Contents

Manufacturing Insight: 7-Axis Cnc

Precision Through Complexity: Honyo Prototype’s Advanced 7-Axis CNC Machining

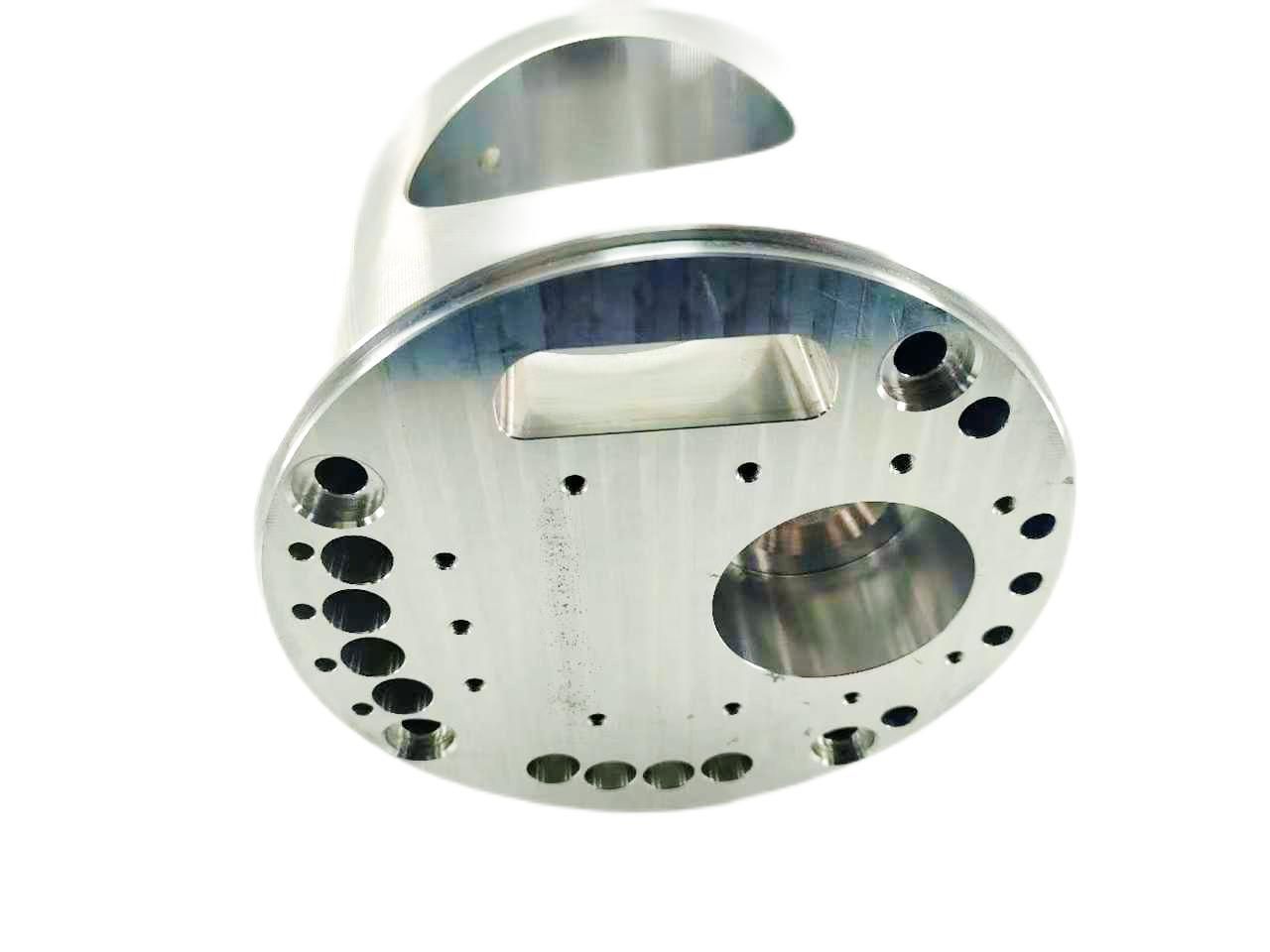

Honyo Prototype delivers unmatched geometric complexity and dimensional accuracy for the most demanding prototyping and low-volume production components through our state-of-the-art 7-axis CNC machining capabilities. This advanced multi-axis technology enables simultaneous machining from virtually any angle, eliminating the need for multiple setups and secondary operations typically required with 3 or 5-axis systems. The result is significantly reduced lead times, minimized part handling errors, and the ability to produce intricate organic shapes, deep cavities, and undercuts in a single operation – critical for aerospace impellers, medical implants, and complex fluid dynamics components.

Our 7-axis machining centers, operating with sub-micron precision across materials ranging from titanium alloys and Inconel to high-performance plastics, transform challenging digital designs into high-fidelity physical realities. This capability directly addresses the core manufacturing bottlenecks faced by engineering teams developing next-generation products, where part consolidation and geometric sophistication are paramount. By integrating 7-axis processing within our comprehensive CNC services, Honyo Prototype ensures your most complex validation parts and pre-production units meet stringent functional and tolerance requirements without compromising speed.

Accelerate your development cycle with Honyo Prototype’s seamless workflow, starting with our Online Instant Quote platform. Upload your CAD model today to receive a detailed, accurate machining quotation within hours – not days – providing immediate clarity on cost, lead time, and manufacturability for your 7-axis CNC project. This transparency allows engineering and procurement teams to make informed decisions rapidly, keeping innovation on schedule.

Technical Capabilities

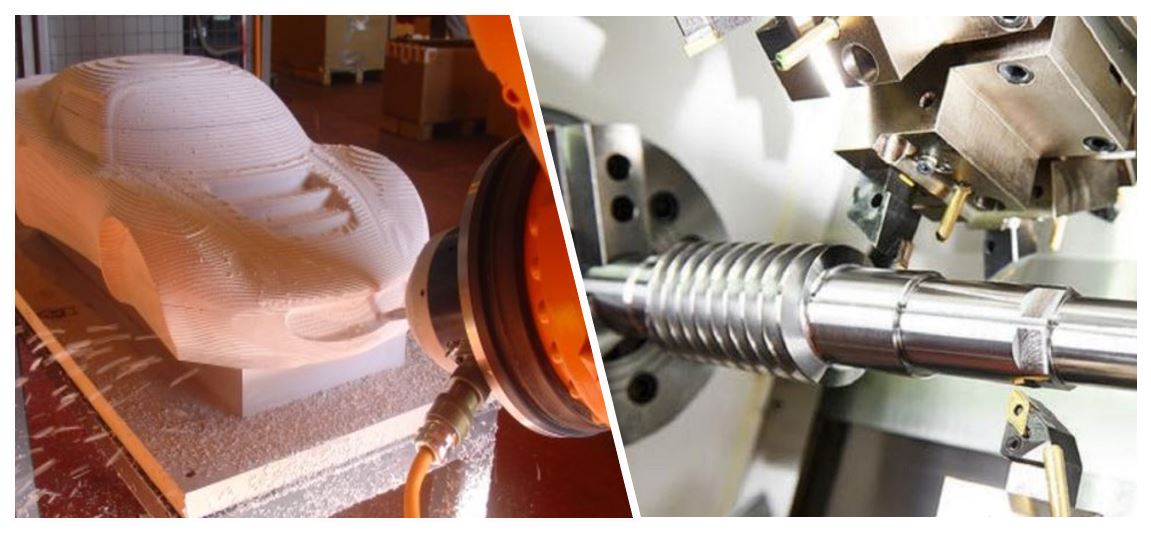

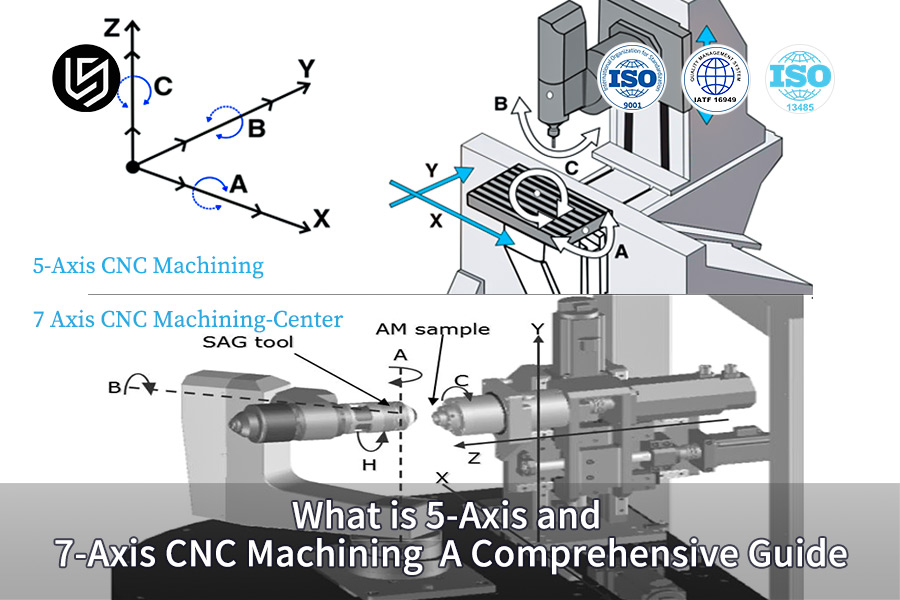

7-axis CNC machines represent an advanced evolution of multi-axis machining by combining the capabilities of 5-axis milling with additional rotational and translational axes, typically integrating mill-turn functionality with robotic or tooling automation. These systems are engineered for high-precision, complex geometry manufacturing with minimal setup changes. In the context of 3/4/5-axis milling and turning operations, the 7-axis configuration often refers to a combination of 5-axis simultaneous milling (X, Y, Z, A, B) plus 2-axis turning (C-axis rotation and sub-spindle movement), enabling full-part machining from raw stock to finished component.

Such machines are ideal for tight-tolerance applications, commonly achieving ±0.0002″ (±0.005 mm) positional accuracy and surface finishes down to Ra 0.8 µm. They support a wide range of materials, including Aluminum, Steel, ABS, and Nylon, each requiring tailored spindle speeds, feed rates, and tooling strategies to maintain dimensional stability and surface integrity.

Below are the technical specifications relevant to 7-axis CNC systems focused on precision milling, turning, and tight-tolerance production across the specified materials:

| Parameter | Specification / Capability |

|---|---|

| Axis Configuration | X, Y, Z linear axes; A, B rotational axes (5-axis milling); C-axis (main spindle rotation); W-axis (sub-spindle or tailstock movement) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00008″ (±0.002 mm) |

| Spindle Speed (Milling) | Up to 20,000 RPM (high-speed for Aluminum, plastics); 8,000–12,000 RPM for Steel |

| Spindle Speed (Turning) | Up to 6,000 RPM (steel), 12,000 RPM (Aluminum, ABS, Nylon) with C-axis control |

| Tool Changer Capacity | 30–120 tools (automatic tool changer with ATC) |

| Work Envelope (Typical) | 500 x 400 x 300 mm (X, Y, Z) – varies by machine model |

| Positioning Resolution | 0.00001″ (0.25 µm) |

| Surface Finish Capability | Ra 0.4 – 1.6 µm (milled), Ra 0.8 – 3.2 µm (turned), depending on material and tool path |

| Materials Supported | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (6, 66, GF-filled) |

| Coolant System | High-pressure through-spindle coolant (for steel, aluminum); air cooling (for plastics) |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7xx with 7-axis interpolation and look-ahead |

| Typical Tolerance Range | ±0.0002″ (±0.005 mm) for critical features; ±0.0005″ (±0.013 mm) for general features |

| Applications | Aerospace components, medical implants, complex housings, high-precision shafts, molds |

These machines are particularly effective when machining high-performance parts from both metals and engineering plastics. For Aluminum and Steel, rigid tool paths with optimized cutting parameters ensure burr-free edges and thermal stability. In the case of thermoplastics like ABS and Nylon, reduced cutting forces, specialized tool geometries (polished flutes), and air blast cooling prevent melting and deformation.

The integration of turning and milling in a 7-axis environment reduces secondary operations, improves concentricity, and enhances overall process control—critical for tight-tolerance components in regulated industries.

From CAD to Part: The Process

Honyo Prototype 7-Axis CNC Manufacturing Process Overview

Honyo Prototype leverages advanced 7-axis CNC machining for complex, high-precision components requiring multi-directional tool access and minimal setups. Our integrated workflow ensures efficiency, quality, and transparency from initial design to delivery. Below is a detailed explanation of each phase.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) via Honyo’s secure customer portal. Our system validates file integrity and extracts critical geometric data, including tolerances, material specifications, and surface finish requirements. This phase establishes the foundational dataset for all subsequent stages, with automated checks for common errors like missing datums or unsupported features.

AI-Powered Quoting

Uploaded CAD data feeds into Honyo’s proprietary AI quoting engine, which analyzes geometry complexity, material utilization, machine time, and secondary operations. The AI cross-references historical production data, current machine availability, and material costs to generate a precise quote within 2–4 hours. Unlike manual quoting, our system flags potential manufacturability risks early—such as extreme thin walls or inaccessible features—and provides preliminary cost-saving suggestions, reducing back-and-forth iterations.

DFM Analysis and Optimization

Upon quote acceptance, our engineering team conducts a rigorous Design for Manufacturability (DFM) review specific to 7-axis capabilities. This phase focuses on optimizing part orientation, minimizing rotary axis movements, and eliminating collision risks during simultaneous 5+2-axis operations. We evaluate:

Feasibility of achieving tight tolerances (±0.005 mm typical) across complex contours

Strategic fixture placement to leverage all seven axes for single-setup machining

Material waste reduction through adaptive toolpath strategies

Recommendations for design modifications to enhance throughput without compromising function

Clients receive a collaborative DFM report with annotated suggestions, enabling informed decisions before production begins.

7-Axis CNC Production

Approved designs move to production on Honyo’s Makino D200Z or DMG MORI NTX 1000 7-axis platforms. These machines integrate dual rotary axes (B and C) with linear X/Y/Z and orthogonal A/B axes, enabling continuous 5-axis contouring while dynamically repositioning the part. Key production protocols include:

In-process inspections using integrated Renishaw probes to verify critical features after each major operation

Real-time tool wear compensation and thermal drift monitoring

Machining of geometries impossible with 5-axis systems (e.g., deep cavities requiring compound angle approaches)

Reduced lead times through elimination of secondary setups, often cutting production time by 30–50% versus traditional methods

Quality-Controlled Delivery

Final parts undergo comprehensive metrology using Zeiss coordinate measuring machines (CMM) and optical scanners, with full inspection reports matching AS9102 or ISO 9001 standards. All shipments include:

Dimensional conformance certificates

Material traceability documentation

Surface roughness validation

First-article inspection (FAI) data for production runs

Parts are packaged in custom anti-static, humidity-controlled containers with serialized tracking. Honyo guarantees on-time delivery through our dynamic scheduling system, which prioritizes urgent jobs while maintaining 99.2% on-time performance.

Continuous Improvement Integration

Post-delivery, Honyo’s system correlates production data with initial AI quotes and DFM feedback to refine future quoting accuracy and process efficiency. This closed-loop approach ensures ongoing cost and lead-time reductions for repeat clients, particularly in aerospace, medical, and energy sectors where 7-axis complexity is critical.

Honyo Prototype’s 7-axis CNC workflow eliminates traditional bottlenecks through AI-driven planning, engineering expertise, and cutting-edge multi-axis technology—delivering uncompromised precision for the most demanding geometries.

Start Your Project

Explore the precision and versatility of 7-axis CNC machining for your most complex manufacturing challenges. At Honyo Prototype, our advanced 7-axis CNC technology enables seamless machining from all angles, reducing setup time and delivering superior accuracy for high-performance components.

With our state-of-the-art facility located in Shenzhen, we provide fast turnaround and consistent quality for industries including aerospace, medical, and automotive.

Contact Susan Leo today to discuss your project requirements and discover how our 7-axis CNC capabilities can elevate your prototyping and production needs.

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.