Introduction: Navigating the Global Market for able edm

The global market for Electrical Discharge Machining (EDM) solutions, particularly for specialized services such as those offered by Able EDM, presents unique challenges for international B2B buyers. Sourcing reliable and high-quality EDM services can be daunting, especially for industries requiring precision and compliance with stringent standards, such as aerospace, defense, and medical sectors. This guide aims to demystify the complexities of the EDM landscape, equipping buyers from regions like Africa, South America, the Middle East, and Europe—including emerging markets in Nigeria and Brazil—with the knowledge they need to make informed purchasing decisions.

In the following sections, we will explore various types of EDM processes—Wire EDM, Sinker EDM, and Small Hole EDM—each with its specific applications and advantages. We will also delve into the critical aspects of supplier vetting, helping you identify reputable manufacturers with the necessary certifications and experience to meet your project requirements. Additionally, we will provide insights into cost considerations, ensuring you can budget effectively without compromising on quality.

By the end of this guide, you will be empowered to navigate the global EDM market confidently, making strategic choices that enhance your operational efficiency and drive business growth. Whether you are seeking to develop prototypes or scale production, understanding the nuances of EDM will enable you to select the right partners and solutions tailored to your unique needs.

Understanding able edm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wire EDM | Utilizes thin, electrically charged wire for precise cutting. | Aerospace, Defense, Medical Devices | Pros: High precision, intricate shapes; Cons: Slower for thick materials. |

| Sinker EDM | Employs shaped electrodes to create complex cavities. | Tool & Die Manufacturing, Aerospace Parts | Pros: Excellent for complex geometries; Cons: Longer setup times. |

| Small Hole EDM | Specializes in drilling small, precise holes. | Electronics, Aerospace, Medical Devices | Pros: High accuracy for tiny holes; Cons: Limited to specific hole sizes. |

| CNC Machining | Combines traditional machining with EDM for versatility. | General Manufacturing, Prototyping | Pros: Versatile for various materials; Cons: May require more extensive tooling. |

| Hybrid EDM | Integrates multiple EDM techniques for enhanced capabilities. | Advanced Aerospace, Defense Applications | Pros: Combines strengths of different EDM types; Cons: Higher initial costs. |

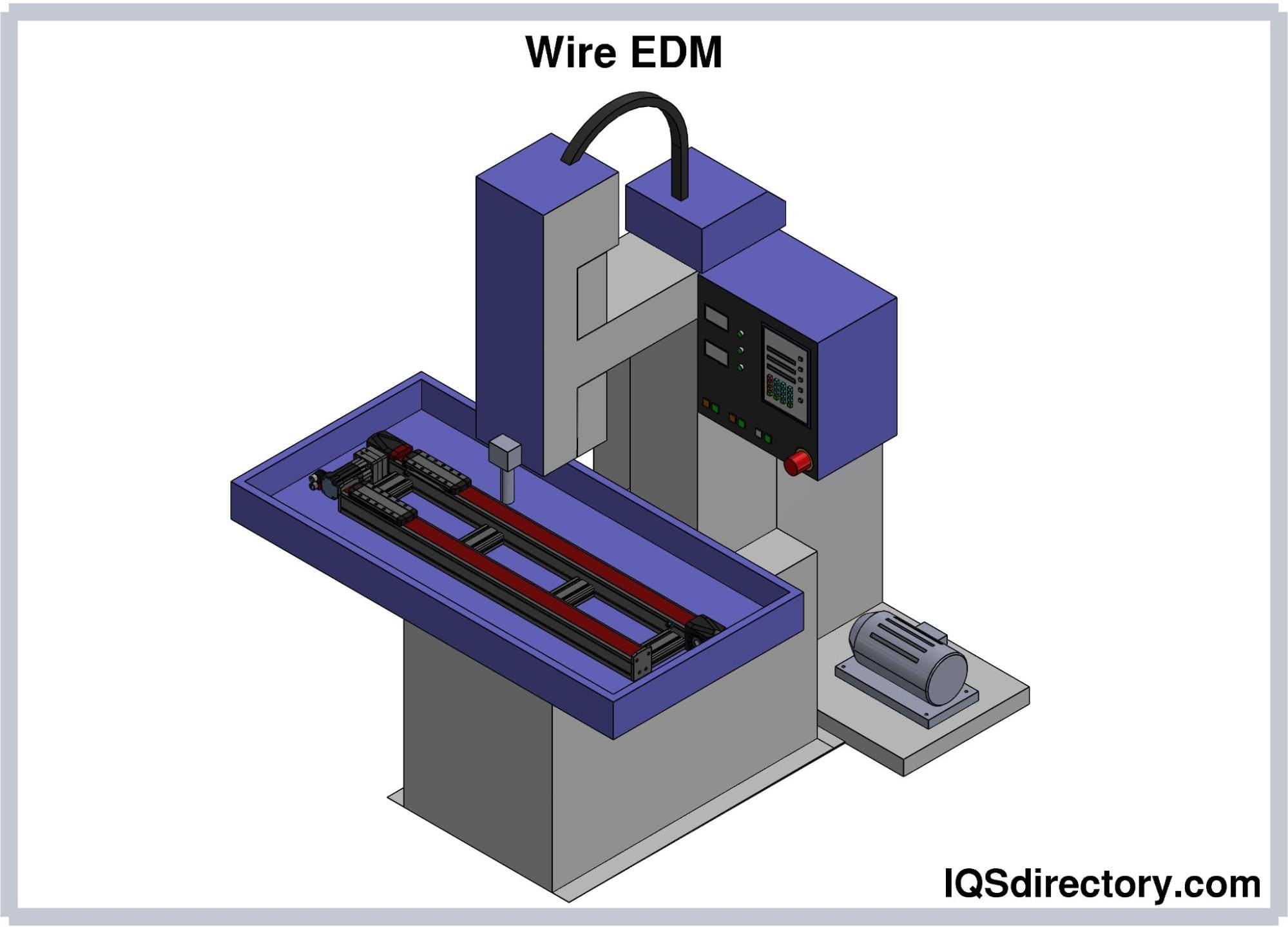

What Are the Key Characteristics of Wire EDM?

Wire EDM (Electrical Discharge Machining) is characterized by its use of a thin, electrically charged wire that moves through the workpiece to cut intricate shapes and contours. This method is particularly well-suited for applications requiring high precision and complex designs, making it ideal for industries such as aerospace and medical device manufacturing. When considering Wire EDM for procurement, buyers should evaluate the thickness of materials, as this process is less efficient with thicker workpieces, leading to longer machining times.

How Does Sinker EDM Stand Out in Complex Machining?

Sinker EDM utilizes shaped electrodes to erode material and create complex cavities within the workpiece. This technique is particularly valuable in tool and die manufacturing and aerospace parts, where intricate geometries are essential. Buyers should consider the potential for longer setup times and the necessity for precise electrode design. However, the ability to achieve complex shapes with high repeatability makes Sinker EDM a compelling choice for specialized applications.

What Are the Advantages of Small Hole EDM?

Small Hole EDM specializes in producing tiny, precise holes in conductive materials, which is crucial for applications in electronics and aerospace. This method employs small-diameter electrodes to create high-quality holes, offering exceptional accuracy. When purchasing Small Hole EDM services, B2B buyers should focus on the specific hole sizes required for their projects, as this technique is limited to certain dimensions. The high precision provided by this method can significantly enhance the functionality of components in critical applications.

Why Is CNC Machining Important for B2B Buyers?

CNC Machining represents a blend of traditional machining and EDM techniques, providing versatility in manufacturing processes. This method is particularly beneficial for general manufacturing and prototyping, allowing for the machining of various materials. Buyers should consider the range of materials and complexity of parts they require, as CNC Machining can accommodate different specifications. However, it may necessitate more extensive tooling compared to dedicated EDM processes, which could impact lead times and costs.

How Does Hybrid EDM Enhance Manufacturing Capabilities?

Hybrid EDM integrates multiple EDM techniques to leverage their strengths, making it suitable for advanced applications in aerospace and defense. This approach allows manufacturers to tackle a wider range of challenges, from intricate designs to difficult materials. However, buyers should be aware of the higher initial costs associated with hybrid systems. Evaluating the long-term benefits against the upfront investment can help determine if Hybrid EDM is the right choice for specific manufacturing needs.

Key Industrial Applications of able edm

| Industry/Sector | Specific Application of able edm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Precision components for aircraft and missiles | High accuracy and reliability in critical components | Certifications (AS9100, ITAR), experience with titanium, and compliance with defense standards |

| Medical Devices | Manufacturing surgical instruments and implants | Enhanced precision for improved patient outcomes | ISO certifications, ability to work with biocompatible materials, and rapid prototyping capabilities |

| Semiconductor | Fabrication of intricate components for chips | Increased efficiency and performance in electronic devices | Expertise in small hole EDM and experience with complex geometries |

| Automotive | Production of specialized tooling and dies | Reduced lead times and improved production efficiency | Capability to handle difficult materials and offer quick turnaround times |

| Tool & Die | Custom tooling solutions for manufacturing | Enhanced durability and precision in manufacturing processes | Proven track record with complex designs and ability to support low-volume production needs |

How is Able EDM Used in Aerospace and Defense Industries?

In the aerospace and defense sectors, able EDM is crucial for manufacturing precision components such as turbine blades, missile parts, and intricate assemblies. The technology allows for the machining of hard materials like titanium and Inconel, which are essential for high-performance applications. International buyers, particularly from Africa and the Middle East, should prioritize suppliers with AS9100 and ITAR certifications, ensuring compliance with stringent defense industry standards and reliability in critical applications.

What Role Does Able EDM Play in Medical Device Manufacturing?

In the medical device industry, able EDM is employed to create surgical instruments and implants that require high precision. The technology enables the production of complex geometries that are vital for effective medical solutions. Buyers from South America and Europe should look for manufacturers with ISO certifications and experience in working with biocompatible materials, as these attributes ensure that the products meet regulatory requirements and enhance patient safety.

How Does Able EDM Enhance Semiconductor Fabrication?

Able EDM plays a significant role in the semiconductor industry by facilitating the fabrication of intricate components used in microchips. The precision of small hole EDM technology allows manufacturers to create high-quality features essential for modern electronics. International buyers, particularly in regions like Europe and South America, must consider suppliers’ expertise in small hole EDM and their ability to manage complex geometries, which are critical for enhancing device performance.

Why is Able EDM Important for Automotive Tooling?

In automotive manufacturing, able EDM is utilized for producing specialized tooling and dies that enhance production efficiency. The capability to machine difficult materials and deliver customized solutions leads to reduced lead times and improved manufacturing processes. For buyers in Africa and South America, sourcing from a provider with a proven track record in tooling solutions and quick turnaround times is essential for maintaining competitive advantage in the automotive market.

How Does Able EDM Support Tool & Die Applications?

Able EDM is instrumental in the tool and die sector, providing custom tooling solutions that enhance durability and precision. The technology allows for the creation of complex shapes and intricate details that are often challenging to achieve through traditional machining methods. Buyers, especially from emerging markets, should seek out manufacturers that demonstrate expertise in complex designs and can accommodate low-volume production requirements, ensuring that their tooling needs are met effectively.

3 Common User Pain Points for ‘able edm’ & Their Solutions

Scenario 1: Navigating Complex Machining Requirements in Aerospace

The Problem: B2B buyers in the aerospace sector often face the challenge of sourcing manufacturers that can handle intricate and highly specific machining requirements. With the industry’s stringent regulations and the need for precision, finding a reliable EDM provider that can work with difficult materials like titanium or Inconel can be daunting. Many buyers worry about quality assurance, as any defect could lead to costly delays and safety concerns.

The Solution: To effectively address these challenges, buyers should prioritize working with an AS9100D/ISO9001:2015 certified EDM provider like Able Wire EDM. This certification guarantees adherence to quality management systems specifically tailored for the aerospace industry. Buyers should begin by outlining their project specifications clearly, including material types, tolerances, and delivery timelines. Engaging in detailed discussions with Able Wire EDM’s engineering team can provide insights into which EDM processes—such as Wire EDM or Sinker EDM—are best suited for their needs. Furthermore, requesting a prototype can help assess the machining quality before full-scale production, ensuring that the final components meet the required standards.

Scenario 2: Overcoming Long Lead Times for Medical Device Manufacturing

The Problem: In the medical device industry, companies often grapple with the issue of long lead times when sourcing precision parts. This challenge can be exacerbated by complex regulations, as manufacturers must ensure that every component meets rigorous safety standards. Delays in receiving these components can significantly impact product launches and patient care timelines.

The Solution: To mitigate lead time issues, B2B buyers should consider establishing a strategic partnership with Able Wire EDM, which offers expedited quoting and emergency services. By using their quick quote system, buyers can receive timely feedback on their projects. Additionally, providing complete CAD files and drawings upfront will facilitate a smoother process, allowing Able Wire EDM to identify potential challenges early on. Implementing a just-in-time (JIT) inventory strategy can also help; by aligning production schedules with delivery timelines, buyers can ensure that they have the necessary parts on hand without overcommitting resources.

Scenario 3: Ensuring Consistent Quality Across Multiple Production Runs

The Problem: Consistency in quality can be a significant pain point for B2B buyers managing production runs across different batches. In industries like defense and aerospace, where precision is paramount, even minor deviations can lead to catastrophic failures or compliance issues. Buyers often struggle to find manufacturers that can guarantee the same level of quality across multiple orders.

The Solution: To ensure consistency, B2B buyers should leverage Able Wire EDM’s commitment to quality management and rigorous inspection protocols. Buyers should engage in regular communication with the manufacturing team, discussing quality benchmarks and expectations before production begins. Implementing a continuous feedback loop, where buyers provide input on the quality of initial batches, can help refine the process. Additionally, utilizing Able Wire EDM’s capabilities for advanced machining technologies will ensure that they achieve the desired precision consistently. Buyers can also request detailed reports on each production run, allowing them to track quality metrics and make informed decisions for future orders.

Strategic Material Selection Guide for able edm

What Are the Key Properties of Titanium for Electrical Discharge Machining (EDM)?

Titanium is renowned for its excellent strength-to-weight ratio and exceptional corrosion resistance, making it a popular choice in aerospace and medical applications. Its ability to withstand high temperatures and pressures further enhances its appeal for components that require durability under extreme conditions. However, titanium’s high melting point can complicate machining processes, necessitating specialized EDM techniques to achieve the desired precision.

What Are the Advantages and Disadvantages of Using Inconel in EDM Applications?

Inconel, a nickel-chromium superalloy, is favored for its outstanding resistance to oxidation and corrosion, particularly in high-temperature environments. This makes it suitable for aerospace, defense, and energy applications. The primary advantage of Inconel is its durability and performance in extreme conditions. However, it can be more challenging to machine due to its toughness, which may lead to increased manufacturing complexity and costs. Additionally, international buyers should be aware of specific compliance standards, as Inconel is often subject to stringent quality requirements.

How Does Copper Perform in EDM Processes?

Copper is widely utilized in EDM due to its excellent electrical conductivity and thermal properties. It is particularly effective for creating intricate shapes and fine details in conductive materials. The main advantage of copper is its cost-effectiveness and ease of machining, making it suitable for high-volume production runs. However, it has lower strength compared to titanium and Inconel, which may limit its application in high-stress environments. Buyers from regions with varying industrial standards should ensure their suppliers meet relevant certifications for copper components.

What Are the Considerations for Using Carbide in EDM?

Carbide is a composite material known for its exceptional hardness and wear resistance, making it ideal for tooling applications. Its ability to maintain sharp edges under high stress is a significant advantage in precision machining. However, carbide can be brittle, which poses risks during machining processes. The high cost of carbide is also a consideration for international buyers, particularly in developing markets where budget constraints may apply. Compliance with international standards, such as ASTM or ISO, is crucial for ensuring quality and performance in carbide applications.

| Material | Typical Use Case for able edm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium | Aerospace components, medical devices | Excellent strength-to-weight ratio | High melting point complicates machining | High |

| Inconel | Aerospace and defense applications | Outstanding oxidation and corrosion resistance | Difficult to machine, increasing complexity | High |

| Copper | Electrical components, intricate shapes | Cost-effective, easy to machine | Lower strength limits high-stress applications | Medium |

| Carbide | Tooling and wear-resistant applications | Exceptional hardness and wear resistance | Brittle nature can lead to breakage | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of commonly used materials in EDM processes. Understanding these factors will facilitate informed decision-making when sourcing components for various applications across different industries.

In-depth Look: Manufacturing Processes and Quality Assurance for able edm

What Are the Key Stages in the Manufacturing Process for Able EDM?

The manufacturing process for Able EDM, particularly in the context of electrical discharge machining (EDM), comprises several critical stages. Understanding these stages can help B2B buyers evaluate the capabilities of potential suppliers and ensure that their specific needs are met effectively.

Material Preparation: How Does It Set the Stage for Precision Machining?

Material preparation is the foundational step in the EDM manufacturing process. This involves selecting the appropriate metals or alloys, often challenging materials like titanium, hastelloy, and inconel, known for their toughness and resistance to deformation. Once selected, materials undergo thorough inspection to verify their specifications, such as hardness and conductivity, which are crucial for successful machining.

Materials are then cut to size using saws or shears, ensuring they meet the dimensions required for subsequent processes. This stage is vital for minimizing waste and ensuring that the machining can proceed without interruption.

Forming: What Techniques Are Employed in EDM?

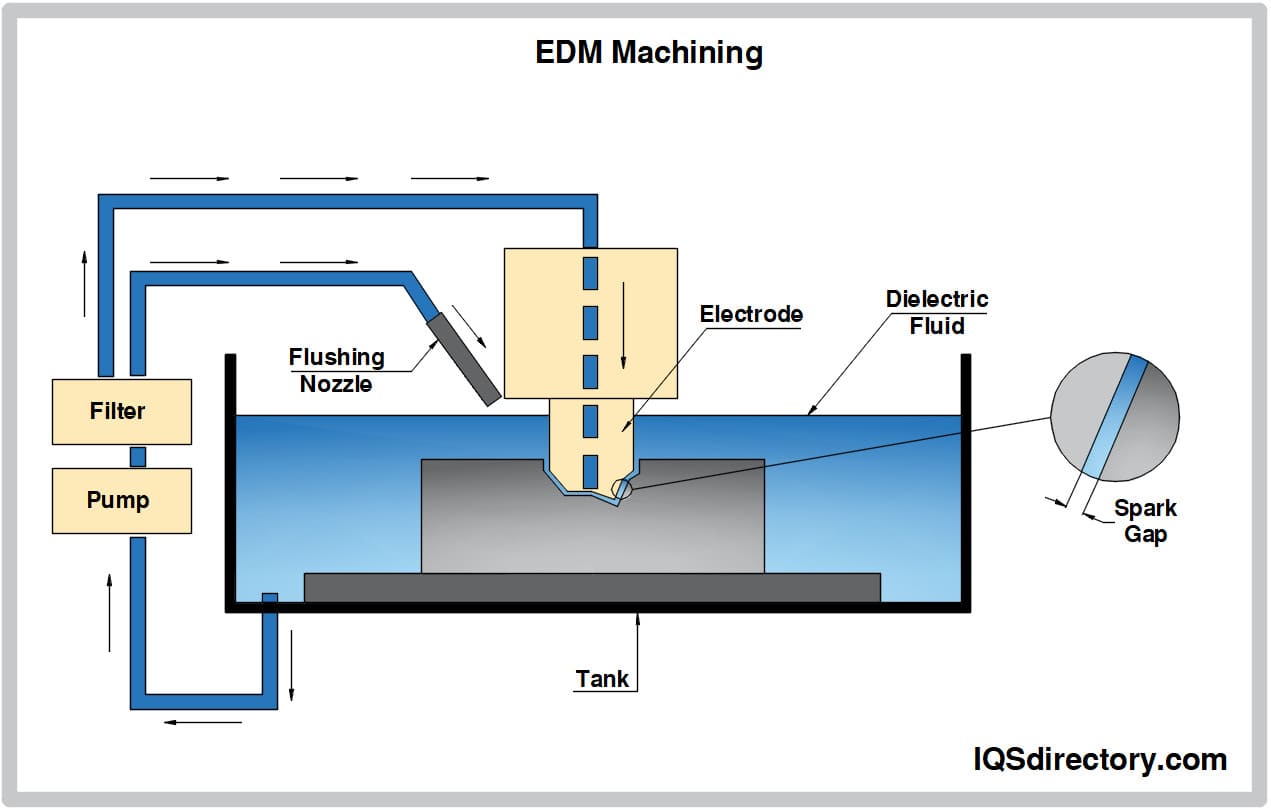

The forming stage in EDM involves the actual machining processes, which include wire EDM, sinker EDM, and small hole EDM.

-

Wire EDM: This technique utilizes a thin, electrically charged wire to cut through conductive materials. The wire moves along programmed paths, allowing for intricate shapes and precise tolerances. Advanced features like automatic wire threading and submerged cutting enhance operational efficiency and surface finish.

-

Sinker EDM: In this method, an electrode is used to create complex cavities and shapes in the workpiece. The electrode, often made from copper or graphite, is shaped to match the desired cavity. This technique is particularly useful for producing molds and dies.

-

Small Hole EDM: As the name suggests, this technique focuses on creating small, precise holes in materials. The process employs small-diameter electrodes, enabling manufacturers to drill holes that are often impossible to achieve with traditional machining methods.

Assembly and Finishing: What Ensures Quality and Precision?

After machining, components may require assembly, particularly when they form part of larger assemblies. This stage may include processes like welding, soldering, or fastening.

Finishing processes are crucial for enhancing the surface quality of machined parts. Techniques such as electroplating, polishing, and coating are employed to improve aesthetics and functional properties, such as corrosion resistance.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance is integral to the manufacturing process at Able EDM, ensuring that products meet international standards and customer specifications.

What International Standards Govern Quality Assurance in EDM?

Able EDM is certified under AS9100D and ISO 9001:2015, which are internationally recognized quality management standards. These certifications indicate a commitment to maintaining high-quality processes and continuous improvement.

Additionally, compliance with ITAR (International Traffic in Arms Regulations) demonstrates Able EDM’s capability to handle sensitive defense-related projects, further establishing their credibility in the aerospace and defense sectors.

What Are the Key Quality Control Checkpoints?

The quality control (QC) process encompasses various checkpoints to ensure that products meet defined specifications:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to verify that they meet required standards before entering the manufacturing process.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor critical parameters, such as dimensional accuracy and surface finish. This proactive approach allows for immediate corrective actions if deviations are detected.

-

Final Quality Control (FQC): After manufacturing, a comprehensive inspection is carried out on the finished product. This may include dimensional checks, visual inspections, and functional tests to ensure compliance with specifications.

What Common Testing Methods Are Used to Verify Quality?

Common testing methods employed by Able EDM include:

- Dimensional Measurement: Using coordinate measuring machines (CMM) to ensure precision in dimensions.

- Surface Roughness Testing: Assessing the surface finish of machined components to confirm they meet customer requirements.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant testing are used to identify potential internal flaws without damaging the components.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is crucial.

What Steps Should Buyers Take to Assess Supplier Quality?

-

Conduct Audits: Regular audits of potential suppliers can reveal their adherence to quality standards and manufacturing capabilities. Buyers should request audit reports and certifications.

-

Review Quality Documentation: Suppliers should provide access to their quality management system documentation, including quality manuals and process flows.

-

Engage Third-Party Inspectors: Employing independent inspectors can provide an unbiased assessment of the supplier’s capabilities and product quality.

-

Request Samples: Before placing large orders, buyers can request samples of the supplier’s products to evaluate their quality and performance firsthand.

What Are the Unique Challenges for International B2B Buyers?

International buyers often face challenges such as varying quality standards and regulations across different regions. Understanding these nuances is crucial for establishing effective partnerships.

How Can Buyers Navigate These Challenges?

- Research Local Regulations: Buyers should familiarize themselves with the local regulations in their industry, ensuring that their suppliers are compliant.

- Establish Clear Communication: Maintaining open lines of communication with suppliers regarding quality expectations and standards can prevent misunderstandings.

- Build Relationships: Developing long-term relationships with suppliers can foster trust and enhance collaboration on quality assurance initiatives.

By understanding the manufacturing processes and quality assurance measures at Able EDM, B2B buyers can make informed decisions and establish partnerships that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘able edm’

To effectively procure ‘able edm’ solutions, it is essential to follow a structured approach that ensures the selection of a reliable supplier capable of meeting your specific needs. This guide outlines key steps for B2B buyers looking to source EDM services, particularly within international markets, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the EDM services you require align with your project’s demands. This includes detailing the materials you intend to work with, the complexity of the parts, and the tolerances required. A comprehensive specification will facilitate accurate quotes and streamline communication with potential suppliers.

- Considerations: List materials such as titanium or Inconel, and specify dimensions, tolerances, and surface finishes.

Step 2: Verify Supplier Certifications

Before engaging with a supplier, it is vital to confirm their certifications, particularly AS9100 and ISO9001, which indicate adherence to quality management systems. Certifications also demonstrate a commitment to maintaining industry standards, which is particularly important in sectors like aerospace and defense.

- Action Points: Request copies of their certifications and check if they are ITAR registered, especially if your projects involve sensitive technologies.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure they can meet your specific needs. This involves reviewing their company profiles, past performance, and client testimonials. Engaging with other businesses that have previously worked with the supplier can provide valuable insights into their reliability and service quality.

- Research Tools: Look for case studies relevant to your industry and ask for references from similar projects.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, lead times, and terms of service. A well-structured quote will provide clarity on what is included in the price, such as tooling costs, setup fees, and post-production support.

- Comparison Metrics: Ensure that quotes are comparable by asking all suppliers to use the same specifications and project parameters.

Step 5: Assess Technical Capabilities

Evaluate the technical capabilities of each supplier, focusing on their machinery and processes. Suppliers should have advanced EDM technology, such as CNC 4-axis wire EDM and small hole EDM machines, which are essential for achieving high precision and efficiency.

- Facility Visits: If feasible, visit the supplier’s facility to observe their operations and assess their equipment firsthand.

Step 6: Inquire About Support Services

A reliable supplier should offer comprehensive support services, including installation, training, and maintenance. These services are crucial for ensuring that your team can effectively operate the EDM equipment and maintain high production standards.

- Service Offerings: Clarify what support is provided post-purchase and whether they offer preventive maintenance plans.

Step 7: Establish Communication Protocols

Finally, establish clear communication protocols to facilitate ongoing dialogue throughout the procurement process. Effective communication can prevent misunderstandings and ensure that both parties are aligned on project goals and timelines.

- Recommended Practices: Set regular check-ins and specify points of contact for different aspects of the project.

By following these steps, B2B buyers can confidently navigate the procurement process for ‘able edm’ solutions, ensuring that they choose a supplier capable of delivering high-quality, precision machining services tailored to their needs.

Comprehensive Cost and Pricing Analysis for able edm Sourcing

What Are the Key Cost Components in Able EDM Sourcing?

When evaluating the costs associated with sourcing from Able EDM, several critical components come into play. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of materials selected for machining significantly influences costs. Able EDM specializes in difficult-to-machine materials such as titanium, inconel, and carbide, which can carry higher price tags compared to standard materials. Understanding the material requirements for your project is essential for accurate cost estimation.

-

Labor: Skilled labor is a crucial component in the EDM process. The expertise required for precision machining impacts labor costs. Companies like Able EDM employ specialized engineers and technicians, and their rates can vary based on project complexity and timelines.

-

Manufacturing Overhead: This includes facility costs, utilities, and equipment maintenance. Given Able EDM’s certification under AS9100 and ISO9001, their adherence to strict quality standards may also increase overhead costs due to the need for compliance and certification processes.

-

Tooling: Tooling costs can vary depending on the complexity of the parts being manufactured. Custom tooling for specialized components can add to the upfront costs but may lead to long-term savings through increased efficiency and precision.

-

Quality Control (QC): Rigorous quality assurance processes are vital, especially in sectors like aerospace and medical devices. The costs associated with QC ensure that the final products meet stringent industry standards, and while they may increase initial costs, they reduce the risk of costly errors in production.

-

Logistics: Transportation and shipping costs must also be factored in, especially for international buyers. The choice of Incoterms can affect these costs, as they define the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: Supplier margins will vary based on market conditions, demand, and competition. Understanding the typical margins in the EDM industry can provide insights into pricing strategies.

How Do Price Influencers Affect Able EDM Quotes?

Several factors can influence pricing when sourcing from Able EDM. Volume and minimum order quantities (MOQ) often play a significant role; larger orders may qualify for discounts, while smaller orders can lead to higher per-unit costs. Customization requests—such as specific dimensions or unique material requirements—can also impact pricing, as they may necessitate additional tooling or processing time.

The quality of materials, certifications, and the supplier’s reputation are additional price influencers. Buyers should verify that suppliers hold the necessary certifications relevant to their industry, as this can assure quality and compliance, potentially justifying higher costs.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Able EDM?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Effectively: Always engage in negotiations. Suppliers may have room to maneuver on pricing, especially for larger orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but the total cost of ownership, including maintenance, potential rework, and shipping costs. This holistic view can lead to better long-term investment decisions.

-

Understand Pricing Nuances: Be aware that international shipping can introduce variables such as tariffs, customs duties, and fluctuating currency exchange rates. These factors can significantly affect the final cost.

-

Leverage Incoterms: Familiarize yourself with Incoterms to clarify responsibilities related to shipping and handling, which can help manage logistics costs effectively.

Disclaimer on Indicative Prices

While this analysis provides insights into cost components and pricing dynamics for sourcing from Able EDM, actual prices may vary based on specific project requirements, market conditions, and negotiation outcomes. Buyers are encouraged to request detailed quotes to obtain accurate pricing for their unique needs.

Alternatives Analysis: Comparing able edm With Other Solutions

Understanding Alternatives in Electrical Discharge Machining

In the realm of precision machining, particularly in industries such as aerospace, medical, and defense, selecting the right technology is crucial for meeting production demands. While Able EDM stands out for its robust capabilities in electrical discharge machining, several alternatives exist that may better align with specific business needs. This analysis compares Able EDM with two viable alternatives: Laser Cutting and Waterjet Cutting.

Comparison Table

| Comparison Aspect | Able EDM | Laser Cutting | Waterjet Cutting |

|---|---|---|---|

| Performance | High precision; ideal for intricate designs and tough materials | Excellent for sheet metal; fast cutting speed | Good for thick materials; versatile |

| Cost | Moderate to high; depends on complexity and volume | Generally lower operational costs | Higher due to equipment and abrasive costs |

| Ease of Implementation | Requires skilled operators and setup time | Easier setup; fewer technical requirements | Moderate; requires training for operation |

| Maintenance | Regular maintenance needed for optimal performance | Low maintenance; minimal wear on parts | High maintenance; wear on abrasives and pumps |

| Best Use Case | Complex geometries in hard metals | Large sheets of metal and plastics | Thick materials and non-metal applications |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of Laser Cutting?

Laser cutting technology excels in efficiency, especially for sheet metal applications. Its operational costs are generally lower compared to EDM, making it attractive for high-volume production runs. The setup process is relatively straightforward, which reduces lead times. However, laser cutting may struggle with very thick materials and intricate designs, where precision is paramount, making it less suitable for industries requiring high accuracy.

How Does Waterjet Cutting Compare to Able EDM?

Waterjet cutting is a versatile method that uses high-pressure water mixed with abrasives to cut through materials. It can handle a wide range of materials, including metals, glass, and composites, making it a go-to solution for diverse applications. While it offers good precision, particularly with thick materials, the operational costs can be higher due to the need for abrasives and frequent maintenance of the cutting equipment. Additionally, the cutting speed is slower compared to both EDM and laser cutting, which can impact productivity in time-sensitive projects.

Conclusion: How to Choose the Right Machining Solution for Your Business

When evaluating machining solutions, B2B buyers should consider their specific production requirements, including the complexity of designs, material types, and budget constraints. Able EDM is a premier choice for intricate, high-precision components, particularly in demanding sectors like aerospace and medical. In contrast, laser cutting may be more cost-effective for high-volume sheet metal tasks, while waterjet cutting offers versatility across various materials. Ultimately, the best solution hinges on aligning the technology’s strengths with the operational needs and strategic objectives of the business.

Essential Technical Properties and Trade Terminology for able edm

What Are the Essential Technical Properties for Able EDM?

1. Material Grade

Material grade refers to the specific type of material used in the manufacturing process, which can include metals like titanium, inconel, and carbide. The grade affects the machining process, tool selection, and the final product’s performance. In B2B transactions, understanding material grades is crucial for ensuring that the components meet specific industry standards and application requirements, particularly in sectors like aerospace and medical devices.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension. In EDM machining, tolerances can be incredibly tight, often within ±0.001 inches or better. Precise tolerances are vital in industries where parts must fit together perfectly, such as in aerospace or surgical applications. For buyers, specifying tolerance levels in RFQs (Requests for Quotes) ensures that the supplier can meet their quality requirements.

3. Surface Finish

Surface finish refers to the texture of a machined surface, often measured in microinches or micrometers. Different processes yield different finishes, which can affect the performance and longevity of components. For B2B buyers, specifying the required surface finish is essential, as it can impact the part’s functionality and compliance with industry standards.

4. Machining Capability

This term refers to the specific capabilities of the EDM machines, including the maximum workpiece size, the type of electrode used, and the complexity of shapes that can be produced. Understanding machining capabilities is essential for buyers to ensure that their specific needs can be met, particularly when dealing with complex geometries or “difficult to machine” materials.

5. Production Volume

Production volume indicates the quantity of parts that can be produced within a specific timeframe. This is critical for buyers who need to meet deadlines or maintain inventory levels. Understanding production volume helps businesses plan their supply chain effectively, ensuring that they can meet customer demands without overcommitting resources.

6. Lead Time

Lead time is the time required from placing an order to the delivery of the finished product. For B2B buyers, knowing the lead time is essential for project planning and inventory management. Suppliers that can provide shorter lead times may offer a competitive advantage, especially in fast-paced industries.

What Are Common Trade Terms in the EDM Industry?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the EDM context, OEMs often require precise components that adhere to strict specifications. Understanding OEM relationships can help buyers identify reliable suppliers that can meet their quality and production needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it can impact purchasing decisions, especially for smaller businesses that may not require large volumes. Knowing the MOQ helps in budgeting and inventory planning.

3. RFQ (Request for Quote)

An RFQ is a document sent by buyers to suppliers to request pricing and terms for specific products or services. This is a critical step in the procurement process, allowing buyers to compare multiple suppliers and make informed decisions based on cost and capabilities.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and duties. Familiarity with these terms is crucial for B2B buyers engaged in global trade, as they help clarify costs and responsibilities throughout the shipping process.

5. CAD (Computer-Aided Design)

CAD refers to the use of software to create precise drawings and technical illustrations. In EDM, CAD files are essential for developing accurate machining processes. Buyers should ensure that their suppliers are proficient in CAD to facilitate smooth communication and efficient production.

6. ITAR (International Traffic in Arms Regulations)

ITAR is a set of U.S. government regulations that control the export and import of defense-related articles and services. For companies in the defense sector, working with ITAR-registered suppliers is crucial to ensure compliance with legal requirements. Understanding these regulations helps buyers mitigate risks associated with international trade in sensitive technologies.

Navigating Market Dynamics and Sourcing Trends in the able edm Sector

What Are the Current Market Dynamics and Key Trends in the Able EDM Sector?

The global Electrical Discharge Machining (EDM) market is experiencing robust growth, driven by the increasing demand for precision machining in various industries such as aerospace, defense, medical, and semiconductor manufacturing. The rise of advanced technologies, including automation and the Internet of Things (IoT), is shaping sourcing trends, enabling manufacturers to optimize production processes and enhance operational efficiency. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed sourcing decisions.

Emerging technologies are facilitating the integration of artificial intelligence and machine learning into EDM operations, which can significantly improve quality control and predictive maintenance. Additionally, the shift towards digital platforms for sourcing and procurement is gaining traction, allowing buyers to access a broader range of suppliers and solutions with greater ease. This trend is particularly beneficial for B2B buyers in developing markets, who can leverage these platforms to connect with reputable EDM service providers globally.

Moreover, the rising focus on customization and rapid prototyping is prompting manufacturers to invest in versatile EDM capabilities. For buyers from Nigeria and Brazil, this means sourcing partners who can handle complex, “difficult to machine” materials, such as titanium and Inconel, is increasingly important. The ability to provide quick turnaround times for prototypes can also be a competitive advantage in these fast-evolving markets.

How Is Sustainability and Ethical Sourcing Influencing the Able EDM Sector?

Sustainability has become a critical factor in B2B sourcing decisions, particularly as environmental concerns gain prominence across industries. The EDM sector is not exempt from this trend; manufacturers are increasingly adopting eco-friendly practices to minimize their environmental impact. For international buyers, this emphasis on sustainability translates into a demand for suppliers who prioritize ethical sourcing and green manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers that demonstrate a commitment to social responsibility, whether through fair labor practices or environmentally friendly materials. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers to gain the trust of discerning buyers.

In the able EDM sector, sourcing materials that are not only high-quality but also sustainable is gaining traction. For instance, the utilization of recycled metals and environmentally benign machining fluids is increasingly being adopted. Buyers looking for sustainable options should actively seek out suppliers who can provide transparency regarding their sourcing practices and environmental certifications.

What Is the Evolution of the Able EDM Sector?

The able EDM sector has evolved significantly since its inception, driven by advancements in technology and changing market demands. Initially focused on basic machining processes, the industry has transformed into a high-tech arena where precision and efficiency are paramount. The introduction of computer numerical control (CNC) technology revolutionized EDM, allowing for greater accuracy and the ability to handle complex geometries.

Over the years, the sector has expanded to cater to specialized industries such as aerospace and medical devices, where stringent quality standards are required. Companies that have adopted certifications like AS9100 and ISO9001 are now more competitive in the global market, ensuring that they meet the rigorous demands of their clients. This evolution underscores the importance of continuous improvement and innovation in the able EDM sector, making it essential for international B2B buyers to partner with manufacturers that are not only experienced but also forward-thinking in their approach to technology and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of able edm

-

How do I ensure quality when sourcing EDM services internationally?

To ensure quality when sourcing EDM services, prioritize suppliers with recognized certifications, such as AS9100 or ISO9001. Request to see their quality assurance processes, including inspection and testing protocols. Additionally, ask for references from previous clients in your industry to gauge their reliability and quality of work. Conducting a factory visit, if feasible, can provide further insight into their operations and quality control measures. -

What is the best EDM machining process for aerospace applications?

For aerospace applications, wire EDM is often the preferred process due to its ability to produce intricate shapes with tight tolerances in conductive materials. This method is ideal for high-strength alloys like titanium and inconel, commonly used in aerospace components. Additionally, sinker EDM can be beneficial for creating complex cavities and geometries, ensuring precision in critical components where performance and reliability are paramount. -

How can I customize my EDM project to meet specific requirements?

Customization in EDM projects starts with clear communication of your specifications, including material types, dimensions, tolerances, and any unique design features. Collaborate closely with your EDM supplier’s engineering team to discuss possible machining solutions. Many suppliers offer tailored services, such as adjusting machining parameters or using specific electrodes to achieve the desired outcome. Providing detailed CAD files can also facilitate accurate customization. -

What are the minimum order quantities (MOQ) for EDM services?

Minimum order quantities for EDM services can vary significantly depending on the supplier and the complexity of the parts required. Typically, for prototypes, suppliers may accept small orders, while production runs could require higher MOQs to justify setup costs. It’s advisable to discuss your specific needs with potential suppliers to understand their MOQ policies and to see if they can accommodate your order size. -

What payment terms should I expect when sourcing EDM services?

Payment terms for EDM services often include options such as upfront deposits, milestone payments, or payment upon completion. International buyers should clarify these terms before engaging in contracts. It’s common to negotiate terms based on order size and relationship with the supplier. Ensure that all payment agreements are documented clearly in the contract to avoid misunderstandings. -

How do I verify the capabilities of an EDM supplier?

To verify the capabilities of an EDM supplier, review their portfolio of past projects, focusing on industries similar to yours. Request documentation of their technical certifications and the specific types of EDM machines they operate. Engaging in preliminary discussions about your project can also reveal their expertise and willingness to collaborate. Additionally, consider requesting samples or a trial run to assess their work quality firsthand. -

What logistics considerations should I keep in mind when importing EDM parts?

When importing EDM parts, consider factors such as shipping methods, customs regulations, and import duties. Work closely with your supplier to understand their shipping capabilities and whether they provide logistics support. It’s also crucial to ensure that all documentation is in order, including invoices, packing lists, and certificates of origin, to facilitate smooth customs clearance and avoid delays. -

How can I address potential communication barriers with international EDM suppliers?

To overcome communication barriers with international EDM suppliers, establish clear channels of communication from the outset. Utilize project management tools that allow for shared documents and updates. Consider appointing a liaison fluent in the supplier’s language if necessary. Regular video calls can also enhance understanding and rapport, ensuring that all parties are aligned on project specifications and timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Able Edm Manufacturers & Suppliers List

1. Able Wire EDM – Precision Machining Solutions

Domain: ablewireedm.com

Registered: 2023 (2 years)

Introduction: Able Wire EDM, INC. specializes in Wire EDM, Sinker EDM, Small Hole EDM, and CNC Machining. They serve various industries including Aerospace, Defense, Surgical, Orthodontics, Missile, Aeronautical, Satellite, Tool & Die, Semiconductor, and Commercial sectors. The company is AS9100:2016/ISO9001:2015 certified and ITAR registered. They focus on prototype and production Wire EDM and have a reputatio…

2. Able Wire EDM – EDM & CNC Machining

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Able Wire EDM – EDM & CNC Machining, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Able Wire EDM Inc. – EDM & CNC Machining Solutions

Domain: cmtc.com

Registered: 1996 (29 years)

Introduction: Able Wire EDM Inc. specializes in all aspects of EDM (Electrical Discharge Machining) and CNC Machining. They utilize 20 electrical discharge machines, including 16 CNC 4-Axis Wire EDMs, 2 Charmilles CNC Sinker EDMs, 2 Belmont CNC small hole EDMs, and 1 Sodick K1C Small Hole EDM. Their capabilities include production and prototype requirements with precision, particularly in machining difficult ma…

4. Able Wire EDM – Wire EDM Machines & Sinker EDM

Domain: electricaldischargemachining.com

Registered: 2000 (25 years)

Introduction: Able Wire EDM, Inc. offers a comprehensive range of EDM products including:

1. Wire EDM Machines: Designed for precise cutting of intricate shapes in conductive materials, featuring advanced control systems, automatic wire threading, submerged cutting, and taper cutting capabilities.

2. Sinker EDM Machines: Used to create intricate shapes and cavities using electrodes and dielectric fluid, with m…

5. Able Grey – Social Media Management

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: This company, Able Grey – Social Media Management, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. LinkedIn – Dedicated API

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

7. Able Wire EDM – EDM & CNC Machining

Domain: m.facebook.com

Registered: 1997 (28 years)

Introduction: This company, Able Wire EDM – EDM & CNC Machining, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Able Wire EDM – Precision Wire EDM Services

Domain: insidejobsales.com

Registered: 2024 (1 years)

Introduction: Able Wire EDM is a specialized manufacturing company focusing on wire electrical discharge machining (EDM) services. They offer high-precision machining that meets stringent tolerances and complex design specifications. The company handles a variety of materials and component sizes, ensuring flexibility and reliability for clients’ production needs. Their capabilities include CNC Machining, specif…

Strategic Sourcing Conclusion and Outlook for able edm

In summary, the strategic sourcing of Electrical Discharge Machining (EDM) services from Able EDM presents significant advantages for international B2B buyers, particularly in high-demand sectors such as aerospace, medical, and defense. Their extensive capabilities in handling complex materials and precision machining position them as a reliable partner for businesses seeking quality and efficiency. The AS9100D and ISO9001:2015 certifications, along with ITAR registration, further underscore their commitment to excellence and compliance with industry standards.

As global supply chains evolve, the emphasis on strategic sourcing becomes increasingly critical. By leveraging Able EDM’s expertise, companies can not only enhance their operational efficiencies but also ensure timely delivery of high-quality components, thus gaining a competitive edge in their respective markets.

Looking ahead, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe should consider establishing partnerships with Able EDM. Doing so will enable them to tap into advanced machining solutions tailored to their specific needs. Connect with Able EDM today to explore how their innovative capabilities can help elevate your manufacturing processes and drive sustainable growth in your business.