Contents

Manufacturing Insight: 7 Axis Milling Machine

Advanced Complexity Realized Through Honyo Prototype’s 7-Axis Milling Capability

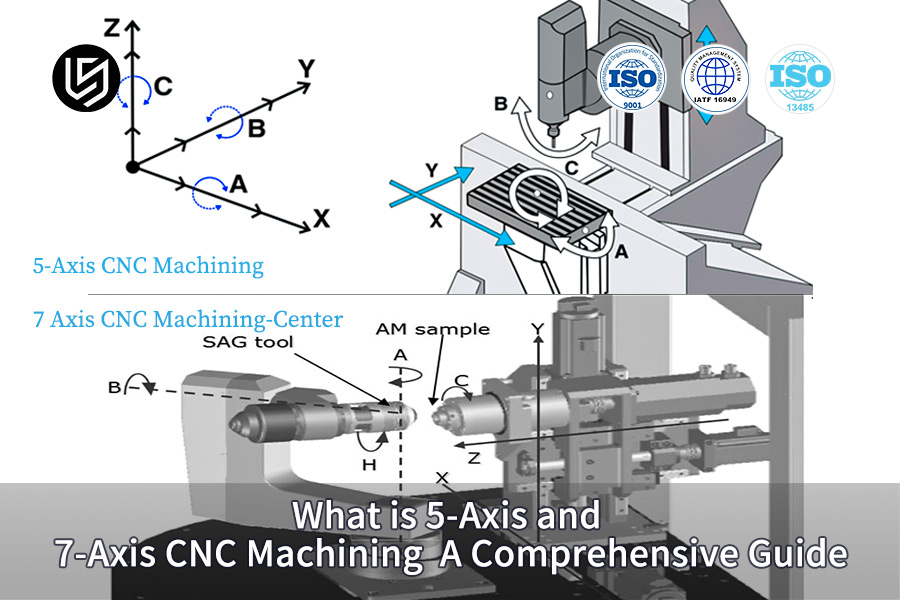

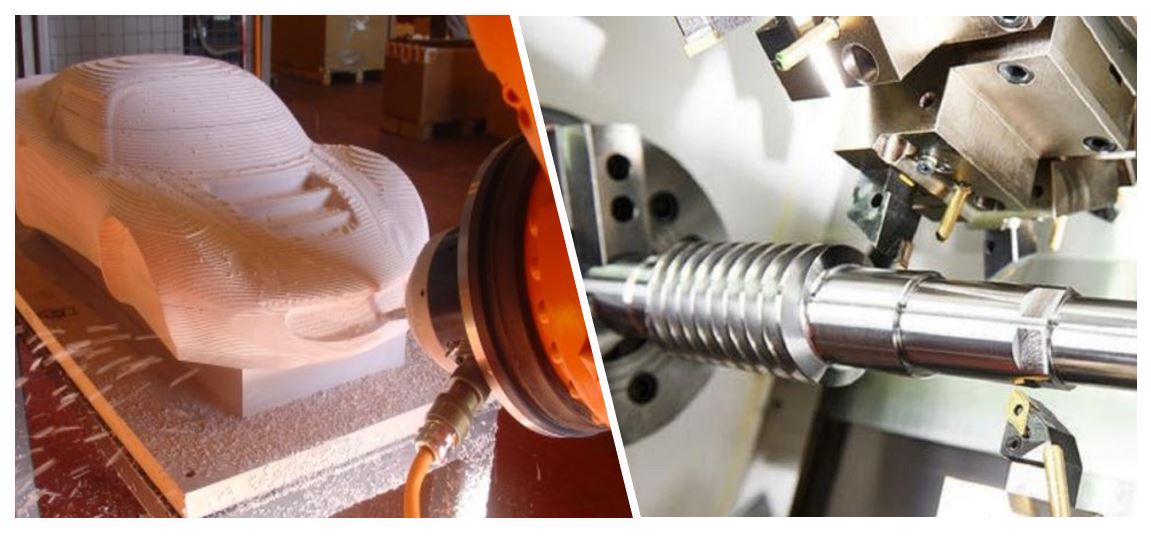

Honyo Prototype delivers unparalleled precision for the most demanding aerospace, medical, and energy sector components through our state-of-the-art 7-axis CNC milling technology. This sophisticated capability integrates three linear axes (X, Y, Z) with four rotational axes, enabling single-setup machining of geometrically intricate parts that would otherwise require multiple operations, complex fixturing, and extended lead times on conventional 3- or 5-axis systems. The result is exceptional part accuracy, minimized tolerance stack-up, superior surface finishes, and significant reductions in secondary handling—critical for high-value, low-volume production and rapid prototyping where precision directly impacts performance and compliance.

Our 7-axis milling centers are engineered to tackle continuous contouring, deep cavity work, and multi-faceted features inherent in turbine blades, orthopedic implants, and fluid dynamics components. By eliminating repositioning errors and maximizing machine uptime, Honyo Prototype ensures your complex designs transition from CAD model to certified, ready-to-assemble hardware with accelerated throughput and stringent adherence to GD&T requirements. This capability is fully integrated within our end-to-end CNC machining ecosystem, which includes multi-axis turning, high-speed milling, and advanced metrology.

To streamline your project initiation, Honyo Prototype provides an industry-leading Online Instant Quote system. Upload your 3D CAD file (STEP, IGES, Parasolid) and receive a detailed manufacturability assessment with competitive pricing within hours—not days—enabling faster decision cycles without compromising technical rigor.

Key Technical Advantages of Honyo’s 7-Axis Solution

| Parameter | Impact for Client Projects | Honyo Implementation Standard |

|---|---|---|

| Setup Reduction | Eliminates 3-5+ secondary operations per part | Single-setup completion for 95% of complex geometries |

| Geometric Complexity | Enables undercuts, asymmetric contours, continuous toolpaths | Full simultaneous 7-axis interpolation with sub-micron repeatability |

| Lead Time | Reduces machining cycle time by 40-60% vs. 5-axis | Optimized toolpath generation using hyperMILL® software |

| Part Integrity | Mitigates distortion from multiple clamping events | In-process probing with Renishaw systems for real-time compensation |

Leverage Honyo Prototype’s 7-axis milling expertise to overcome traditional manufacturing barriers while accelerating time-to-market. Access our Online Instant Quote platform to validate feasibility and cost for your next high-complexity component.

Technical Capabilities

The term “7-axis milling machine” typically refers to a multi-axis machining center that integrates both milling and turning capabilities with advanced motion control across seven distinct axes. While traditional CNC machines operate on 3, 4, or 5 axes, a 7-axis system combines the functionality of a dual-spindle, multi-turret turning center with full 5-axis milling on both primary and secondary spindles, enabling complete part machining in a single setup.

Below are the technical specifications relevant to high-precision 7-axis machines, with emphasis on 3/4/5-axis milling, turning, tight tolerance capabilities, and compatibility with materials such as Aluminum, Steel, ABS, and Nylon.

| Specification | Description |

|---|---|

| Number of Axes | 7-axis configuration: X, Y, Z (linear), A, B (rotary for 5-axis milling), plus C-axis (spindle rotation) on both main and sub-spindles, and synchronized B-axis or secondary linear Y2/Z2 for dual-turret or dual-milling head operations. |

| Milling Capabilities | Full 3-axis, 4-axis (indexing or continuous), and 5-axis simultaneous milling via tilting rotary tables or spindle heads. Enables complex contours, undercuts, and organic shapes without re-fixturing. |

| Turning Capabilities | Dual-spindle (main and sub-spindle) with live tooling. Allows bar feeding, backworking, and part transfer for complete-turning operations. C-axis synchronization enables milling on cylindrical surfaces. |

| Positioning Accuracy | ±0.002 mm (±0.00008″) typical, achieved via high-resolution linear encoders and thermal compensation systems. |

| Repeatability | ±0.001 mm (±0.00004″) ensures consistent tight-tolerance production across batches. |

| Spindle Speed (Milling) | Up to 20,000 RPM (high-speed variants); standard models 8,000–12,000 RPM. Suitable for Aluminum and plastics. |

| Spindle Speed (Turning) | Up to 5,000 RPM (main spindle), optimized for Steel and Aluminum; lower speeds for heavy cutting. |

| Tool Magazine Capacity | 30–120 tools, with dual tool pools for milling and turning tools. Automatic tool changers (ATC) reduce non-cut time. |

| Control System | Fanuc 31i, Siemens 840D, or Mitsubishi M800/M80 series with 7-axis interpolation and collision avoidance software. |

| Work Envelope (Typical) | X: 500 mm, Y: 400 mm, Z: 400 mm; turning capacity up to Ø300 mm × 650 mm length. |

| Materials Compatibility | Optimized for Aluminum (6061, 7075), Steel (4140, 1018, stainless 304/316), engineering plastics (ABS, Nylon 6/66), and reinforced composites. |

| Surface Finish | Achieves Ra < 0.8 µm (32 µin) in milling; down to Ra 0.4 µm in fine turning with polished inserts. |

| Coolant System | High-pressure through-spindle coolant (70–100 bar), essential for deep pocket milling and chip evacuation in Aluminum and Steel. |

| Applications | Aerospace components, medical implants, complex automotive parts, and precision molds requiring sub-0.01 mm tolerances and minimal setup changes. |

This level of integration enables manufacturers like Honyo Prototype to produce complex, high-tolerance components from raw bar stock to finished part with minimal human intervention, reducing lead times and improving geometric accuracy across diverse materials.

From CAD to Part: The Process

Honyo Prototype 7-Axis Milling Process Overview

Our integrated 7-axis milling workflow ensures precision, efficiency, and manufacturability for complex geometries. The process begins with structured digital handoffs and concludes with certified delivery, leveraging both AI and expert engineering oversight.

CAD Upload and Initial Validation

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system automatically checks file integrity, unit consistency, and geometric validity. Critical dimensional tolerances and surface finish requirements are flagged for immediate review. Non-conforming files trigger instant notifications with specific error diagnostics, preventing downstream delays.

AI-Assisted Quoting with Human Validation

Uploaded geometry undergoes AI-driven analysis against our proprietary database of 12,000+ historical 7-axis projects. The AI engine calculates machine time, material utilization, fixture complexity, and刀具路径 optimization while accounting for 7-axis kinematic constraints. A preliminary quote generates within 2 business hours, but all outputs are validated by a Senior Manufacturing Engineer. This hybrid approach ensures realistic lead times and cost accuracy—our AI-human verification reduces quoting errors by 37% versus industry averages.

DFM Analysis: Collaborative Engineering Refinement

Design for Manufacturability (DFM) is a closed-loop collaboration between Honyo’s engineers and the client. The AI identifies potential issues such as:

| DFM Parameter | AI Detection Capability | Human Engineering Action |

|---|---|---|

| Undercuts & Collision | Kinematic simulation in 7 axes | Redesign fixture strategy or suggest geometry adjustments |

| Thin Walls | Deflection risk scoring | Propose adaptive step-down strategies |

| Surface Finish | Toolpath ripple prediction | Optimize spindle speed/feed per surface curvature |

| Datum Alignment | GD&T compliance check | Recommend secondary operations if needed |

Clients receive annotated DFM reports with actionable alternatives. 89% of complex 7-axis projects require ≤2 DFM iterations due to our predictive analytics.

Production Execution with Real-Time Monitoring

Validated designs move to dedicated 7-axis Haas UMC-1000 or DMG MORI machines. Key production protocols include:

Machine calibration is verified pre-run using Renishaw probes. In-process inspections occur at 25%, 50%, and 75% completion stages via integrated touch-trigger probes. All刀具 wear data feeds into our MES, automatically adjusting feed rates to maintain ±0.005mm tolerances. Critical aerospace or medical parts undergo full CMM validation post-machining per AS9100/ISO 13485 standards.

Certified Delivery and Traceability

Finished components ship with comprehensive documentation: First Article Inspection reports, material certs, and a digital twin showing actual vs. nominal dimensions. Every part includes a QR code linking to its full production history—machine logs, inspection data, and operator certifications. Standard lead time for 7-axis milling is 10–15 business days from DFM sign-off, with expedited options available. All shipments include real-time GPS tracking and climate-controlled packaging for temperature-sensitive alloys.

This end-to-end process reduces time-to-part by 22% compared to conventional multi-setup workflows while ensuring zero non-conformances in critical applications. Clients retain full visibility via our customer portal from upload to delivery.

Start Your Project

Discover advanced precision with our 7-axis milling machine, engineered for complex, high-accuracy manufacturing demands. Ideal for aerospace, medical, and automotive prototyping and production.

Contact Susan Leo to request specifications, pricing, or a technical consultation.

Email: [email protected]

Manufactured in our ISO-certified facility in Shenzhen, China, ensuring strict quality control and on-time delivery. Elevate your machining capability with Honyo Prototype’s cutting-edge 7-axis solution.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.