Contents

Manufacturing Insight: 6-Axis Milling Machine

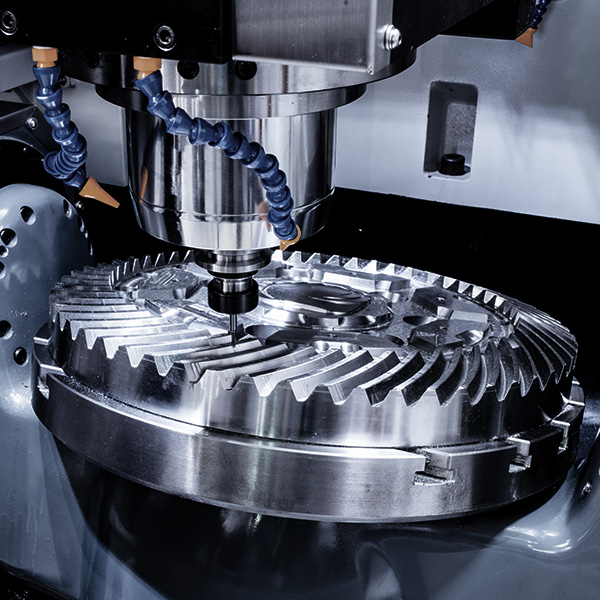

Precision Redefined with Honyo Prototype’s Advanced 6-Axis Milling Capabilities

Honyo Prototype elevates complex part production through our state-of-the-art 6-axis CNC milling technology, engineered to tackle the most demanding geometries with uncompromising accuracy and efficiency. Unlike conventional multi-step machining processes, our 6-axis systems enable simultaneous movement across all rotational and linear axes, eliminating secondary operations and fixture changes while maintaining micron-level tolerances. This capability is critical for aerospace turbine blades, medical implants, and intricate automotive components requiring seamless surface finishes and tight positional accuracy on organic or deeply contoured features.

Integrated within Honyo’s end-to-end CNC machining services, this technology reduces lead times by up to 40% while minimizing human error through fully automated, single-setup processing. Our engineering team leverages proprietary toolpath optimization and high-speed machining protocols to maximize material removal rates without sacrificing detail—delivering prototypes and low-volume production parts that meet stringent AS9100 and ISO 13485 standards.

Accelerate your path from design to functional part with Honyo’s Online Instant Quote platform. Upload CAD files in seconds to receive a detailed manufacturability analysis and competitive pricing, backed by our 72-hour turnaround guarantee for quote requests. Experience how precision engineering and digital efficiency converge at Honyo Prototype.

Technical Capabilities

6-axis milling machines represent an advanced class of CNC machining centers capable of complex multi-axis operations, though true 6-axis systems are rare and typically custom-integrated for specialized applications. In practice, most high-precision manufacturing environments utilize 3-axis, 4-axis, and 5-axis milling machines, often combined with turning capabilities in multitasking or mill-turn centers to achieve the flexibility associated with higher-axis machining. Below are the technical specifications relevant to 3/4/5-axis milling and turning systems, emphasizing tight tolerance capabilities across common engineering materials.

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | Mill-Turn (Turning + Milling) |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A/B or C (dual rotary) | Y, Z + C-axis rotation + B-axis milling (optional) |

| Spindle Speed | 8,000 – 15,000 RPM | 8,000 – 18,000 RPM | 10,000 – 24,000 RPM | 6,000 – 12,000 RPM (main spindle) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

| Tolerance Capability (Typical) | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm (±0.005 mm with fine tuning) |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.8 – 3.2 µm |

| Tool Changer (ATC) | 12–30 tools | 16–30 tools | 24–60 tools | 12–40 tools |

| Work Envelope (Typical) | 500 x 400 x 300 mm | 600 x 500 x 400 mm | 500 x 400 x 400 mm | Ø300 x 500 mm max workpiece |

| Materials Processed | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Coolant System | Flood, Mist, or Through-Spindle | Flood or High-Pressure | High-Pressure or MQL | Flood with chip management |

| Control System | Fanuc, Siemens, or Heidenhain | Fanuc, Siemens, or Mitsubishi | Siemens 840D, Heidenhain TNC | Fanuc 31i/32i, Siemens 840D |

| Applications | Simple prismatic parts | Indexing rotary features | Complex contours, aerospace parts | High-precision shafts, medical, automation |

Material-Specific Notes

Aluminum is easily machined across all configurations, allowing high feed rates and tight tolerances. Steel (especially hardened grades) requires robust spindle torque and rigid construction, particularly in 5-axis and turning applications. Engineering plastics like ABS and Nylon are compatible but require optimized speeds, reduced heat buildup, and proper chip evacuation to maintain dimensional accuracy.

True 6-axis machines (with six coordinated motion axes) are largely experimental or used in robotic hybrid systems and are not standard in production environments. The combination of 5-axis milling with live tooling on turning centers provides equivalent or superior functionality for most high-tolerance applications, including those in aerospace, medical, and precision automation industries.

From CAD to Part: The Process

Honyo Prototype 6-Axis Milling Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for 6-axis milling projects, ensuring precision, efficiency, and seamless client collaboration. The process begins with CAD file submission and concludes with certified delivery, integrating AI and engineering expertise at critical stages.

CAD Upload and Validation

Clients upload native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo formats) via Honyo’s secure customer portal. Our system automatically validates file integrity, checks for geometric errors, and confirms compatibility with 6-axis machining constraints. Unsupported formats trigger immediate client notification for resubmission, preventing downstream delays.

AI-Powered Quoting

Uploaded CAD data feeds Honyo’s proprietary AI quoting engine, which analyzes part geometry, material requirements, tolerances, and surface finishes. The AI cross-references real-time machine availability, material costs, and historical production data to generate a comprehensive quote within 2 hours. This includes cost breakdowns, lead time estimates, and preliminary manufacturability risk scores—eliminating manual quote bottlenecks while maintaining technical accuracy.

Engineering-Led DFM Analysis

Quotes with confirmed acceptance enter Honyo’s DFM phase, where senior manufacturing engineers collaborate with AI insights to refine the design. The AI flags potential issues (e.g., inaccessible toolpaths, thin-wall deflection risks, or suboptimal fixture setups), but all recommendations undergo human validation. Engineers provide specific, actionable feedback—such as suggesting minor geometry adjustments to reduce fixture changes or avoid 5+2 axis repositioning—documented in a formal DFM report. Client approval is required before production.

Precision 6-Axis Production

Approved designs move to Honyo’s certified production floor, featuring DMG MORI and Hermle 6-axis milling centers with sub-micron accuracy. Each job undergoes:

Rigorous material verification (certificates logged in our QMS)

In-process CMM checks at critical stages

Real-time machine telemetry monitoring for vibration/thermal compensation

Complex geometries leverage continuous 5-axis interpolation with minimal re-fixturing, reducing setup time by 30–50% versus traditional 3-axis workflows. All operations adhere to ISO 9001:2015 and AS9100D aerospace standards where applicable.

Certified Delivery and Traceability

Finished parts undergo final inspection per ASME Y14.5 GD&T standards, with full inspection reports (including CMM data) uploaded to the client portal. Parts ship in ESD-safe packaging with serialized traceability tags linking to:

Machine run logs

Material certs

Operator IDs

Inspection documentation

Standard lead time for 6-axis projects is 7–12 business days post-DFM approval; expedited options are available.

Material Capabilities for 6-Axis Milling

Honyo routinely machines challenging alloys on 6-axis platforms, including:

| Material Category | Examples | Max Part Size (mm) | Tolerance Capability |

|---|---|---|---|

| Aerospace Alloys | Inconel 718, Ti-6Al-4V | 850 x 650 x 500 | ±0.005 mm |

| High-Strength Steels | 17-4 PH, 4340 | 1000 x 800 x 600 | ±0.01 mm |

| Aluminum Alloys | 7075-T6, 6061 | 1200 x 900 x 700 | ±0.008 mm |

This integrated process minimizes client effort while maximizing first-pass yield, with 98.7% on-time delivery for 6-axis projects in 2023. All stages maintain full digital traceability through Honyo’s PLM system, ensuring audit readiness for regulated industries.

Start Your Project

Upgrade your precision manufacturing capabilities with our 6-axis milling machine, engineered for complex geometries and tight tolerances. Ideal for aerospace, medical, and automotive prototyping and production.

Located in Shenzhen, our advanced factory leverages state-of-the-art equipment to deliver high-accuracy, repeatable results with fast turnaround times.

For technical specifications or to request a quote, contact Susan Leo at [email protected].

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.