Introduction: Navigating the Global Market for 8 gauge steel

Navigating the global market for 8 gauge steel can be a complex endeavor, especially for B2B buyers in regions such as Africa, South America, the Middle East, and Europe. The challenge lies in sourcing high-quality steel that meets specific project requirements while also considering factors such as cost, supplier reliability, and local market regulations. This guide aims to demystify the process of sourcing 8 gauge steel by providing a comprehensive overview of its characteristics, applications, and the nuances of international procurement.

Throughout this guide, we will explore the various types of 8 gauge steel available, from mild to galvanized and stainless options, and their respective applications across industries like construction, manufacturing, and automotive. Additionally, we will delve into effective strategies for vetting suppliers, understanding pricing structures, and navigating potential logistical hurdles.

By empowering international B2B buyers with actionable insights and data-driven recommendations, this guide serves as an invaluable resource for making informed purchasing decisions. Whether you are seeking to enhance your supply chain efficiency or ensure compliance with regional standards, our expertise will help you successfully navigate the complexities of sourcing 8 gauge steel in a competitive global market.

Understanding 8 gauge steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mild Steel | High ductility, weldability, and strength | Construction, automotive, fabrication | Pros: Cost-effective, versatile; Cons: Susceptible to corrosion without coating |

| Stainless Steel | Corrosion resistance, high strength-to-weight ratio | Food processing, medical equipment | Pros: Durable, hygienic; Cons: Higher cost compared to mild steel |

| Galvanized Steel | Coated with zinc for corrosion protection | Outdoor structures, automotive parts | Pros: Enhanced durability, low maintenance; Cons: May chip or scratch, exposing steel |

| Aluminum Steel | Lightweight, excellent corrosion resistance | Aerospace, marine applications | Pros: Lightweight, non-corrosive; Cons: Lower tensile strength than steel |

| Tool Steel | High hardness and wear resistance | Manufacturing tools, dies | Pros: Long-lasting, maintains sharpness; Cons: More expensive, requires specific machining |

What Are the Characteristics and Applications of Mild Steel 8 Gauge Steel?

Mild steel is known for its excellent ductility and weldability, making it an ideal choice for a variety of applications. With a thickness of approximately 0.1644 inches, it is commonly used in construction, automotive, and general fabrication. When purchasing mild steel, buyers should consider its susceptibility to corrosion, which can be mitigated through protective coatings or treatments.

How Does Stainless Steel 8 Gauge Steel Stand Out?

Stainless steel offers superior corrosion resistance and a high strength-to-weight ratio, making it suitable for demanding environments such as food processing and medical equipment. With its thickness of around 0.17187 inches, it ensures durability and hygiene. However, buyers must weigh the higher cost against its long-term benefits, particularly in industries where cleanliness and material longevity are critical.

What Are the Benefits of Galvanized Steel 8 Gauge Steel?

Galvanized steel features a protective zinc coating, enhancing its durability and making it ideal for outdoor structures and automotive parts. The 8 gauge thickness (approximately 0.1681 inches) provides robust support while minimizing maintenance needs. Buyers should consider the potential for the coating to chip or scratch, which can compromise its protective qualities.

Why Choose Aluminum Steel 8 Gauge Steel?

Aluminum steel is lightweight and boasts excellent corrosion resistance, making it perfect for aerospace and marine applications. At approximately 0.1285 inches thick, it allows for easy handling and installation. Buyers should note that while aluminum is less dense, it may not provide the same tensile strength as traditional steel, which can be a crucial factor depending on the application.

What Makes Tool Steel 8 Gauge Steel a Preferred Choice?

Tool steel is characterized by its high hardness and wear resistance, making it ideal for manufacturing tools and dies. With a thickness that can vary, it is essential for buyers to confirm specifications based on their requirements. While tool steel offers exceptional performance and longevity, it comes at a higher price point, necessitating careful consideration of budget versus performance needs.

Key Industrial Applications of 8 gauge steel

| Industry/Sector | Specific Application of 8 gauge steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural components for buildings and frameworks | Provides strength and durability, ensuring safety and longevity | Compliance with local building codes and regulations |

| Automotive | Chassis and body panels | Enhances vehicle safety and performance | Availability of corrosion-resistant finishes |

| Manufacturing | Fabrication of heavy machinery and equipment | Supports high-load applications, reducing maintenance costs | Precision in dimensions and thickness, along with quality certifications |

| Energy | Fabrication of oil and gas pipelines | Ensures reliability and durability in harsh environments | Sourcing from suppliers with experience in energy sector standards |

| Furniture | Heavy-duty furniture frames | Offers stability and aesthetic appeal | Options for customization and surface finishes |

How is 8 Gauge Steel Utilized in the Construction Industry?

In the construction sector, 8 gauge steel is commonly used for structural components such as beams, columns, and frames. Its thickness provides the necessary strength to support significant loads, making it ideal for both residential and commercial applications. International buyers, particularly from regions like Africa and the Middle East, must ensure that the steel meets local building codes and regulations, which may vary significantly. Additionally, considerations around sourcing should include the steel’s resistance to environmental factors, particularly in humid or coastal areas.

What Role Does 8 Gauge Steel Play in the Automotive Sector?

In the automotive industry, 8 gauge steel is primarily utilized in the manufacturing of chassis and body panels. This thickness is essential for enhancing vehicle safety, as it provides the structural integrity needed to withstand collisions. Buyers in Europe, such as those in Germany, often prioritize sourcing from suppliers who offer corrosion-resistant finishes to prolong the lifespan of automotive components. Furthermore, compliance with industry standards for safety and emissions is crucial, necessitating thorough documentation from suppliers.

Why is 8 Gauge Steel Important for Manufacturing Heavy Machinery?

Manufacturers of heavy machinery and equipment rely on 8 gauge steel for its strength and durability in fabricating components that face high stress and load. This steel thickness is particularly advantageous in applications such as frames and supports, where failure could lead to costly downtime or safety incidents. B2B buyers should focus on sourcing from suppliers who provide precise dimensions and thicknesses, as these factors are critical in ensuring compatibility with existing machinery designs. Quality certifications are also vital to ensure reliability.

How is 8 Gauge Steel Used in the Energy Sector?

In the energy sector, particularly for oil and gas pipelines, 8 gauge steel is favored for its durability and ability to withstand harsh environmental conditions. This steel thickness is essential for ensuring the integrity of pipelines, which can be subject to high pressures and corrosive materials. International buyers should seek suppliers experienced in energy sector standards and regulations, as compliance is crucial for operational safety. Additionally, sourcing considerations should include the steel’s resistance to corrosion and the availability of specialized coatings.

What are the Applications of 8 Gauge Steel in Furniture Manufacturing?

In the furniture industry, 8 gauge steel is used to create heavy-duty frames that offer both stability and aesthetic appeal. This application is especially popular in commercial settings, such as restaurants and offices, where durable furniture is essential. Buyers should consider options for customization to fit specific design needs, as well as various surface finishes that can enhance the visual appeal while providing protection against wear and tear. Sourcing from reputable suppliers who understand the demands of the furniture market is key to ensuring quality and durability.

3 Common User Pain Points for ‘8 gauge steel’ & Their Solutions

Scenario 1: Navigating Gauge Confusion in International Markets

The Problem: B2B buyers often face confusion regarding the gauge system, especially when sourcing 8 gauge steel internationally. The inconsistency in measurement standards across different regions can lead to miscommunication and errors in orders. For instance, a buyer in Europe may assume that their specifications align with those from a supplier in South America, only to discover that the gauge thicknesses differ significantly, resulting in production delays and increased costs. This confusion can severely impact project timelines and budgets.

The Solution: To mitigate this issue, B2B buyers should utilize comprehensive gauge conversion charts specific to the type of steel being purchased, such as mild, stainless, or galvanized. It is essential to clearly communicate the exact thickness required in both gauge and decimal formats when placing orders. Establishing a standardized terminology within contracts can also help avoid misunderstandings. Additionally, leveraging technology, such as digital platforms with built-in conversion tools, can further streamline the ordering process. Ensuring that all stakeholders are educated on the gauge system will facilitate smoother transactions and reduce the risk of errors.

Scenario 2: Understanding Material Properties and Performance

The Problem: Buyers frequently struggle to understand the specific properties and performance capabilities of 8 gauge steel, which can vary based on the type of steel (e.g., mild, stainless, or galvanized). This lack of understanding can lead to the selection of inappropriate materials for their applications, such as using mild steel in corrosive environments instead of galvanized or stainless steel. The consequence is often premature failure of products, leading to costly repairs and lost trust in suppliers.

The Solution: To overcome this challenge, buyers should invest time in researching the mechanical properties and suitable applications for different types of 8 gauge steel. Manufacturers often provide detailed specifications and data sheets that outline tensile strength, corrosion resistance, and other relevant properties. Establishing strong relationships with suppliers who can provide expert guidance on material selection is invaluable. Furthermore, considering trial runs or prototypes can help assess performance before full-scale production. By prioritizing education on material properties, buyers can ensure they select the most appropriate steel for their specific needs, thereby enhancing product longevity and reliability.

Scenario 3: Managing Supply Chain and Lead Time Issues

The Problem: Lead time variability is a significant pain point for B2B buyers dealing with 8 gauge steel. Factors such as global supply chain disruptions, fluctuating demand, and transportation delays can significantly impact the availability of materials. Buyers often find themselves in a position where they have to delay projects or rush orders, which can lead to increased costs and frustration for both the buyer and their clients.

The Solution: To address lead time challenges, buyers should adopt a proactive approach by diversifying their supplier base. Engaging multiple suppliers across different regions can reduce dependency on a single source and provide alternatives in case of disruptions. Establishing long-term contracts with key suppliers may also result in more predictable lead times and better pricing. Additionally, implementing inventory management practices, such as Just-In-Time (JIT) inventory, allows for optimized stock levels while minimizing holding costs. Communicating openly with suppliers about lead time expectations and building a collaborative relationship can also lead to better forecasting and planning, ultimately resulting in smoother operations and enhanced project delivery.

Strategic Material Selection Guide for 8 gauge steel

What are the Key Properties of 8 Gauge Steel and Its Common Alternatives?

When selecting materials for 8 gauge steel applications, it is essential to consider various alternatives that may offer specific advantages depending on the intended use. Here, we analyze four common materials: mild steel, stainless steel, galvanized steel, and aluminum. Each material has distinct properties, pros and cons, and implications for international buyers.

How Does Mild Steel Compare to 8 Gauge Steel?

Mild steel, often used interchangeably with carbon steel, is known for its excellent weldability and machinability. It has a relatively high tensile strength, making it suitable for structural applications. However, mild steel has limited corrosion resistance, which can be a significant drawback in humid or corrosive environments.

Pros:

– High durability and strength.

– Cost-effective for large-scale applications.

– Easy to fabricate and weld.

Cons:

– Prone to rusting without protective coatings.

– Limited performance in high-temperature applications.

Impact on Application:

Mild steel is commonly used in construction, automotive, and manufacturing industries. However, its lack of corrosion resistance may limit its use in coastal or industrial environments.

Considerations for International Buyers:

Mild steel complies with various standards, including ASTM A36 and EN 10025. Buyers from regions like Europe and the Middle East should ensure compliance with local regulations regarding material specifications and environmental impact.

What Advantages Does Stainless Steel Offer for 8 Gauge Applications?

Stainless steel is renowned for its corrosion resistance, making it ideal for applications exposed to moisture or chemicals. It retains strength at high temperatures and is often used in food processing, medical equipment, and architectural applications.

Pros:

– Exceptional corrosion resistance.

– High strength-to-weight ratio.

– Aesthetic appeal for visible applications.

Cons:

– Higher cost compared to mild steel.

– More challenging to weld and machine.

Impact on Application:

Stainless steel is suitable for environments where hygiene and corrosion are critical, such as food and beverage manufacturing or marine applications.

Considerations for International Buyers:

Stainless steel grades like 304 and 316 are widely recognized. Buyers should look for compliance with ASTM standards and consider local preferences for specific grades based on environmental factors.

How Does Galvanized Steel Enhance the Performance of 8 Gauge Steel?

Galvanized steel is mild steel coated with a layer of zinc to improve corrosion resistance. This makes it an excellent choice for outdoor applications or environments where moisture is prevalent.

Pros:

– Cost-effective corrosion protection.

– Extended lifespan compared to uncoated mild steel.

– Suitable for a variety of applications, including construction and automotive.

Cons:

– The zinc coating can be damaged, exposing the steel underneath.

– Limited high-temperature performance.

Impact on Application:

Galvanized steel is commonly used in construction, fencing, and HVAC systems, where exposure to the elements is a concern.

Considerations for International Buyers:

Galvanized steel should meet standards such as ASTM A123 for hot-dip galvanizing. Buyers in regions like South America and Africa should ensure compliance with local standards for construction materials.

What Role Does Aluminum Play in 8 Gauge Applications?

Aluminum is a lightweight alternative to steel, offering excellent corrosion resistance and thermal conductivity. It is often used in applications where weight savings are critical, such as in aerospace and automotive industries.

Pros:

– Lightweight, reducing transportation costs.

– Excellent corrosion resistance.

– Good thermal and electrical conductivity.

Cons:

– Lower strength compared to steel.

– More expensive than mild steel.

Impact on Application:

Aluminum is suitable for applications requiring weight savings and corrosion resistance, such as in aircraft components and marine environments.

Considerations for International Buyers:

Aluminum grades such as 6061 and 7075 are commonly recognized. Buyers should ensure compliance with standards like ASTM B221 and consider local preferences for aluminum alloys.

Summary Table of Material Selection for 8 Gauge Steel

| Material | Typical Use Case for 8 Gauge Steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | Structural applications | High durability and strength | Prone to rust without coatings | Low |

| Stainless Steel | Food processing, medical equipment | Exceptional corrosion resistance | Higher cost and fabrication complexity | High |

| Galvanized Steel | Outdoor construction, fencing | Cost-effective corrosion protection | Zinc coating can be damaged | Medium |

| Aluminum | Aerospace, automotive components | Lightweight with excellent corrosion resistance | Lower strength compared to steel | High |

This guide provides a comprehensive overview of the strategic material selection process for 8 gauge steel, helping international B2B buyers make informed decisions based on specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 8 gauge steel

What Are the Main Stages in the Manufacturing Process of 8 Gauge Steel?

The manufacturing process of 8 gauge steel typically involves several critical stages, which ensure the material’s quality, strength, and usability in various applications. Understanding these stages can help B2B buyers make informed decisions when sourcing this material.

-

Material Preparation

The first step involves selecting high-quality raw materials, typically hot-rolled or cold-rolled steel sheets. The chosen steel is then subjected to initial inspections to verify its chemical composition and mechanical properties. This stage is crucial, as the quality of the raw material directly affects the final product’s performance. -

Forming

Once the material is prepared, it undergoes various forming techniques. Common methods include shearing, bending, and rolling. For 8 gauge steel, which measures approximately 0.1644 inches or 4.175 mm in thickness, precise cutting and bending are essential to achieve the desired shapes and dimensions. Advanced technologies such as CNC (Computer Numerical Control) machines are often employed to ensure high accuracy and repeatability during this process. -

Assembly

In many applications, 8 gauge steel is not used as a standalone product but is assembled with other components. This may involve welding, riveting, or fastening, depending on the design requirements. The assembly process must be executed with precision to maintain the structural integrity of the final product. -

Finishing

The final stage of manufacturing involves various finishing processes, such as surface treatment and coating. Techniques like galvanization, powder coating, or painting are often applied to enhance corrosion resistance and aesthetic appeal. These finishing processes not only improve durability but also meet specific industry standards.

What Quality Control Measures Are Essential for 8 Gauge Steel?

Quality assurance is a vital aspect of the manufacturing process, particularly for industries where safety and reliability are paramount. International and industry-specific standards guide manufacturers in maintaining high-quality production processes.

-

Relevant International Standards

Compliance with international standards such as ISO 9001 is essential for manufacturers of 8 gauge steel. This standard outlines the criteria for a quality management system, emphasizing continuous improvement and customer satisfaction. Additionally, certifications like CE marking and API (American Petroleum Institute) are crucial for specific sectors, ensuring that products meet European and industry-specific regulations. -

Quality Control Checkpoints

Effective quality control involves several key checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage assesses raw materials for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process ensure that each stage meets quality standards, reducing the risk of defects.

- Final Quality Control (FQC): Once manufacturing is complete, the final product undergoes a comprehensive inspection and testing to verify its compliance with all specifications and standards.

- Common Testing Methods

Various testing methods are employed to ensure the integrity and performance of 8 gauge steel. Common techniques include:

- Tensile Testing: Measures the material’s strength and ductility, essential for applications requiring load-bearing capabilities.

- Hardness Testing: Assesses the material’s resistance to deformation, which is critical for durability.

- Visual Inspection: A thorough examination of the surface for any defects, such as cracks or inconsistencies.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is paramount. Here are actionable steps to ensure supplier reliability:

-

Conduct Audits

Buyers should perform regular audits of potential suppliers. This can involve on-site visits to evaluate manufacturing processes, quality control measures, and overall operational standards. An audit can help identify any gaps in compliance with international standards. -

Request Quality Reports

Suppliers should provide detailed quality control reports, including results from IQC, IPQC, and FQC. These documents should outline the testing methods used, results obtained, and any corrective actions taken in case of non-compliance. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can add an additional layer of assurance. These independent entities can conduct thorough evaluations of the manufacturing process and final products, providing unbiased reports to the buyer.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate various nuances related to quality control that can differ by region and industry. Understanding these factors can enhance the procurement process:

-

Cultural and Regulatory Differences

Different countries may have unique regulations and standards for steel manufacturing. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may focus on local compliance standards. Awareness of these differences is crucial for ensuring compliance. -

Supply Chain Considerations

The global supply chain can affect the availability and quality of materials. Buyers should consider the reliability of logistics and transportation methods, as delays or mishandling can impact the quality of the steel upon arrival. -

Language and Communication Barriers

Effective communication is vital in maintaining quality standards. Buyers should ensure that suppliers can provide documentation and support in a language that is clear and comprehensible to avoid misunderstandings.

Conclusion

Understanding the manufacturing processes and quality assurance measures for 8 gauge steel is critical for B2B buyers looking to source this material. By focusing on the main stages of production, relevant quality control standards, and effective verification methods, buyers can make informed decisions that ensure the reliability and performance of their steel products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8 gauge steel’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure 8 gauge steel. Sourcing the right steel is critical for ensuring product quality, compliance with specifications, and cost-effectiveness. By following this structured approach, buyers can navigate the procurement process efficiently and effectively.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the 8 gauge steel you need. This includes specifying dimensions, tolerances, and any particular finishes or coatings required.

– Consider the application: Different projects may require specific properties, such as corrosion resistance or strength.

– Reference gauge charts: Use a gauge chart to confirm that 8 gauge corresponds to the desired thickness (approximately 0.1644 inches or 4.175 mm).

Step 2: Research Potential Suppliers

Identify and compile a list of suppliers who specialize in 8 gauge steel. A thorough market research can reveal the most reputable and reliable suppliers.

– Look for industry experience: Suppliers with a track record in your specific industry may better understand your needs.

– Check geographic relevance: Ensure that the suppliers can service your region effectively, particularly in Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that potential suppliers hold relevant certifications. This is vital for ensuring quality and compliance with international standards.

– Look for ISO certifications: These indicate adherence to quality management systems.

– Check for material certifications: Ensure that the steel meets industry-specific standards such as ASTM or EN specifications.

Step 4: Request Material Samples

Always request samples of the 8 gauge steel to assess its quality before placing a bulk order. This step helps confirm that the material meets your specifications.

– Inspect the samples: Check for physical attributes such as finish, thickness, and any signs of defects.

– Conduct tests if necessary: Depending on your application, you may want to perform further tests, like tensile strength or corrosion resistance tests.

Step 5: Analyze Pricing Structures

Understand the pricing models of your shortlisted suppliers. Prices can vary widely based on factors such as order volume, delivery terms, and payment conditions.

– Consider total cost of ownership: Beyond the purchase price, factor in shipping costs, potential tariffs, and storage fees.

– Negotiate terms: Don’t hesitate to negotiate pricing, especially if you plan on making regular purchases.

Step 6: Review Delivery and Lead Times

Confirm the lead times for delivery and ensure they align with your project timelines. Delays can significantly impact project schedules and costs.

– Ask about production capacity: Ensure that the supplier can meet your quantity requirements within your desired timeframe.

– Clarify shipping arrangements: Understand how shipping will be handled, especially for international orders.

Step 7: Establish Communication Channels

Set up clear communication channels with your chosen supplier. Effective communication is essential for resolving issues quickly and ensuring a smooth procurement process.

– Identify key contacts: Establish who will be your point of contact for any inquiries or issues.

– Schedule regular updates: Agree on a schedule for progress updates to stay informed about your order status.

By following these steps, B2B buyers can streamline their sourcing process for 8 gauge steel, ensuring that they select the best suppliers and materials for their specific needs.

Comprehensive Cost and Pricing Analysis for 8 gauge steel Sourcing

What Are the Key Cost Components in Sourcing 8 Gauge Steel?

When sourcing 8 gauge steel, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The cost of raw materials significantly influences the final price. 8 gauge steel typically consists of mild steel, stainless steel, or galvanized steel, with price variations based on the type and quality of steel used.

-

Labor: Labor costs involve the wages of workers engaged in manufacturing processes, including cutting, welding, and finishing. These costs can vary by region, particularly between developed and developing countries.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and factory rent. Efficient operations can minimize these costs, affecting overall pricing.

-

Tooling: Tooling costs are incurred from the machinery and tools required for the production of steel sheets. These costs are amortized over the volume of production, making them a critical factor in pricing.

-

Quality Control (QC): Ensuring product quality through testing and inspection incurs additional costs. Certifications may be necessary for international trade, especially in markets with stringent regulations.

-

Logistics: Transportation and handling costs are particularly significant for international shipments. Factors like distance, mode of transport, and fuel prices will affect these logistics costs.

-

Margin: Suppliers will add a margin to cover their business expenses and profit. This margin can vary widely between suppliers based on their business model and market position.

How Do Volume and Customization Influence 8 Gauge Steel Pricing?

Volume plays a crucial role in determining the price of 8 gauge steel. Suppliers often provide discounts for bulk purchases, making it beneficial for buyers to negotiate minimum order quantities (MOQs). Additionally, the specific requirements, such as customization in dimensions or finishes, can affect pricing. Customization typically incurs extra charges due to the need for specialized tooling or processes.

What Are the Key Price Influencers for International Buyers?

International buyers should be aware of several factors that influence pricing:

-

Quality and Certifications: Buyers in regions like Europe and the Middle East often require specific certifications that can increase costs. Ensuring compliance with local standards can lead to higher upfront costs but may save money in the long run by avoiding penalties or product rejections.

-

Supplier Factors: The choice of supplier can significantly impact pricing. Established suppliers may offer better quality assurance and service, while newer or less reputable suppliers might have lower prices but could pose risks in terms of quality and reliability.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is crucial. They dictate who is responsible for shipping, insurance, and tariffs, which can affect the total cost of ownership.

What Are the Best Negotiation Tips for B2B Buyers in 8 Gauge Steel?

Effective negotiation can lead to better pricing and terms. Here are some strategies for buyers:

-

Leverage Volume: Use larger order sizes as leverage to negotiate better pricing. Suppliers are often willing to offer discounts for higher quantities.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Obtain multiple quotes to understand the market rate and use this information to negotiate.

-

Assess Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the long-term costs associated with logistics, maintenance, and quality issues. A lower initial price may not always be the best deal if it leads to higher TCO.

-

Build Relationships: Establishing a long-term relationship with suppliers can lead to better terms and pricing over time. Suppliers may offer loyalty discounts or more favorable terms to repeat customers.

What Should Buyers Know About Pricing Nuances in Different Regions?

Buyers from Africa, South America, the Middle East, and Europe should consider regional pricing nuances. For example, tariffs and import duties can vary significantly, affecting the landed cost of steel. Additionally, fluctuating currency exchange rates can impact pricing for international transactions. Understanding these regional specifics can provide a competitive advantage when sourcing 8 gauge steel.

Conclusion

Sourcing 8 gauge steel requires a nuanced understanding of various cost components and pricing influencers. By considering factors such as volume, customization, and regional specifics, buyers can make informed decisions that align with their budget and quality requirements. Always remember to assess the total cost of ownership and leverage negotiation strategies to secure the best deals.

Alternatives Analysis: Comparing 8 gauge steel With Other Solutions

Introduction: What Alternatives Are Available to 8 Gauge Steel?

When considering materials for industrial applications, 8 gauge steel is often a popular choice due to its durability and strength. However, there are viable alternatives that may better suit specific project requirements or budget constraints. This analysis will compare 8 gauge steel with two notable alternatives: aluminum and galvanized steel. Each alternative presents unique advantages and disadvantages that can significantly impact decision-making for B2B buyers in diverse markets.

Comparison Table

| Comparison Aspect | 8 Gauge Steel | Aluminum | Galvanized Steel |

|---|---|---|---|

| Performance | High tensile strength, excellent for heavy-duty applications | Moderate strength, lightweight, resistant to corrosion | Good strength, corrosion-resistant due to zinc coating |

| Cost | Generally lower cost per unit, but heavier transport costs | Higher initial cost but lighter, reducing transport expenses | Moderate cost, influenced by zinc coating process |

| Ease of Implementation | Requires heavier machinery for handling and installation | Easier to cut and shape, can be handled with less equipment | Similar to steel, but requires specific handling due to coating |

| Maintenance | Requires regular maintenance to prevent rust | Low maintenance, corrosion-resistant | Moderate maintenance, as zinc can wear off over time |

| Best Use Case | Structural applications, heavy-duty frames | Lightweight structures, automotive, aerospace | Construction applications, outdoor structures |

Detailed Breakdown of Alternatives

Aluminum

Aluminum offers a lightweight alternative to 8 gauge steel, making it easier to transport and manipulate during installation. Its resistance to corrosion makes it ideal for outdoor applications or environments prone to moisture. However, aluminum has a lower tensile strength compared to steel, which may limit its use in heavy-duty applications. The initial cost of aluminum is typically higher, which may be a concern for budget-conscious buyers, yet its long-term durability can offset these costs over time.

Galvanized Steel

Galvanized steel combines the strength of traditional steel with a protective zinc coating, enhancing its resistance to corrosion. This makes it suitable for applications where exposure to harsh weather is a factor. While its cost is moderate, it can vary depending on the thickness of the zinc coating. Galvanized steel is similar in handling and installation to 8 gauge steel, but care must be taken to avoid damaging the coating during processing. Its performance in outdoor applications is a significant advantage, but buyers should consider the maintenance of the zinc layer over time.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right material for your project involves evaluating your specific needs against the characteristics of each option. For projects requiring heavy-duty strength and structural integrity, 8 gauge steel remains a strong contender. However, if weight reduction and corrosion resistance are priorities, aluminum may be the better choice, despite its higher cost. On the other hand, galvanized steel offers a balanced option with good strength and weather resistance. By carefully assessing factors such as performance requirements, budget constraints, and long-term maintenance, B2B buyers can make informed decisions that best align with their operational goals.

Essential Technical Properties and Trade Terminology for 8 gauge steel

What Are the Key Technical Properties of 8 Gauge Steel?

When evaluating 8 gauge steel, it’s crucial to understand its technical specifications, as these directly influence its suitability for various applications. Here are some essential properties to consider:

-

Material Grade

8 gauge steel typically falls under mild steel categories such as ASTM A36 or A1011. These grades denote the steel’s chemical composition and mechanical properties, which are critical for applications requiring strength and durability. Understanding the grade helps buyers ensure that the steel meets industry standards and is appropriate for their specific use cases. -

Thickness

The actual thickness of 8 gauge steel is approximately 0.1644 inches (4.175 mm). This measurement is essential for applications where space constraints or weight considerations are critical. Buyers should refer to a gauge conversion chart to confirm the thickness, as gauge numbers do not correspond directly to actual measurements across different materials. -

Tolerance

Tolerance refers to the permissible variation in the thickness of the steel. For 8 gauge steel, tolerances can vary but typically range from ±0.005 to ±0.015 inches. Understanding these tolerances is vital for manufacturers and fabricators to ensure that the steel fits precisely within their designs and specifications. -

Yield Strength

Yield strength is the amount of stress a material can withstand without permanent deformation. For mild steel, the yield strength is generally around 36,000 psi (pounds per square inch). This property is essential for B2B buyers, particularly in construction and manufacturing, as it determines how much load the steel can support without failing. -

Corrosion Resistance

While 8 gauge steel is not inherently corrosion-resistant, it can be treated or coated (e.g., galvanized) to enhance its longevity in harsh environments. Understanding corrosion resistance is crucial for applications in industries such as construction and transportation, where exposure to moisture and chemicals is common. -

Weldability

The weldability of 8 gauge steel is another critical property, particularly for construction and fabrication projects. The ease with which the steel can be welded affects assembly processes and overall structural integrity. Knowing the weldability helps buyers select appropriate welding techniques and equipment.

What Are Common Trade Terms Related to 8 Gauge Steel?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms related to 8 gauge steel:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products or components that are sold under another company’s brand. Understanding OEM relationships is crucial for buyers looking to source steel components that meet specific quality standards for their products. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers, as it can affect inventory management and cost-efficiency. Knowing the MOQ helps businesses plan their purchases according to production needs. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. This term is vital in the procurement process, as it allows buyers to compare costs and terms from multiple suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B transactions, as they clarify who bears the risk and costs associated with shipping and delivery. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the goods. This term is essential for supply chain management, as it impacts production schedules and inventory levels. Buyers should account for lead times when planning their projects to avoid delays. -

Fabrication

Fabrication involves the process of cutting, bending, and assembling metal to create a finished product. Understanding this term is crucial for buyers who need specific designs or modifications to 8 gauge steel for their applications. It helps in selecting suppliers that offer the necessary fabrication services.

Understanding these properties and terms enables B2B buyers to make informed decisions when sourcing 8 gauge steel, ultimately leading to better project outcomes and cost savings.

Navigating Market Dynamics and Sourcing Trends in the 8 gauge steel Sector

What Are the Current Market Dynamics and Key Trends in the 8 Gauge Steel Sector?

The 8 gauge steel sector is experiencing a transformation driven by several global factors, particularly in the context of international B2B trade. A surge in construction and infrastructure projects across Africa, South America, the Middle East, and Europe has heightened demand for strong, durable materials like 8 gauge steel. Notably, regions such as Saudi Arabia and Germany are investing heavily in sustainable urban development and industrial applications, leading to increased procurement activities.

Emerging technologies are reshaping sourcing trends as well. The adoption of digital platforms for procurement is on the rise, enabling buyers to streamline their sourcing processes. E-commerce solutions allow international buyers to compare suppliers more effectively and access real-time pricing and inventory data. Additionally, the integration of Artificial Intelligence (AI) in supply chain management is enhancing predictive analytics, which assists in optimizing inventory levels and reducing lead times.

Furthermore, there is a notable shift towards local sourcing to mitigate risks associated with global supply chain disruptions. Buyers are increasingly looking to establish partnerships with regional suppliers who can provide 8 gauge steel with shorter lead times and lower transportation costs. This trend is particularly relevant for B2B buyers in regions facing logistical challenges or tariffs on imported steel products.

How Is Sustainability Influencing Ethical Sourcing of 8 Gauge Steel?

Sustainability has become a pivotal consideration for B2B buyers, especially in the sourcing of materials like 8 gauge steel. The environmental impact of steel production is significant, contributing to greenhouse gas emissions and resource depletion. As a result, buyers are more frequently prioritizing suppliers who practice sustainable manufacturing processes and adhere to environmental regulations.

Ethical sourcing practices are gaining traction as businesses recognize the importance of transparency in their supply chains. Buyers are increasingly demanding information about the origins of their materials, ensuring they are sourced from suppliers committed to responsible practices. Certifications such as ISO 14001, which focuses on effective environmental management systems, and LEED (Leadership in Energy and Environmental Design) ratings are becoming essential criteria for evaluating suppliers.

Moreover, the demand for recycled steel is on the rise, as it presents a lower environmental footprint compared to virgin steel production. B2B buyers are actively seeking suppliers who can provide 8 gauge steel products made from recycled materials, thereby contributing to circular economy initiatives and reducing overall environmental impact.

What Is the Historical Context of the 8 Gauge Steel Market?

The gauge system, which includes 8 gauge steel, has its roots in the British wire industry and has evolved over time to become a standard for measuring metal thickness across various applications. Historically, the gauge system was primarily used for wire, but as the demand for sheet metal grew in construction and manufacturing, it became a critical measure for specifying material thickness.

The 8 gauge steel, with a thickness of approximately 0.1644 inches (4.175 mm), is often utilized in structural applications, automotive components, and heavy equipment. Over the decades, advancements in metallurgy and manufacturing processes have enhanced the quality and performance of steel products. This evolution has made 8 gauge steel a reliable choice for diverse applications, solidifying its position in the global market.

As international B2B buyers navigate this sector, understanding the historical context and current market dynamics will empower them to make informed sourcing decisions that align with both operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 8 gauge steel

-

How do I determine the right thickness of 8 gauge steel for my project?

To determine the appropriate thickness of 8 gauge steel for your project, refer to a sheet metal gauge chart. For 8 gauge mild steel, the thickness is approximately 0.1644 inches (4.175 mm). Consider the specific requirements of your application, such as load-bearing capacity, environmental exposure, and fabrication processes. Consulting with a supplier or an engineer can also help ensure you select the correct gauge for optimal performance. -

What applications are best suited for 8 gauge steel?

8 gauge steel is commonly used in applications requiring durability and strength, such as industrial machinery, structural components, and storage tanks. It is also suitable for manufacturing parts in automotive and construction sectors, where resistance to deformation and wear is critical. Understanding your specific application needs will guide you in leveraging the benefits of 8 gauge steel effectively. -

What factors should I consider when vetting suppliers for 8 gauge steel?

When vetting suppliers for 8 gauge steel, assess their industry reputation, experience, and certifications. Check for customer reviews and case studies that showcase their reliability. Additionally, inquire about their quality assurance processes, production capabilities, and compliance with international standards. Establishing a strong partnership with a reputable supplier can significantly impact your procurement success. -

What is the minimum order quantity (MOQ) for 8 gauge steel?

Minimum order quantities for 8 gauge steel can vary widely based on the supplier’s policies and your specific needs. Typically, suppliers may have an MOQ ranging from a few sheets to several tons. It’s advisable to discuss your requirements directly with potential suppliers to negotiate favorable terms, especially if you are looking for smaller quantities or customized sizes. -

What are the common payment terms for international purchases of 8 gauge steel?

Payment terms for international purchases of 8 gauge steel often include options like letters of credit, advance payments, or payment upon delivery. Terms can vary based on the supplier’s policies and the buyer’s creditworthiness. It’s essential to clarify payment expectations upfront and consider using secure payment methods to mitigate risks associated with international transactions. -

How can I ensure the quality of 8 gauge steel I purchase?

To ensure the quality of your 8 gauge steel, request certifications and test reports from your supplier that confirm compliance with industry standards. Look for materials that have undergone rigorous quality control processes. Additionally, consider conducting third-party inspections or testing to verify the steel’s properties, particularly if your project has strict quality requirements. -

What logistics considerations should I keep in mind when sourcing 8 gauge steel internationally?

When sourcing 8 gauge steel internationally, consider shipping methods, customs regulations, and lead times. Ensure your supplier can provide reliable shipping options and track your orders to avoid delays. Familiarize yourself with the import duties and taxes that may apply to your purchase, and communicate with your logistics provider to streamline the transportation process. -

Can I customize 8 gauge steel to meet specific project requirements?

Yes, many suppliers offer customization options for 8 gauge steel, including cutting to size, forming, or finishing treatments. Discuss your specific requirements with potential suppliers to understand their capabilities and limitations. Customization can optimize the material for your project, ensuring it meets the exact specifications and performance criteria necessary for your application.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 8 Gauge Steel Manufacturers & Suppliers List

1. Metal Supermarkets – Sheet Metal Gauge Chart

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Sheet Metal Gauge Chart – Metal Supermarkets offers a variety of metals including Mild Steel, Aluminum, Stainless Steel, Alloy Steel, Brass, Bronze, and Copper. The gauge system is used to specify the thickness of sheet metal, with different gauges corresponding to different thicknesses for various metals. The chart includes gauge numbers, their corresponding thickness in inches and millimeters fo…

2. Metals Depot – Hot Rolled Steel Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“type”:”Hot Rolled Steel Sheet”,”specification”:”ASTM A1011 CS Type B”,”description”:”Economical steel sheets with a slightly grainy surface, ideal for painting.”,”popular_uses”:[“general fabrication”,”equipment panels”,”tool boxes”,”hoppers”,”drip pans”],”thickness_options”:[{“gauge”:”16 GA”,”thickness”:”.060″,”weight”:”2.50 lb/sqft”},{“gauge”:”14 GA”,”thickness”:”.075″,”weight”:”3….

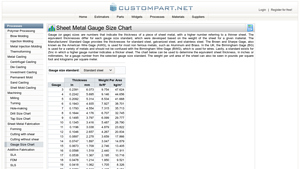

3. CustomPartNet – Sheet Metal Gauge Size Chart

Domain: custompartnet.com

Registered: 2006 (19 years)

Introduction: Sheet Metal Gauge Size Chart: Gauge sizes indicate the thickness of sheet metal, with higher numbers representing thinner sheets. Different gauge size standards exist, including the Manufacturers’ Standard Gage for steel types, the Brown and Sharpe Gage for non-ferrous metals, and the Birmingham Gage in the UK. The chart provides equivalent thicknesses in inches and millimeters, as well as weight …

4. TruSupply – 8 Gauge Galvanized Steel Wire

Domain: trusupply.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “8 Gauge Galvanized Steel Wire”, “Weight”: “50 lb”, “Coil Length”: “Approx. 714 LF per Coil”, “Material”: “Galvanized Steel”, “Gauge Options”: [8, 9, 10, 11, 12, 14, 16], “Available Coil Weights”: [50 lb, 100 lb], “Price”: “$68.50”, “Item Number”: “AWT-TW-G-8GA-50-IMP”, “Availability”: “In Stock”, “Shipping Time”: “Usually ships in 2-5 Business Days”, “Applications”: [“Constructio…

5. Liberty Safe – Steel Gauge Security

Domain: libertysafe.com

Registered: 1996 (29 years)

Introduction: The rating for steel gauge indicates that a smaller number corresponds to a thicker steel. For example, 7 gauge steel is thicker than 12 gauge steel. Thicker steel enhances the security level of safes, making them more difficult to cut through, heavier, and harder to tip over or pry open. It also improves fire protection ratings. The specific thicknesses for different gauges of steel are: 7-gauge …

Strategic Sourcing Conclusion and Outlook for 8 gauge steel

As the demand for 8 gauge steel continues to rise across various industries, strategic sourcing emerges as a critical component for B2B buyers aiming to enhance operational efficiency and cost-effectiveness. Understanding the specific applications and properties of 8 gauge steel, such as its thickness of 0.1644 inches (4.175 mm), enables businesses to make informed decisions tailored to their unique needs. Additionally, leveraging gauge conversion charts can ensure precise specifications, minimizing production delays and material wastage.

Establishing strong supplier relationships is vital for securing competitive pricing and ensuring the availability of quality materials. By focusing on suppliers with robust logistics capabilities, buyers can mitigate risks associated with international shipping and fluctuating market conditions. Furthermore, incorporating sustainable sourcing practices not only aligns with global trends but also enhances corporate responsibility.

Looking ahead, international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are encouraged to proactively seek partnerships that prioritize innovation and adaptability in sourcing 8 gauge steel. This strategic approach will position businesses to thrive in an increasingly competitive landscape, ensuring they meet the evolving demands of their markets effectively. Engage with your suppliers today to secure the resources that will drive your success tomorrow.