Introduction: Navigating the Global Market for a1008 steel

In the competitive landscape of global steel procurement, sourcing a1008 steel presents unique challenges for international B2B buyers. With its excellent weldability and formability, a1008 steel is an essential material for various applications, including home appliances, automotive parts, and furniture. However, navigating the complexities of supplier selection, pricing, and quality assurance can be daunting, especially for businesses in regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Germany.

This comprehensive guide aims to equip B2B buyers with the critical insights needed to make informed purchasing decisions regarding a1008 steel. We delve into various types of a1008 steel, their specific applications, and the nuances of supplier vetting to ensure quality and reliability. Additionally, we cover essential cost factors and offer strategies for negotiating favorable terms. By providing a thorough understanding of the a1008 steel market, this guide empowers businesses to optimize their sourcing processes, mitigate risks, and ultimately enhance their competitive edge in the marketplace.

With actionable insights and expert recommendations, this resource is designed to simplify your procurement journey and help you harness the full potential of a1008 steel for your operational needs.

Understanding a1008 steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CS Type A | Commercial steel with good formability and weldability. | Home appliances, furniture, automotive. | Pros: Cost-effective, versatile. Cons: Limited strength. |

| CS Type B | Higher yield strength than Type A, suitable for moderate forming. | Automotive body panels, structural parts. | Pros: Better performance in forming. Cons: Slightly higher cost. |

| DS Type A | Drawing steel with excellent elongation properties. | Deep drawn parts, complex shapes. | Pros: Superior formability. Cons: Requires careful handling to avoid defects. |

| DDS | Extra deep drawing steel, designed for very complex shapes. | Automotive components, intricate designs. | Pros: Exceptional deep drawing capabilities. Cons: Higher price point. |

| HSLAS-F | High-strength low-alloy steel with improved formability. | Structural applications, automotive frames. | Pros: Lightweight with high strength. Cons: More expensive than standard grades. |

What are the Characteristics of CS Type A A1008 Steel?

CS Type A is a commercial steel variant known for its good formability and weldability, making it a popular choice in various industries. With a low carbon content, it offers ease of fabrication while maintaining adequate strength for applications such as home appliances and furniture. B2B buyers should consider its cost-effectiveness and versatility, though its limited strength may not be suitable for high-stress applications.

How Does CS Type B Differ from Other Variants?

CS Type B features a higher yield strength compared to Type A, which enhances its suitability for moderate forming processes. This type is often utilized in the automotive sector for body panels and structural components where additional strength is necessary. While it offers improved performance, buyers should weigh the slightly higher cost against the benefits of its enhanced properties.

Why Choose DS Type A for Your Projects?

DS Type A, or drawing steel, is characterized by its excellent elongation properties, making it ideal for applications requiring deep drawing and complex shapes. Industries that manufacture intricate components will find this type particularly beneficial. However, buyers must handle DS Type A with care during processing to prevent defects, which can impact production efficiency.

What Advantages Does DDS Provide for Complex Applications?

Extra deep drawing steel (DDS) is specifically engineered for applications involving very complex shapes, such as automotive components. Its exceptional deep drawing capabilities allow manufacturers to create intricate designs that standard steels cannot achieve. While the benefits are significant, the higher price point may be a consideration for budget-conscious buyers.

When Should You Consider HSLAS-F?

High-strength low-alloy steel with improved formability (HSLAS-F) is ideal for structural applications where reducing weight while maintaining strength is critical. This steel variant is particularly valuable in automotive frames and similar applications. Although it comes at a premium price, the advantages of weight savings and increased strength can justify the investment for many businesses looking to enhance performance.

Key Industrial Applications of a1008 steel

| Industry/Sector | Specific Application of a1008 steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Home Appliances | Manufacturing of appliance casings and components | Lightweight yet durable materials enhance energy efficiency | Need for precise dimensions and surface finish standards |

| Automotive | Production of automotive body panels and structural parts | Improved strength-to-weight ratio contributes to fuel efficiency | Compliance with automotive safety and performance standards |

| Furniture | Fabrication of metal furniture frames | Aesthetic appeal and durability in design | Customization options for design and finish are essential |

| Construction | Use in structural components and panels | Cost-effective material with good weldability and formability | Requirements for corrosion resistance and local availability |

| Electrical Equipment | Creation of enclosures for electrical devices | Enhanced safety and protection for sensitive components | Specifications for thermal conductivity and electrical safety |

How is A1008 Steel Used in Home Appliances?

In the home appliance industry, A1008 steel is widely utilized for manufacturing casings and internal components. Its excellent weldability and formability allow for intricate designs that enhance both functionality and aesthetics. This steel’s lightweight nature contributes to energy efficiency, a critical factor for modern appliances. Buyers should ensure that the sourced material meets specific dimensional tolerances and surface finish standards to maintain product quality and performance in competitive markets.

What Role Does A1008 Steel Play in Automotive Manufacturing?

A1008 steel is integral to the automotive sector, particularly in the production of body panels and structural parts. Its high strength-to-weight ratio is vital for improving vehicle fuel efficiency while maintaining safety standards. Additionally, the ability to easily weld and form this steel allows manufacturers to meet stringent automotive safety regulations. International buyers must consider compliance with regional automotive standards, ensuring that the steel meets both performance and environmental requirements.

How is A1008 Steel Beneficial in Furniture Manufacturing?

In furniture manufacturing, A1008 steel is employed to create robust metal frames that offer both durability and aesthetic appeal. The material’s versatility allows designers to craft innovative and stylish furniture pieces that cater to contemporary tastes. Businesses sourcing A1008 steel for furniture must prioritize customization options, including various finishes and coatings, to enhance the product’s marketability and longevity.

In What Ways is A1008 Steel Used in Construction?

A1008 steel is commonly used in the construction industry for structural components and panels. Its cost-effectiveness, combined with good weldability and formability, makes it an attractive choice for builders. This steel can help meet structural integrity requirements while minimizing overall project costs. Buyers should be aware of local regulations regarding corrosion resistance, especially in regions prone to harsh weather conditions, to ensure the longevity of their structures.

How is A1008 Steel Applied in Electrical Equipment Manufacturing?

In the electrical equipment sector, A1008 steel is used to create enclosures that protect sensitive components from environmental factors. The material’s mechanical properties ensure safety and reliability, which are critical in electrical applications. When sourcing A1008 steel for this purpose, businesses should focus on specifications for thermal conductivity and electrical safety to comply with industry standards and regulations, ensuring that their products perform reliably over time.

3 Common User Pain Points for ‘a1008 steel’ & Their Solutions

Scenario 1: Challenges with Corrosion Resistance in A1008 Steel

The Problem: Many B2B buyers in regions with high humidity or corrosive environments face significant challenges when using A1008 steel. This low-carbon steel, while excellent for its formability and weldability, lacks inherent corrosion resistance. Consequently, applications in outdoor structures, automotive parts, or even household appliances can suffer from rapid oxidation and rusting. Buyers often find that the lifespan of their products is compromised, leading to increased maintenance costs and dissatisfaction from end-users.

The Solution: To combat the corrosion challenges associated with A1008 steel, it is essential to implement protective coatings. Galvanizing—where the steel is coated with a layer of zinc—can significantly enhance corrosion resistance, making it suitable for outdoor applications. Additionally, applying a paint or powder coating can provide a barrier against moisture and corrosive elements. Buyers should prioritize sourcing A1008 steel that is pre-treated or consider post-processing options that include surface treatments. Engaging with suppliers who offer customized finishing services can ensure that the steel meets specific environmental challenges. Furthermore, regular maintenance and inspections can help to identify any early signs of corrosion, allowing for timely interventions.

Scenario 2: Difficulty in Sourcing Quality A1008 Steel

The Problem: International B2B buyers often struggle to source high-quality A1008 steel, especially in markets like Africa and South America, where supply chains may be less robust. Issues such as inconsistent quality, lack of certification, and unreliable delivery times can hinder production schedules and lead to project delays. This can result in increased costs and a loss of trust from clients who depend on timely deliveries and quality materials.

The Solution: To mitigate sourcing challenges, buyers should establish relationships with reputable suppliers who have a proven track record in the industry. It’s advisable to request material certifications, such as ASTM A1008 compliance, to ensure that the steel meets required standards. Buyers should also consider leveraging technology to enhance their procurement processes—using online marketplaces or platforms that specialize in industrial materials can provide access to a broader range of suppliers and product options. Additionally, forming strategic partnerships with local distributors can help facilitate quicker deliveries and reduce lead times. Regular audits and performance reviews of suppliers can further ensure that quality standards are maintained consistently.

Scenario 3: Understanding the Mechanical Properties of A1008 Steel

The Problem: Another common issue faced by B2B buyers is the lack of understanding regarding the mechanical properties of A1008 steel, which can lead to improper application and product failures. Buyers may not be fully aware of the steel’s yield strength, tensile strength, or elongation characteristics, resulting in the selection of inappropriate grades for specific applications. This can lead to products that fail to meet performance expectations, causing costly reworks and damaged reputations.

The Solution: To address this knowledge gap, buyers should invest time in understanding the specifications and mechanical properties of A1008 steel. Comprehensive product guides, technical datasheets, and consultation with metallurgical experts can provide valuable insights into the appropriate use of A1008 steel for different applications. Buyers should also participate in industry seminars or workshops that focus on material selection and engineering practices. Utilizing tools like strength calculators or simulation software can help predict how A1008 steel will perform under various conditions. When placing orders, specifying the desired grade and mechanical properties upfront can further ensure that the right material is sourced for specific projects, minimizing the risk of performance-related issues.

Strategic Material Selection Guide for a1008 steel

What Are the Key Properties of A1008 Steel?

A1008 steel is a cold-rolled carbon steel known for its excellent weldability and formability. It typically contains about 0.40% manganese, which enhances its mechanical properties while maintaining a low carbon content. This combination results in a material that is strong yet malleable, making it suitable for various applications, including home appliances, automotive components, and furniture. A1008 steel also exhibits good corrosion resistance, although it may require protective coatings in more aggressive environments.

What Are the Advantages and Disadvantages of A1008 Steel?

Pros:

– Durability: A1008 steel has high tensile strength, ranging from 49.9 to 65 ksi, making it suitable for structural applications where strength is crucial.

– Cost-Effectiveness: This material is relatively inexpensive compared to higher alloy steels, making it a budget-friendly option for manufacturers.

– Manufacturing Flexibility: Its excellent formability allows for various processing methods, including bending, drawing, and welding, without requiring special precautions.

Cons:

– Corrosion Vulnerability: While it has good corrosion resistance, A1008 steel is not immune to rusting and may require painting or galvanization for long-term durability, especially in humid or corrosive environments.

– Limited High-Temperature Performance: A1008 steel may not perform well under extreme temperature conditions, which could limit its use in certain applications.

How Does A1008 Steel Impact Specific Applications?

A1008 steel is particularly well-suited for applications that require moderate strength and good formability. Its compatibility with various manufacturing processes allows it to be used in producing components for home appliances, automotive parts, and furniture. However, its susceptibility to corrosion means that it is less suitable for applications exposed to harsh environments unless adequately protected. International buyers should consider the specific media compatibility and environmental conditions of their applications when selecting A1008 steel.

What Should International B2B Buyers Consider When Selecting A1008 Steel?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local standards and regulations. A1008 steel conforms to ASTM standards, which may be recognized in various markets. Buyers should also consider local preferences for material specifications, as European countries may favor DIN standards, while others might lean towards JIS standards. Understanding these nuances can facilitate smoother procurement processes and ensure that the selected materials meet the required performance criteria.

Summary Table of A1008 Steel Material Selection

| Material | Typical Use Case for A1008 Steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| A1008 Steel | Home appliances, automotive parts | Excellent weldability and formability | Susceptible to corrosion without protection | Low |

| Galvanized Steel | Outdoor furniture, automotive exteriors | Enhanced corrosion resistance | Higher cost due to galvanization process | Medium |

| Stainless Steel | Medical equipment, high-end appliances | Superior corrosion resistance and durability | Higher manufacturing complexity and cost | High |

| Aluminum | Lightweight structures, automotive components | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

This analysis provides B2B buyers with a comprehensive understanding of A1008 steel and its alternatives, enabling informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for a1008 steel

What Are the Key Stages in the Manufacturing Process of A1008 Steel?

The manufacturing process of A1008 steel involves several critical stages that ensure the material meets industry standards and customer specifications. Each stage is designed to enhance the steel’s properties, making it suitable for various applications, including automotive, home appliances, and furniture manufacturing.

1. Material Preparation

The first step in the manufacturing process involves sourcing high-quality raw materials. A1008 steel is primarily produced from low-carbon iron ore, which is melted in electric arc furnaces (EAF). The quality of the raw materials is essential, as impurities can significantly affect the final product’s properties. Once melted, the steel is subjected to a refining process to achieve the desired chemical composition, typically containing around 0.40% manganese.

2. Forming

After material preparation, the molten steel is cast into slabs or coils. The casting process is followed by cold rolling, where the steel is passed through rollers at room temperature. This process enhances its strength and surface finish while allowing for precise thickness control. Cold rolling also improves the steel’s formability, making it easier to work with during subsequent manufacturing stages.

3. Assembly

In the assembly stage, the rolled sheets are cut into specified dimensions and shapes according to customer requirements. This stage may involve additional processes like shearing, punching, or laser cutting, depending on the end-use application. Manufacturers often employ automated machinery to ensure precision and efficiency.

4. Finishing

Finishing processes, such as annealing, are crucial for enhancing the mechanical properties of A1008 steel. Annealing involves heating the steel to a specific temperature and then allowing it to cool, which relieves internal stresses and improves ductility. Surface treatments, such as galvanizing or painting, may also be applied to enhance corrosion resistance, particularly for applications exposed to harsh environments.

How Is Quality Assurance Implemented During A1008 Steel Production?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for A1008 steel, ensuring that the final product meets both international standards and customer expectations. The QA process is multi-faceted, encompassing various checkpoints and testing methods throughout production.

Relevant International Standards and Certifications

Manufacturers of A1008 steel typically adhere to internationally recognized standards such as ISO 9001 for quality management systems. Additionally, compliance with industry-specific standards, such as CE marking for products sold in the European market or API standards for oil and gas applications, is crucial for global trade.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet required specifications. Any material that does not pass this inspection is rejected and replaced.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted at critical points to monitor production parameters. This includes checks on dimensions, surface quality, and mechanical properties.

-

Final Quality Control (FQC): Once the manufacturing process is complete, the final product undergoes rigorous testing to verify compliance with specifications. This may include mechanical testing (tensile strength, yield strength), chemical composition analysis, and surface integrity checks.

What Testing Methods Are Commonly Used for A1008 Steel?

Several testing methods are employed to ensure A1008 steel meets the required standards:

-

Tensile Testing: Measures the steel’s strength and ductility by pulling samples until they fracture.

-

Hardness Testing: Determines the hardness of the steel using methods such as Rockwell or Brinell tests.

-

Chemical Analysis: Conducted using spectrometry to verify the composition of the steel against the specified grades.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing or magnetic particle inspection are used to detect internal flaws without damaging the material.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures directly. This provides insight into the supplier’s capabilities and adherence to standards.

-

Quality Reports: Requesting detailed quality assurance reports, including test results and certifications, can help buyers assess the quality of materials before procurement.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes, ensuring compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, especially in diverse markets like Africa, South America, the Middle East, and Europe, several nuances in quality control may arise:

-

Regulatory Compliance: Different regions have varying standards and regulations. Understanding the specific requirements of the target market is crucial for ensuring compliance.

-

Cultural Differences: Communication styles and business practices can differ significantly across regions. Establishing clear expectations and maintaining open lines of communication with suppliers can mitigate misunderstandings.

-

Logistics and Supply Chain Considerations: Quality control does not end with manufacturing. Ensuring that the material is handled and transported properly is vital for maintaining quality throughout the supply chain.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing A1008 steel, ensuring that they receive high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘a1008 steel’

To effectively procure A1008 steel, international B2B buyers must navigate various considerations to ensure quality, compliance, and suitability for their applications. This checklist serves as a practical guide to streamline your sourcing process and maximize your investment in A1008 steel.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the A1008 steel you need. Consider aspects such as thickness, width, and mechanical properties like yield strength and elongation. Specifications should also include the intended application, whether for automotive parts, furniture, or home appliances, as this will influence your choice of grade and finish.

Step 2: Research and Identify Qualified Suppliers

Conduct thorough research to identify potential suppliers that specialize in A1008 steel. Utilize industry directories, trade associations, and online marketplaces to compile a list. Focus on suppliers with a proven track record in your region—especially in Africa, South America, the Middle East, and Europe—as local expertise can facilitate smoother transactions and logistics.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to evaluate their reliability and capabilities. Request detailed company profiles, case studies, and references from other buyers within your industry. Pay attention to their production capacity, quality control measures, and delivery timelines, as these factors can significantly impact your supply chain.

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications to meet international standards, such as ASTM A1008. Certifications indicate that the steel has been tested for quality and performance. Additionally, check for compliance with local regulations and environmental standards, which can vary by region.

Step 5: Request Samples for Testing

Before placing a large order, request samples of the A1008 steel for testing. This allows you to assess the material’s quality, formability, and weldability in real-world applications. Conduct tests that reflect your specific requirements, such as tensile strength and corrosion resistance, to ensure that the steel meets your expectations.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget constraints and any additional costs that may arise, such as shipping or customs duties. A transparent negotiation process can lead to a more favorable agreement for both parties.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your supplier can provide significant advantages, such as better pricing, priority service, and improved communication. Keep open lines of communication and provide feedback on product performance. A collaborative approach can foster trust and lead to mutually beneficial outcomes in future transactions.

By following this structured checklist, B2B buyers can efficiently navigate the sourcing process for A1008 steel, ensuring that they select the best materials for their needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for a1008 steel Sourcing

What Are the Key Cost Components for A1008 Steel Sourcing?

When sourcing A1008 steel, understanding the cost structure is vital for effective budgeting and procurement. The primary cost components include:

-

Materials: A1008 steel is a low-carbon steel that is generally less expensive than alloyed steels. The cost can vary based on market conditions and supplier pricing strategies. Prices are influenced by the quality of the raw materials, with higher grades commanding higher prices.

-

Labor: Labor costs encompass both direct and indirect expenses associated with the manufacturing process. This includes wages for skilled workers who handle the steel processing and fabrication. Regions with lower labor costs may provide more competitive pricing for international buyers.

-

Manufacturing Overhead: This includes fixed and variable costs associated with running a manufacturing facility, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these overhead costs, translating to lower prices for buyers.

-

Tooling: Tooling costs refer to the equipment and machinery necessary for processing A1008 steel. Custom tooling may be required for specific applications, which can increase initial costs but lead to better product quality and efficiency in production.

-

Quality Control (QC): Ensuring the quality of A1008 steel involves testing and inspection processes that incur additional costs. Certification and compliance with international standards (like ASTM) can add to expenses but are crucial for maintaining product integrity.

-

Logistics: Transportation and handling costs can significantly impact the total cost of ownership (TCO). Factors such as shipping distance, mode of transport, and customs duties must be considered, especially for international shipments.

-

Margin: Suppliers typically add a profit margin to the cost of goods sold. This margin can vary widely based on supplier reputation, service quality, and market competition.

How Do Price Influencers Affect A1008 Steel Procurement?

Several factors can influence the pricing of A1008 steel, particularly for B2B buyers in diverse markets:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually benefit from bulk pricing discounts. Understanding the MOQ set by suppliers can help buyers negotiate better rates.

-

Specifications and Customization: Custom specifications may lead to higher costs due to the need for specialized production processes or materials. Buyers should carefully evaluate whether customization is essential for their applications.

-

Materials and Quality Certifications: The presence of quality certifications (e.g., ISO, ASTM) can affect pricing. Steel that meets rigorous standards may be priced higher, but it ensures reliability and performance.

-

Supplier Factors: The supplier’s market position, reputation, and location can influence pricing. Established suppliers with a proven track record may charge premium prices but offer better service and reliability.

-

Incoterms: The terms of sale can significantly impact the total cost. For instance, choosing “Delivered Duty Paid” (DDP) terms may seem more expensive upfront but can provide clarity on total costs and reduce risks related to customs and logistics.

What Are the Best Buyer Tips for Cost-Efficient A1008 Steel Sourcing?

To maximize value and minimize costs when sourcing A1008 steel, consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions to explore pricing flexibility, especially for bulk orders. Building a good relationship can lead to long-term cost savings.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, logistics, and potential delays. A lower upfront cost may not always translate to savings over time.

-

Understand Pricing Nuances for International Buyers: Each region may have different pricing dynamics influenced by local demand, tariffs, and transportation costs. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify the best sourcing options.

-

Stay Informed on Market Trends: Regularly monitoring steel market trends, including demand and pricing fluctuations, can help buyers make informed purchasing decisions and capitalize on favorable market conditions.

Disclaimer

Prices for A1008 steel can fluctuate based on market conditions, supplier negotiations, and other factors. It is advisable to request quotes from multiple suppliers to ensure competitive pricing and to keep abreast of any changes in the cost structure.

Alternatives Analysis: Comparing a1008 steel With Other Solutions

In the realm of materials selection, businesses often face the challenge of choosing the most suitable option for their specific applications. A1008 steel, known for its excellent formability and weldability, presents a strong choice for various industries. However, there are alternative materials and methods that can also meet similar needs. This analysis compares A1008 steel with two viable alternatives: Aluminum Alloy 6061 and Galvanized Steel, focusing on key performance aspects.

| Comparison Aspect | A1008 Steel | Aluminum Alloy 6061 | Galvanized Steel |

|---|---|---|---|

| Performance | High strength, good weldability | Lightweight, corrosion-resistant | Good strength, corrosion-resistant |

| Cost | Relatively low | Higher cost | Moderate cost |

| Ease of Implementation | Requires standard welding techniques | Easier to machine, weldable | Requires special welding for coatings |

| Maintenance | Prone to rust without coating | Minimal maintenance | Low maintenance due to coating |

| Best Use Case | Automotive, furniture, appliances | Aerospace, automotive parts | Construction, outdoor applications |

What Are the Advantages and Disadvantages of Aluminum Alloy 6061 Compared to A1008 Steel?

Aluminum Alloy 6061 is a versatile material known for its lightweight and corrosion-resistant properties. Its ease of machining and welding makes it a favorite in industries such as aerospace and automotive. However, the higher cost of aluminum may deter budget-conscious buyers. Additionally, while its strength-to-weight ratio is advantageous, it may not match the tensile strength of A1008 steel in heavy-duty applications.

How Does Galvanized Steel Compare to A1008 Steel in Performance and Cost?

Galvanized Steel offers a strong alternative with good corrosion resistance due to its zinc coating. This material is often used in construction and outdoor applications where environmental exposure is a concern. While its cost is moderate, the requirement for specialized welding techniques can complicate the implementation process. Galvanized steel is also heavier than A1008, which may impact applications where weight is a critical factor.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right material, B2B buyers should evaluate their specific requirements, including application, budget constraints, and performance needs. A1008 steel remains a strong contender for applications requiring high strength and formability at a lower cost. Conversely, if weight and corrosion resistance are paramount, Aluminum Alloy 6061 may be preferable despite its higher cost. For projects focused on outdoor durability, Galvanized Steel stands out, though buyers must consider the implications of its welding requirements.

Ultimately, the choice between A1008 steel and its alternatives should be guided by a comprehensive assessment of each material’s characteristics in relation to the intended application, ensuring optimal performance and value for the investment.

Essential Technical Properties and Trade Terminology for a1008 steel

What Are the Key Technical Properties of A1008 Steel?

Understanding the technical properties of A1008 steel is crucial for businesses looking to make informed purchasing decisions. Here are some critical specifications:

-

Material Grade

A1008 is classified under ASTM A1008, which denotes it as a cold-rolled, carbon steel sheet with high strength and improved formability. This specification is essential for B2B buyers as it indicates the suitability of the material for various applications, from automotive to home appliances. Selecting the correct grade ensures product reliability and performance in demanding environments. -

Tensile Strength

The tensile strength of A1008 steel typically ranges between 49.9 to 51.9 ksi. This property measures the material’s resistance to being pulled apart and is crucial in applications where structural integrity is vital. A higher tensile strength allows for thinner sections without compromising strength, which can lead to cost savings and weight reductions in final products. -

Yield Strength

Yield strength for A1008 steel falls between 26.1 to 34.8 ksi. This value indicates the stress at which the material begins to deform plastically. Understanding yield strength is important for manufacturers as it helps in determining the maximum load that can be applied without permanent deformation, ensuring the safety and longevity of the end product. -

Formability

A1008 exhibits excellent formability, with elongation percentages ranging from 23% to 25%. This property is vital for industries that require bending, drawing, or shaping of steel sheets. High formability allows manufacturers to create complex shapes and components without cracking or losing material integrity. -

Corrosion Resistance

While A1008 steel has good weldability, it is essential to note that it requires protective coatings (like galvanization) to enhance its corrosion resistance. For B2B buyers, understanding the corrosion resistance is crucial for applications in harsh environments, where untreated steel can lead to premature failure and increased maintenance costs. -

Machinability

A1008 has a machinability rating of approximately 55%. This property reflects how easily the steel can be cut, shaped, or finished. For manufacturers, knowing the machinability is important for estimating production time and costs, especially in high-volume applications.

What Common Trade Terms Should B2B Buyers Know?

Navigating the steel procurement process involves understanding specific trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of A1008 steel, OEMs often require specific grades and properties to meet their production standards. Understanding OEM requirements can streamline the sourcing process and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is important for buyers, particularly small to medium enterprises, as it affects inventory management and cash flow. Knowing the MOQ can help in planning procurement strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. For buyers of A1008 steel, issuing an RFQ helps in comparing prices, delivery times, and terms, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is crucial for B2B transactions, as they clarify who bears the costs and risks associated with transporting goods, which can significantly impact total purchase costs. -

Lead Time

Lead time refers to the amount of time from placing an order to its delivery. It is a critical consideration for B2B buyers, as longer lead times can disrupt production schedules. Knowing the lead times associated with A1008 steel helps in planning and inventory management. -

Certification

Certification is the process of verifying that a product meets certain standards or specifications. For A1008 steel, certifications can include compliance with ASTM standards or quality assurance from relevant authorities. Certifications provide buyers with confidence in the material’s quality and performance, which is essential in regulated industries.

Understanding these technical properties and trade terms can significantly enhance a B2B buyer’s ability to navigate the steel procurement landscape, ensuring informed decisions that align with business objectives.

Navigating Market Dynamics and Sourcing Trends in the a1008 steel Sector

What Are the Key Market Dynamics and Trends Impacting the A1008 Steel Sector?

The A1008 steel market is currently experiencing robust growth driven by several global factors. Increasing demand for low-carbon steel in automotive, home appliance, and furniture sectors has heightened the need for reliable sourcing. Notably, regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in infrastructure development and manufacturing activities, thereby amplifying the need for high-strength, low-alloy steels like A1008.

One emerging trend is the integration of digital technologies in sourcing and procurement processes. B2B buyers are increasingly utilizing advanced analytics and AI-driven platforms to optimize inventory management and streamline supply chains. This shift towards technology enables companies to make data-informed decisions, enhancing their operational efficiency and responsiveness to market fluctuations.

Furthermore, the emphasis on sustainability is reshaping sourcing strategies. Buyers are becoming more selective, favoring suppliers who adhere to eco-friendly practices and can demonstrate their commitment to reducing carbon footprints. As a result, the A1008 steel sector is not only adapting to these changing market dynamics but also positioning itself to meet the evolving expectations of international B2B buyers.

How Is Sustainability Shaping Sourcing Strategies for A1008 Steel?

Sustainability has emerged as a critical consideration for B2B buyers in the A1008 steel sector. The environmental impact of steel production is significant, with traditional processes contributing to high levels of greenhouse gas emissions. Consequently, buyers are increasingly prioritizing ethical sourcing and sustainable practices when selecting suppliers.

The importance of ethical supply chains cannot be overstated. A transparent supply chain ensures that materials are sourced responsibly, minimizing negative environmental impacts and promoting fair labor practices. Buyers are now seeking suppliers who can provide certifications that validate their sustainability claims, such as ISO 14001 for environmental management systems or LEED certification for sustainable building materials.

Moreover, the availability of ‘green’ materials, including recycled A1008 steel, is becoming a competitive differentiator. Utilizing recycled steel not only reduces waste but also significantly lowers the energy consumption and emissions associated with steel production. As such, B2B buyers are encouraged to engage with suppliers who can offer sustainable A1008 steel options, thus aligning their procurement strategies with broader environmental goals.

What Is the Historical Context of A1008 Steel and Its Relevance Today?

The A1008 steel specification has its roots in the early development of cold-rolled steel technology, which gained prominence in the mid-20th century. Initially designed to meet the burgeoning demands of the automotive and appliance industries, A1008 steel has evolved to incorporate improved formability and strength characteristics.

Today, A1008 steel is recognized for its versatility and cost-effectiveness, making it a preferred choice for manufacturers across various sectors. Its historical context is vital for B2B buyers, as understanding the evolution of A1008 steel aids in appreciating its mechanical properties and suitability for specific applications. This knowledge empowers buyers to make informed decisions when sourcing steel, ensuring they select the most appropriate materials for their production needs.

In conclusion, the A1008 steel sector is navigating a landscape shaped by technological advancements, sustainability imperatives, and evolving market demands. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for effective sourcing and long-term partnerships with suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of a1008 steel

-

How do I determine the right specifications for A1008 steel for my project?

To select the appropriate specifications for A1008 steel, consider the application and the required mechanical properties. A1008 is available in various grades, including commercial steels and drawing steels, each offering different strength and formability levels. Evaluate factors such as yield strength, tensile strength, and elongation percentages based on your project’s demands. Collaborate with suppliers who can provide detailed technical data sheets and expert advice tailored to your specific requirements. This ensures you choose the right grade that aligns with your operational needs. -

What are the key applications of A1008 steel in various industries?

A1008 steel is widely utilized across multiple sectors, including automotive, furniture, and home appliances. Its excellent weldability and formability make it suitable for producing extruded and cold-formed parts. Additionally, industries looking for high-strength, low-alloy solutions will find A1008 beneficial due to its cost-effectiveness and versatility. Understanding these applications can help you identify if A1008 is the right material for your manufacturing processes. -

What minimum order quantity (MOQ) should I expect when sourcing A1008 steel?

The MOQ for A1008 steel can vary significantly depending on the supplier and specific product requirements. Typically, suppliers may impose an MOQ ranging from a few tons to several tons, particularly for custom orders. It’s advisable to communicate your needs directly with potential suppliers to negotiate terms that align with your project size. Some suppliers may offer flexibility for smaller orders, especially if you’re willing to pay a premium. -

How can I verify the quality and compliance of A1008 steel before purchasing?

To ensure the quality of A1008 steel, request mill test reports (MTRs) from your supplier. These documents provide detailed information about the steel’s chemical composition, mechanical properties, and compliance with ASTM standards. Additionally, consider conducting third-party inspections or certifications, especially for larger or critical projects. This proactive approach helps mitigate risks associated with material performance and compliance with international standards. -

What payment terms should I negotiate with suppliers for A1008 steel?

When negotiating payment terms with suppliers, consider factors like your purchasing volume, delivery timelines, and the supplier’s reputation. Common practices include a deposit upfront, followed by payment upon delivery or after inspection. Discussing favorable terms such as extended payment periods or discounts for early payments can help improve cash flow. It’s crucial to establish clear agreements to avoid misunderstandings and ensure timely transactions. -

What logistics considerations should I be aware of when importing A1008 steel?

Logistics play a vital role in sourcing A1008 steel, especially for international transactions. Consider shipping methods, customs regulations, and potential tariffs based on your destination country. Engage with logistics providers experienced in handling steel shipments to navigate these complexities. Additionally, factor in lead times for production and shipping to ensure that your supply chain remains uninterrupted and that materials arrive on schedule. -

What are the advantages of sourcing A1008 steel from international suppliers?

Sourcing A1008 steel from international suppliers can offer several advantages, including access to a broader range of products, competitive pricing, and specialized grades not available locally. Additionally, international suppliers may provide advanced technologies and processing capabilities that enhance the material’s performance. However, it’s essential to conduct thorough due diligence on potential suppliers to ensure reliability and compliance with quality standards. -

How can I customize A1008 steel to meet specific project needs?

Customizing A1008 steel is achievable through various processes such as cutting, forming, and surface treatments. Discuss your specific requirements with potential suppliers, who can provide processing options tailored to your project. Factors such as thickness, coating for corrosion resistance, and specific dimensions can often be accommodated. Collaborating closely with your supplier ensures that the final product meets your precise specifications and enhances overall project efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 A1008 Steel Manufacturers & Suppliers List

1. Alro – Cold-Rolled Carbon Sheet

Domain: alro.com

Registered: 1996 (29 years)

Introduction: Product Name: Cold-Rolled Carbon Sheet

Standard: ASTM A1008 CS Type B

Chemical Composition:

– Carbon: 0.15% (Max)

– Manganese: 0.60% (Max)

– Phosphorus: 0.030% (Max)

– Sulphur: 0.035% (Max)

Properties: Improved formability, excellent weldability, good drawing and spinning characteristics, smooth surface typically oiled to prevent rust, typically bought to meet chemistry requirements.

Typical Uses:…

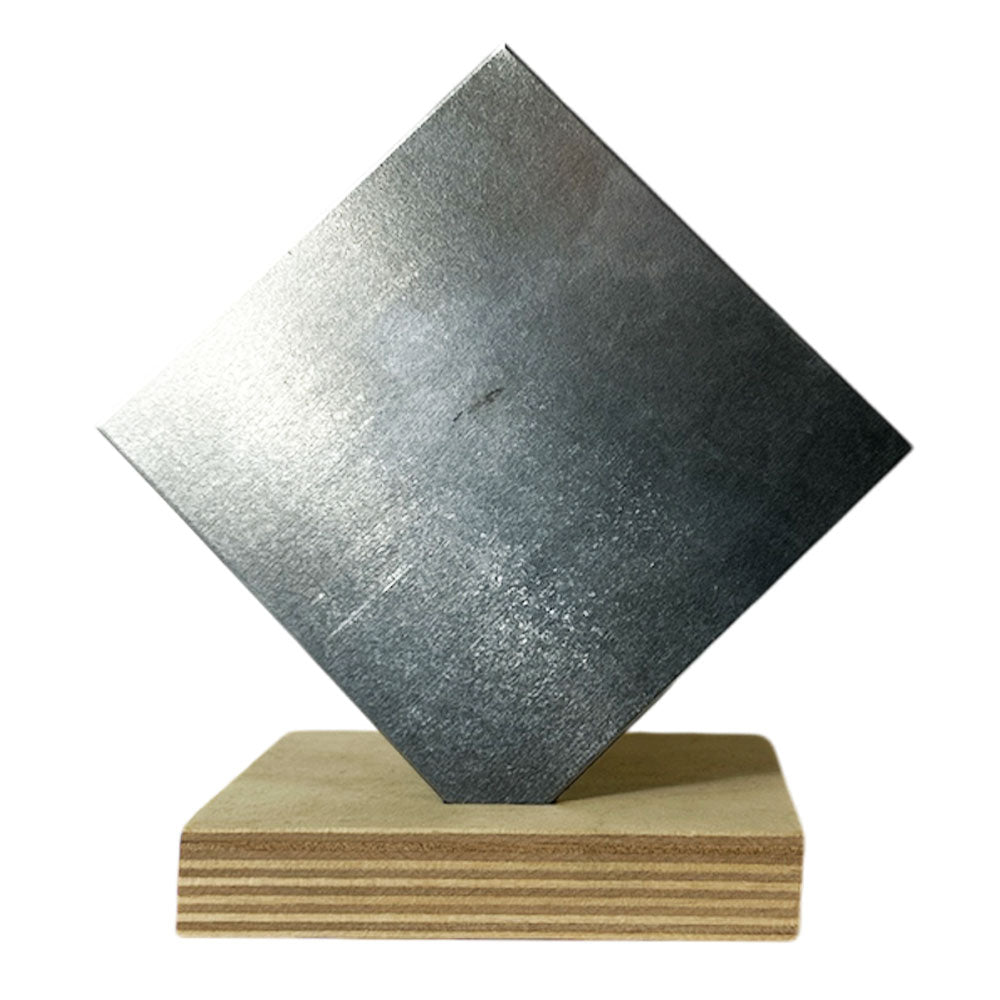

2. Steel Warehouse – ASTM A1008 Steel

Domain: steelwarehouse.com

Registered: 1997 (28 years)

Introduction: ASTM A1008 Steel is a cold-rolled, carbon, structural, high-strength low-alloy steel sheet available in coils and cut lengths. It contains approximately 0.40% manganese, offering excellent weldability and formability. This standard carbon steel plate is primarily used in extruded, cold headed, cold upset, and cold pressed parts and forms. Recommended applications include home appliances, furniture…

3. Online Metals – A1008 Carbon Steel

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “A1008 Carbon Steel”, “Overview”: “A common low-carbon steel with excellent weldability and formability. 1008 steel can be easily welded without special precautions. However, it needs to be painted or otherwise maintained to avoid quick oxidization and rusting.”, “Applications”: [“Home Appliances”, “Furniture”, “Automotive”], “Common Trade Names”: [“UNS G10080”, “AISI 1008”], “Phy…

4. Industrial Metal Supply – 1008 Aluminum & Low-Carbon Steel

Domain: industrialmetalsupply.com

Registered: 1999 (26 years)

Introduction: 1008 Aluminum | ASTM A1008 | CQ-SAE-1008 | Low-carbon steel | Exceptional weldability | Ideal for bending or forming exposed or unexposed parts | Available in metal sheets & plates | Custom cut options available | Locations: Inland Empire, Los Angeles, Orange County, San Diego, San Jose, Phoenix, Tucson.

5. Kloeckner Metals – ASTM A1008 Steel

Domain: kloecknermetals.com

Registered: 2011 (14 years)

Introduction: ASTM A1008 is a structural, high strength low-alloy steel known for its excellent formability and weldability. It is widely used in the construction industry for applications such as bridges, buildings, guardrails, and handrails. A1008 is also utilized in automotive and aerospace industries due to its high strength and weldability. Key advantages include its ease of machining, formability, and wel…

6. Alcobra Metals – 11 ga. A1008 Cold Rolled Steel Sheet

Domain: alcobrametals.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “11 ga. (.12″) A1008 Cold Rolled Steel Sheet”, “price_range”: “$36.16 – $138.49”, “SKU”: “5476e3316545”, “category”: “Carbon Steel – Sheet / Plate – A1008 Cold Rolled Sheet”, “available_lengths”: [“12×12”, “12×24”, “12×36”, “12×48”, “24×24”, “24×36”, “24×48”, “36×36”, “36×48”], “description”: “Crafted from high-quality A1008 steel, this sheet offers excellent formability and surfa…

7. Fast Metals – Cold Finished ASTM A1008 Sheet

Domain: fastmetals.com

Registered: 2013 (12 years)

Introduction: Cold Finished ASTM A1008 Sheet – Improved Strength & Formability

8. MakerStock – Carbon Steel Cold Rolled ASTM A1008

Domain: makerstock.com

Registered: 2012 (13 years)

Introduction: {“product_name”:”Carbon Steel Cold Rolled ASTM A1008″,”material”:”Carbon Steel”,”type”:”Cold Rolled”,”standard”:”ASTM A1008″,”thickness”:”Varies by product”,”width”:”Varies by product”,”length”:”Varies by product”,”finish”:”Cold Rolled”,”application”:”General manufacturing, automotive, and construction industries”}

Strategic Sourcing Conclusion and Outlook for a1008 steel

In the evolving landscape of steel procurement, A1008 steel emerges as a versatile choice for various applications, particularly in home appliances, automotive, and furniture manufacturing. Its unique properties, including excellent weldability and formability, make it an attractive option for businesses looking to enhance their product offerings while maintaining cost-effectiveness.

Strategic sourcing of A1008 steel not only ensures access to high-quality materials but also fosters long-term relationships with reliable suppliers. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships that align with their specific needs, considering factors such as supply chain reliability and material certifications to mitigate risks.

As global market demands shift, staying informed about trends in the steel industry is crucial. With ongoing developments in manufacturing technologies and material specifications, there is a significant opportunity for businesses to leverage A1008 steel to meet evolving consumer demands.

Take the next step in optimizing your sourcing strategy by engaging with reputable suppliers who can provide tailored solutions. Embrace the potential of A1008 steel to drive innovation and efficiency in your operations.