Introduction: Navigating the Global Market for 6061 t6511 properties

In the ever-evolving landscape of global manufacturing, sourcing high-quality materials like 6061 T6511 aluminum alloy poses unique challenges for B2B buyers. With its exceptional mechanical properties, corrosion resistance, and versatility, 6061 T6511 is a preferred choice across various industries, including aerospace, automotive, and construction. However, navigating the complexities of international supply chains, quality assurance, and cost-effectiveness can be daunting. This guide is designed to empower international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria, by providing a comprehensive overview of 6061 T6511 properties.

Within these pages, you will find in-depth analyses of different temper variations, including T6 and T651, alongside detailed insights into their specific applications and benefits. We will also explore crucial factors such as supplier vetting processes, pricing considerations, and logistical strategies to ensure a seamless procurement experience. By equipping you with actionable insights and expert knowledge, this guide aims to facilitate informed purchasing decisions, enabling your organization to leverage the full potential of 6061 T6511 aluminum alloy in your projects. Whether you are involved in structural engineering, manufacturing, or product design, understanding these properties will enhance your competitive edge in the global market.

Understanding 6061 t6511 properties Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6061-T6 | Solution heat-treated and artificially aged, providing high strength and good corrosion resistance. | Aerospace components, automotive parts, marine hardware. | Pros: High strength-to-weight ratio. Cons: Limited thickness options. |

| 6061-T651 | Similar to T6 but with added stress relief, reducing warping during machining. | Structural frames, bridges, and architectural applications. | Pros: Enhanced dimensional stability. Cons: Slightly lower strength than T6. |

| 6061-T6511 | Extruded, stress-relieved, and may be straightened; commonly available in bar and rod forms. | Manufacturing of rods, bars, and structural components. | Pros: Good machinability and surface finish. Cons: May have slight variations in properties compared to T6. |

| 6061-T6511 (Sheet) | Thin, flat products with excellent formability; often used in applications requiring bending. | Automotive body panels, furniture, and decorative applications. | Pros: Lightweight with good aesthetic appeal. Cons: Lower strength compared to thicker options. |

| 6061-T6511 (Plate) | Thick, flat products with high strength and rigidity; ideal for heavy-duty applications. | Heavy machinery, construction equipment, and marine vessels. | Pros: Excellent load-bearing capacity. Cons: More expensive due to thickness and processing. |

What Are the Key Characteristics of 6061-T6 Aluminum Alloy?

6061-T6 aluminum is a versatile alloy known for its excellent mechanical properties and high corrosion resistance. It undergoes solution heat treatment followed by artificial aging, resulting in improved strength. This alloy is suitable for applications in the aerospace and automotive industries due to its high strength-to-weight ratio. B2B buyers should consider its limited thickness options, which may restrict its use in certain structural applications.

How Does 6061-T651 Differ from Other Variants?

6061-T651 aluminum shares similar properties with T6 but incorporates an additional stress relief process. This characteristic reduces warping and distortion during machining, making it an ideal choice for structural frames and architectural applications. Buyers should note that while it offers enhanced dimensional stability, it has slightly lower strength compared to T6, which may influence material selection for specific projects.

Why Choose 6061-T6511 for Extruded Products?

The 6061-T6511 variant is specifically designed for extruded applications, offering stress relief and potential straightening. It is commonly available in bar and rod forms, making it a preferred choice for manufacturing various structural components. The machinability and surface finish are generally excellent, but buyers should be aware of potential property variations compared to the T6 temper, which may affect performance in critical applications.

What Are the Benefits of Using 6061-T6511 Sheets?

6061-T6511 sheets are characterized by their excellent formability, making them ideal for applications requiring bending and shaping, such as automotive body panels and furniture. They offer a lightweight solution with good aesthetic appeal. However, B2B buyers should consider that the strength is lower compared to thicker aluminum products, which may limit their use in heavy-duty applications.

When to Opt for 6061-T6511 Plates in Heavy-Duty Applications?

6061-T6511 plates are known for their high strength and rigidity, making them suitable for heavy-duty applications such as construction equipment and marine vessels. The load-bearing capacity of these plates is excellent, providing reliable performance in demanding environments. Buyers should be prepared for a higher cost due to the thickness and processing requirements but can expect long-term durability and performance in critical applications.

Key Industrial Applications of 6061 t6511 properties

| Industry/Sector | Specific Application of 6061 t6511 properties | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft fittings and structural components | High strength-to-weight ratio enhances fuel efficiency and safety | Certification of material properties and compliance with aviation standards |

| Automotive | Chassis and structural parts for vehicles | Improved performance and reduced overall vehicle weight | Availability of specific shapes and sizes for custom designs |

| Marine | Boat hulls and fittings | Corrosion resistance ensures longevity in harsh marine environments | Sourcing suppliers with a proven track record in marine applications |

| Construction | Structural framing and support systems | Durability and lightweight characteristics reduce costs and improve safety | Compliance with local building codes and regulations |

| Consumer Goods | Bicycles and sporting equipment | Enhanced performance and aesthetic appeal through excellent finish | Availability of various forms (tubes, sheets) for diverse designs |

How is 6061 T6511 Used in Aerospace Applications?

In the aerospace sector, 6061 T6511 aluminum is predominantly used for aircraft fittings and structural components. Its high strength-to-weight ratio is critical for enhancing fuel efficiency and ensuring the safety of aircraft. Buyers from regions like Europe and the Middle East must ensure that their suppliers can provide certified materials that meet stringent aviation standards. This includes thorough documentation of material properties and compliance with international regulations.

What Role Does 6061 T6511 Play in the Automotive Industry?

The automotive industry utilizes 6061 T6511 for manufacturing chassis and structural parts, capitalizing on its lightweight nature to improve vehicle performance and fuel efficiency. B2B buyers in South America and Africa should prioritize sourcing from suppliers that can provide specific shapes and sizes to accommodate custom designs. Additionally, understanding the alloy’s mechanical properties is essential for ensuring optimal performance in various automotive applications.

Why is 6061 T6511 Preferred in Marine Applications?

In marine environments, the corrosion resistance of 6061 T6511 makes it an ideal choice for boat hulls and fittings. This property ensures longevity and reliability, critical factors for marine operators. Buyers in regions like Africa and Europe should seek suppliers with a proven history in marine applications to guarantee the quality and performance of the aluminum products. Additionally, understanding local marine regulations can guide sourcing decisions.

How Does 6061 T6511 Benefit Construction Projects?

In construction, 6061 T6511 is frequently used for structural framing and support systems. Its durability and lightweight characteristics contribute to cost savings and improved safety in building projects. Buyers, especially in developing regions, should consider suppliers who comply with local building codes and regulations to avoid potential legal issues and ensure project success. The ability to provide customized solutions is also a significant advantage.

What Advantages Does 6061 T6511 Offer in Consumer Goods Manufacturing?

For consumer goods, particularly in bicycles and sporting equipment, 6061 T6511 is valued for its excellent surface finish and mechanical properties. This enhances both performance and aesthetic appeal, making products more attractive to consumers. B2B buyers should focus on sourcing a variety of forms, such as tubes and sheets, to facilitate diverse design needs. Ensuring suppliers can deliver consistent quality is crucial for maintaining brand reputation in competitive markets.

3 Common User Pain Points for ‘6061 t6511 properties’ & Their Solutions

Scenario 1: Inconsistent Quality of 6061 T6511 Deliveries

The Problem: B2B buyers often face challenges with the quality and consistency of Aluminum 6061 T6511 received from suppliers. Variations in alloy composition, mechanical properties, and surface finish can lead to significant issues during production. For industries such as aerospace and automotive, where precision and reliability are paramount, receiving subpar materials can cause project delays, increased costs, and even safety concerns.

The Solution: To mitigate these risks, buyers should establish strong relationships with reputable suppliers who provide detailed material certifications and mill test reports. Before placing bulk orders, consider requesting samples to verify the quality against your specific requirements. Additionally, implement a robust quality assurance process upon receiving materials. This should include checks for mechanical properties like tensile strength and elongation, as well as visual inspections for surface defects. Regular audits of suppliers can also ensure they adhere to industry standards and maintain consistent quality levels.

Scenario 2: Difficulty in Machining 6061 T6511 to Required Specifications

The Problem: Many B2B buyers encounter issues when machining Aluminum 6061 T6511, particularly in achieving tight tolerances or complex geometries. The alloy’s properties can lead to challenges such as tool wear and poor surface finish, resulting in increased production costs and lead times. This is particularly problematic for industries that require precision components, such as medical devices or high-performance automotive parts.

The Solution: To enhance machinability, buyers should prioritize sourcing 6061 T6511 with a well-defined temper and proper heat treatment, as these factors significantly affect performance. Collaborating closely with machinists early in the design phase can help identify potential challenges and allow for the selection of optimal machining parameters. It may also be beneficial to utilize specialized cutting tools designed for aluminum alloys, which can improve surface finish and extend tool life. Additionally, incorporating lubrication during machining can reduce friction and heat, leading to better results.

Scenario 3: Misunderstanding the Applications of 6061 T6511 Properties

The Problem: B2B buyers often struggle to fully understand the range of applications suitable for 6061 T6511. This lack of knowledge can lead to selecting inappropriate materials for specific projects, resulting in performance failures or increased costs. For example, using this alloy in high-stress applications without recognizing its limitations could jeopardize product integrity.

The Solution: To address this knowledge gap, buyers should invest time in comprehensive material education. This includes understanding the mechanical properties of 6061 T6511, such as its tensile strength, yield strength, and corrosion resistance. Engaging with industry experts or attending workshops can provide valuable insights into the alloy’s capabilities and limitations. Furthermore, buyers should conduct a thorough application analysis to determine if 6061 T6511 meets the requirements for their specific use cases. Leveraging case studies or consulting with manufacturers who have successfully used the alloy in similar applications can guide decision-making and help avoid costly mistakes.

Strategic Material Selection Guide for 6061 t6511 properties

What Are the Key Properties of 6061 T6511 Aluminum Alloy?

6061 T6511 aluminum alloy is renowned for its excellent mechanical properties, corrosion resistance, and versatility in various applications. Its composition includes a significant percentage of aluminum (95.8 – 98.6%), along with magnesium (0.8 – 1.2%), silicon (0.4 – 0.8%), and trace amounts of other elements. These properties contribute to its high strength-to-weight ratio, making it suitable for demanding environments.

What Are the Pros and Cons of Using 6061 T6511 Aluminum Alloy?

Pros:

– Durability: The T6511 temper enhances strength and hardness, making it suitable for structural applications.

– Corrosion Resistance: Its excellent resistance to corrosion allows for use in marine and industrial environments.

– Machinability: The alloy is easy to machine, facilitating complex designs and reducing manufacturing time.

Cons:

– Cost: While generally affordable, the price can be higher than some alternative materials, especially for specialized forms.

– Thermal Sensitivity: The alloy’s properties can be affected by extreme temperatures, requiring careful consideration in high-heat applications.

How Does 6061 T6511 Impact Specific Applications?

6061 T6511 is widely used in various industries, including aerospace, automotive, and construction. Its compatibility with different media makes it suitable for structural components in bridges, railings, and marine fittings. However, buyers must consider specific application requirements, such as temperature and pressure ratings, to ensure optimal performance.

What Should International B2B Buyers Consider When Selecting 6061 T6511?

For international buyers, particularly in Africa, South America, the Middle East, and Europe, compliance with regional standards is crucial. Familiarity with standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards) is essential. Buyers should also consider logistical aspects, including shipping costs and lead times, which may vary significantly across regions.

Summary Table of 6061 T6511 Properties

| Material | Typical Use Case for 6061 t6511 properties | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 T6511 | Structural components in bridges and railings | High strength-to-weight ratio | Higher cost compared to some alternatives | Medium |

| 6061 T6511 | Marine hardware and fittings | Excellent corrosion resistance | Thermal sensitivity in extreme conditions | Medium |

| 6061 T6511 | Aerospace parts and automotive applications | Good machinability | Requires careful handling in high heat | Medium |

| 6061 T6511 | Consumer goods like bicycles and furniture | Versatile and widely available | Limited performance in extreme temperatures | Medium |

This analysis provides a comprehensive overview of 6061 T6511 properties, enabling B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 6061 t6511 properties

What Are the Main Stages in the Manufacturing Process of 6061 T6511 Aluminum?

The manufacturing process of 6061 T6511 aluminum involves several critical stages, each designed to enhance the material’s properties while ensuring efficiency and quality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with sourcing high-quality aluminum ingots, which are carefully selected based on their chemical composition to meet the specifications for 6061 T6511. Once the ingots are obtained, they are cleaned and prepped for melting. This stage may also involve alloying, where precise amounts of elements like magnesium, silicon, and copper are added to achieve desired mechanical properties. -

Forming Techniques

The prepared aluminum is then subjected to various forming techniques, including extrusion and rolling. In the extrusion process, the aluminum is heated and forced through a die to create specific shapes such as bars, tubes, or profiles. Rolling involves passing the material through a series of rollers to achieve flat sheets or plates. Both methods ensure that the final product retains the excellent mechanical properties and surface finish characteristic of T6511. -

Assembly Operations

After forming, components may require assembly. This stage can involve welding, machining, or fastening, depending on the end application. For instance, in the aerospace or automotive industries, components may need to be joined using specialized techniques that preserve the integrity of the aluminum alloy while ensuring strength and durability. -

Finishing Processes

The final stage includes various finishing processes such as anodizing, painting, or coating. Anodizing not only enhances corrosion resistance but also allows for aesthetic customization. Finishing is essential for applications that demand high surface quality and performance, particularly in demanding environments like marine or aerospace applications.

What Quality Control Standards Are Relevant for 6061 T6511 Aluminum?

Quality control (QC) is a crucial aspect of the manufacturing process for 6061 T6511 aluminum, ensuring that the final products meet international and industry-specific standards.

-

International Standards

One of the most recognized standards in quality management systems is ISO 9001. This certification ensures that manufacturers have established processes for consistent quality management, focusing on customer satisfaction and continuous improvement. For B2B buyers, sourcing from ISO 9001-certified suppliers can provide confidence in the quality and reliability of products. -

Industry-Specific Standards

Depending on the application, other certifications may be relevant. For example, the CE marking is crucial for products sold in the European market, indicating compliance with safety and environmental standards. In the oil and gas sector, the American Petroleum Institute (API) standards may apply, particularly for components used in harsh environments.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process to ensure compliance with specifications and standards.

-

Incoming Quality Control (IQC)

At the IQC stage, raw materials and components are inspected upon arrival to verify that they meet specified standards. This includes checking the chemical composition, physical dimensions, and any certifications from suppliers. -

In-Process Quality Control (IPQC)

During manufacturing, IPQC involves regular inspections and testing of products at different stages. This may include monitoring temperature and pressure during extrusion or rolling, as well as dimensional checks to ensure that products conform to design specifications. -

Final Quality Control (FQC)

The FQC phase involves comprehensive testing of the finished products before they are shipped. Common methods include tensile strength tests, hardness tests, and surface finish evaluations. Documentation of these tests is crucial for traceability and compliance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must ensure that their suppliers adhere to strict quality control practices, particularly when sourcing materials like 6061 T6511 aluminum from international suppliers.

-

Supplier Audits

Conducting supplier audits is an effective way to verify quality control practices. These audits can assess compliance with international standards and provide insights into the manufacturer’s processes, equipment, and workforce capabilities. -

Quality Reports and Certifications

Requesting quality reports and certifications from suppliers can offer additional assurance. These documents should detail the results of testing and inspections, along with any relevant quality certifications. -

Third-Party Inspections

Engaging third-party inspection services can further validate the quality of the products. These independent assessments can provide unbiased evaluations of the supplier’s manufacturing processes and product quality.

What QC and Certification Nuances Should International Buyers Consider?

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification.

-

Regional Standards

Different regions may have varying standards and regulations. Buyers should familiarize themselves with local compliance requirements, such as those set by the European Union or specific countries. Understanding these nuances can prevent costly delays and ensure compliance in the target market. -

Documentation and Language Barriers

When dealing with international suppliers, language barriers can complicate the understanding of quality documentation. It is advisable to clarify any uncertainties and ensure that all technical specifications and quality certifications are well-documented and translated, if necessary. -

Cultural Differences in Business Practices

Different cultures may have varying approaches to business and quality assurance. Establishing clear communication and mutual understanding of quality expectations can facilitate smoother transactions and foster long-term relationships with suppliers.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance practices for 6061 T6511 aluminum is essential for B2B buyers. By familiarizing themselves with the stages of production, relevant quality standards, key checkpoints, and verification methods, buyers can make informed decisions that align with their operational needs and ensure high-quality outcomes in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6061 t6511 properties’

When sourcing 6061 T6511 aluminum properties, it is essential to follow a structured approach to ensure you procure high-quality material that meets your specific needs. This guide provides actionable steps for B2B buyers to facilitate an efficient and effective sourcing process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it is crucial to outline your technical requirements for 6061 T6511 aluminum. Consider factors such as the desired dimensions, shapes (e.g., sheets, extrusions, bars), and any specific mechanical properties like tensile strength or corrosion resistance. Clear specifications will help in obtaining accurate quotes and reduce the likelihood of miscommunication.

Step 2: Research Potential Suppliers

Thoroughly research suppliers who specialize in aluminum products, particularly those offering 6061 T6511. Utilize online directories, trade shows, and industry publications to compile a list of potential vendors. Look for suppliers with a strong reputation and proven experience in your industry, as this often correlates with reliability and quality.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that your chosen suppliers possess the necessary certifications. Check for ISO 9001 or other relevant quality management certifications that demonstrate adherence to industry standards. Certifications ensure that the supplier follows rigorous quality control measures, which is critical when sourcing materials for demanding applications.

Step 4: Request Material Certifications

When considering a supplier, request material certifications, such as mill test reports or certificates of compliance. These documents provide essential information about the alloy’s chemical composition and mechanical properties, ensuring it meets your specifications. Confirm that the certifications are up to date and relevant to the specific batch of material you intend to purchase.

Step 5: Assess Pricing and Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. While cost is a significant factor, consider the overall value, including delivery times, order quantities, and any additional services offered. Be cautious of suppliers with prices that seem unusually low, as this may indicate lower quality or hidden costs.

Step 6: Check for Customer Support and After-Sales Service

Evaluate the level of customer support provided by each supplier. A responsive supplier who offers technical assistance, guidance on material selection, and after-sales service can significantly enhance your sourcing experience. Good communication can help resolve issues quickly and foster a long-term partnership.

Step 7: Conduct a Trial Purchase

Before committing to a large order, consider making a smaller trial purchase to evaluate the supplier’s product quality and service reliability. This step allows you to assess the material’s performance and the supplier’s ability to meet delivery schedules and handle any issues that may arise. A trial purchase minimizes risk and provides a clearer picture of the supplier’s capabilities.

By following this checklist, B2B buyers can streamline their procurement process for 6061 T6511 aluminum, ensuring they select the right supplier and receive high-quality materials tailored to their specific requirements.

Comprehensive Cost and Pricing Analysis for 6061 t6511 properties Sourcing

What Are the Key Cost Components for Sourcing 6061 T6511 Properties?

When evaluating the cost structure for sourcing 6061 T6511 aluminum properties, several key components come into play. Materials are the primary cost driver, with prices influenced by global aluminum market trends, alloy composition, and certification requirements. The average cost of 6061 T6511 is typically higher than other alloys due to its enhanced mechanical properties and corrosion resistance.

Labor costs vary by region and are influenced by the level of expertise required for machining and handling aluminum. In areas with lower labor costs, such as certain parts of Africa and South America, buyers might find competitive pricing, but this could come with trade-offs in terms of quality and lead times.

Manufacturing overhead includes expenses related to facility maintenance, utilities, and administrative costs. Tooling costs are significant as they involve the initial setup and ongoing maintenance of equipment used to process the aluminum. These costs can be amortized over larger production runs, making it essential to consider volume when negotiating prices.

Quality Control (QC) is another vital aspect, particularly for international buyers who may require specific certifications. The cost associated with QC processes can add to the overall expense but is crucial for ensuring compliance with industry standards.

Logistics also plays a pivotal role, especially for international shipments. Factors such as transportation, insurance, and customs duties can significantly impact the final cost, making it essential to understand the specific Incoterms agreed upon in contracts.

How Do Pricing Influencers Affect 6061 T6511 Costs?

Several factors influence the pricing of 6061 T6511 aluminum properties. Volume and Minimum Order Quantity (MOQ) are critical; suppliers often provide discounts for larger orders, which can substantially reduce the per-unit cost. Buyers should aim to consolidate orders to maximize savings.

Specifications and Customization also affect pricing. Customized products or those with stringent specifications typically incur higher costs due to additional processing and quality assurance measures. Therefore, understanding the necessary specifications upfront can aid in effective budgeting.

Material quality and certifications can lead to price variances. High-grade materials with recognized certifications (e.g., ISO standards) command premium prices. It’s advisable for buyers to communicate their quality requirements clearly to avoid unexpected costs later in the sourcing process.

Supplier factors, including reputation and reliability, can also influence pricing. Established suppliers with a track record of quality may charge more, but they often provide better service and assurance of compliance, which can be worth the additional investment.

What Are the Best Negotiation Strategies for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings. Start by researching market prices and understanding the current demand-supply dynamics for 6061 T6511. This knowledge empowers buyers during negotiations.

Consider leveraging Total Cost of Ownership (TCO) in discussions. This approach emphasizes not just the purchase price but also factors such as logistics, lead times, and potential quality issues. Highlighting these aspects can persuade suppliers to offer more competitive pricing.

When negotiating pricing nuances, be aware of currency fluctuations and their impact on total costs. Establishing payment terms in stable currencies can mitigate risks associated with exchange rate volatility.

Lastly, build strong relationships with suppliers. A collaborative approach can lead to long-term partnerships, often resulting in more favorable pricing and terms as both parties understand each other’s needs better.

Conclusion: Understanding Costs and Pricing for 6061 T6511 Sourcing

In conclusion, sourcing 6061 T6511 aluminum properties involves navigating a complex landscape of costs and pricing influences. By understanding the various cost components and employing strategic negotiation tactics, international buyers can optimize their sourcing decisions. Keep in mind that indicative prices can fluctuate based on market conditions, so staying informed and adaptable is crucial in securing the best deals.

Alternatives Analysis: Comparing 6061 t6511 properties With Other Solutions

Understanding Alternatives in Material Selection for B2B Buyers

When selecting materials for industrial applications, it is crucial for B2B buyers to consider not just the primary option, such as 6061 T6511 aluminum, but also viable alternatives. This analysis will help decision-makers understand how 6061 T6511 compares against other materials in terms of performance, cost, and suitability for specific applications.

Comparison Table

| Comparison Aspect | 6061 T6511 Properties | Alternative 1: 7075 Aluminum | Alternative 2: Stainless Steel 304 |

|---|---|---|---|

| Performance | High strength, good corrosion resistance | Superior strength, lower corrosion resistance | Excellent corrosion resistance, lower strength |

| Cost | Moderate cost | Higher cost due to alloying elements | Generally higher than aluminum alloys |

| Ease of Implementation | Easy to machine and weld | Difficult to machine; requires special tools | Moderate; requires specific welding techniques |

| Maintenance | Low maintenance | Low maintenance, but susceptible to stress corrosion | Low maintenance, excellent longevity |

| Best Use Case | Structural applications, automotive, marine | Aerospace, military applications | Food processing, chemical industries |

In-Depth Comparison of Alternatives

What Are the Advantages and Disadvantages of 7075 Aluminum Compared to 6061 T6511?

7075 aluminum is known for its exceptional strength, making it a popular choice in aerospace and military applications. Its tensile strength surpasses that of 6061 T6511, making it ideal for high-stress applications. However, this strength comes at a higher cost due to the alloying elements used, such as zinc. Additionally, 7075 is more challenging to machine, which may lead to increased manufacturing times and costs. While its corrosion resistance is lower than that of 6061 T6511, it performs well in dry environments.

How Does Stainless Steel 304 Compare with 6061 T6511?

Stainless Steel 304 is renowned for its excellent corrosion resistance, making it suitable for environments exposed to moisture and chemicals. Its longevity is a significant advantage, particularly in industries like food processing and pharmaceuticals. However, it has a lower strength-to-weight ratio compared to 6061 T6511, making it less suitable for applications where weight is a critical factor. Moreover, stainless steel is generally more expensive and requires specific welding techniques, which could complicate fabrication processes.

Conclusion: How Should B2B Buyers Choose the Right Material?

Choosing the right material involves balancing performance, cost, and application needs. For structural applications where weight and machinability are crucial, 6061 T6511 aluminum remains a solid choice due to its favorable properties and moderate cost. However, for applications demanding higher strength, 7075 aluminum may be more suitable despite its higher price and machining challenges. Conversely, in environments prone to corrosion, Stainless Steel 304 offers unparalleled resistance, albeit at a higher cost and reduced strength. Ultimately, B2B buyers should assess their specific requirements, including performance criteria and budget constraints, to make informed material selections that align with their operational goals.

Essential Technical Properties and Trade Terminology for 6061 t6511 properties

What Are the Key Technical Properties of 6061 T6511 Aluminum?

Understanding the technical specifications of 6061 T6511 aluminum is crucial for B2B buyers, especially when considering the material for various industrial applications. Here are some essential properties that define its usability and performance:

-

Material Grade

The 6061 T6511 designation indicates a specific aluminum alloy categorized under the 6000 series. This grade is known for its excellent mechanical properties, including high strength and corrosion resistance. For businesses, selecting the right material grade is vital for ensuring product durability and performance in demanding environments, such as aerospace and marine applications. -

Tensile Strength

With a typical tensile strength of 45,000 psi (310 MPa), 6061 T6511 provides robust performance under stress. This property is particularly important for structural applications, as it defines how much load the material can withstand before failing. Buyers must assess tensile strength to ensure that the selected aluminum can handle operational demands without compromising safety. -

Yield Strength

The yield strength of 6061 T6511 is around 40,000 psi (276 MPa). This value indicates the maximum stress that can be applied before the material begins to deform permanently. Understanding yield strength is essential for manufacturers to design components that maintain their shape and functionality under load, thus reducing maintenance costs and enhancing product lifespan. -

Elongation at Break

This alloy exhibits an elongation at break of about 17%, which measures its ductility. A higher elongation percentage means that the material can be stretched before breaking, making it suitable for applications requiring complex shapes or forms. For B2B buyers, this property is critical when evaluating how well the material can be processed and fabricated into desired shapes without failure. -

Corrosion Resistance

6061 T6511 is renowned for its excellent resistance to corrosion, making it ideal for outdoor applications and environments with moisture exposure. This characteristic is particularly valuable for industries such as construction and automotive, where long-term durability is essential. Buyers should prioritize materials with high corrosion resistance to minimize the risk of product degradation over time.

What Are Common Trade Terms Related to 6061 T6511 Aluminum?

In addition to understanding technical properties, familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help in sourcing high-quality components that meet specific application standards. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand pricing structures and inventory management. Knowing the MOQ helps in budgeting and planning for procurement. -

RFQ (Request for Quotation)

An RFQ is a standard business process wherein a buyer requests price quotes from suppliers for specific products or services. For B2B buyers, issuing an RFQ is essential for comparing costs and ensuring competitive pricing, especially for bulk purchases. -

Incoterms (International Commercial Terms)

These are predefined commercial terms that outline the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, insurance, and liability, ensuring smooth logistics and minimizing risks. -

T6511 vs. T6 Temper Designation

The T6511 temper indicates that the aluminum has been extruded, aged, and stress-relieved, while T6 refers to a non-extruded version. Knowing the differences between these designations helps buyers select the appropriate material for their specific applications. -

Mill Test Report (MTR)

An MTR is a document provided by the manufacturer that certifies the material’s compliance with specified standards. For B2B buyers, requesting an MTR is vital to verify the quality and specifications of the aluminum being purchased.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 6061 T6511 aluminum, ensuring that they choose the right material for their specific needs and applications.

Navigating Market Dynamics and Sourcing Trends in the 6061 t6511 properties Sector

What Are the Key Trends Influencing the 6061 T6511 Properties Market?

The global market for aluminum 6061 T6511 is experiencing significant growth, driven by a variety of factors including increased demand for lightweight materials in transportation, construction, and consumer goods. The aerospace and automotive sectors particularly favor 6061 T6511 due to its excellent strength-to-weight ratio and corrosion resistance. As international buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, the demand for this alloy is expected to rise.

Emerging B2B technology trends such as digital sourcing platforms and supply chain automation are reshaping how businesses procure 6061 T6511 materials. These platforms enable buyers to compare prices, assess supplier reliability, and streamline procurement processes, facilitating faster decision-making and minimizing operational risks. Additionally, advancements in additive manufacturing and fabrication techniques are allowing for more innovative applications of 6061 T6511, further expanding its market potential.

Market dynamics indicate that regional variances in availability and pricing may influence sourcing strategies. For instance, European suppliers often emphasize quality certifications, while African and South American buyers may focus on cost-effectiveness. Understanding these regional differences is crucial for international buyers looking to optimize their supply chains and ensure reliable access to high-quality materials.

How Can Sustainability and Ethical Sourcing Impact the 6061 T6511 Properties Market?

Sustainability has become a pivotal concern in the B2B landscape, particularly in the sourcing of aluminum alloys like 6061 T6511. The environmental impact of aluminum production is significant, with energy-intensive processes contributing to carbon emissions. Consequently, buyers are increasingly seeking suppliers who prioritize sustainable practices, such as recycling and the use of renewable energy sources in their operations.

Ethical supply chains are gaining traction as well. Buyers are now more inclined to partner with suppliers who uphold fair labor practices and demonstrate social responsibility. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming important indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the growing demand for ‘green’ materials is leading to the development of aluminum alloys produced with lower environmental footprints. This trend not only aligns with global sustainability goals but also enhances brand reputation and customer loyalty for companies that prioritize ethical sourcing. For B2B buyers, selecting suppliers who adhere to these principles is not just a compliance measure but a strategic advantage in a competitive marketplace.

What Is the Historical Context of 6061 T6511 in the B2B Sector?

The 6061 T6511 aluminum alloy has a rich history that dates back to its introduction in the 1930s. Initially developed for aerospace applications, its favorable mechanical properties and corrosion resistance quickly made it a go-to material across various industries, including automotive and construction. Over the decades, the alloy has evolved through advancements in processing techniques and heat treatments, enhancing its performance and expanding its applicability.

The T6511 temper, characterized by additional stress relief processes, emerged as a response to the need for greater dimensional stability during machining. This evolution has allowed manufacturers to produce more intricate designs and components, meeting the growing demands of modern engineering and manufacturing. As a result, 6061 T6511 has cemented its position as a critical material in the global supply chain, catering to the needs of diverse sectors while continuously adapting to market trends and technological advancements.

This historical context not only highlights the alloy’s versatility but also underscores its importance as a strategic material for international B2B buyers aiming to innovate and enhance their product offerings.

Frequently Asked Questions (FAQs) for B2B Buyers of 6061 t6511 properties

-

How do I ensure the quality of 6061 T6511 aluminum from suppliers?

To guarantee quality, request material certification or mill test reports from your supplier. These documents provide assurance that the aluminum meets the specified standards for composition and mechanical properties. Additionally, consider conducting third-party inspections or audits of the supplier’s facilities to verify their quality control processes. Establishing a long-term relationship with a reputable supplier who has experience in international trade can also help ensure consistent quality. -

What is the best application for 6061 T6511 aluminum?

6061 T6511 aluminum is ideal for structural and mechanical applications due to its high strength-to-weight ratio and excellent corrosion resistance. Common applications include aerospace components, automotive parts, marine fittings, and architectural structures such as bridges and railings. Its machinability also makes it suitable for custom parts in various industries, including consumer goods like bicycles and furniture. -

What are the typical minimum order quantities (MOQ) for 6061 T6511 aluminum?

Minimum order quantities can vary significantly based on the supplier and the specific product form (e.g., sheets, bars, tubes). Generally, MOQs range from 500 kg to several tons. It’s advisable to discuss your needs with potential suppliers to find flexible options that accommodate smaller orders, especially for prototyping or smaller projects. Be prepared to negotiate based on your order size and frequency. -

What payment terms should I expect when sourcing 6061 T6511 aluminum internationally?

Payment terms can differ by supplier and region, but common practices include a 30% deposit upfront and the balance upon delivery or before shipment. Some suppliers may offer letter of credit arrangements for larger orders. Ensure you clarify the payment terms early in negotiations to avoid misunderstandings, and consider using secure payment methods that offer buyer protection. -

How can I customize 6061 T6511 aluminum products for my specific needs?

Customization options depend on the supplier’s capabilities. Many suppliers can provide various forms, sizes, and finishes of 6061 T6511 aluminum. Discuss your specific requirements, such as dimensions, surface treatments, and mechanical properties, with the supplier. Some may offer CNC machining or fabrication services to create tailored solutions that fit your application. -

What logistics considerations should I keep in mind when importing 6061 T6511 aluminum?

When importing, consider the shipping method, lead times, and customs regulations in your country. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but may take longer. Ensure that the supplier provides the necessary documentation for customs clearance, and familiarize yourself with import duties and taxes to avoid unexpected costs. -

How do I evaluate the reliability of a 6061 T6511 aluminum supplier?

To assess a supplier’s reliability, review their history and reputation within the industry. Look for customer testimonials, case studies, or references from previous clients. Verify their certifications and compliance with international quality standards such as ISO 9001. Additionally, consider their responsiveness and communication style during initial interactions as indicators of their customer service approach. -

What are the common challenges in sourcing 6061 T6511 aluminum internationally?

Challenges may include fluctuating material prices, varying quality standards, and logistical issues such as delays in shipping. Currency exchange rates can also affect overall costs. To mitigate these risks, conduct thorough market research, establish clear agreements with suppliers, and consider sourcing from multiple vendors to ensure competitive pricing and consistent supply. Regular communication with suppliers can help address potential issues proactively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 6061 T6511 Properties Manufacturers & Suppliers List

1. FastMetals – Aluminum 6061 T6511 Products

Domain: fastmetals.com

Registered: 2013 (12 years)

Introduction: Aluminum 6061 T6511: Properties, Applications & Products | FastMetals. Available shapes include Angle, Channel, Flat, Hex, I-Beam, Pipe, Plate, Rectangular Tube, Round, Square, Tee, and Tread. Key products include Aluminum Extruded Angle 6061 T6, Aluminum Extruded Flat Bar 6061 T6511, Aluminum Extruded Round Bar 6061 T6511, Aluminum Plate 6061 T651, Aluminum Pipe 6061 T6 Schedule 40, and Aluminum …

2. ASM – Aluminum 6061-T6

Domain: asm.matweb.com

Registered: 1997 (28 years)

Introduction: {“Material Name”: “Aluminum 6061-T6; 6061-T651”, “Subcategory”: “6000 Series Aluminum Alloy”, “Composition”: {“Al”: “95.8 – 98.6 %”, “Cr”: “0.04 – 0.35 %”, “Cu”: “0.15 – 0.4 %”, “Fe”: “Max 0.7 %”, “Mg”: “0.8 – 1.2 %”, “Mn”: “Max 0.15 %”, “Si”: “0.4 – 0.8 %”, “Ti”: “Max 0.15 %”, “Zn”: “Max 0.25 %”}, “General Characteristics”: “Excellent joining characteristics, good acceptance of applied coatings, …

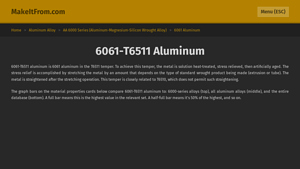

3. Make It From – 6061-T6511 Aluminum Alloy

Domain: makeitfrom.com

Registered: 2009 (16 years)

Introduction: {“name”: “6061-T6511 Aluminum”, “type”: “Aluminum Alloy”, “temper”: “T6511”, “mechanical_properties”: {“Elastic_Modulus”: “69 GPa”, “Elongation_at_Break”: “9.0%”, “Fatigue_Strength”: “100 MPa”, “Poissons_Ratio”: “0.33”, “Shear_Modulus”: “26 GPa”, “Shear_Strength”: “170 MPa”, “Tensile_Strength_UTS”: “290 MPa”, “Tensile_Strength_Yield”: “270 MPa”}, “thermal_properties”: {“Latent_Heat_of_Fusion”: “40…

4. Coremark Metals – 6061 Aluminum Round Bar

Domain: coremarkmetals.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “6061 Aluminum Round Bar”, “description”: “6061 extruded Aluminum round bar is an excellent candidate for most processing techniques with good corrosion resistance. It’s a lightweight material with a smooth finish, defined edges, and high strength to weight ratio. Frequently found in aircraft construction, marine, and electronic applications. It is also commonly used for brackets,…

5. Online Metals – Aluminum 6061

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: Aluminum 6061 is the most commonly used aluminum alloy in the world, known for its strength, heat treatability, easy machining, and weldability. It can be anodized for added protection. Common applications include aircraft components, cameras, couplings, marine fittings, electrical components, decorative hardware, pins, brake and hydraulic pistons, valves, and bicycle frames. Trade names include U…

6. LinkedIn – 6061 Aluminum Alloy

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: 6061 Aluminum Alloy:

– Type: Precipitation-hardened alloy containing magnesium and silicon.

– Common Tempers: 6061-T6511 and 6061-T651.

6061-T6511:

– Process: Solution heat treatment, stretching, and artificial aging.

– Key Properties:

– Tensile Strength: Approximately 310 MPa (45,000 psi)

– Yield Strength: Approximately 276 MPa (40,000 psi)

– Elongation at Break: 12-15%

– Brinel…

7. Tuofa – Aluminum 6061 T6 Comparison

Domain: tuofa-cncmachining.com

Registered: 2022 (3 years)

Introduction: Aluminum 6061 T6 vs T651 vs T6511: Comparison of tempering processes for aluminum alloys.

6061 T6 Aluminum:

– High strength and exceptional mechanical properties.

– Excellent corrosion resistance and good weldability.

– Commonly used in aerospace and automotive industries.

– Heat treatment process: solution heat treated at 525°C, quenched in water, followed by artificial aging.

– Mechanical…

Strategic Sourcing Conclusion and Outlook for 6061 t6511 properties

In the competitive landscape of international manufacturing, understanding the properties and applications of Aluminum 6061-T6511 is crucial for strategic sourcing. This alloy stands out for its excellent mechanical properties, corrosion resistance, and versatility across various industries, including aerospace, automotive, and construction. Its superior strength-to-weight ratio and machinability make it an ideal choice for structural and mechanical components, while its availability in multiple forms enhances its utility in diverse applications.

Strategic sourcing of 6061-T6511 involves not only evaluating the material’s specifications but also considering supplier reliability and market trends. Buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers who can provide certifications and consistent quality, ensuring that they meet stringent engineering requirements.

Looking ahead, the demand for lightweight and durable materials is expected to grow, particularly in emerging markets. By leveraging the properties of 6061-T6511 and fostering strong supplier relationships, international buyers can position themselves for success in their respective industries. Engage with trusted suppliers today to explore how 6061-T6511 can enhance your product offerings and drive competitive advantage.