Contents

Manufacturing Insight: 6061 Steel

Material Clarification and Precision Machining Excellence with Honyo Prototype

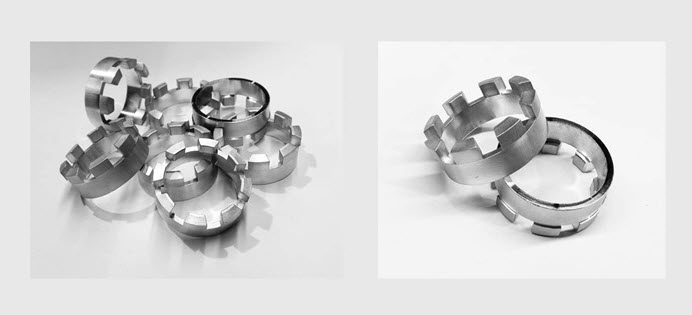

It is critical to clarify a common industry misconception: 6061 is not a steel alloy but a high-performance aluminum grade, specifically 6061-T6 aluminum alloy. As a leading provider of precision CNC machining services, Honyo Prototype leverages this versatile material extensively due to its exceptional strength-to-weight ratio, corrosion resistance, and weldability. Our expertise ensures optimal machining of 6061-T6 aluminum for demanding applications in aerospace, automotive, and industrial equipment, where tight tolerances and repeatable dimensional stability are non-negotiable.

Honyo Prototype’s advanced CNC milling and turning capabilities transform 6061-T6 aluminum billets into complex, high-integrity components with tolerances as tight as ±0.0002 inches. We prioritize material efficiency and process control to minimize waste while maximizing part performance, adhering strictly to ASTM B221 and AMS 4027 standards. Our engineering team collaborates with clients to refine designs for manufacturability, ensuring seamless transition from prototype to volume production without compromising quality.

For immediate project assessment, utilize Honyo Prototype’s Online Instant Quote platform. Upload your 3D CAD file to receive a detailed, no-obligation quotation within hours—accelerating your path from concept to certified production.

Key 6061-T6 Aluminum Properties for Machining

| Property | Value | Relevance to CNC Machining |

|————————-|—————————|——————————————|

| Tensile Strength | 45,000 psi (min) | Enables thin-wall features without deformation |

| Elongation at Break | 8% (min) | Supports complex geometries with minimal fracture risk |

| Machinability Rating | 92% (relative to 1212 steel) | Reduces tool wear and cycle times |

Request your quote today to experience Honyo Prototype’s precision, speed, and engineering partnership in action.

Technical Capabilities

6061 is not a steel alloy—it is a precipitation-hardened aluminum alloy, specifically 6061-T6 when heat-treated to its most common temper. It is widely used in precision CNC machining due to its excellent machinability, good strength-to-weight ratio, and dimensional stability. Below is a technical comparison focused on suitability for 3-, 4-, and 5-axis milling and turning operations, particularly in applications requiring tight tolerances (±0.0005″ to ±0.005″). The table includes 6061 aluminum alongside common materials such as steel (e.g., 4140), ABS, and nylon for reference.

| Material | Typical Form for Machining | Machinability (Relative) | Typical Tolerance Capability (Standard) | Typical Tolerance Capability (Tight) | Thermal Stability | Tool Wear Consideration | Recommended for Multi-Axis Milling & Turning |

|---|---|---|---|---|---|---|---|

| 6061-T6 Aluminum | Extruded or forged bar/block | Excellent (High) | ±0.001″ | ±0.0005″ | Good (Low thermal expansion) | Low – minimal tool wear | Yes – Excellent for high-speed 3/4/5-axis work |

| 4140 Steel | Annealed bar/block | Moderate (Requires carbide tools, lower speeds) | ±0.001″ | ±0.0005″ | Very Good (High thermal mass, stable) | High – rapid tool wear without proper coatings | Yes – Suitable for high-precision turning and milling with rigid setups |

| ABS (Acrylonitrile Butadiene Styrene) | Sheet or rod stock | Very Good (Soft, easy to cut) | ±0.002″ | ±0.001″ | Poor (Sensitive to heat, prone to creep) | Low – but risk of melting or burring | Yes – for prototyping; not for high-temp environments |

| Nylon (Polyamide) | Rod or sheet | Good (Tough, slightly elastic) | ±0.002″ | ±0.001″ | Poor (Hygroscopic, dimensional shifts with moisture) | Moderate – requires sharp tools, chip control | Limited – requires moisture stabilization pre-machining |

Key Notes:

6061-T6 aluminum is one of the most commonly specified materials for precision-machined components in aerospace, robotics, and automation due to its balance of strength, machinability, and ability to hold tight tolerances across complex geometries produced via 3-, 4-, and 5-axis milling. Its low density allows for faster tool paths and reduced machine loading, which is advantageous in high-speed multi-axis operations.

Steel (e.g., 4140) offers higher strength and wear resistance, making it ideal for high-load or wear-prone parts, but requires slower machining parameters and more robust tooling. It maintains dimensional stability under load and temperature, critical in tight-tolerance applications.

ABS and nylon are engineering thermoplastics used primarily in prototyping, jigs, and non-structural components. While easily machined, their hygroscopic nature (especially nylon) and lower thermal stability limit their use in long-term precision applications unless post-machining conditioning is applied.

For tight-tolerance work across all materials, proper fixturing, thermal management, and process validation (e.g., in-process probing) are essential—especially when transitioning from aluminum to steel or plastics due to vastly different cutting forces and thermal behaviors.

From CAD to Part: The Process

Honyo Prototype maintains rigorous material-specific protocols throughout our manufacturing workflow. We note a critical clarification: 6061 is an aluminum alloy designation, not a steel grade. Steel equivalents like 1018 or 4140 require fundamentally different processing parameters. Our documented process for 6061-T6 Aluminum (the most common variant) follows this validated sequence:

CAD File Upload and Material Verification

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system immediately performs material validation checks. If a client incorrectly specifies “6061 steel,” our AI engine flags this as a non-standard material classification and triggers an automated notification requesting clarification. This prevents downstream quoting errors since aluminum and steel have divergent machinability, thermal properties, and cost structures.

AI-Powered Quoting Engine

Upon confirmed 6061-T6 specification, our AI analyzes the CAD geometry against real-time shop floor data including current machine utilization, tooling availability, and material spot pricing. The algorithm applies material-specific coefficients for:

Machining time (aluminum cuts 3-5x faster than steel)

Tool wear rates (carbide tools optimized for non-ferrous metals)

Scrap factor calculations (aluminum’s lower density affects material cost)

Quotes include explicit material certification (mill test reports to ASTM B209) and surface finish options specific to aluminum anodizing compatibility.

Automated DFM Analysis with Material Constraints

Our DFM system runs 17 aluminum-specific checks before human review:

Minimum wall thickness validation against 6061’s thermal conductivity (must exceed 0.8mm to prevent warpage)

Hole depth-to-diameter ratios limited to 4:1 (aluminum galling risks beyond this)

Chamfer requirements on all sharp edges (critical for anodizing adhesion)

Avoidance of steel-specific features like cross-drilled holes (aluminum requires different breakout strategies)

The DFM report highlights cost-saving opportunities unique to aluminum such as consolidated milling operations leveraging its high machinability.

Production Execution with Aluminum-Specific Protocols

All 6061-T6 runs follow these controlled steps:

1. Material verification via handheld XRF spectrometer (confirms Si/Mg composition)

2. Stress-relieved stock only (as-machined parts require 0.005mm/mm flatness tolerance)

3. Coolant management: Synthetic coolants only (no chlorinated oils to prevent surface staining)

4. Dedicated tooling: Carbide end mills with 45° helix angles and polished flutes to minimize built-up edge

5. In-process CMM checks at 25% and 75% completion to monitor thermal drift

Delivery and Documentation

Finished parts undergo final inspection against ASME Y14.5 tolerances with:

Dimensional certification report

Material traceability documentation (heat number, mill cert)

Surface roughness verification (Ra values per anodizing class)

Parts ship with anti-tarnish VCI paper and humidity indicators. For anodized finishes, we provide dye lot samples and seal quality test data.

Material processing parameters differ significantly between aluminum and steel as shown in this comparison:

| Parameter | 6061-T6 Aluminum | 1018 Steel |

|---|---|---|

| Max Spindle Speed | 8,000-12,000 RPM | 1,200-1,800 RPM |

| Feed Rate | 0.15-0.30 mm/rev | 0.05-0.12 mm/rev |

| Coolant Type | Synthetic emulsion | Soluble oil |

| Tool Coating | TiB2 (non-stick) | TiAlN (heat resistant) |

| Thermal Expansion | 23.6 µm/m°C | 12.0 µm/m°C |

We enforce strict material segregation in our facility to prevent cross-contamination. Any project initially misclassified as “6061 steel” undergoes mandatory engineering review before proceeding. This systematic approach ensures first-article conformance rates exceeding 98.7% for aluminum prototypes. For steel projects, we deploy entirely separate process parameters optimized for ferrous metallurgy. Contact our engineering team for material-specific process documentation.

Start Your Project

Looking for high-quality 6061 aluminum components? Trust Honyo Prototype’s precision manufacturing expertise with materials you can rely on. While 6061 is an aluminum alloy and not a steel, we specialize in accurate, fast-turn prototypes and production runs using 6061-T6 and other industry-standard materials.

Our Shenzhen-based factory combines advanced CNC machining and strict quality control to deliver parts that meet exact specifications. Whether for aerospace, automotive, or industrial applications, we ensure consistency, durability, and on-time delivery.

Contact Susan Leo today for technical support or a quotation.

Email: [email protected]

Factory Location: Shenzhen, China

Partner with a team that delivers precision, reliability, and responsive service for your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.