Introduction: Navigating the Global Market for able wire edm inc

In today’s competitive landscape, sourcing precision machining services like those offered by Able Wire EDM, Inc. can be a daunting challenge for international B2B buyers. With the increasing demand for high-quality electrical discharge machining (EDM) solutions across industries such as aerospace, defense, and medical, it is crucial for companies in regions like Africa, South America, the Middle East, and Europe to navigate the complexities of supplier selection. This guide serves as a comprehensive resource, addressing key considerations such as types of EDM services available, applications across various sectors, effective supplier vetting processes, and cost factors that impact procurement decisions.

By delving into the intricacies of Able Wire EDM’s offerings, this guide empowers B2B buyers to make informed purchasing decisions. It highlights the company’s extensive capabilities, including wire EDM, sinker EDM, and CNC machining, which are essential for tackling complex projects that require precision and reliability. Additionally, the guide emphasizes the importance of certifications such as AS9100:2016 and ISO9001:2015, which ensure adherence to stringent quality standards.

Through actionable insights and expert recommendations, this guide equips international buyers with the knowledge needed to partner with a trusted EDM provider like Able Wire EDM, Inc. Whether you are seeking to enhance your production processes or require specialized machining solutions, understanding the global market dynamics is key to achieving operational success.

Understanding able wire edm inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wire EDM | Utilizes a thin, electrically charged wire to cut materials. | Aerospace, Defense, Medical Devices, Tool & Die | Pros: High precision, excellent surface finish. Cons: Limited to conductive materials. |

| Sinker EDM | Employs shaped electrodes to create complex cavities. | Aerospace components, Molds, Medical implants | Pros: Capable of intricate designs. Cons: Slower than wire EDM for certain tasks. |

| Small Hole EDM | Specialized for drilling tiny, precise holes in materials. | Aerospace, Electronics, Medical device manufacturing | Pros: High accuracy for small diameters. Cons: Limited to smaller hole sizes. |

| CNC Machining | Combines traditional machining with EDM for versatile solutions. | General manufacturing, Prototyping | Pros: Versatile for various shapes and materials. Cons: May require more setup time. |

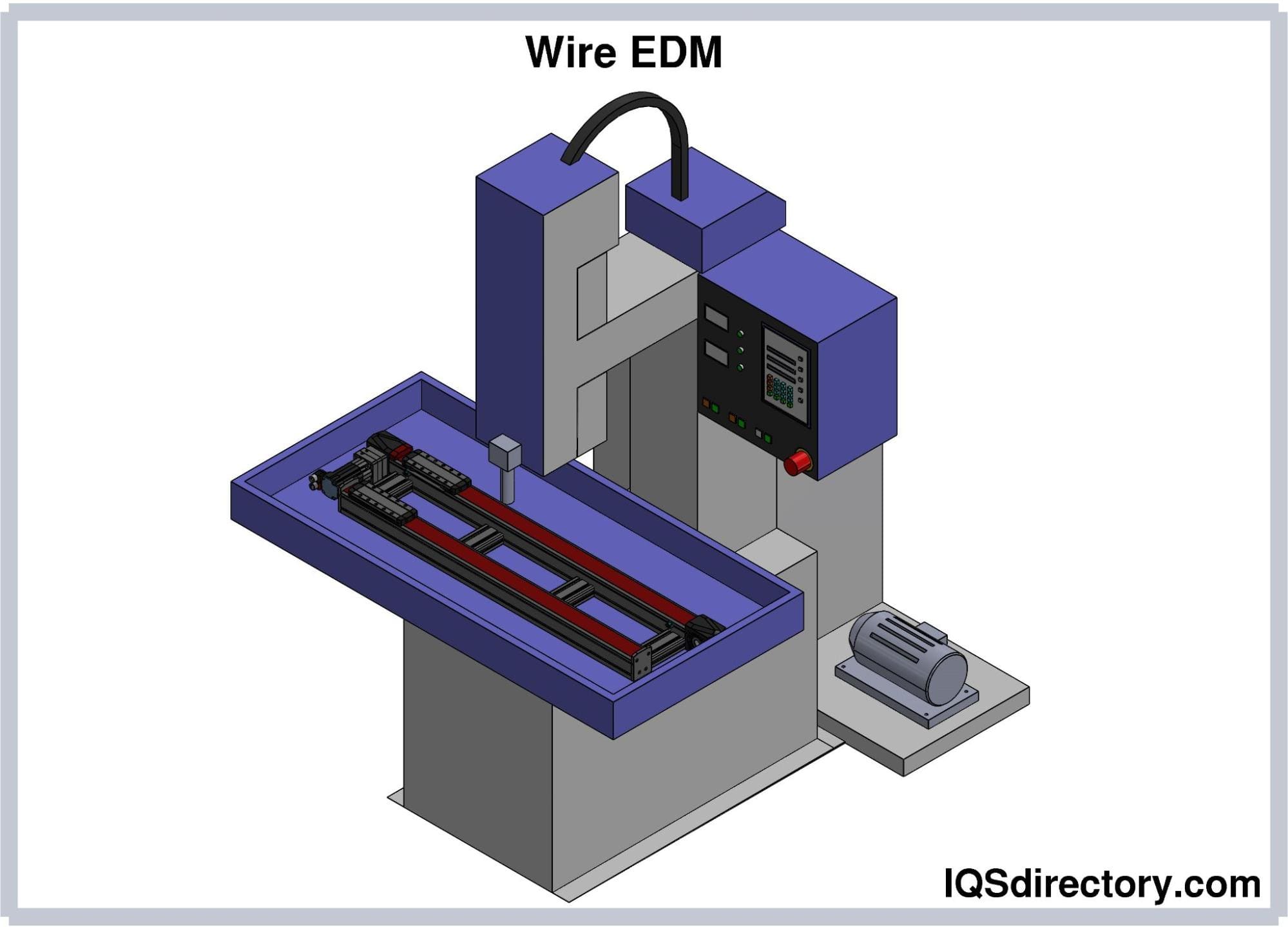

What are the Key Characteristics of Wire EDM?

Wire EDM (Electrical Discharge Machining) is renowned for its ability to achieve high precision and intricate designs. This method employs a thin, electrically charged wire that moves through the workpiece, effectively cutting conductive materials with exceptional accuracy. It is particularly suitable for industries that require tight tolerances and complex geometries, such as aerospace and medical device manufacturing. B2B buyers should consider the material compatibility and the specific tolerances required for their projects when opting for wire EDM services.

How Does Sinker EDM Differ in Application?

Sinker EDM utilizes shaped electrodes to erode material and create complex cavities and contours. This method is especially beneficial for producing intricate molds and specialized components in the aerospace and medical sectors. Its ability to handle challenging materials like titanium and inconel makes it a go-to choice for industries demanding high durability and precision. When purchasing sinker EDM services, buyers should evaluate the provider’s expertise in their specific application and the complexity of the parts required.

What Advantages Does Small Hole EDM Offer for Precision Drilling?

Small Hole EDM is designed for creating highly accurate and small-diameter holes in conductive materials. This technique is vital in sectors such as electronics and medical device manufacturing, where precision is paramount. The machines used in small hole EDM can drill holes with exceptional positional accuracy and speed, making them ideal for applications that require intricate detailing. Buyers should assess the service provider’s capabilities in handling the specific dimensions and materials needed for their projects.

Why Choose CNC Machining in Combination with EDM?

CNC Machining combines traditional machining techniques with EDM, offering a versatile solution for various manufacturing needs. This approach is particularly useful for businesses looking to produce prototypes or complex parts that require both machining and electrical discharge processes. While CNC machining provides flexibility in material selection and design, it may involve longer setup times compared to dedicated EDM processes. Buyers should consider their production timeline and the complexity of parts when deciding on CNC machining services alongside EDM.

Key Industrial Applications of able wire edm inc

| Industry/Sector | Specific Application of able wire edm inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components for aircraft systems | Enhanced safety and performance through reliable parts | Certification requirements (AS9100D, ITAR compliance) |

| Medical Devices | Surgical instruments and implants | High precision reduces risk in surgical procedures | Material compatibility and biocompatibility standards |

| Defense | Custom parts for military equipment | Improved operational efficiency and mission success | Compliance with defense regulations and standards |

| Semiconductor | Manufacturing of intricate semiconductor components | Increased yield and performance in electronic devices | Advanced quality control and precision machining needs |

| Tool & Die | Production of complex tooling for manufacturing | Optimized production processes and reduced lead times | Customization capabilities and material specifications |

How is Able Wire EDM Inc. Used in the Aerospace Industry?

In the aerospace sector, Able Wire EDM Inc. specializes in the production of precision components critical to aircraft systems, such as turbine blades, structural parts, and intricate fittings. The high precision and reliability of these components are essential for ensuring safety and performance in flight operations. International buyers from regions like Europe and the Middle East must consider certification requirements, such as AS9100D and ITAR compliance, when sourcing these components to meet stringent aviation standards.

What Role Does Able Wire EDM Inc. Play in Medical Device Manufacturing?

For medical device manufacturers, Able Wire EDM Inc. provides high-precision surgical instruments and implants that are vital for patient safety. The ability to work with difficult-to-machine materials like titanium and cobalt-chromium allows for the production of durable and biocompatible devices. Buyers from Africa and South America should focus on material compatibility and biocompatibility standards to ensure compliance with local health regulations and enhance patient outcomes.

How is Able Wire EDM Inc. Essential for the Defense Sector?

Able Wire EDM Inc. supports the defense industry by manufacturing custom parts for military equipment, including components for missiles and defense systems. The precision and reliability of these parts can significantly enhance operational efficiency and mission success. International buyers, especially from the Middle East, should ensure that sourcing partners comply with defense regulations and standards, which are critical for maintaining national security.

How Does Able Wire EDM Inc. Contribute to the Semiconductor Industry?

In the semiconductor industry, Able Wire EDM Inc. produces intricate components essential for electronic devices, such as circuit boards and connectors. The precision machining capabilities help increase yield and performance, making it a valuable partner for manufacturers. Buyers from regions like South America should prioritize advanced quality control measures and precision machining capabilities when sourcing these components to ensure optimal performance in their products.

Why is Able Wire EDM Inc. Important for Tool & Die Manufacturing?

Able Wire EDM Inc. excels in producing complex tooling for various manufacturing processes, allowing companies to optimize production and reduce lead times. The ability to customize tooling solutions to specific manufacturing needs is a significant advantage. Buyers should consider the customization capabilities and material specifications when sourcing tooling solutions to ensure they meet their unique operational requirements.

3 Common User Pain Points for ‘able wire edm inc’ & Their Solutions

Scenario 1: Complex Material Machining Challenges

The Problem: Many B2B buyers in industries such as aerospace, defense, and medical face the challenge of machining complex and difficult materials like titanium, inconel, and hastalloy. These materials often require precise tolerances and intricate designs that standard machining processes cannot achieve. Buyers may encounter delays in production schedules or increased costs when working with less experienced EDM providers who lack the necessary expertise and technology to handle these demanding materials. The frustration of reworking parts or facing production bottlenecks can severely impact their operational efficiency and profitability.

The Solution: To effectively tackle the challenge of machining complex materials, buyers should leverage the specialized capabilities of Able Wire EDM, Inc. When requesting quotes or consultations, it’s crucial to provide detailed specifications, including CAD drawings and material types. Able Wire EDM’s extensive experience with difficult-to-machine materials makes them an ideal partner for such projects. By utilizing their advanced CNC machining capabilities and expertise in electrical discharge machining (EDM), buyers can ensure precision and quality in their components. Establishing a collaborative relationship with the engineering team at Able Wire EDM will allow buyers to optimize their designs for manufacturability, thus reducing lead times and enhancing overall project success.

Scenario 2: Urgent Production Needs and Turnaround Times

The Problem: In fast-paced industries, B2B buyers often find themselves in situations where they require rapid prototypes or urgent production runs. Delays in sourcing parts can lead to missed deadlines, lost contracts, and dissatisfied clients. This is especially true for companies in sectors like medical device manufacturing, where the demand for quick turnaround times is critical due to the nature of product development and regulatory compliance.

The Solution: Buyers can address urgent production needs by utilizing the quick-response services offered by Able Wire EDM, Inc. They provide expedited quoting and production services, allowing buyers to receive fast responses to their requests. To ensure that the process is seamless, buyers should communicate their timelines and urgency clearly when submitting RFQs. Including specific details about the project’s requirements, such as expected delivery dates and quantities, will help the team at Able Wire EDM prioritize and allocate resources effectively. Additionally, taking advantage of their emergency quote process, which includes direct communication with key personnel, can further streamline the project initiation, ensuring that buyers meet their critical deadlines without compromising quality.

Scenario 3: Navigating Compliance and Quality Assurance in EDM Projects

The Problem: B2B buyers in regulated industries like aerospace and medical devices must adhere to stringent compliance and quality assurance standards. Many struggle with understanding how to ensure that their suppliers meet these requirements, which can lead to complications in certification processes and product recalls. The complexity of compliance documentation and quality certifications can be overwhelming, especially for companies operating on an international scale.

The Solution: To navigate compliance and quality assurance challenges, buyers should prioritize working with suppliers like Able Wire EDM, Inc., who are AS9100D/ISO 9001:2015 certified and ITAR registered. When engaging with Able Wire EDM, buyers should request detailed documentation regarding quality control processes and certifications to ensure alignment with their own compliance requirements. Conducting a thorough audit of the supplier’s quality management system can also provide peace of mind. Buyers should actively engage in conversations about how Able Wire EDM manages quality assurance at every stage of the machining process, from initial design reviews to final inspections. By fostering open communication and understanding the supplier’s quality protocols, buyers can mitigate risks associated with compliance and improve the reliability of their supply chain.

Strategic Material Selection Guide for able wire edm inc

What Are the Key Properties and Considerations for Common Materials Used in Wire EDM?

When selecting materials for Wire EDM processes at Able Wire EDM Inc., understanding the unique properties, advantages, and challenges associated with each material is crucial. Below, we analyze four common materials frequently machined by Able Wire EDM, focusing on their characteristics relevant to B2B buyers.

1. Titanium: A Lightweight Champion with High Strength

Key Properties:

Titanium is renowned for its high strength-to-weight ratio and excellent corrosion resistance, making it ideal for aerospace and medical applications. It can withstand high temperatures and has a melting point of approximately 1,668°C (3,034°F).

Pros & Cons:

The primary advantage of titanium is its durability and resistance to environmental degradation, which is essential for components exposed to harsh conditions. However, it is relatively expensive and can present manufacturing complexities due to its toughness and tendency to work-harden.

Impact on Application:

Titanium is compatible with various media, including seawater and aggressive chemicals, making it suitable for marine and medical devices.

Considerations for International Buyers:

B2B buyers from regions like the Middle East and Europe should be aware of compliance with ASTM standards for titanium, particularly ASTM B348 for bar and rod. Understanding local regulations regarding aerospace and medical applications is also critical.

2. Inconel: The Superalloy for Extreme Environments

Key Properties:

Inconel is a nickel-chromium superalloy known for its exceptional resistance to heat and corrosion. It maintains its strength and stability at high temperatures, typically up to 1,093°C (2,000°F).

Pros & Cons:

The key advantage of Inconel is its ability to perform in extreme environments, making it perfect for aerospace and chemical processing applications. However, its high cost and machining difficulty can be limiting factors, requiring specialized techniques like those offered by Able Wire EDM.

Impact on Application:

Inconel is particularly suitable for applications involving high-pressure and high-temperature environments, such as gas turbines and nuclear reactors.

Considerations for International Buyers:

Buyers should ensure compliance with international standards like ASTM B637 and DIN 17744. In regions like Africa and South America, understanding local sourcing and supply chain logistics for Inconel can also impact project timelines.

3. Copper: The Electrical Conductor

Key Properties:

Copper is well-known for its excellent electrical and thermal conductivity, making it a preferred choice in electrical applications. It has a melting point of about 1,984°C (3,603°F) and is relatively easy to machine.

Pros & Cons:

The primary advantage of copper is its cost-effectiveness and ease of machining, which allows for rapid production cycles. However, it is less durable than other metals and can corrode over time, particularly in acidic environments.

Impact on Application:

Copper is widely used in electrical components and heat exchangers, where conductivity is paramount.

Considerations for International Buyers:

Buyers should consider compliance with JIS standards for copper products and be aware of the local market conditions that may affect copper prices and availability, particularly in regions like Vietnam.

4. Carbide: The Hardness Leader

Key Properties:

Carbide is a composite material known for its hardness and wear resistance. It can withstand high temperatures and is often used for cutting tools and wear-resistant applications.

Pros & Cons:

The significant advantage of carbide is its durability, which translates to longer tool life and reduced downtime. However, its brittleness can be a drawback, as it may fracture under high impact.

Impact on Application:

Carbide is ideal for applications requiring high precision and wear resistance, such as tooling and dies.

Considerations for International Buyers:

International buyers should ensure compliance with DIN standards for carbide products and be aware of the specific requirements for tooling applications in their respective industries.

Summary Table of Material Selection for Able Wire EDM Inc.

| Material | Typical Use Case for Able Wire EDM Inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components, medical devices | High strength-to-weight ratio, corrosion resistance | Expensive, complex to machine | High |

| Inconel | Gas turbines, nuclear reactors | Excellent heat and corrosion resistance | High cost, difficult to machine | High |

| Copper | Electrical components, heat exchangers | Cost-effective, easy to machine | Less durable, prone to corrosion | Medium |

| Carbide | Cutting tools, wear-resistant applications | Exceptional hardness and durability | Brittle, can fracture under impact | Medium |

This analysis provides a comprehensive overview of common materials used in Wire EDM processes, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for able wire edm inc

What Are the Typical Manufacturing Processes at Able Wire EDM Inc.?

Able Wire EDM Inc. employs a sophisticated approach to manufacturing, particularly in the realm of Electrical Discharge Machining (EDM). The processes are designed to cater to complex machining requirements for industries such as aerospace, defense, and medical devices. The manufacturing stages can be divided into four main phases: material preparation, forming, assembly, and finishing.

How Is Material Prepared for EDM Processes?

The journey begins with material preparation, where raw materials are sourced based on stringent specifications. Able Wire EDM specializes in challenging materials like titanium, hastelloy, and inconel, which require careful handling. The materials undergo thorough inspection to ensure they meet the required standards. This includes checking for imperfections and verifying dimensions, which is crucial for maintaining the integrity of the final product.

What Techniques Are Used in Forming and Machining?

In the forming stage, Able Wire EDM utilizes advanced CNC technology to execute precision machining tasks. The company operates an extensive fleet of EDM machines, including 16 CNC 4-Axis Wire EDMs and various sinker and small hole EDM machines. These machines operate on the principle of electrical discharges that erode material to create intricate shapes and cavities. The use of submerged cutting and automatic wire threading enhances both accuracy and efficiency, allowing for the production of complex geometries that are often required in high-tech applications.

How Is Assembly Managed in the Manufacturing Process?

Although Able Wire EDM primarily focuses on EDM processes, assembly is an integral part of the production flow for certain projects. When assembly is required, the company employs meticulous techniques to ensure that each component fits precisely into its designated place. This may involve additional machining or adjustments to accommodate the specific requirements of the assembly. The engineering team plays a crucial role in overseeing this phase, ensuring that all parts meet the design specifications before moving on to the finishing stage.

What Finishing Techniques Are Applied to Ensure Quality?

The finishing stage is where the final touches are added to the components. This may involve polishing, surface treatment, or additional machining to achieve the desired surface finish and dimensional accuracy. The company’s climate-controlled facilities help maintain optimal conditions for these processes, reducing the risk of defects caused by environmental factors.

How Does Able Wire EDM Inc. Ensure Quality Assurance in Manufacturing?

Quality assurance at Able Wire EDM is paramount, especially given its certifications such as AS9100D and ISO 9001:2015. These international standards not only reflect the company’s commitment to quality but also enhance its credibility in the global market. The quality assurance process is multi-faceted, involving various checkpoints throughout the manufacturing lifecycle.

What International Standards Govern Quality Assurance?

Able Wire EDM adheres to several international standards, including ISO 9001 for quality management systems and AS9100 for aerospace quality management. These certifications require regular audits and strict adherence to documented procedures, ensuring consistency and reliability in the manufacturing process. Additionally, the company is ITAR registered, which is essential for businesses dealing with defense-related products.

What Are the Key Quality Control Checkpoints?

The quality control (QC) process includes several checkpoints, categorized as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC: This initial checkpoint involves inspecting incoming materials to verify their compliance with specifications before they enter the production line.

-

IPQC: During the manufacturing process, continuous monitoring is conducted to ensure that each stage adheres to quality standards. This may include dimensional checks and functional tests.

-

FQC: The final inspection is crucial, where the completed components undergo rigorous testing to ensure they meet all design and quality specifications. This could involve functional testing, visual inspections, and measurement verifications.

What Testing Methods Are Commonly Used in Quality Assurance?

Able Wire EDM employs a variety of testing methods to validate the quality of its products. Common techniques include:

- Dimensional Inspection: Utilizing precision measuring tools to ensure components meet specified tolerances.

- Functional Testing: Assessing the performance of parts under operational conditions to ensure they function as intended.

- Material Analysis: Conducting tests such as hardness testing and chemical composition analysis to verify material properties.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is essential. There are several avenues to ensure that suppliers meet quality standards:

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers can conduct supplier audits to assess the manufacturer’s compliance with quality standards. This may involve on-site visits to review the manufacturing processes, quality control procedures, and certifications. A thorough audit can reveal a supplier’s commitment to quality and their ability to meet specific requirements.

How Can Quality Reports and Certifications Be Accessed?

Requesting quality reports and certification documentation is another effective way to gauge a supplier’s capabilities. Buyers should ask for copies of ISO certifications, quality manuals, and test reports from previous projects. This documentation can provide insights into the supplier’s quality management practices and their history of compliance with international standards.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These independent entities can conduct inspections and audits, providing an additional layer of assurance that products meet required specifications and standards.

Conclusion

Able Wire EDM Inc. exemplifies excellence in manufacturing and quality assurance through its structured processes and adherence to international standards. For B2B buyers, understanding these processes and verifying supplier quality control are crucial steps in establishing reliable partnerships. By leveraging thorough audits, requesting documentation, and considering third-party inspections, buyers can ensure that they choose a supplier capable of meeting their high-quality demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘able wire edm inc’

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring services from Able Wire EDM, Inc. Whether you represent a company in Africa, South America, the Middle East, or Europe, understanding the procurement process will ensure you make informed decisions that meet your specific machining needs.

Step 1: Define Your Technical Specifications

Before initiating contact with Able Wire EDM, clearly outline your technical requirements. This includes understanding the type of materials you need processed (e.g., titanium, copper, or inconel) and the specific machining processes required (Wire EDM, Sinker EDM, or Small Hole EDM). A well-defined specification not only streamlines communication but also helps ensure that the services you receive align perfectly with your project’s demands.

Step 2: Verify Supplier Certifications

Confirm that Able Wire EDM holds relevant certifications such as AS9100D and ISO9001:2015. These certifications indicate a commitment to quality management and compliance with industry standards, which is especially crucial in sectors like aerospace and defense. Check their ITAR registration as well, especially if your project involves sensitive materials or technologies.

Step 3: Evaluate Service Capabilities

Investigate the range of services offered by Able Wire EDM. Understanding their capabilities—such as their expertise in machining difficult materials and their advanced machinery—will help you assess whether they can meet your specific needs. Look for detailed descriptions of their machining processes, including any specialized equipment that may enhance the precision and quality of your project.

Step 4: Request a Quote

Initiate a request for quotation (RFQ) by sending an email to Able Wire EDM. Include any relevant drawings, CAD files, and detailed instructions to ensure they can provide an accurate quote. A timely response is often indicative of their customer service and operational efficiency, which are critical factors in establishing a long-term partnership.

Step 5: Assess Lead Times and Production Capacity

Inquire about the lead times for your project and their overall production capacity. Understanding how quickly they can deliver your components is essential for planning your supply chain. This step is particularly important if you have tight deadlines or ongoing production needs that require consistent output.

Step 6: Check References and Past Projects

Ask for references from previous clients, especially those in similar industries or with comparable project specifications. Reviewing case studies or success stories can provide insights into Able Wire EDM’s reliability, quality of work, and ability to meet deadlines. This information can be invaluable in building confidence in your decision.

Step 7: Establish Communication Protocols

Effective communication is key to a successful partnership. Discuss and agree upon communication methods, frequency of updates, and points of contact on both sides. Establishing clear protocols ensures that any issues can be addressed promptly, leading to smoother project execution and greater satisfaction.

By following these steps, B2B buyers can streamline their sourcing process and forge a successful partnership with Able Wire EDM, Inc., ultimately enhancing their manufacturing capabilities.

Comprehensive Cost and Pricing Analysis for able wire edm inc Sourcing

What Are the Key Cost Components for Sourcing from Able Wire EDM Inc.?

When considering sourcing from Able Wire EDM Inc., understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The choice of materials significantly impacts costs, especially since Able specializes in challenging materials like titanium and inconel, which are more expensive than standard metals. Prices can vary depending on market fluctuations and availability, necessitating timely procurement.

-

Labor: Skilled labor is a critical factor in EDM processes. The complexity of the machining tasks requires experienced technicians, which can drive up labor costs. Adequate training and retention of skilled workers are vital for maintaining quality and efficiency.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Given that Able operates climate-controlled facilities, these expenses may be higher, reflecting the need for precision in the machining process.

-

Tooling: The cost of tooling can vary based on the intricacy of the parts being produced. Custom tooling may be necessary for specialized projects, impacting the overall pricing structure.

-

Quality Control (QC): Adhering to stringent quality standards, including AS9100 and ISO certifications, adds to costs but is crucial for industries like aerospace and defense. Investments in QC processes ensure that products meet regulatory and customer specifications.

-

Logistics: International shipping costs can fluctuate based on distance, shipping method, and Incoterms. Buyers must consider these factors when calculating total expenses.

-

Margin: The final pricing will also reflect the company’s desired profit margin, which can vary based on market demand and competition.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence pricing for EDM services at Able Wire EDM Inc.:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, making it essential for buyers to evaluate their needs accurately. Consolidating orders can lead to cost efficiencies.

-

Specifications and Customization: Highly customized parts typically incur higher costs due to the additional engineering and tooling required. Clear communication of specifications can help avoid costly revisions.

-

Material Selection: The choice of raw materials plays a significant role in determining the final price. High-performance materials will raise costs, but they may also provide better performance and longevity.

-

Quality and Certifications: Products that require specific certifications or compliance with international standards will generally be priced higher. Buyers should assess whether these requirements are critical to their operations.

-

Supplier Factors: The reliability and reputation of Able Wire EDM can influence pricing. Established suppliers may charge a premium for their proven track record of quality and service.

-

Incoterms: Understanding the agreed-upon Incoterms can clarify responsibility for shipping costs, insurance, and risk. This knowledge is crucial for budgeting and managing total expenses.

What Tips Can Help Buyers Negotiate Cost-Efficient Deals?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can benefit from several negotiation strategies:

-

Emphasize Total Cost of Ownership (TCO): Rather than focusing solely on initial pricing, consider the long-term costs associated with quality, durability, and maintenance. This approach can justify a higher upfront cost if it leads to lower operational expenses.

-

Negotiate Based on Volume: Leverage order size as a negotiation tool. Committing to larger volumes can yield better pricing and terms.

-

Clarify Specifications Early: Providing detailed specifications upfront can minimize revisions and associated costs later. A well-defined scope of work helps both parties understand expectations.

-

Explore Flexible Payment Terms: Discuss payment terms that can ease cash flow, such as installment payments or early payment discounts.

-

Consider Logistics in Pricing Discussions: Engage in discussions about logistics and shipping responsibilities early in the negotiation to avoid unexpected costs.

Conclusion and Disclaimer

Understanding the cost components and pricing influencers associated with sourcing from Able Wire EDM Inc. is crucial for making informed purchasing decisions. While indicative prices can provide a starting point, actual costs will vary based on specific project requirements and market conditions. Buyers should conduct thorough due diligence and engage in open discussions with suppliers to achieve the best possible terms.

Alternatives Analysis: Comparing able wire edm inc With Other Solutions

Understanding Alternatives in Electrical Discharge Machining

In the competitive landscape of electrical discharge machining (EDM), businesses often face the challenge of selecting the most suitable provider or technology for their specific machining needs. While Able Wire EDM, Inc. offers a robust array of services and capabilities, exploring alternatives can provide valuable insights into different technologies and methods that may also meet operational requirements. This analysis focuses on comparing Able Wire EDM, Inc. with two viable alternatives: traditional CNC machining and laser cutting.

Comparison Table

| Comparison Aspect | Able Wire EDM Inc | Traditional CNC Machining | Laser Cutting |

|---|---|---|---|

| Performance | High precision for complex shapes, especially in hard materials | Good for a wide range of materials, but less precision in intricate designs | Excellent for sheet metal and non-ferrous materials, fast cutting speeds |

| Cost | Generally higher due to specialized processes | Moderate; costs vary with complexity and material | Competitive, especially for large volumes |

| Ease of Implementation | Requires skilled operators and setup time | Requires programming and setup, but more familiar to many machinists | Easier setup for standard parts; less training needed |

| Maintenance | Regular maintenance needed for EDM machines | Routine maintenance required; generally straightforward | Minimal maintenance; focuses on optics and cooling systems |

| Best Use Case | Aerospace, medical, and defense industries needing high precision | General machining for various industries | High-volume production of flat parts and prototypes |

Detailed Breakdown of Alternatives

Traditional CNC Machining

Traditional CNC machining involves the use of computer-controlled machines to remove material from a workpiece to achieve desired shapes and dimensions. This method is versatile, capable of working with a wide range of materials, including metals and plastics. The primary advantages of CNC machining are its adaptability and lower costs for simpler designs. However, it may struggle with intricate geometries and the tight tolerances required in specialized sectors like aerospace and medical, where Able Wire EDM excels.

Laser Cutting

Laser cutting employs focused laser beams to melt or vaporize materials, making it a popular choice for cutting sheets of metal or other thin materials. This method is particularly advantageous for high-speed production and can achieve intricate designs with clean edges. While laser cutting is cost-effective for large volumes, it is not suitable for thicker materials or those that require high precision, such as titanium or inconel, which are commonly machined by Able Wire EDM. Additionally, laser cutting can create heat-affected zones that may alter material properties, a consideration that is critical in sensitive applications.

Conclusion: Choosing the Right EDM Solution for Your Business

For international B2B buyers evaluating their options in electrical discharge machining, the choice between Able Wire EDM, Inc. and alternative solutions like traditional CNC machining or laser cutting should be guided by specific project requirements. Factors such as the complexity of the part, material types, production volume, and budget constraints are vital in making an informed decision. By carefully assessing these aspects, businesses can select the most appropriate machining technology that aligns with their operational needs and strategic goals, ensuring optimal performance and quality in their manufacturing processes.

Essential Technical Properties and Trade Terminology for able wire edm inc

What Are the Key Technical Properties for Able Wire EDM Inc.?

Understanding the technical specifications of Able Wire EDM Inc.’s services is crucial for international B2B buyers. Here are some essential properties that define the capabilities and offerings of this company:

1. Material Grades

Able Wire EDM specializes in machining difficult materials such as titanium, Inconel, Hastelloy, and carbide. These high-performance alloys are often used in aerospace, defense, and medical applications. The ability to work with these materials ensures that Able Wire EDM can meet stringent industry standards for durability and performance.

2. Tolerance Levels

Precision machining requires strict adherence to tolerance levels, which can often be as tight as ±0.0001 inches. These tolerances are critical in industries like aerospace and defense, where even minor deviations can lead to failure or safety issues. By maintaining high tolerance standards, Able Wire EDM ensures the reliability and quality of its components.

3. Surface Finish

Surface finish is a key factor in the performance of machined parts. For applications in aerospace and medical devices, a superior surface finish can enhance durability and reduce friction. Able Wire EDM employs advanced machining techniques that allow for exceptional surface finishes, meeting the rigorous requirements of its clients.

4. CNC Machining Capabilities

Able Wire EDM utilizes state-of-the-art CNC (Computer Numerical Control) machines, including 4-axis and small hole EDM machines. CNC technology allows for high precision and repeatability, essential for producing complex geometries and intricate designs. This capability is particularly important for prototype and production runs in specialized industries.

5. Production Volume

Able Wire EDM caters to both prototype and production needs, providing flexibility in order quantities. This is especially beneficial for B2B buyers who may require small batch runs for testing or larger quantities for full-scale production. Understanding production volume capabilities helps buyers plan their projects effectively.

6. Certification Standards

Being AS9100D and ISO9001:2015 certified indicates that Able Wire EDM adheres to international quality management standards. This certification is particularly important for B2B buyers in regulated industries, as it assures them of the company’s commitment to quality and continuous improvement.

What Are Common Trade Terms Relevant to Able Wire EDM Inc.?

Familiarity with industry terminology can streamline communication and negotiations. Here are several key terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding whether Able Wire EDM operates as an OEM is crucial for aligning with supply chain needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Knowing the MOQ for Able Wire EDM’s services can help buyers plan their orders and manage inventory effectively.

3. RFQ (Request for Quote)

An RFQ is a document sent by potential buyers to suppliers to obtain pricing and terms for specific products or services. For Able Wire EDM, submitting an RFQ can initiate the process of receiving tailored quotes based on specific project requirements.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers when negotiating shipping and delivery conditions with Able Wire EDM.

5. Lead Time

Lead time refers to the amount of time required to fulfill an order from receipt to delivery. For B2B buyers, knowing the lead time for Able Wire EDM’s services helps in planning project timelines and managing expectations with end clients.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when engaging with Able Wire EDM Inc., ensuring they receive high-quality machining solutions tailored to their specific needs.

Navigating Market Dynamics and Sourcing Trends in the able wire edm inc Sector

What Are the Current Market Dynamics and Key Trends Affecting Able Wire EDM, Inc.?

The global market for Electrical Discharge Machining (EDM), particularly in specialized sectors such as aerospace, defense, and medical devices, is experiencing significant growth driven by technological advancements and increasing demand for precision machining. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly interested in sourcing high-quality machining services due to the rising need for intricate components made from difficult-to-machine materials like titanium and Inconel.

Current trends indicate a shift towards automation and advanced robotics in manufacturing processes, enhancing production efficiency and accuracy. The integration of Industry 4.0 technologies, such as IoT and AI, is revolutionizing EDM operations by enabling predictive maintenance and real-time monitoring, which are crucial for maintaining quality standards and reducing downtime. Moreover, the increasing emphasis on just-in-time (JIT) manufacturing is prompting companies to seek reliable suppliers capable of quick turnaround times, making Able Wire EDM’s rapid response capabilities particularly attractive to potential clients.

Emerging sourcing trends highlight the importance of establishing long-term partnerships with manufacturers who can provide not only precision machining but also comprehensive support services, including application consulting and maintenance. For buyers in regions such as Vietnam and Saudi Arabia, understanding local regulations and standards, particularly in defense and aerospace sectors, is essential for successful procurement and compliance.

How Does Sustainability and Ethical Sourcing Impact Able Wire EDM, Inc.?

Sustainability is becoming a cornerstone of B2B procurement strategies, with buyers increasingly prioritizing suppliers that demonstrate environmental responsibility. For Able Wire EDM, this means not only optimizing machining processes to reduce waste and energy consumption but also sourcing materials that align with sustainable practices. The use of eco-friendly cutting fluids and recyclable materials can enhance the company’s appeal to environmentally conscious buyers in Africa and South America, where sustainable practices are gaining traction.

Moreover, ethical sourcing is critical in today’s global supply chain landscape. Buyers are more vigilant about ensuring that their suppliers adhere to ethical labor practices and maintain transparency throughout their operations. Able Wire EDM’s certifications, including AS9100 and ISO9001, signify a commitment to quality and ethical standards, providing an added layer of confidence for international buyers.

Investing in green certifications and promoting sustainable materials not only enhances Able Wire EDM’s market positioning but also aligns with the growing demand for responsible sourcing among B2B buyers. This trend is particularly relevant in Europe, where regulations around sustainability and ethical sourcing are becoming more stringent.

What Is the Evolution of Able Wire EDM, Inc. and Its Significance for B2B Buyers?

Founded in 1988 by Vietnam War veteran John W. Marquardt, Able Wire EDM, Inc. has evolved from a small operation into one of the largest EDM shops in the United States. With over 35 years of experience, the company has built a reputation for tackling complex machining challenges and serving high-profile clients in the aerospace, defense, and medical sectors.

The company’s commitment to quality is underscored by its AS9100D and ISO9001:2015 certifications, which are essential for international B2B transactions, particularly in regulated industries. This rich history not only reflects the company’s resilience and adaptability but also provides potential buyers with assurance regarding its reliability and expertise in delivering precision machining solutions.

For international buyers, particularly in fast-growing markets, partnering with a seasoned player like Able Wire EDM can facilitate access to advanced manufacturing capabilities, ensuring compliance with stringent quality standards while meeting the increasing demand for innovative machining solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of able wire edm inc

-

How can I ensure the quality of components manufactured by Able Wire EDM, Inc.?

Able Wire EDM, Inc. is AS9100:2016 and ISO9001:2015 certified, indicating adherence to international quality management standards. To further ensure quality, you can request documentation of their certifications, quality control processes, and testing methods. They have a dedicated Quality Department that oversees all manufacturing processes, allowing for rigorous inspections and compliance with industry standards. Engaging with their team for specific quality assurance protocols related to your project will provide additional confidence in their capabilities. -

What types of materials can Able Wire EDM, Inc. machine?

Able Wire EDM specializes in difficult-to-machine materials such as titanium, hastelloy, copper, brass, kovar, inconel, and carbide. Their advanced EDM technology enables precise machining of these materials, making them suitable for various industries, including aerospace, defense, and medical devices. When discussing your project, be specific about the materials you intend to use, as their expertise can help identify the best machining solutions tailored to your needs. -

What are the minimum order quantities (MOQ) for projects with Able Wire EDM, Inc.?

Minimum order quantities can vary based on the complexity and requirements of your project. Able Wire EDM, Inc. is equipped to handle both prototype and production runs, allowing flexibility in order sizes. It is best to discuss your specific needs directly with their sales team, who can provide guidance on MOQs and any associated pricing structures to accommodate your project scope. -

How do I request a quote for my machining project with Able Wire EDM, Inc.?

To request a quote, you can send an email to their sales team, including any drawings, CAD files, and detailed instructions related to your project. Able Wire EDM emphasizes quick response times, typically replying within one hour. For urgent requests, you can also reach out via text message to notify them of a “HOT” request, ensuring immediate attention to your needs. -

What payment terms does Able Wire EDM, Inc. offer for international buyers?

Payment terms for international buyers can vary, and it is advisable to discuss this directly with their sales team. Common options may include wire transfers, letters of credit, or other secure payment methods. Understanding your payment options will help you manage your budget and cash flow effectively, so be sure to inquire about any potential upfront deposits or payment schedules related to your order. -

How does Able Wire EDM, Inc. handle logistics and shipping for international orders?

Able Wire EDM, Inc. partners with trusted logistics providers to ensure safe and timely delivery of components. They can accommodate various shipping methods based on your preferences and urgency, whether by air or sea freight. Discussing your logistics needs with their team will help establish a clear timeline and address any customs requirements to facilitate smooth international shipping. -

What customization options are available for my machining needs with Able Wire EDM, Inc.?

Able Wire EDM offers extensive customization options tailored to meet specific project requirements. Their team can work closely with you to develop custom machining processes and designs that align with your project goals. Be prepared to share detailed specifications and any unique challenges you face, as this collaboration will enable them to provide solutions that best suit your needs. -

How can I verify the reliability of Able Wire EDM, Inc. as a supplier?

To assess the reliability of Able Wire EDM, Inc., consider reviewing customer testimonials, case studies, and references from other B2B clients in similar industries. Their certifications, such as AS9100 and ISO9001, also reflect a commitment to quality and reliability. Engaging in preliminary discussions with their team can further clarify their capabilities and responsiveness, helping you make an informed decision about entering a partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Able Wire Edm Inc Manufacturers & Suppliers List

1. Able Wire EDM – Electrical Discharge Machining Services

Domain: ablewireedm.com

Registered: 2023 (2 years)

Introduction: Able Wire EDM, INC. specializes in Electrical Discharge Machining (EDM) services including Wire EDM, Sinker EDM, and Small Hole EDM. They cater to various industries such as Aerospace, Defense, Medical, Semiconductor, and Commercial sectors. The company is AS9100:2016/ISO9001:2015 certified and ITAR registered. Their capabilities include CNC 4-Axis Wire EDM, CNC Sinker EDM, and CNC Small Hole EDM,…

2. Able Wire EDM – EDM & CNC Machining

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Able Wire EDM – EDM & CNC Machining, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Able Wire EDM – Electrical Discharge Machining

Domain: cmtc.com

Registered: 1996 (29 years)

Introduction: Able Wire EDM Inc. specializes in electrical discharge machining (EDM) and CNC machining. They utilize 20 electrical discharge machines, including 16 CNC 4-Axis Wire EDMs, 2 Charmilles CNC Sinker EDMs, 2 Belmont CNC small hole EDMs, and 1 Sodick K1C Small Hole EDM. Their capabilities include production and prototype requirements with precision, particularly in machining difficult materials such as…

4. Able Wire EDM – Wire EDM Machines

Domain: electricaldischargemachining.com

Registered: 2000 (25 years)

Introduction: Able Wire EDM, Inc. offers a comprehensive range of EDM products including: 1. Wire EDM Machines: Designed for precise cutting of intricate shapes in conductive materials, featuring advanced control systems, automatic wire threading, submerged cutting, and taper cutting capabilities. 2. Sinker EDM Machines: Used to create intricate shapes and cavities with electrodes and dielectric fluid, offering…

5. LinkedIn – Dedicated API

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

6. Able Wire EDM – EDM & CNC Machining

Domain: m.facebook.com

Registered: 1997 (28 years)

Introduction: This company, Able Wire EDM – EDM & CNC Machining, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Able Wire EDM Inc – Precision Machining Services

Domain: local.yahoo.com

Registered: 1995 (30 years)

Introduction: This company, Able Wire EDM Inc – Precision Machining Services, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Able Wire EDM – Precision Machining Services

Domain: insidejobsales.com

Registered: 2024 (1 years)

Introduction: Able Wire EDM is a specialized manufacturing company focusing on wire electrical discharge machining (EDM) services. They offer high-precision machining that meets stringent tolerances and complex design specifications. The company handles a variety of materials and component sizes, ensuring flexibility and reliability for clients’ production needs. Their commitment to precision and quality makes …

Strategic Sourcing Conclusion and Outlook for able wire edm inc

In navigating the complexities of global supply chains, strategic sourcing remains a pivotal aspect for B2B buyers seeking reliable partners like Able Wire EDM Inc. This veteran-owned enterprise excels in Electrical Discharge Machining (EDM) and CNC machining, catering to demanding sectors such as aerospace, defense, and medical industries. With AS9100D and ISO9001:2015 certifications, Able Wire EDM not only guarantees precision but also compliance with international standards, making it a trusted source for intricate machining needs.

For international buyers from Africa, South America, the Middle East, and Europe, engaging with Able Wire EDM provides access to advanced manufacturing capabilities and a commitment to quality that is essential in today’s competitive landscape. Their expertise in handling difficult-to-machine materials positions them uniquely to meet specialized requirements.

As industries evolve, the demand for innovative machining solutions will continue to rise. B2B buyers are encouraged to leverage Able Wire EDM’s capabilities to enhance their production processes and achieve operational excellence. Reach out today to discover how Able Wire EDM can become an integral part of your sourcing strategy, ensuring you stay ahead in a rapidly changing market.