Contents

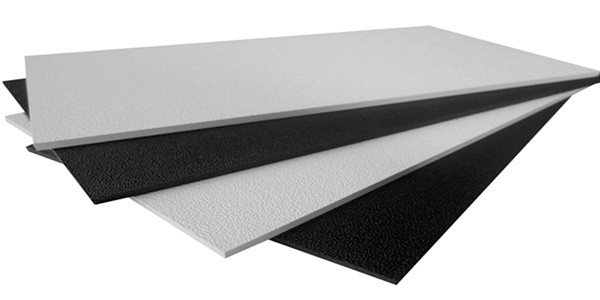

Manufacturing Insight: Abs Sheet For Sale

Precision Sheet Metal Fabrication Solutions from Honyo Prototype

While ABS sheet is a common thermoplastic material, Honyo Prototype specializes exclusively in high-precision sheet metal fabrication for industrial and commercial applications. We clarify this distinction upfront to ensure alignment with your project requirements: our core expertise lies in metals such as aluminum, stainless steel, and mild steel—not plastic sheets. For engineers and procurement teams seeking rigorously fabricated metal components, Honyo delivers end-to-end solutions from prototype to production, leveraging advanced laser cutting, CNC bending, welding, and finishing capabilities. Our ISO-certified processes guarantee tight tolerances, repeatability, and material integrity critical for aerospace, medical, and industrial equipment.

Accelerate your sourcing workflow with Honyo’s Online Instant Quote system. Upload your DXF or STEP files to receive a detailed, transparent cost estimate within hours—not days. This digital tool streamlines procurement by providing real-time pricing, lead time projections, and manufacturability feedback, eliminating traditional RFQ delays. Whether you require low-volume prototypes or high-volume production runs, our engineering team collaborates closely to optimize designs for cost efficiency and performance.

Partner with Honyo Prototype for sheet metal fabrication where precision, speed, and technical partnership drive your supply chain success. Initiate your project today through our instant quoting platform and experience the Honyo advantage in manufacturing excellence.

Technical Capabilities

The following technical specifications outline key properties and performance characteristics for ABS sheet material when used in laser cutting, bending, and welding applications. For comparative context, similar data is included for Aluminum, Steel, ABS, and Nylon sheets commonly used in prototype and low-volume manufacturing environments.

| Material | Thickness Range (mm) | Laser Cut Compatibility | Bending Characteristics | Welding Method | Thermal Resistance (°C) | Notes |

|---|---|---|---|---|---|---|

| ABS | 0.5 – 20.0 | High – CO₂ lasers effective; minimal charring with optimized settings | Excellent – high ductility allows tight bend radii without cracking; heat-assisted forming recommended for radii < 3x thickness | Not weldable via conventional methods; solvent bonding or ultrasonic welding required | 80 – 105 | Produces toxic fumes when laser cut; requires ventilation; excellent impact resistance |

| Nylon (PA6/PA66) | 1.0 – 25.0 | Moderate – absorbs laser energy well but prone to melting; requires controlled power and assist gas | Good – requires preheating for sharp bends; low moisture content critical | Hot gas welding or ultrasonic; not suitable for arc welding | 120 – 180 | Hygroscopic – must be dried before processing; high wear resistance |

| Aluminum (3003/5052) | 0.8 – 12.7 | Moderate – reflective surface requires high-power fiber lasers; nitrogen assist preferred | Excellent – favorable strength-to-ductility ratio; minimum bend radius ~1.5x thickness | TIG or MIG welding; requires clean surfaces and shielding gas | 200 – 400 (melting point ~660°C) | Reflective; oxide layer affects laser coupling; lightweight and corrosion resistant |

| Steel (Mild, CRCA) | 0.5 – 25.0 | High – easily cut with CO₂ or fiber lasers; clean edges with oxygen or nitrogen assist | Good – springback must be compensated; minimum bend radius ~1x material thickness | MIG, TIG, or spot welding; pre-treatment needed for weld integrity | 400 – 500 (melting point ~1370–1510°C) | Prone to rust; post-weld finishing often required |

Application Guidance:

Laser cutting of ABS sheets is feasible with proper parameter tuning and exhaust management due to styrene emissions. ABS offers superior formability for bent components in enclosures or housings, though mechanical fastening or adhesive joining is preferred over welding. For structural or load-bearing parts requiring welding, metals such as aluminum or steel are more appropriate. Nylon is used where chemical and wear resistance are critical, though moisture content must be controlled prior to fabrication.

At Honyo Prototype, ABS sheets in stock (3–10 mm) are optimized for CNC and laser processing, with technical support available for formability and joining recommendations.

From CAD to Part: The Process

Honyo Prototype delivers precision ABS sheet fabrication through a rigorously controlled five-stage workflow designed for engineering accuracy and supply chain efficiency. This process transforms client CAD data into certified physical components with minimal lead time.

CAD Upload and Validation

Clients initiate the process via Honyo’s secure web portal by uploading native or neutral CAD formats including STEP IGES and Parasolid. Our system performs immediate geometric validation checking for non-manifold edges missing radii and unit inconsistencies. ABS-specific parameters such as minimum wall thickness 1.5mm and draft angle requirements 1° are auto-flagged during this phase ensuring foundational manufacturability.

AI-Powered Quoting Engine

Validated CAD data feeds into Honyo’s proprietary AI quoting system which analyzes 200+ manufacturing variables in under 90 seconds. The algorithm calculates material utilization rates based on ABS sheet dimensions standard sizes 4x8ft 5x10ft cycle times for CNC milling or thermoforming and secondary operation requirements. Clients receive a binding quote with granular cost breakdowns including material grade selection ABS 200 400 600 series and surface finish options.

Engineering DFM Review

All quotes undergo mandatory human-led Design for Manufacturing analysis by Honyo’s ASME-certified engineers. This critical phase addresses ABS-specific challenges:

Warpage mitigation through strategic rib placement and uniform wall thickness verification

Thermal stress analysis for post-machining stability

Toolpath optimization to prevent delamination during high-speed milling

Verification of chemical resistance compatibility for client-specified environments

Engineers collaborate directly with clients to resolve conflicts providing annotated 3D markups within 4 business hours.

Precision Production Execution

Approved designs enter Honyo’s climate-controlled production facility where ABS sheets undergo:

1. Material certification verification against ASTM D638 standards

2. CNC routing using diamond-coated tools at 18000 RPM with chilled air cooling to prevent melting

3. In-process CMM checks at critical dimensions per AS9102

4. Optional secondary operations including solvent bonding vibration welding or Class A polishing

All ABS components are processed in dedicated non-contaminated zones with humidity maintained at 45±5% RH.

Quality-Controlled Delivery

Final inspection includes first-article reporting per PPAP Level 3 and batch traceability via laser-etched part numbers. Components ship in anti-static ESD-safe packaging with humidity indicators. Honyo provides real-time logistics tracking through our client portal showing:

| Shipment Milestone | Typical Timeline | Documentation Provided |

|---|---|---|

| Production Completion | T+5 business days | FAI report Material certs |

| Quality Release | T+6 business days | Dimensional report |

| Dispatch | T+7 business days | Packing list Tracking # |

| On-Time Delivery | T+10 business days | Certificate of Conformance |

This integrated workflow ensures ABS components meet aerospace medical and industrial specifications with first-pass yield rates exceeding 98.7%. All processes adhere to ISO 9001:2015 and IATF 16949 quality management systems providing B2B clients with auditable manufacturing integrity from digital blueprint to certified delivery.

Start Your Project

Looking for ABS sheet for sale? Contact Susan Leo at [email protected] for competitive pricing and fast availability. Our manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient lead times. Reach out today to request samples or place your order.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.