Introduction: Navigating the Global Market for 6061 t6 aluminum vs 7075 t6

In the competitive landscape of international manufacturing, sourcing the right aluminum alloy—whether 6061 T6 or 7075 T6—can pose a significant challenge for B2B buyers. Each alloy offers unique properties that cater to specific applications, making informed decisions crucial for optimizing product performance and cost efficiency. This comprehensive guide delves into the intricate differences between 6061 T6 aluminum and 7075 T6, covering essential aspects such as chemical composition, mechanical properties, machinability, corrosion resistance, and suitability for various applications.

By examining the strengths and weaknesses of each alloy, this guide empowers international B2B buyers—particularly those from regions like Africa, South America, the Middle East, and Europe (including Brazil and Germany)—to navigate the complexities of aluminum sourcing. In addition to exploring the technical specifications, we will provide insights into supplier vetting processes, cost considerations, and industry best practices.

Armed with this knowledge, decision-makers can confidently evaluate their options, ensuring that their choice of aluminum alloy aligns with their specific project requirements and operational goals. Whether you are involved in aerospace, automotive, or general manufacturing, understanding the nuances of 6061 T6 and 7075 T6 aluminum will enhance your purchasing strategy and drive business success.

Understanding 6061 t6 aluminum vs 7075 t6 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6061-T6 Aluminum | Good strength, excellent weldability, and corrosion resistance | Structural components, marine applications, automotive parts | Pros: Versatile, easy to machine, good corrosion resistance. Cons: Lower strength compared to 7075. |

| 7075-T6 Aluminum | Exceptional strength, higher hardness, less formable | Aerospace, military applications, high-stress components | Pros: High strength, ideal for demanding applications. Cons: Poor weldability, more difficult to machine. |

| 6061-O Aluminum | Unheat-treated variant with high formability | Fabrication projects, non-structural applications | Pros: Excellent machinability, good for forming. Cons: Lower strength than T6 variants. |

| 7075-O Aluminum | Annealed variant, softer and more workable | Custom fabrication, applications needing shape changes | Pros: Easier to form than T6, retains good strength. Cons: Reduced strength compared to T6. |

| 6061-F Aluminum | As-fabricated, often used for extrusions | Architectural applications, decorative uses | Pros: Ready to use, good for specific applications. Cons: Limited strength and durability. |

What Are the Characteristics and Suitability of 6061-T6 Aluminum?

6061-T6 aluminum is a widely used alloy known for its good mechanical properties and excellent weldability. It features a balanced combination of strength, corrosion resistance, and formability, making it suitable for various applications, including structural components and marine fittings. B2B buyers should consider its versatility and ease of machining, which allows for cost-effective production. However, its strength is lower than that of 7075-T6, which may not be suitable for high-stress applications.

How Does 7075-T6 Aluminum Compare for High-Strength Applications?

7075-T6 aluminum is renowned for its exceptional strength, making it the preferred choice for aerospace and military applications. This alloy exhibits nearly double the tensile strength of 6061-T6, offering superior performance in demanding environments. However, its higher zinc content makes it less formable and weldable, which is a crucial consideration for B2B buyers. While it excels in high-stress situations, the challenges in machining and forming mean that careful planning and specialized equipment may be necessary for fabrication.

What Are the Benefits of 6061-O Aluminum for Fabrication?

6061-O aluminum is the unheat-treated form of 6061, offering excellent formability and machinability. This variant is ideal for fabrication projects where shaping and forming are required, making it a popular choice for non-structural applications. B2B buyers looking for ease of processing will find 6061-O advantageous; however, it does come with lower strength compared to its heat-treated counterparts. Buyers should assess the specific strength requirements of their projects to determine if 6061-O meets their needs.

Why Choose 7075-O Aluminum for Custom Fabrication?

7075-O aluminum is the annealed variant of 7075, providing a softer and more workable material that retains significant strength. It is particularly suitable for custom fabrication projects where shape changes are necessary. This alloy allows for easier forming compared to its T6 variant, making it a practical option for B2B applications that require a balance of strength and workability. However, buyers should be aware that while it is easier to work with, the strength is less than that of 7075-T6, making it essential to match the material to the application requirements.

What Is the Role of 6061-F Aluminum in Architectural Applications?

6061-F aluminum is often used in architectural applications and decorative uses due to its as-fabricated condition, which makes it ready for immediate use. This type is particularly advantageous for projects that require specific shapes and finishes without extensive machining. While it offers good corrosion resistance, B2B buyers should note that it has limited strength and durability compared to other variants. This alloy is ideal for applications where aesthetic appeal is prioritized over structural integrity.

Key Industrial Applications of 6061 t6 aluminum vs 7075 t6

| Industry/Sector | Specific Application of 6061 t6 aluminum vs 7075 t6 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft structures and components | High strength-to-weight ratio reduces fuel consumption and enhances performance. | Compliance with aviation standards and certifications. |

| Automotive | Vehicle frames and chassis components | Improved durability and reduced weight lead to better fuel efficiency. | Availability of specific alloys and forms; machining capabilities. |

| Marine | Boat hulls and marine fittings | Corrosion resistance and strength ensure longevity in harsh environments. | Sourcing from suppliers with marine-grade certifications. |

| Construction | Structural components for buildings and bridges | Versatile applications with good weldability and corrosion resistance. | Local regulations and standards for construction materials. |

| Defense and Military | Military vehicles and equipment | Exceptional strength and reliability are critical for safety and performance. | Availability of high-strength alloys and adherence to defense contracts. |

How is 6061 T6 Aluminum Used in Aerospace Applications?

6061 T6 aluminum is widely utilized in aerospace for structural components due to its excellent strength-to-weight ratio. This alloy is particularly favored for parts such as aircraft frames and fittings, where reducing weight can significantly enhance fuel efficiency. International buyers, especially from regions like Europe and the Middle East, must ensure compliance with stringent aviation standards, requiring reliable sourcing from certified suppliers who can meet these regulations.

What are the Benefits of Using 7075 T6 Aluminum in Automotive Applications?

7075 T6 aluminum is a preferred choice in the automotive industry for vehicle frames and chassis components. Its superior strength allows for lighter designs, contributing to improved fuel efficiency and performance. For B2B buyers in South America and Africa, sourcing this alloy requires consideration of local manufacturing capabilities and the need for precise machining processes to achieve the desired specifications.

Why is 6061 T6 Aluminum Ideal for Marine Applications?

In marine applications, 6061 T6 aluminum is valued for its corrosion resistance and durability, making it suitable for boat hulls and marine fittings. This alloy can withstand harsh marine environments, ensuring longevity and reliability. Buyers in regions with significant maritime industries, such as Brazil, should prioritize suppliers that offer marine-grade certifications and can provide protective coatings to enhance corrosion resistance.

How Does 7075 T6 Aluminum Benefit Construction Projects?

7075 T6 aluminum’s exceptional strength makes it a viable option for structural components in construction, including beams and supports for buildings and bridges. Its good weldability allows for versatile applications, crucial in regions where construction materials must adhere to local standards. Buyers from Europe and the Middle East should consider the availability of this alloy in various forms and ensure compliance with construction regulations.

What Role Does 6061 T6 Aluminum Play in Defense Applications?

In defense and military sectors, 6061 T6 aluminum is used in vehicles and equipment where reliability and strength are paramount. Its excellent mechanical properties ensure that military applications can withstand demanding conditions. For international buyers, particularly in the Middle East and Africa, sourcing requires adherence to defense contracts and the assurance of high-quality standards in manufacturing processes.

3 Common User Pain Points for ‘6061 t6 aluminum vs 7075 t6’ & Their Solutions

Scenario 1: Choosing the Right Alloy for High-Stress Applications

The Problem: A B2B buyer in the aerospace sector is tasked with selecting an aluminum alloy for a new aircraft component. They know that strength is critical, but they also face pressure to minimize costs. Unsure whether to go with the high-strength 7075 T6 or the more affordable 6061 T6, the buyer worries that opting for the wrong material could lead to product failure, safety issues, and financial losses.

The Solution: To make an informed choice, the buyer should conduct a detailed analysis of the specific application requirements. If the component will face extreme stress and potential fatigue, 7075 T6 is clearly the superior option due to its nearly double tensile strength compared to 6061 T6. The buyer should also consider long-term performance and maintenance costs. If the application allows for it, sourcing 7075 T6 from reliable suppliers who offer competitive pricing, or exploring bulk purchasing options, can help mitigate cost concerns. Additionally, integrating a risk assessment process can guide the decision by highlighting the implications of using a lower-strength material.

Scenario 2: Navigating Machinability Challenges

The Problem: A manufacturing company is experiencing delays in production due to difficulties in machining 7075 T6 aluminum. Their CNC machines are struggling with the harder alloy, leading to increased tool wear and downtime. As a result, they are falling behind schedule on critical projects, risking contractual penalties and client dissatisfaction.

The Solution: The company should evaluate its machining processes and consider transitioning to 6061 T6 aluminum for components where machinability is a priority. 6061 T6 offers superior machinability, allowing for smoother cuts and longer tool life, which can significantly reduce operational downtime. To facilitate this transition, the buyer can work closely with machining experts to optimize tool selection and settings specifically tailored for 6061 T6. Additionally, investing in high-performance tooling designed for aluminum can enhance productivity and reduce wear, ultimately streamlining operations and keeping projects on track.

Scenario 3: Addressing Corrosion Resistance for Marine Applications

The Problem: A buyer in the marine industry is faced with the dilemma of selecting aluminum for boat fittings that will be exposed to harsh saltwater environments. They are aware that both 6061 T6 and 7075 T6 offer some level of corrosion resistance but are unsure which alloy will provide adequate protection without additional coatings, especially considering maintenance costs over the lifespan of the vessels.

The Solution: The buyer should prioritize 6061 T6 for marine applications due to its excellent corrosion resistance when properly anodized. Although 7075 T6 is stronger, its lower resistance to corrosion makes it less suitable for direct exposure to seawater without protective measures. The buyer can enhance the longevity of 6061 T6 components by specifying a high-quality anodized finish, which not only provides additional protection but also improves the aesthetic appeal. Furthermore, establishing a regular maintenance schedule for inspections and touch-ups on anodized surfaces will ensure long-term performance and reduce the risk of costly repairs, making it a practical solution for marine applications.

Strategic Material Selection Guide for 6061 t6 aluminum vs 7075 t6

What Are the Key Properties of 6061 T6 Aluminum?

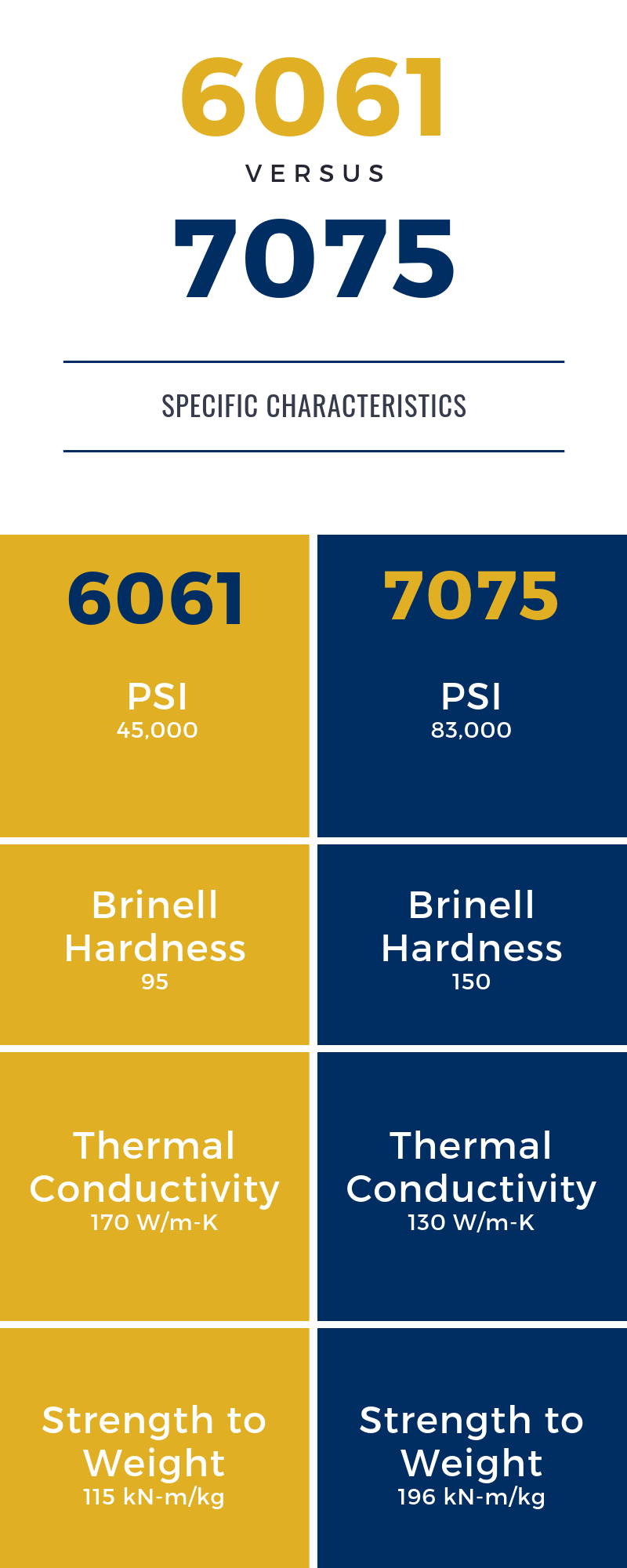

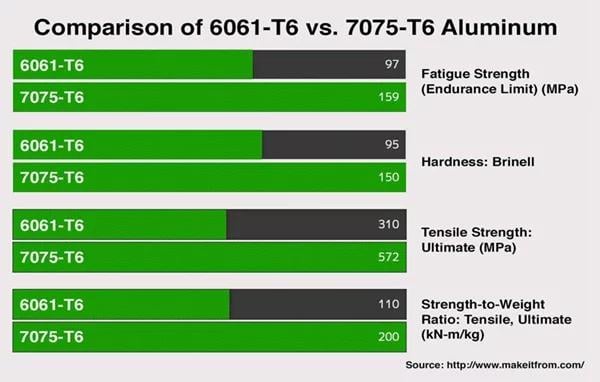

6061 T6 aluminum is renowned for its excellent mechanical properties, including good tensile strength (around 310 MPa) and yield strength (approximately 275 MPa). Its corrosion resistance is notable, as it forms a protective oxide layer when exposed to moisture, making it suitable for various environments, including marine applications. The alloy’s ability to withstand temperatures up to 150°C (302°F) without significant degradation adds to its versatility.

Pros & Cons: The advantages of 6061 T6 aluminum include its good weldability and formability, making it a preferred choice for complex shapes and structures. However, its lower strength compared to 7075 T6 aluminum may limit its use in high-stress applications. Additionally, while it is cost-effective, the need for protective coatings in corrosive environments can add to overall project expenses.

Impact on Application: 6061 T6 aluminum is compatible with various media, including water and chemicals, making it ideal for applications like piping systems and structural components in buildings. Its resistance to corrosion is particularly beneficial in humid or coastal regions.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local standards and compliance requirements, such as ASTM or ISO certifications. In Europe, DIN standards are often preferred, and ensuring that suppliers meet these specifications can be crucial for project success.

How Does 7075 T6 Aluminum Compare in Terms of Performance?

7075 T6 aluminum is recognized for its exceptional strength, boasting a tensile strength of about 570 MPa and a yield strength of around 505 MPa. This alloy is less corrosion-resistant than 6061 due to its higher copper content, which can lead to pitting in marine environments. However, it can withstand higher temperatures than 6061, making it suitable for applications that experience significant thermal stress.

Pros & Cons: The primary advantage of 7075 T6 aluminum is its strength-to-weight ratio, making it ideal for aerospace and military applications. However, its poor weldability and formability can complicate manufacturing processes. Additionally, the higher cost associated with 7075 T6 aluminum may deter some buyers, especially in price-sensitive markets.

Impact on Application: 7075 T6 is often used in applications requiring high strength and low weight, such as aircraft components, military vehicles, and high-stress structural parts. However, its limited corrosion resistance necessitates protective coatings or careful selection of operating environments.

Considerations for International Buyers: For buyers in the Middle East and Europe, understanding the specific applications and environments where 7075 T6 will be used is critical. Compliance with local standards (e.g., ASTM, DIN) is essential, and buyers should ensure that their suppliers can provide the necessary documentation and certifications.

Summary of Material Selection for 6061 T6 vs. 7075 T6 Aluminum

When selecting between 6061 T6 and 7075 T6 aluminum, it is vital to consider the specific requirements of the application, including strength, corrosion resistance, and manufacturing capabilities. Each alloy has its strengths and weaknesses, making them suitable for different industries and applications. Understanding these factors can help international B2B buyers make informed decisions that align with their project needs and regional compliance standards.

| Material | Typical Use Case for 6061 T6 Aluminum vs 7075 T6 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 T6 Aluminum | Structural components, marine fittings, automotive parts | Good weldability and formability | Lower strength compared to 7075 | Medium |

| 7075 T6 Aluminum | Aerospace components, military applications, high-stress structures | Exceptional strength-to-weight ratio | Poor weldability and higher cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for 6061 t6 aluminum vs 7075 t6

What Are the Main Manufacturing Processes for 6061 T6 Aluminum and 7075 T6 Aluminum?

The manufacturing processes for both 6061 T6 and 7075 T6 aluminum involve several critical stages that ensure the desired properties and characteristics of each alloy are achieved. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for 6061 T6 and 7075 T6 Aluminum?

Material preparation is the first step in the manufacturing process. This involves sourcing high-quality aluminum ingots or billets, which undergo rigorous inspection to ensure they meet the required specifications. For both alloys, the primary alloying elements—silicon and magnesium for 6061, and zinc and copper for 7075—must be precisely controlled to maintain the integrity of the final product.

Once the material is sourced, it is cut to size based on the specific requirements of the intended application. This may involve sawing or shearing operations, followed by heat treatment. The T6 designation indicates that both alloys undergo solution heat treatment followed by aging, enhancing their mechanical properties.

What Forming Techniques Are Commonly Used for These Alloys?

Forming is a critical stage in the manufacturing process where the prepared material is shaped into desired geometries. For 6061 T6 aluminum, which exhibits good formability, techniques such as extrusion, rolling, and bending are commonly employed. These methods allow for the creation of complex shapes and structures, making 6061 a versatile choice for various applications.

In contrast, 7075 T6 aluminum, known for its superior strength but lower formability, often requires more careful handling. Techniques like forging and machining are favored, especially when producing high-stress components. It’s essential to manage the forming process closely to avoid cracking or other defects, as 7075’s hardness can make it more challenging to work with compared to 6061.

How Does Assembly Occur in the Manufacturing Process of These Alloys?

The assembly stage generally follows forming and involves joining different components to create a finished product. For 6061 T6 aluminum, which has excellent weldability, various joining methods such as welding, riveting, and adhesive bonding are utilized. Its good mechanical properties and corrosion resistance make it suitable for applications that require robust and durable assemblies.

7075 T6 aluminum, while also weldable, is less forgiving during the joining process. The higher zinc content can lead to issues such as weld cracking if not managed properly. As such, specialized techniques like friction stir welding or the use of filler materials that are compatible with 7075 are often employed to ensure strong and reliable joints.

What Finishing Techniques Are Applied to 6061 T6 and 7075 T6 Aluminum?

Finishing processes play a vital role in enhancing the appearance and performance of aluminum components. Both 6061 T6 and 7075 T6 aluminum can undergo anodizing, which improves corrosion resistance and provides a decorative finish. However, the anodizing process can behave differently depending on the alloy’s composition. For instance, excessive zinc in 7075 can lead to a brown oxide layer, which may not be aesthetically pleasing.

Additional finishing techniques such as painting, powder coating, or applying protective films are also common. These methods not only enhance the visual appeal of the products but also offer additional layers of protection against environmental factors, particularly important for applications in harsh climates.

What Quality Control Standards Are Relevant for 6061 T6 and 7075 T6 Aluminum?

Quality assurance is paramount in the production of aluminum components, particularly for international B2B buyers. Both 6061 T6 and 7075 T6 aluminum products should adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications may be relevant depending on the application. For instance, aerospace components often require compliance with AS9100, while marine applications might need to meet specific standards set by the American Bureau of Shipping (ABS) or other relevant bodies.

How Are Quality Control Checkpoints Established During Production?

Quality control (QC) checkpoints are essential for maintaining the integrity of the manufacturing process. Typically, these checkpoints are categorized into three main phases: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials and components upon receipt. For 6061 T6 and 7075 T6 aluminum, verification of chemical composition and physical properties is crucial to ensure compliance with specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor parameters such as dimensions, tolerances, and surface finish. This helps identify potential issues before they escalate.

-

Final Quality Control (FQC): The final inspection phase assesses the completed products against predefined specifications. Common testing methods include tensile testing, hardness testing, and non-destructive testing (NDT) methods such as ultrasonic or radiographic inspection.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Buyers should consider the following approaches:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can help identify potential risks and ensure compliance with international standards.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can provide insights into their testing methodologies, results, and adherence to standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. This is particularly valuable for high-stakes projects where product integrity is critical.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must be aware of specific nuances regarding quality control and certifications. Different countries may have varying standards and regulations. For example, European buyers might require CE marking for certain products, while buyers in the Middle East might prioritize compliance with local standards such as GSO or SASO.

Additionally, understanding the supply chain’s logistics is crucial. Buyers should ensure that their suppliers can provide traceability for the materials used, which is particularly important for industries like aerospace or defense.

In conclusion, the manufacturing processes and quality assurance measures for 6061 T6 and 7075 T6 aluminum are intricate and demand close attention to detail. By understanding these processes and implementing thorough quality control verification, B2B buyers can ensure they source high-quality aluminum products that meet their specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6061 t6 aluminum vs 7075 t6’

When sourcing aluminum alloys for industrial applications, particularly 6061 T6 and 7075 T6, a structured approach is essential for making informed decisions. This guide provides a step-by-step checklist to ensure that B2B buyers can procure the right alloy based on their specific needs.

Step 1: Define Your Technical Specifications

Clearly outline your project requirements, including strength, weight, corrosion resistance, and machining capabilities. Understanding these specifications is critical, as 6061 T6 is more versatile and easier to machine, while 7075 T6 offers superior strength. Make a list of these attributes to guide your sourcing efforts.

Step 2: Identify Application Requirements

Determine where and how the aluminum alloy will be used. Applications may range from aerospace components (favoring 7075 T6) to general structural elements (where 6061 T6 shines). Knowing the end-use will help you decide which alloy’s properties best align with your project needs.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with international standards such as ISO 9001. This ensures that the materials you receive meet quality and safety benchmarks. Additionally, request documentation that confirms the alloy’s specifications and treatment processes.

Step 4: Request Material Samples

Always ask for material samples before placing a large order. This allows you to test the alloys for strength, machinability, and corrosion resistance in real-world conditions. Ensure the samples are representative of the final product you intend to purchase.

Step 5: Compare Pricing and Delivery Times

Gather quotes from multiple suppliers and compare not just the prices but also the delivery timelines. Consider the total cost of ownership, including shipping and handling fees. Timely delivery is crucial, especially for projects with tight deadlines.

Step 6: Assess Technical Support and Customer Service

Evaluate the level of technical support offered by potential suppliers. A supplier with knowledgeable staff can assist in resolving issues related to material selection and processing. Good customer service is vital for ongoing support throughout the procurement process.

Step 7: Review Past Client Feedback and Case Studies

Investigate the supplier’s reputation by reviewing client testimonials and case studies relevant to your industry. Understanding how the supplier has performed in similar situations can provide valuable insights into their reliability and quality of service.

By following these steps, B2B buyers can make informed decisions when sourcing aluminum alloys, ensuring that they select the right material for their specific applications while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 6061 t6 aluminum vs 7075 t6 Sourcing

What Are the Key Cost Components for Sourcing 6061 T6 and 7075 T6 Aluminum?

When evaluating the cost structure for sourcing 6061 T6 and 7075 T6 aluminum, several components come into play. Understanding these cost elements is essential for making informed purchasing decisions.

-

Materials: The primary cost driver is the raw material itself. 7075 T6 aluminum, known for its superior strength, typically commands a higher price than 6061 T6 due to its alloy composition, which includes a higher percentage of zinc and copper. This means that while 6061 is more economical for general applications, 7075 is preferred for high-stress environments, justifying its higher cost.

-

Labor and Manufacturing Overhead: Labor costs vary based on the complexity of machining and fabricating each alloy. 6061 T6, with its better machinability, often results in lower labor costs compared to 7075 T6. The manufacturing overhead also reflects the operational costs associated with processing these materials, which may be higher for 7075 due to the need for specialized equipment or techniques.

-

Tooling and Quality Control (QC): Tooling costs can differ significantly between the two alloys. The harder nature of 7075 may require more durable tooling, increasing initial investment costs. Additionally, stringent quality control measures are crucial, especially for 7075 used in aerospace or military applications, which can further elevate costs.

-

Logistics and Margin: Logistics costs include shipping, handling, and potential tariffs, which can vary based on the supplier’s location and the destination market. For international buyers, these logistics costs can be influenced by Incoterms, which define who is responsible for shipping costs and risks. Margins will also vary by supplier, depending on their operational efficiencies and market positioning.

How Do Price Influencers Affect the Sourcing of Aluminum Alloys?

Several factors can influence the pricing of 6061 T6 and 7075 T6 aluminum, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes typically leads to lower per-unit costs. Suppliers may offer discounts for bulk orders, making it beneficial for businesses that can commit to higher quantities.

-

Specifications and Customization: Custom specifications, such as thickness, finish, or specific alloy treatments, can increase costs. Buyers should clearly communicate their requirements to avoid unexpected price hikes.

-

Quality and Certifications: The presence of quality certifications (e.g., ISO, ASTM) can impact pricing. Alloys with higher quality assurance may come at a premium, but they can also reduce the risk of defects and improve product reliability.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge higher prices due to their proven track record, while newer or less reputable suppliers might offer lower prices but with increased risk.

What Are Effective Buyer Tips for Negotiating Prices?

For B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, negotiating favorable terms is crucial.

-

Leverage Total Cost of Ownership (TCO): Buyers should consider the total cost of ownership, not just the initial purchase price. This includes factoring in logistics, maintenance, and potential downtime costs associated with lower-quality materials.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing, priority service, and more favorable terms. Regular communication and trust can also facilitate negotiations.

-

Understand Market Trends: Keeping abreast of market trends and fluctuations in aluminum pricing can empower buyers during negotiations. Being informed allows for more strategic discussions regarding price adjustments based on market conditions.

-

Use Incoterms to Your Advantage: Familiarize yourself with Incoterms to effectively manage shipping responsibilities and costs. This knowledge can be a negotiating tool to secure better terms and reduce overall expenses.

Conclusion and Disclaimer

When sourcing 6061 T6 and 7075 T6 aluminum, understanding the comprehensive cost structure, price influencers, and negotiation strategies is vital for international B2B buyers. Prices can vary significantly based on numerous factors, so it is advisable to seek multiple quotes and conduct thorough due diligence. The prices mentioned are indicative and can fluctuate based on market conditions and specific project requirements.

Alternatives Analysis: Comparing 6061 t6 aluminum vs 7075 t6 With Other Solutions

Understanding Alternatives for Aluminum Alloys in B2B Applications

When selecting materials for industrial applications, B2B buyers often face the challenge of choosing between different aluminum alloys, such as 6061 T6 and 7075 T6. However, there are alternative solutions that may offer comparable performance or cost benefits depending on the specific requirements of the project. This section provides a comparative analysis of 6061 T6 aluminum and 7075 T6 aluminum against alternative materials like carbon steel and titanium alloys.

Comparison Table

| Comparison Aspect | 6061 T6 Aluminum Vs 7075 T6 | Carbon Steel | Titanium Alloys |

|---|---|---|---|

| Performance | Moderate strength, good corrosion resistance | High strength, lower corrosion resistance | Exceptional strength, lightweight, excellent corrosion resistance |

| Cost | Moderate cost | Generally low cost | High cost |

| Ease of Implementation | Good machinability, easy to weld | Easy to machine, but requires rust prevention | Difficult to machine, requires specialized techniques |

| Maintenance | Low maintenance, resistant to corrosion | Moderate maintenance, prone to rust | Low maintenance, resistant to corrosion |

| Best Use Case | Structural applications, marine components | Construction, automotive | Aerospace, medical implants |

Detailed Breakdown of Alternatives

Carbon Steel

Carbon steel is a widely used material in various industries due to its strength and cost-effectiveness. It offers high tensile strength, making it suitable for heavy-duty applications such as construction and automotive components. However, carbon steel is prone to corrosion, requiring protective coatings or regular maintenance to prevent rust. While it is easier to machine than aluminum alloys, its weight can be a disadvantage in applications where weight savings are critical.

Titanium Alloys

Titanium alloys are renowned for their exceptional strength-to-weight ratio and superior corrosion resistance, making them ideal for high-performance applications such as aerospace and medical implants. While they outperform both 6061 and 7075 aluminum in terms of strength and durability, titanium alloys come with a significantly higher cost and present challenges in machining and fabrication. Specialized techniques and tools are often necessary, which can lead to longer lead times and higher production costs.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between 6061 T6 aluminum, 7075 T6 aluminum, and alternative materials such as carbon steel and titanium alloys, B2B buyers must evaluate their specific application requirements. Factors such as performance needs, cost constraints, ease of implementation, and maintenance considerations play a critical role in the decision-making process. By carefully analyzing these aspects, buyers can select the most suitable material that aligns with their project objectives, ensuring both efficiency and effectiveness in their operations.

Essential Technical Properties and Trade Terminology for 6061 t6 aluminum vs 7075 t6

What Are the Key Technical Properties of 6061 T6 and 7075 T6 Aluminum Alloys?

When selecting between 6061 T6 and 7075 T6 aluminum alloys, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade: 6061 and 7075 are classified under the 6xxx and 7xxx series, respectively. 6061 is known for its versatility and is commonly used in structural applications, while 7075 is recognized for its superior strength, making it ideal for aerospace and military applications. Selecting the appropriate grade ensures that the material meets the specific demands of the project.

-

Tensile Strength: The tensile strength of 7075 T6 aluminum is approximately 570 MPa, nearly double that of 6061 T6, which typically has a tensile strength around 310 MPa. This significant difference means that 7075 is better suited for high-stress applications, such as aircraft components, where strength is paramount.

-

Machinability: 6061 aluminum is often preferred for machining due to its favorable machinability characteristics. This property allows for easier cutting, drilling, and milling, which can reduce production times and costs. Conversely, 7075 has fair machinability but may require specialized tools and techniques, impacting manufacturing efficiency.

-

Corrosion Resistance: Both alloys exhibit good corrosion resistance, but 6061 is more susceptible due to its copper content. Understanding corrosion resistance is essential for applications in marine environments or industries where exposure to moisture is high. Proper coatings can enhance the corrosion resistance of 6061.

-

Weldability: 6061 T6 is known for its excellent weldability, making it suitable for projects requiring structural integrity through welding. In contrast, 7075 T6 is more challenging to weld due to its hardness and higher zinc content, which may limit its application in welded assemblies.

-

Anodizing Potential: Both alloys can undergo anodizing, which enhances surface protection and aesthetics. However, 6061 provides a clearer anodized finish, while excessive zinc in 7075 can lead to discoloration. Anodizing is vital for applications requiring enhanced durability and corrosion resistance.

What Are Common Trade Terminology and Acronyms Related to Aluminum Alloys?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminum alloys, OEMs often specify particular grades and treatments, such as 6061 T6 or 7075 T6, for their products.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for buyers to manage inventory and costs effectively, especially when dealing with high-strength materials like 7075 T6.

-

RFQ (Request for Quotation): An RFQ is a standard business process where a buyer requests pricing and terms from suppliers. This document is crucial for comparing offers and ensuring that the selected aluminum alloy meets specific requirements at a competitive price.

-

Incoterms (International Commercial Terms): These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to negotiate favorable shipping terms for their aluminum orders.

-

Heat Treatment: This process involves heating and cooling metals to alter their physical and sometimes chemical properties. For aluminum alloys, heat treatment is critical for achieving desired mechanical properties, such as the T6 condition, which enhances strength and hardness.

-

Alloying Elements: These are metals added to aluminum to enhance specific properties. For example, zinc and copper in 7075 increase strength, while magnesium and silicon in 6061 improve weldability and corrosion resistance. Understanding these elements helps buyers select the right alloy for their applications.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing aluminum alloys, ensuring that their projects meet performance and budgetary requirements.

Navigating Market Dynamics and Sourcing Trends in the 6061 t6 aluminum vs 7075 t6 Sector

What Are the Current Market Dynamics and Key Trends Influencing the 6061 T6 and 7075 T6 Aluminum Sector?

The global aluminum market is witnessing significant shifts driven by the demand for lightweight materials in various industries, particularly aerospace, automotive, and construction. The distinct properties of 6061 T6 and 7075 T6 aluminum alloys cater to different applications, with 7075 T6 being preferred for high-strength needs, such as in aircraft manufacturing, while 6061 T6 is favored for its versatility and workability in construction and automotive components.

Emerging trends include the increasing adoption of advanced manufacturing technologies, such as additive manufacturing, which allows for the creation of complex geometries using aluminum alloys. Additionally, digital transformation in supply chain management is streamlining procurement processes, facilitating real-time tracking of materials, and enhancing inventory management. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are leveraging these technologies to optimize their sourcing strategies and reduce lead times.

Moreover, geopolitical factors and supply chain disruptions are prompting companies to diversify their supplier base. Buyers are increasingly looking towards local suppliers to mitigate risks associated with long-distance shipping and to ensure timely delivery. This trend is particularly evident in regions like Brazil and Germany, where there is a push for local sourcing to bolster domestic industries.

How Is Sustainability and Ethical Sourcing Influencing the 6061 T6 and 7075 T6 Aluminum Supply Chain?

The aluminum industry is under growing pressure to adopt sustainable practices, with a focus on reducing environmental impact. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability, particularly in the sourcing of materials like 6061 T6 and 7075 T6 aluminum. This includes sourcing from suppliers that use recycled aluminum, which not only reduces energy consumption but also minimizes waste.

Ethical sourcing is becoming a critical concern, with buyers demanding transparency throughout the supply chain. Certifications such as the Aluminum Stewardship Initiative (ASI) are gaining traction, as they provide assurance that materials are sourced responsibly, adhering to environmental and social governance standards.

Furthermore, the move towards ‘green’ materials is influencing the development of new alloys and coatings that are less harmful to the environment. Suppliers who can demonstrate compliance with these green certifications are likely to gain a competitive edge in the market.

How Has the 6061 T6 and 7075 T6 Aluminum Sector Evolved Over Time?

The evolution of aluminum alloys like 6061 T6 and 7075 T6 reflects advancements in metallurgical technology and changing market needs. Initially, aluminum was primarily used for its lightweight properties; however, the introduction of alloying elements such as zinc, magnesium, and copper has significantly enhanced the strength and versatility of these materials.

Over the decades, 6061 T6 has become synonymous with versatility and ease of fabrication, making it a staple in various industries, from automotive to construction. Meanwhile, 7075 T6 has carved out its niche as an “aircraft-grade” aluminum, favored for applications requiring exceptional strength and resistance to fatigue.

As the demand for lightweight, high-performance materials continues to rise, the development of these alloys has kept pace with technological advancements, ensuring they remain relevant in a competitive marketplace. This historical context is crucial for B2B buyers as they navigate their sourcing decisions, understanding the performance characteristics and application suitability of these alloys.

Frequently Asked Questions (FAQs) for B2B Buyers of 6061 t6 aluminum vs 7075 t6

-

1. How do I determine which aluminum alloy is best for my application?

To choose between 6061 T6 and 7075 T6 aluminum, consider the specific requirements of your application. If strength is paramount, 7075 T6, known for its superior tensile and shear strength, is ideal for high-stress environments such as aerospace and military applications. Conversely, if formability and weldability are critical, 6061 T6 is preferable due to its excellent machinability and versatility across various industries, including automotive and construction. -

2. What are the key differences in the chemical composition of 6061 T6 and 7075 T6 aluminum?

The primary difference lies in their alloying elements. 7075 T6 aluminum contains significant amounts of zinc and copper, contributing to its high strength but also making it less corrosion-resistant. In contrast, 6061 T6 aluminum is alloyed mainly with magnesium and silicon, offering better corrosion resistance and improved workability. Understanding these compositions helps buyers select the appropriate alloy for their specific environmental and mechanical requirements. -

3. What should I consider when vetting suppliers for aluminum alloys?

When sourcing aluminum alloys, assess suppliers based on their industry reputation, quality certifications (like ISO), and experience with international trade. Request samples and review their product specifications to ensure they meet your quality standards. Additionally, inquire about their production capabilities, lead times, and customer support to ensure they can meet your specific needs and handle logistics efficiently, particularly in diverse regions like Africa, South America, and Europe. -

4. Are there minimum order quantities (MOQ) for 6061 T6 and 7075 T6 aluminum?

Minimum order quantities can vary widely depending on the supplier and your specific requirements. Typically, suppliers may set MOQs based on production costs and inventory management practices. It’s advisable to discuss your needs directly with potential suppliers to negotiate MOQs that suit your project, particularly if you are looking for customized solutions or smaller batches for prototyping. -

5. What payment terms should I expect when sourcing aluminum internationally?

Payment terms can differ based on the supplier and the trade agreements in place. Common terms include advance payment, letters of credit, or net payment terms (30, 60, or 90 days). It’s crucial to clarify payment methods upfront and ensure they align with your financial processes. For large orders, consider negotiating more favorable terms based on your company’s creditworthiness and history with the supplier. -

6. How can I ensure quality assurance for my aluminum orders?

To ensure quality assurance, request detailed documentation from your supplier, including material certifications, testing reports, and compliance with relevant standards (such as ASTM or EN). Establish a clear quality control process that includes pre-shipment inspections and, if possible, on-site audits. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and any potential issues. -

7. What logistics considerations should I keep in mind for international aluminum shipments?

When planning logistics for international shipments of aluminum, consider factors such as shipping methods (air vs. sea), customs regulations, and import duties. Choose a logistics partner experienced in handling metal shipments to ensure compliance and timely delivery. Additionally, factor in lead times for production and shipping to avoid delays in your project timelines, especially when sourcing from different continents. -

8. Can I customize my aluminum orders for specific applications?

Yes, many suppliers offer customization options for aluminum orders, including specific dimensions, finishes, and alloy treatments. Discuss your requirements with potential suppliers to determine their capabilities for customization. Providing detailed specifications will help ensure that the final product meets your application needs, whether for structural components, aerospace parts, or other specialized uses.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 6061 T6 Aluminum Vs 7075 T6 Manufacturers & Suppliers List

1. Thyssenkrupp – 7075 Aluminium

Domain: thyssenkrupp-materials.co.uk

Registered: 2017 (8 years)

Introduction: 7075 Aluminium: 7XXX series, main alloying elements are copper and zinc. Chemical composition: 97.9% Aluminium, 5.6% Zinc, 2.5% Magnesium, 0.23% Chromium, 1.6% Copper. Strength: tensile strength nearly double that of 6061 T6, higher shear strength (1.5 times), harder than 6061 T6. Machinability: fair machinability. Formability and welding: not conducive unless annealed. Corrosion resistance: excel…

2. Aluminum Comparison – 6061 vs 7075

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 6061 aluminum is a softer material, easier to mill, but structurally not as tough as 7075 aluminum. 7075 aluminum has double the tensile strength of 6061, making it more durable, especially at critical points like takedown pins. 6061 has a yield strength of approximately 35,000 psi, which can withstand around 550 lbs of force at stress concentration points. Forged 7075 is generally stronger than m…

3. Kormax – Aluminium Alloys 6061 & 7075

Domain: kormax.com

Registered: 1998 (27 years)

Introduction: Aluminium 6061 and 7075 are two common aluminium alloys with distinct properties. 6061 is known for excellent corrosion resistance and weldability, making it suitable for structural components and general engineering. It has a yield strength of 276 MPa and is easier to machine, commonly used in automotive parts, bicycle frames, and marine applications. 7075, on the other hand, is celebrated for it…

4. Make It From – Aluminum Alloys 6061-T6 & 7075-T6

Domain: makeitfrom.com

Registered: 2009 (16 years)

Introduction: This company, Make It From – Aluminum Alloys 6061-T6 & 7075-T6, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Practical Machinist – Aluminum Alloy Machining Comparison

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 7075-T6 and 6061-T6 are two aluminum alloys discussed in terms of their machining characteristics. 7075-T6 is noted for better chip breaking compared to 6061-T6, which is described as gummy and difficult to handle during machining. Users report that 6061-T6 can lead to issues like birdnesting of chips and requires adjustments in machining parameters such as speed, feed, and depth of cut. The hardn…

6. BikeForums – Aluminum Chainring Comparison

Domain: bikeforums.net

Registered: 2001 (24 years)

Introduction: 6061 aluminum is much softer than 7075 aluminum. 6061 is easier to machine with CNC due to its softness, but chainrings made from 6061 last significantly less than those made from 7075 due to the difference in hardness. There is a concern about sellers misrepresenting products, where a buyer may order a 7075 chainring but receive a 6061 one instead.

7. Metal Supermarkets – 6061 Aluminum

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: 6061 Aluminum:

– Alloy Series: 6XXX

– Chemical Composition: Higher silicon, significant magnesium, moderate copper

– Mechanical Properties: Moderate tensile strength, good ductility, weldable, easier to machine and form

– Applications: Automotive parts, electronic hardware, medical assemblies, construction components, tanks

7075 Aluminum:

– Alloy Series: 7XXX

– Chemical Composition: Higher…

8. Wayken – 6061 Aluminum Solutions

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: 6061 Aluminum: Commonly used aluminum alloy known for great strength, heat treatability, and easy machinability and weldability. Main alloying elements are magnesium and silicon, providing excellent corrosive resistance. Available in forms like extrusion, sheets, and architectural shapes. Good anodizing response. 7075 Aluminum: High strength aluminum alloy primarily used in aerospace and defense i…

Strategic Sourcing Conclusion and Outlook for 6061 t6 aluminum vs 7075 t6

In conclusion, the choice between 6061 T6 and 7075 T6 aluminum alloys hinges on the specific needs of your application. For projects requiring high strength and resistance to wear, 7075 T6 is unparalleled, making it ideal for aerospace and military applications. Conversely, 6061 T6 offers excellent machinability, formability, and weldability, making it suitable for a diverse array of industries, including automotive and construction.

Strategic sourcing plays a critical role in optimizing supply chains, particularly for international buyers looking to procure these materials in regions such as Africa, South America, the Middle East, and Europe. By understanding the unique properties of each alloy, businesses can make informed decisions that enhance operational efficiency and product performance.

Looking ahead, as industries evolve and demand for lightweight, high-strength materials continues to rise, the significance of selecting the right aluminum alloy will only grow. We encourage international B2B buyers to engage with trusted suppliers to explore the best sourcing options tailored to their specific needs. The future of your projects depends on the materials you choose today.