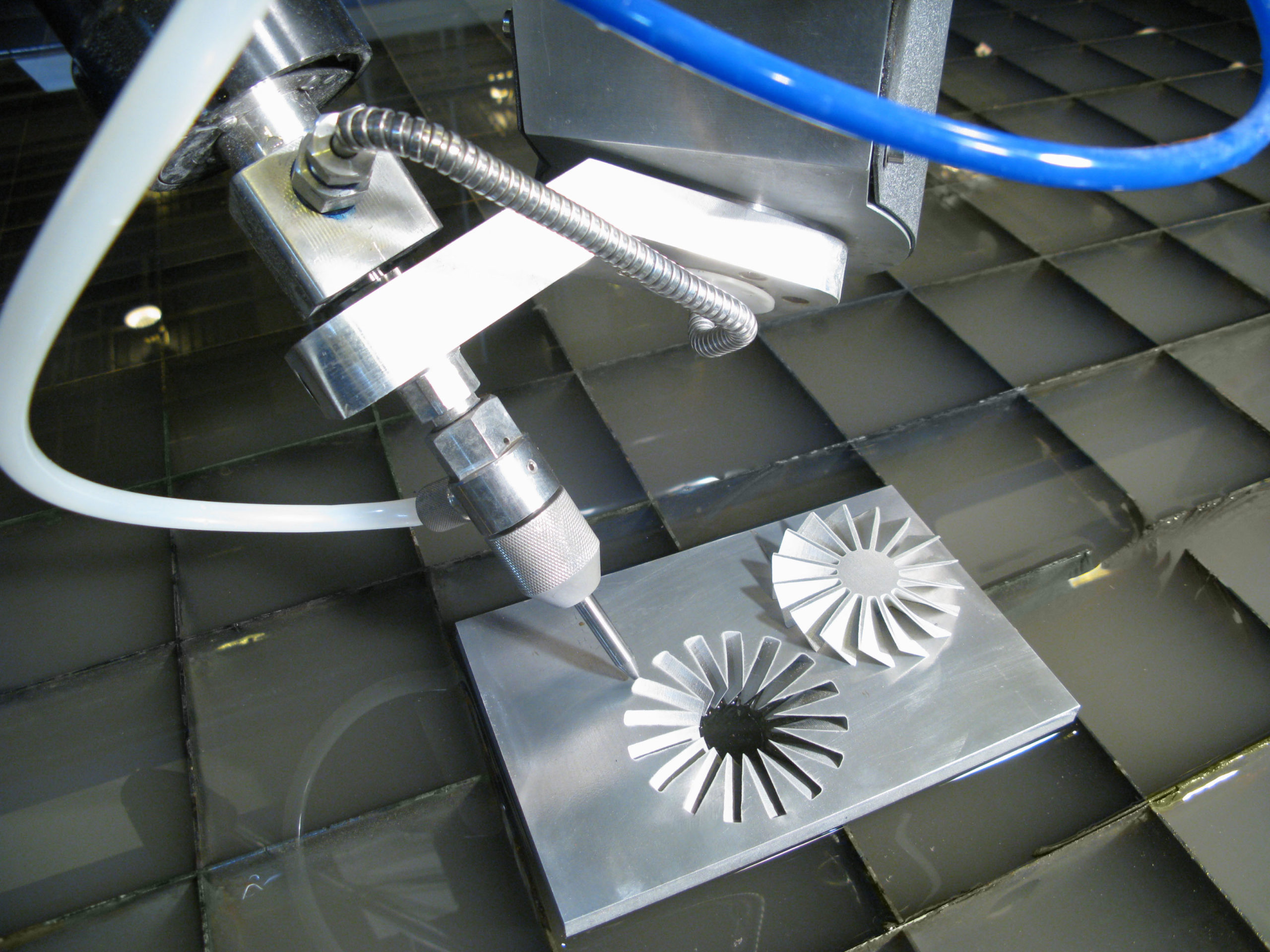

Precision Waterjet Cutting Services

State-of-the-art waterjet systems delivering ±0.001″ precision for intricate geometries and complex designs

Zero thermal distortion—ideal for heat-sensitive materials like titanium, composites, and high-strength alloys

Capable of cutting metals up to 150mm thick with smooth edges, eliminating secondary machining

Versatile material compatibility: stainless steel, aluminum, copper, brass, and non-metallics

AI-Powered Quoting & Optimization

Instant online quotes: Upload your CAD file, receive real-time pricing, lead time, and design feedback in seconds

AI-driven path optimization reduces material waste by up to 25% and accelerates production timelines

Seamless design validation for manufacturability improvements before production begins

Scalable Production Capacity

From 1 prototype to 10,000+ units with consistent precision and quality

Prototypes in 24–48 hours—flexible scheduling for urgent deadlines without compromising accuracy

Batch production optimized for cost-efficiency at any volume, from R&D to mass production

Rigorous Quality Assurance

ISO 9001 certified processes ensuring every part meets exact specifications

Multi-stage inspection protocols with 100% traceability and real-time quality monitoring

Zero-defect manufacturing commitment for mission-critical components

Why Choose Honyo for Waterjet Cutting?

Cost-effective solutions tailored for enclosures, brackets, and chassis—delivering superior value without compromising precision

End-to-end integration with our laser cutting, bending, and powder coating services for full fabrication workflows

Shenzhen-based manufacturing with global shipping, ensuring fast delivery and supply chain reliability

Innovative, solution-focused partnership: We optimize your design-to-production journey, not just cut parts

Materials & Surface Finishes

Material Options & Finishes for Precision Waterjet Cutting

At Honyo Prototype, we engineer precision from the ground up. Your choice of material and finish directly impacts performance, cost, and time-to-market. Our waterjet cutting services—backed by AI-driven optimization—deliver unparalleled accuracy for enclosures, brackets, and chassis. With real-time quoting and rapid turnaround, we turn your designs into reality faster than ever.

Precision Materials for Every Application

Aluminum (6061, 7075): Lightweight, corrosion-resistant, and ideal for aerospace and consumer electronics enclosures. Waterjet cutting preserves material integrity with zero heat distortion—critical for tight-tolerance assemblies.

Stainless Steel (304, 316): High strength and corrosion resistance for medical devices, marine components, and food-grade applications. Our waterjet process ensures burr-free edges for seamless welding and assembly.

Mild Steel (A36, 1018): Cost-effective structural solution for brackets and chassis. Waterjet delivers clean, precise cuts with minimal post-processing, reducing lead times for high-volume projects.

Copper & Brass: Excellent electrical conductivity for custom connectors and heat sinks. Waterjet cutting maintains conductivity without thermal damage, ensuring optimal performance for sensitive electronics.

Premium Surface Finishes for Enhanced Performance

Anodizing: Enhances aluminum’s durability and aesthetics with customizable colors. Ideal for enclosures requiring corrosion resistance and a professional finish.

Powder Coating: Durable, eco-friendly finish for steel and aluminum. Available in matte, gloss, or textured options to match brand identity while protecting against wear.

Electroplating: Adds conductivity and wear resistance for copper and steel components—perfect for connectors and electrical housings.

Polishing: High-gloss finish for decorative or precision parts, perfect for visible surfaces requiring a luxury aesthetic.

Paint & E-Coating: Cost-effective protection for structural components with complex geometries, ensuring uniform coverage even in recessed areas.

Optimize Your Project with Honyo’s AI-Driven Material Selection

AI-Powered Optimization: Our platform analyzes your design specs, material requirements, and budget to recommend the optimal combination of material and finish—ensuring maximum precision and cost efficiency.

Online Instant Quote: Upload your CAD file and receive real-time pricing, lead times, and material suggestions in seconds—no guesswork, no delays.

Fast Turnaround: Prototype to production in 24–48 hours with our streamlined workflow and in-house finishing capabilities.

Cost-Effective Solutions: Leverage our expertise to balance performance and budget—ideal for startups scaling from prototype to volume production.

“At Honyo, we don’t just cut materials—we engineer solutions. Whether you’re prototyping a sleek enclosure or manufacturing rugged chassis, our waterjet precision + AI-driven workflow ensures your project hits the mark, every time.”

— Susan Leo, Founder of Honyo Prototype

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, our AI-driven workflow eliminates guesswork and delays—delivering precise waterjet cutting services with unmatched speed and transparency. Here’s how we transform your designs into precision parts:

1. Upload Your CAD File

Drag-and-drop your design files (STEP, DXF, DWG, IGES) into our intuitive platform

Instant automated validation checks flag potential issues before production begins

No technical expertise required—our system handles complex geometries with surgical precision

2. Instant AI-Powered Quote

Proprietary AI engine generates accurate, transparent pricing in under 60 seconds

Clear breakdown: material costs, machine time, and handling fees—zero hidden charges

Adjust variables like thickness or quantity to see real-time cost optimizations

3. Proactive DFM Analysis

Senior engineers review your design for manufacturability, suggesting cost-saving tweaks for enclosures, brackets, and chassis

Optimize tolerances, material usage, and cutting paths to maximize waterjet efficiency

Receive actionable feedback with no obligation—perfect your design before production starts

4. Rapid Production & Delivery

Streamlined workflow from waterjet cutting to secondary operations (bending, welding, powder coating) in our Shenzhen facility

Typically delivers precision parts in 3–5 business days—expedited options for urgent projects

Real-time order tracking via customer portal, with quality certifications included at every stage

Why it matters: We combine cutting-edge technology with human expertise to turn your ideas into reality faster, cheaper, and with fewer compromises—so you can focus on innovation, not logistics.

Start Your Project with Honyo

Start Your Project with Honyo Prototype

Precision Waterjet Cutting, Engineered for Efficiency

AI-Powered Instant Quote Platform: Get real-time pricing in seconds—no manual estimates. Our smart system analyzes material, thickness, and geometry to deliver accurate, competitive quotes instantly.

Optimized for Cost-Effective Production: Specializing in enclosures, brackets, and chassis, we minimize waste through intelligent cutting paths and high-efficiency workflows—delivering precision without premium costs.

Fast Turnaround, Guaranteed: Streamlined processes ensure parts ship 30–50% faster than industry averages, accelerating your time-to-market with zero compromise on quality.

Why Partner with Honyo?

Founder-Led Innovation: Susan Leo and our engineering team bring 15+ years of manufacturing expertise to every project, ensuring micron-level accuracy and seamless scalability.

End-to-End Solutions: From waterjet cutting to laser fabrication, bending, welding, and powder coating—all under one roof for end-to-end consistency and reduced supply chain complexity.

Local Expertise, Global Standards: Experience our advanced Shenzhen/Dongguan facilities firsthand—where cutting-edge technology meets agile, customer-centric manufacturing.

Ready to transform your design into reality? Contact us today:

📧 [email protected]

📞 +86 139 2843 8620

Visit our facilities in Shenzhen and Dongguan to see precision manufacturing in action—where innovation meets execution.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.