Introduction: Navigating the Global Market for a36 steel angle

In the ever-evolving landscape of global trade, sourcing quality A36 steel angle can present a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The need for reliable suppliers who offer not only competitive pricing but also the assurance of material quality and compliance with international standards is paramount. This guide serves as a comprehensive resource, addressing key aspects such as the various types of A36 steel angle available, their diverse applications across industries, and essential supplier vetting criteria.

Understanding the nuances of A36 steel angle—from hot-rolled to cold-rolled options—can empower international buyers to make informed purchasing decisions. We delve into cost considerations, best practices for negotiating with suppliers, and logistics that impact the supply chain. By equipping B2B buyers with actionable insights and expert recommendations, this guide aims to streamline the procurement process, ensuring that companies can secure the materials they need without compromising on quality or budget.

Whether you are involved in construction, manufacturing, or structural engineering, navigating the complexities of sourcing A36 steel angle is made simpler with the knowledge provided here. Engage with this resource to enhance your purchasing strategy and foster successful supplier relationships in the global market.

Understanding a36 steel angle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Equal Leg Angle | Both legs are of equal length, typically available in various sizes and thicknesses. | Structural support, brackets, frames. | Pros: Easy to work with; versatile. Cons: Limited load distribution compared to unequal leg angles. |

| Unequal Leg Angle | One leg is longer than the other, providing unique load distribution properties. | Construction, machinery, and trailer frames. | Pros: Better suited for specific load applications. Cons: More complex to source and cut. |

| Galvanized Steel Angle | Coated with a layer of zinc for enhanced corrosion resistance. | Outdoor structures, marine applications. | Pros: Increased durability; rust-resistant. Cons: Higher initial cost than non-galvanized options. |

| Hot Rolled Steel Angle | Manufactured through hot rolling, resulting in a rough surface and lower cost. | General construction, structural applications. | Pros: Cost-effective; readily available. Cons: Surface imperfections may require finishing. |

| Cold Rolled Steel Angle | Processed through cold rolling for improved surface finish and tolerance. | Precision applications, automotive parts. | Pros: Enhanced dimensional accuracy; smoother finish. Cons: Higher cost and less availability than hot rolled. |

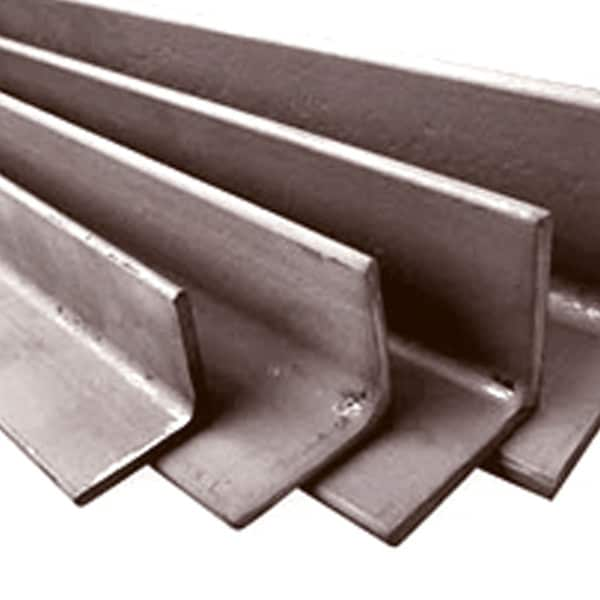

What Are the Key Characteristics of Equal Leg Angles?

Equal leg angles are characterized by two legs of the same length, making them a highly versatile choice for various applications. Their symmetrical design allows for uniform load distribution, making them suitable for structural support in buildings, brackets, and frames. When purchasing equal leg angles, buyers should consider the specific weight requirements and whether the standard sizes available will meet their project needs. The ease of welding and cutting also makes them a popular choice among manufacturers.

How Do Unequal Leg Angles Differ in Functionality?

Unequal leg angles feature one leg longer than the other, which allows for tailored load distribution. This design is particularly advantageous in applications where specific structural reinforcement is needed, such as in machinery and trailer frames. Buyers should assess the load requirements carefully, as the unequal distribution can provide enhanced support in certain scenarios. However, sourcing unequal leg angles may require additional customization, which can extend lead times and increase costs.

Why Choose Galvanized Steel Angles for Outdoor Applications?

Galvanized steel angles are coated with zinc, significantly enhancing their resistance to corrosion. This makes them ideal for outdoor structures or environments prone to moisture, such as marine applications. While they typically come at a higher upfront cost, the long-term savings due to reduced maintenance and replacement costs can be substantial. Buyers should weigh the initial investment against the durability and longevity benefits when considering galvanized options.

What Advantages Do Hot Rolled Steel Angles Offer?

Hot rolled steel angles are produced through a process that involves rolling steel at high temperatures. This results in a rough surface finish but allows for cost-effective pricing and widespread availability. They are commonly used in general construction and structural applications due to their affordability. Buyers should note that while hot rolled angles are budget-friendly, their surface imperfections may necessitate additional finishing for aesthetic applications.

When Should Buyers Consider Cold Rolled Steel Angles?

Cold rolled steel angles undergo a process that enhances their dimensional accuracy and surface finish, making them suitable for precision applications like automotive parts. They typically carry a higher price tag than hot rolled options, reflecting their increased manufacturing complexity. Buyers should consider cold rolled angles for projects where precision and appearance are critical, balancing the additional cost against the benefits of higher quality and performance.

Key Industrial Applications of a36 steel angle

| Industry/Sector | Specific Application of a36 steel angle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural framing and support | Provides strong support and stability for buildings and infrastructure | Ensure compliance with local building codes and standards; consider weight and size specifications. |

| Manufacturing | Machinery and equipment bases | Enhances the durability and reliability of manufacturing equipment | Look for custom cutting services to meet specific dimensions and tolerances. |

| Transportation | Trailer and vehicle frames | Lightweight yet strong, improving fuel efficiency and load capacity | Assess corrosion resistance, especially for regions with high humidity or salt exposure. |

| Energy | Support structures for solar panels | Maximizes the efficiency and longevity of renewable energy installations | Evaluate the material’s resistance to environmental factors and availability in required sizes. |

| Mining | Conveyor systems and structural supports | Increases operational efficiency and safety in material handling | Consider sourcing options that allow for quick delivery to remote locations. |

How is A36 Steel Angle Utilized in the Construction Industry?

In the construction sector, A36 steel angle is primarily used for structural framing and support. It provides the necessary strength and stability for various structures, including buildings, bridges, and infrastructure projects. The lightweight nature of A36 steel angle allows for easier handling during installation, while its high tensile strength ensures that it can withstand significant loads. International buyers must consider local building codes and standards to ensure compliance, as well as the specific weight and size specifications required for their projects.

What Role Does A36 Steel Angle Play in Manufacturing?

In manufacturing, A36 steel angle serves as a robust base for machinery and equipment. It enhances the durability and reliability of various manufacturing processes by providing a stable and secure framework. This material is particularly valued for its ability to be easily cut and welded, allowing for customization to meet specific operational requirements. When sourcing A36 steel angle, buyers should prioritize suppliers that offer custom cutting services to ensure that the angles meet precise dimensions and tolerances.

How is A36 Steel Angle Beneficial in Transportation?

The transportation industry utilizes A36 steel angle in the construction of trailer and vehicle frames. Its combination of lightweight properties and high strength improves the overall fuel efficiency and load capacity of vehicles. This is especially important in regions where transportation costs significantly impact profitability. Buyers should assess the corrosion resistance of A36 steel angle, particularly in areas with high humidity or salt exposure, to ensure the longevity and safety of their transport solutions.

What is the Importance of A36 Steel Angle in Energy Applications?

A36 steel angle is frequently employed in the construction of support structures for solar panels. Its strength and resistance to environmental factors enhance the efficiency and longevity of renewable energy installations. For international buyers in the energy sector, it is crucial to evaluate the material’s durability against weather conditions and its availability in sizes that meet specific project requirements. Sourcing A36 steel angle that meets these criteria can significantly impact the success of energy projects.

How Does A36 Steel Angle Support Mining Operations?

In the mining industry, A36 steel angle is commonly used in conveyor systems and structural supports. Its robust nature increases operational efficiency and safety during material handling processes. Given the often remote locations of mining operations, buyers should consider sourcing options that allow for quick delivery and availability of A36 steel angle in various sizes. This ensures that mining operations can maintain productivity without delays caused by material shortages.

3 Common User Pain Points for ‘a36 steel angle’ & Their Solutions

Scenario 1: Difficulties in Sourcing Quality A36 Steel Angle

The Problem: Many B2B buyers face challenges when sourcing A36 steel angles due to varying quality standards and inconsistent supplier reliability. This can lead to delays in project timelines and increased costs if the materials delivered do not meet the required specifications. Buyers often struggle with ensuring that the steel they receive complies with ASTM standards, which can result in structural integrity issues and project failures.

The Solution: To navigate these challenges, it’s essential to thoroughly vet potential suppliers before placing orders. Buyers should prioritize suppliers who are ISO 9001 certified, as this indicates a commitment to quality management systems. Requesting material test reports and certifications can provide additional assurance of quality. Additionally, establishing strong relationships with suppliers who offer transparent communication and reliable lead times can help mitigate sourcing issues. Implementing a just-in-time inventory strategy can also ensure that materials are available when needed, reducing the risk of project delays.

Scenario 2: Miscalculating Steel Angle Requirements for Projects

The Problem: B2B buyers often miscalculate the quantities and sizes of A36 steel angles required for their projects. This miscalculation can stem from a lack of understanding of the structural requirements or from failing to account for cutting losses during fabrication. As a result, companies may find themselves either over-ordering, leading to excess inventory costs, or under-ordering, causing project delays and increased shipping fees for rush orders.

The Solution: To avoid miscalculations, it’s crucial to use precise metal calculators and structural design software that can help determine the right dimensions and quantities of A36 steel angles needed for specific applications. Collaborating with structural engineers during the planning phase can ensure accurate specifications. Additionally, employing a supplier that offers custom cut-to-size services can minimize waste and allow for more accurate ordering. Implementing a thorough review process before finalizing orders can also help catch potential errors in specifications.

Scenario 3: Concerns About Corrosion and Durability of A36 Steel Angle

The Problem: Buyers often worry about the corrosion resistance and overall durability of A36 steel angles, especially in harsh environments or applications exposed to moisture. Without proper treatment or coating, A36 steel is susceptible to rust, which can compromise the longevity of the project and increase maintenance costs over time. This concern is particularly prevalent in regions with high humidity or industrial settings where exposure to chemicals is common.

The Solution: To address corrosion concerns, buyers should consider sourcing galvanized A36 steel angles, which provide enhanced corrosion resistance through a protective zinc coating. Additionally, applying suitable protective coatings during fabrication can help extend the lifespan of the steel in challenging environments. Buyers should also discuss environmental conditions with suppliers to ensure that the right type of steel and protective measures are employed. Regular inspections and maintenance schedules should be established to monitor the condition of the steel over time, allowing for timely interventions to prevent severe damage.

Strategic Material Selection Guide for a36 steel angle

What Are the Key Properties of A36 Steel Angle?

A36 steel angle is a low-carbon structural steel that is widely used in construction and manufacturing due to its excellent mechanical properties. It typically has a yield strength of 36,000 psi and is characterized by good weldability and machinability. This makes it suitable for various applications, including structural support and framing. However, it is essential to consider its limitations, particularly regarding corrosion resistance, as it can be susceptible to rust if not properly treated.

What Are the Advantages and Disadvantages of A36 Steel Angle?

When evaluating A36 steel angle, several advantages stand out. Its affordability makes it a popular choice for many B2B applications. The material is lightweight yet strong, which allows for easy handling and installation. Additionally, A36 steel is readily available in various sizes and shapes, making it versatile for different projects.

On the downside, A36 steel lacks inherent corrosion resistance, which can be a significant drawback in humid or corrosive environments. While galvanization can enhance its durability, this process adds to the overall cost. Furthermore, A36 steel may not perform well in high-temperature applications, which could limit its use in specific industries.

How Does A36 Steel Angle Impact Application Performance?

The performance of A36 steel angle is influenced by its mechanical properties and the environments in which it is used. For example, in construction projects, its strength and lightweight nature allow for effective load-bearing capabilities. However, when exposed to moisture or chemicals, the risk of corrosion increases, necessitating protective coatings or alternate materials in certain applications.

For international buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding local environmental conditions is crucial. Compliance with international standards such as ASTM, DIN, or JIS can also affect material selection. Buyers should ensure that their suppliers can provide documentation that meets these standards to avoid potential legal and operational issues.

What Specific Considerations Should International Buyers Keep in Mind?

International buyers must consider several factors when selecting A36 steel angle. Compliance with local regulations and standards is paramount, as different regions may have varying requirements for material properties and safety. In addition, understanding the local market’s material preferences can guide purchasing decisions. For instance, in regions with high humidity, buyers may prefer galvanized A36 steel to mitigate corrosion risks.

Logistical considerations, such as shipping costs and delivery times, are also important. Buyers should work with suppliers who have experience in international trade to ensure timely and compliant delivery of materials.

| Material | Typical Use Case for A36 Steel Angle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| A36 Steel Angle | Structural support in buildings and bridges | Affordable and widely available | Susceptible to corrosion | Low |

| Galvanized A36 Angle | Outdoor structures and marine applications | Enhanced corrosion resistance | Higher cost due to galvanization | Medium |

| Cold Rolled Steel Angle | Precision components in machinery | Superior surface finish and tolerance | More expensive than hot-rolled | Medium |

| Hot Rolled Steel Angle | General construction and fabrication | Good weldability and machining | Rough surface finish | Low |

This analysis provides a comprehensive overview of A36 steel angle and its variants, aiding international B2B buyers in making informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for a36 steel angle

What Are the Main Stages in the Manufacturing Process of A36 Steel Angle?

The manufacturing process of A36 steel angle involves several key stages, each critical to ensuring the quality and performance of the final product.

Material Preparation

The first step in the manufacturing process is material preparation. A36 steel, known for its low carbon content and good weldability, typically starts as hot-rolled steel. Steel slabs are heated and passed through rollers to achieve the desired thickness and shape. The initial processing often includes cutting the steel into manageable sizes, which can be further processed based on specific order requirements.

Forming Techniques

After preparation, the forming process begins. A36 steel angles are typically formed using hot rolling or cold rolling techniques. Hot rolling involves deforming the heated steel, which allows for easier manipulation into the desired angle shape. This process results in a rough finish but enhances the material’s structural integrity. Cold rolling, on the other hand, is performed at room temperature and results in a smoother finish with tighter tolerances.

Advanced techniques such as laser cutting, water jet cutting, or plasma cutting may also be employed to create precise dimensions and intricate designs based on customer specifications. These methods ensure that the angles can be customized to fit various applications in construction, manufacturing, and other industries.

Assembly and Finishing Processes

Once the angles are formed, they undergo assembly and finishing processes. This may involve additional cutting, welding, or fabrication to meet specific project requirements. For instance, angles might be joined with other structural components to create larger assemblies.

Finishing processes, such as galvanization, are crucial for enhancing corrosion resistance, especially for applications in harsh environments. Galvanization involves coating the steel with zinc to prevent rusting and increase longevity. Other finishing options might include painting or applying protective coatings based on the end-use conditions.

What Quality Assurance Measures Are Commonly Used in A36 Steel Angle Production?

Quality assurance is paramount in the manufacturing of A36 steel angles to ensure that they meet international standards and customer expectations.

What International Standards Govern A36 Steel Angle Production?

A36 steel angle production is governed by various international standards, with ISO 9001 being one of the most significant. This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

Additionally, regional standards may apply, such as CE marking in Europe, which indicates compliance with safety, health, and environmental protection standards. In the Middle East, standards set by the Gulf Cooperation Council (GCC) may also influence quality assurance practices.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integral to the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): This ongoing assessment occurs during the manufacturing process, where various parameters are monitored to ensure compliance with quality standards.

- Final Quality Control (FQC): At this stage, finished products undergo comprehensive testing and inspections to verify that they meet all specifications before shipping.

Common testing methods include tensile testing, hardness testing, and visual inspections to identify any defects in the steel angles.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for mitigating risks associated with procurement.

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request and review supplier audits and quality control reports. These documents provide insights into the supplier’s adherence to international standards and their quality management processes. Regular audits by third-party inspectors can also ensure that the supplier maintains compliance with industry standards.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. These inspections typically include detailed evaluations of manufacturing processes, materials, and finished products, ensuring they meet the required specifications and standards.

What Are the QC and Certification Nuances for International B2B Buyers?

Understanding the nuances of quality control and certification is vital for international B2B buyers.

How Do Regional Standards Impact Quality Assurance?

Regional standards can significantly impact the quality assurance processes and certifications required for A36 steel angles. For instance, European buyers may need to ensure CE marking, while buyers in the Middle East may have specific GCC standards to consider.

Why Is Traceability Important for International Transactions?

Traceability of materials and processes is essential in international transactions. Buyers should ensure that suppliers can provide documentation demonstrating the origin of materials and the quality control measures implemented throughout the manufacturing process. This documentation can be crucial for compliance with local regulations and for resolving disputes that may arise regarding product quality.

Conclusion

The manufacturing processes and quality assurance measures for A36 steel angles are complex and multifaceted. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers. Ensuring compliance with international standards, engaging in thorough quality control practices, and verifying supplier certifications are all critical steps in securing high-quality A36 steel angles that meet project requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘a36 steel angle’

Introduction

This guide provides a practical checklist for B2B buyers looking to procure A36 steel angles, ensuring a smooth and efficient sourcing process. A36 steel angles are versatile and widely used in various industries for structural support, brackets, and framing. Following this checklist will help you make informed decisions and establish a reliable supply chain.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your project is crucial before starting the procurement process. Determine the dimensions, weight capacity, and any specific treatments (e.g., galvanized) needed for your A36 steel angles. This clarity will help you communicate effectively with suppliers and ensure you receive the correct products.

Step 2: Research Potential Suppliers

Invest time in identifying suppliers who specialize in A36 steel angles. Look for manufacturers or distributors with a solid reputation in the industry, particularly those with experience in your target markets, such as Africa, South America, or the Middle East. Consider using online directories, trade shows, and industry networks to gather a list of potential partners.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with relevant industry standards. Look for certifications like ISO 9001, which indicates a commitment to quality management. Ensure the supplier can provide mill test reports for the steel, confirming it meets ASTM A36 specifications.

Step 4: Request Samples and Quotes

Obtaining samples allows you to assess the quality of the A36 steel angles firsthand. Request quotes from multiple suppliers to compare pricing, lead times, and terms of service. This step not only helps you gauge the market price but also provides insights into each supplier’s customer service and responsiveness.

Step 5: Assess Delivery Capabilities

Consider the supplier’s logistics and delivery options, especially if you are sourcing from international locations. Verify their ability to meet your timelines, whether through local delivery or export arrangements. Ensure they have experience handling customs and regulations for your specific regions, such as Saudi Arabia or Europe.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to establish favorable terms. Discuss payment options, bulk order discounts, and warranties. Clear agreements on these aspects can save you significant costs and protect your interests in case of issues with the supplied materials.

Step 7: Establish a Long-Term Relationship

After your initial purchase, focus on building a long-term relationship with your supplier. Regular communication and feedback will help you address any concerns and adapt to changing project needs. A reliable supplier can provide ongoing support, competitive pricing, and consistent quality, ultimately benefiting your business in the long run.

By following this checklist, you can navigate the complexities of sourcing A36 steel angles effectively, ensuring that you receive the best products for your projects while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for a36 steel angle Sourcing

What Are the Key Cost Components in A36 Steel Angle Sourcing?

When sourcing A36 steel angles, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The raw material cost is often the most significant expense. A36 steel is a low-carbon steel, which typically offers a competitive price point due to its widespread availability. Prices can fluctuate based on global steel market trends and the price of raw materials like iron ore and scrap steel.

-

Labor: Labor costs encompass both direct and indirect labor involved in processing the steel angles. This includes cutting, welding, and any additional fabrication services requested by the buyer.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and equipment depreciation. Efficient production processes can help lower these costs.

-

Tooling: Specialized tooling for cutting and shaping steel angles can add to the overall cost, particularly for customized or intricate designs.

-

Quality Control (QC): Ensuring that the steel angles meet industry standards (like ASTM A36) requires an investment in quality control measures, which can include material testing and certifications.

-

Logistics: Shipping costs can vary significantly based on the distance from the supplier to the buyer, transportation method, and any special handling requirements. For international buyers, this can include import duties and tariffs.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market conditions and supplier relationships.

How Do Price Influencers Affect A36 Steel Angle Costs?

Several factors influence the pricing of A36 steel angles:

-

Volume/MOQ: Buying in bulk can lead to significant discounts. Suppliers often have Minimum Order Quantities (MOQ) that can affect pricing. Larger orders generally attract better rates.

-

Specifications/Customization: Custom sizes or specifications can increase costs due to additional labor and tooling requirements. Standard sizes are more cost-effective.

-

Materials: The grade and quality of the steel used can impact pricing. Higher quality or specialized steel may come at a premium.

-

Quality/Certifications: Certifications like ISO 9001 can add to costs but may be essential for buyers requiring assurance of quality and compliance.

-

Supplier Factors: The supplier’s reputation, location, and their own operational efficiencies can influence pricing. Suppliers with established relationships and efficient processes may offer better rates.

-

Incoterms: The chosen Incoterms can significantly impact the total cost of ownership. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, affecting the final pricing structure.

What Are the Best Buyer Tips for Negotiating A36 Steel Angle Prices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, here are actionable tips for effective negotiation:

-

Research Market Prices: Understand current market prices for A36 steel angles to negotiate effectively. This includes being aware of the fluctuations in steel prices and economic conditions affecting the steel industry.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in shipping, handling, and potential customs duties to understand the true cost of sourcing A36 steel angles.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms and delivery schedules. Suppliers may offer flexibility that can help with cash flow and project timelines.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships may yield loyalty discounts and priority service.

-

Be Aware of Pricing Nuances: International buyers should consider currency fluctuations and economic stability in both the supplier’s and buyer’s countries, as these can affect pricing and payment terms.

Disclaimer on Indicative Prices

It is essential to note that prices for A36 steel angles can vary widely based on market conditions, supplier negotiations, and specific project requirements. Always request formal quotes from suppliers to get the most accurate pricing for your specific needs.

Alternatives Analysis: Comparing a36 steel angle With Other Solutions

Exploring Alternatives to A36 Steel Angle: A Comparative Analysis

In the realm of structural materials, A36 steel angle is widely recognized for its strength and versatility. However, B2B buyers must consider various alternatives that may better suit specific applications or project requirements. This analysis will compare A36 steel angle with two viable alternatives: stainless steel angle and aluminum angle, helping international buyers make informed decisions.

| Comparison Aspect | A36 Steel Angle | Stainless Steel Angle | Aluminum Angle |

|---|---|---|---|

| Performance | High strength, good weldability | Excellent corrosion resistance | Lightweight, good strength-to-weight ratio |

| Cost | Generally low cost | Higher initial investment | Moderate cost, varies by alloy |

| Ease of Implementation | Simple to cut and weld | Requires specialized tools for welding | Easy to work with, can be cut with standard tools |

| Maintenance | Requires regular maintenance to prevent rust | Low maintenance, does not rust | Minimal maintenance, can corrode in saltwater |

| Best Use Case | General construction, structural support | Marine applications, corrosive environments | Lightweight structures, portable applications |

What Are the Advantages and Disadvantages of Stainless Steel Angle?

Stainless steel angle offers superior corrosion resistance compared to A36 steel, making it an ideal choice for environments exposed to moisture or chemicals. Its longevity and aesthetic appeal are significant advantages, especially in architectural applications. However, the higher cost and the need for specialized welding techniques can be drawbacks for budget-conscious projects. For buyers in regions with high humidity or corrosive conditions, stainless steel angle can be a worthwhile investment.

How Does Aluminum Angle Compare to A36 Steel Angle?

Aluminum angle is known for its lightweight characteristics, making it a preferred choice for applications where reducing overall weight is essential. It also boasts good strength and is resistant to corrosion, which is beneficial in outdoor settings. While aluminum is easier to work with using standard tools, its cost can be moderate and varies depending on the specific alloy. This makes aluminum angle suitable for portable structures and frames, particularly in industries such as aerospace and automotive.

Conclusion: How to Choose the Right Solution for Your Needs?

When selecting between A36 steel angle and its alternatives, buyers should evaluate their specific requirements, including environmental conditions, budget constraints, and intended applications. A36 steel angle is an excellent choice for general structural support due to its affordability and strength. Conversely, stainless steel angle is better suited for corrosive environments, while aluminum angle is ideal for lightweight and portable applications. Understanding these factors will help B2B buyers make the most informed decision for their projects, ultimately leading to enhanced performance and value.

Essential Technical Properties and Trade Terminology for a36 steel angle

What Are the Key Technical Properties of A36 Steel Angle?

A36 steel angle is a versatile material widely used in construction and manufacturing due to its favorable properties. Understanding its technical specifications is crucial for B2B buyers to ensure they select the right material for their applications.

-

Material Grade: A36 refers to the ASTM A36 standard, which specifies a low carbon steel with a yield strength of 36,000 psi (250 MPa). This material is known for its excellent weldability and machinability, making it suitable for structural components in buildings, bridges, and various fabrication projects. For B2B buyers, selecting the right grade ensures that the steel will meet the strength requirements of their projects.

-

Chemical Composition: The typical chemical makeup of A36 steel includes carbon (C), manganese (Mn), phosphorus (P), and sulfur (S). For example, the carbon content is around 0.26%, which influences the steel’s hardness and strength. Understanding the chemical composition is vital for buyers who require specific properties for their applications, such as corrosion resistance or weldability.

-

Mechanical Properties: A36 steel exhibits notable mechanical properties, including an ultimate tensile strength of approximately 58,000 psi (400 MPa) and a yield strength of about 47,700 psi (315 MPa). These properties dictate the steel’s performance under load, making it essential for buyers to consider when designing load-bearing structures.

-

Tolerances and Dimensions: A36 steel angles are available in a range of sizes and thicknesses, typically adhering to specific tolerances. For example, dimensions might vary slightly due to manufacturing processes, but understanding these tolerances is important for ensuring compatibility with other components in a project. Buyers should verify that the specifications align with their design requirements.

-

Surface Finish: A36 steel is usually hot-rolled, resulting in a rough, blue-grey finish. This surface condition may be important for aesthetic considerations or for the application of protective coatings. Buyers should consider whether additional surface treatments, such as galvanization, are necessary for their specific environments.

-

Availability and Sourcing: A36 steel angles are commonly available in various lengths and can often be customized. Understanding lead times, stock availability, and potential for custom orders can significantly affect project timelines and costs for B2B buyers.

What Are the Common Trade Terminologies Associated with A36 Steel Angle?

Navigating the terminology in the steel industry can be daunting for non-technical decision-makers. Here are several essential terms that are relevant to A36 steel angle transactions:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships is critical when sourcing A36 steel angles, especially when specific standards or quality certifications are required.

-

MOQ (Minimum Order Quantity): MOQ represents the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ for A36 steel angles is essential for budgeting and planning inventory, as purchasing below this threshold may lead to higher costs per unit.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing for specific products or services. B2B buyers should prepare comprehensive RFQs that detail the required specifications for A36 steel angles to receive accurate and competitive quotes.

-

Incoterms: International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risk management, and delivery responsibilities when procuring A36 steel angles from global suppliers.

-

Lead Time: This term refers to the time it takes from placing an order to receiving the product. For A36 steel angles, lead times can vary based on stock availability and manufacturing processes. Buyers should factor in lead times when planning projects to avoid delays.

-

Galvanization: This is a process where steel is coated with a layer of zinc to prevent corrosion. Understanding galvanization is vital for B2B buyers, especially when A36 steel angles will be exposed to harsh environmental conditions.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, ensuring that their projects are successful and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the a36 steel angle Sector

What Are the Key Market Dynamics and Trends Influencing the A36 Steel Angle Sector?

The A36 steel angle market is currently experiencing significant transformations driven by global economic conditions, technological advancements, and evolving customer needs. One major driver is the increased demand for infrastructure development, particularly in emerging markets across Africa, South America, and the Middle East. Countries like Saudi Arabia and Vietnam are ramping up construction projects, which boosts the need for robust materials like A36 steel angles, known for their durability and versatility in structural applications.

Furthermore, technological advancements in sourcing and procurement are reshaping how international buyers approach their supply chains. The adoption of digital platforms for sourcing, coupled with Just-In-Time (JIT) manufacturing practices, enables companies to minimize inventory costs while ensuring timely delivery of materials. Buyers are increasingly leveraging platforms that offer real-time pricing, stock availability, and custom cutting services, enhancing their operational efficiency.

Another noteworthy trend is the growing preference for sustainable sourcing practices. International buyers are now more inclined to partner with suppliers who demonstrate a commitment to environmental stewardship and ethical sourcing. This shift is not only driven by regulatory pressures but also by increasing consumer awareness regarding sustainability issues. As a result, suppliers are enhancing their product offerings by incorporating green certifications and environmentally-friendly practices into their operations.

How Important Is Sustainability and Ethical Sourcing in the A36 Steel Angle Market?

Sustainability and ethical sourcing have become critical focal points in the A36 steel angle sector, influencing purchasing decisions among B2B buyers. The environmental impact of steel production, including greenhouse gas emissions and energy consumption, has prompted companies to seek out suppliers committed to sustainable practices. This includes using recycled materials, reducing waste, and employing energy-efficient manufacturing processes.

Furthermore, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ sourcing practices to ensure compliance with labor standards and fair trade principles. Companies that prioritize ethical sourcing not only enhance their brand reputation but also mitigate risks associated with supply chain disruptions.

In response to these trends, many suppliers are pursuing green certifications and developing eco-friendly materials. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to compete in the global market. By choosing suppliers with these certifications, B2B buyers can align their purchasing strategies with sustainability goals, thus contributing to a more responsible and eco-conscious industry.

What Is the Historical Context of the A36 Steel Angle?

The A36 steel angle has its roots in the evolution of structural steel as a fundamental building material. Initially standardized by ASTM (American Society for Testing and Materials) in the early 20th century, A36 became a go-to choice for construction due to its excellent weldability and machinability. Over the decades, as industrialization accelerated, the demand for reliable and versatile materials like A36 steel angles surged, particularly in the construction and manufacturing sectors.

As global markets expanded, the A36 standard was adopted widely, leading to increased production capabilities and innovations in steel fabrication techniques. Today, A36 steel angles are integral to various applications, including bridges, buildings, and machinery, reflecting the material’s resilience and adaptability in meeting the demands of modern engineering and construction practices.

Frequently Asked Questions (FAQs) for B2B Buyers of a36 steel angle

-

How do I choose the right A36 steel angle for my project?

Choosing the appropriate A36 steel angle depends on your project’s specific requirements. Consider factors like the angle’s dimensions (height, width, and thickness), the load it needs to support, and the environment it will be used in. For structural applications, ensure the angle meets the necessary strength and durability standards. It’s also essential to consider the availability of custom sizes and whether the supplier offers cutting services to fit your specifications. -

What are the common applications for A36 steel angles in construction?

A36 steel angles are versatile and commonly used in various construction applications, including structural support, framing, brackets, and bracing. They are ideal for creating frameworks in buildings, bridges, and equipment due to their strength and durability. Additionally, they can be used in manufacturing trailers and in the automotive industry, making them a popular choice for many industrial projects. -

What is the typical lead time for sourcing A36 steel angles internationally?

Lead times for sourcing A36 steel angles can vary significantly based on the supplier’s location, inventory levels, and shipping methods. Typically, international orders can take anywhere from a few weeks to several months. It’s advisable to communicate directly with suppliers to confirm lead times and discuss potential expedited shipping options if your project timeline is tight. -

How can I vet suppliers for A36 steel angles?

When vetting suppliers, consider their industry reputation, experience, and certifications. Look for suppliers with ISO certifications or those compliant with ASTM standards, as these indicate quality assurance in their products. Additionally, request references from previous clients and inquire about their experience with international shipments, including customs handling and delivery reliability. -

What is the minimum order quantity (MOQ) for A36 steel angles?

Minimum order quantities for A36 steel angles can vary by supplier and may depend on factors such as the size and type of angle required. Generally, MOQs can range from a few hundred kilograms to several tons. Discuss your project needs with potential suppliers to find one that accommodates smaller orders or offers flexibility in MOQs. -

What payment terms should I expect when purchasing A36 steel angles internationally?

Payment terms can differ significantly among suppliers, but common practices include upfront payments, letters of credit, or net 30/60 days after delivery. It’s crucial to negotiate terms that protect your interests, especially for larger orders. Consider using secure payment methods and ensure that the terms are documented in a formal contract to avoid misunderstandings. -

How can I ensure quality assurance for my A36 steel angles?

To ensure quality, request material test reports from suppliers that detail the chemical composition and mechanical properties of the A36 steel angles. Additionally, consider suppliers who provide third-party inspections or certifications. Establishing clear specifications and quality standards in your purchase agreement can also help guarantee that the products meet your requirements. -

What logistics considerations should I keep in mind for shipping A36 steel angles?

When planning logistics for shipping A36 steel angles, consider factors such as shipping method, costs, and customs regulations in your country. Ensure that the supplier has experience with international shipping and can handle documentation, including bills of lading and customs declarations. Additionally, evaluate the potential impact of tariffs or duties on your total cost and delivery timeline, and consider insurance for valuable shipments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 A36 Steel Angle Manufacturers & Suppliers List

1. Industrial Metal Supply – Steel Angles

Domain: industrialmetalsupply.com

Registered: 1999 (26 years)

Introduction: Steel Angle | Hot Rolled & Cold Rolled Steel Fabrications

– Locations: Inland Empire, Los Angeles, Orange County, San Diego, San Jose, Phoenix, Tucson

– Product Types: Hot-rolled steel angles, cold-rolled steel angles, galvanized steel angles

– Benefits: Affordable, lightweight, superior weight-bearing strength, durable, versatile, easy to cut, weld, form, low-maintenance, recyclable

– Cutting Ser…

2. Coremark Metals – A36 Hot Rolled Angles

Domain: coremarkmetals.com

Registered: 2018 (7 years)

Introduction: This company, Coremark Metals – A36 Hot Rolled Angles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Metals Depot – Steel Angle A36

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Steel Angle A36”, “description”: “One of the most popular hot rolled, low carbon steel shapes used in manufacturing, fabrication, and repair projects. Its 90 degree angle shape adds strength and rigidity to any project for a lower price compared to other shapes and types of metal. It is easy to weld, cut, form and machine.”, “specifications”: {“material”: “ASTM A36 Steel”, “finis…

4. Midwest Steel Supply – A36 Hot Roll Steel Angle

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: This company, Midwest Steel Supply – A36 Hot Roll Steel Angle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Stock Car Steel – A36 Hot Rolled Steel Angle

Domain: stockcarsteel.com

Registered: 2002 (23 years)

Introduction: This company, Stock Car Steel – A36 Hot Rolled Steel Angle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Online Metal Supply – A36 Hot Rolled Steel Angle

Domain: onlinemetalsupply.com

Registered: 2005 (20 years)

Introduction: A36 Steel Angle Hot Rolled

– Material: Low Carbon (Mild) Steel

– Finish: Hot Rolled (Rough Surface)

– Shape: Angle (Rounded or Tapered Legs)

– Corrosion Resistance: Good

– Weldability: Easy to weld, cut, form, and machine

– Stock Availability: All listed angles are in stock and ship free to lower 48 states.

– Sizes Available:

1. 1″ x 1″ x 1/8″ x 30″ – Price: $21.70

2. 1-1/2″ x 1-1/2″ x 1/4″ x …

7. Kloeckner Metals – A36 Angles

Domain: kloecknermetals.com

Registered: 2011 (14 years)

Introduction: A36 Angles are structural steel components made from a lightweight, hot-rolled, low-carbon steel alloy. They are commonly used in buildings and bridges and are known for their strength, affordability, and flexibility. The alloy composition includes manganese (1.03%), silicon (0.28%), carbon (0.25-0.29%), copper (0.2%), sulfur (0.5%), and phosphorus (0.4%). A36 steel angles have a yield point of 36…

8. Engineers Edge – ASTM A36 Structural Steel Angle

Domain: engineersedge.com

Registered: 2000 (25 years)

Introduction: ASTM A36 Structural Steel Angle is a widely used carbon steel in the industry. It is weldable, formable, and machinable. Galvanizing increases its corrosion-resistance. The product details include various sizes ranging from L2 to L31, with properties such as weight per foot, cross section area, area moment of inertia, and wall thickness. Specific sizes and their properties include: L8x8x11/8 (Weig…

Strategic Sourcing Conclusion and Outlook for a36 steel angle

In the evolving landscape of global steel procurement, A36 steel angle stands out as a versatile and cost-effective choice for various structural applications. Its low carbon content facilitates excellent weldability and formability, making it suitable for industries ranging from construction to automotive. Strategic sourcing of A36 steel angle not only ensures access to high-quality materials but also enhances supply chain efficiency, particularly for international buyers in Africa, South America, the Middle East, and Europe.

By leveraging local suppliers and optimizing logistics, businesses can reduce lead times and costs, ultimately improving project timelines and profitability. As the demand for sustainable practices rises, sourcing A36 steel, which is recyclable and widely available, aligns with environmental goals and corporate responsibility.

Looking ahead, international B2B buyers should prioritize establishing robust relationships with reliable suppliers who offer tailored solutions, including custom cut-to-size services and just-in-time delivery options. Embrace the opportunities presented by A36 steel angle to strengthen your operations and drive growth in an increasingly competitive market. Consider engaging with trusted suppliers today to secure the best material solutions for your projects and stay ahead in the steel industry.