Contents

Manufacturing Insight: 6-Axis Cnc Machining

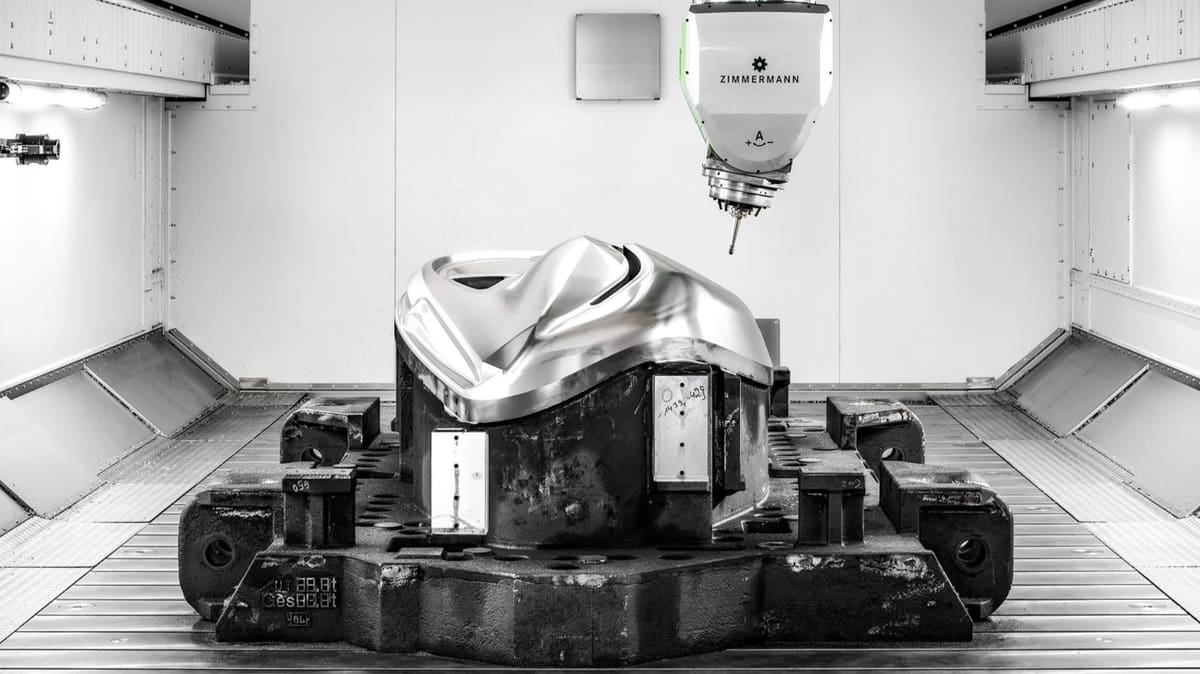

Precision Through Complexity: Honyo Prototype’s Advanced 6-Axis CNC Machining

At Honyo Prototype, we recognize that the most demanding manufacturing challenges require capabilities beyond conventional 3-axis or even 5-axis systems. Our state-of-the-art 6-axis CNC machining centers represent the pinnacle of subtractive manufacturing technology, enabling the production of exceptionally complex geometries with unparalleled precision and efficiency. This advanced capability eliminates the need for multiple fixturing setups, significantly reducing lead times while maintaining critical tolerances often down to ±0.0002 inches across intricate multi-faceted components. We leverage this technology across a broad spectrum of aerospace, medical, and defense applications where part consolidation, organic shapes, and stringent surface finish requirements are paramount.

Honyo Prototype’s 6-axis machining service delivers tangible value through reduced handling errors, minimized secondary operations, and the ability to machine features inaccessible to lower-axis systems. Our engineering team collaborates closely with clients from the design phase, utilizing sophisticated simulation to optimize toolpaths and ensure manufacturability, ultimately translating complex CAD models into high-integrity physical parts in materials ranging from advanced alloys and composites to high-temperature plastics. This integrated approach guarantees that your most sophisticated designs are realized without compromise on quality or performance.

Accelerate your prototyping and low-volume production timelines with Honyo Prototype. Experience the technical advantage of true 6-axis machining combined with our commitment to engineering excellence. Initiate your project immediately by accessing our Online Instant Quote system, where detailed pricing and lead time estimates are generated within minutes based on your uploaded CAD files, providing transparency and speed at the earliest project stage.

Technical Capabilities

6-axis CNC machining extends the capabilities of traditional multi-axis systems by integrating simultaneous motion control across six axes, enabling complex geometries, improved tool access, and reduced need for manual repositioning. While 3-axis, 4-axis, and 5-axis milling remain industry standards for high-precision work, 6-axis systems are emerging in advanced prototyping and aerospace applications. Below is a comparative technical specification table focusing on capabilities relevant to Honyo Prototype’s core services in precision machining.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | 6-Axis Machining (Advanced) | CNC Turning |

|---|---|---|---|---|---|

| Number of Controlled Axes | X, Y, Z | X, Y, Z, A (rotary around X) | X, Y, Z, A, B (or C) | X, Y, Z, A, B, C (full spatial orientation) | Typically 2-axis (X, Z); with live tooling up to 4-axis |

| Typical Spindle Speed | 8,000 – 15,000 RPM | 8,000 – 15,000 RPM | 10,000 – 20,000 RPM | 10,000 – 24,000 RPM | 3,000 – 10,000 RPM |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.002 mm | ±0.005 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.001 mm | ±0.003 mm |

| Common Applications | Simple prismatic parts, flat surfaces | Indexing features, light contouring | Complex contours, aerospace components, molds | Robotic CNC integration, freeform surfaces | Cylindrical parts, shafts, bushings |

| Tight Tolerance Capability | Up to ±0.010 mm | Up to ±0.010 mm | Up to ±0.005 mm | Up to ±0.003 mm | Up to ±0.005 mm (with live tooling) |

| Surface Finish (Typical) | 1.6 – 3.2 µm Ra | 1.6 – 3.2 µm Ra | 0.8 – 1.6 µm Ra | 0.4 – 0.8 µm Ra | 0.8 – 1.6 µm Ra |

| Materials – Aluminum | Excellent | Excellent | Excellent | Excellent | Excellent |

| Materials – Steel (Mild, Stainless) | Good | Good | Excellent | Excellent | Excellent |

| Materials – ABS | Good (risk of melting) | Good | Good (with cooling) | Moderate (requires low force) | Good |

| Materials – Nylon | Moderate (chatter control needed) | Moderate | Moderate (with optimized feeds) | Limited (flexibility challenges) | Good (with proper tooling) |

| Setup Complexity | Low | Low to Moderate | Moderate to High | High | Low to Moderate |

| Tool Access & Undercuts | Limited | Improved with A-axis | Full 3D access | Full spatial access | Limited without live tooling |

Honyo Prototype specializes in 5-axis milling and multi-axis turning for tight-tolerance components in aluminum and steel, with proven success in engineering plastics such as ABS and nylon. While 6-axis systems offer theoretical advantages, our current focus remains on optimizing 5-axis and turn-mill processes to deliver precision within ±0.005 mm for critical features. Material selection is matched to process capability, ensuring dimensional stability and surface quality across production runs.

From CAD to Part: The Process

Honyo Prototype 6-Axis CNC Machining Process Flow

Honyo Prototype executes 6-axis CNC machining through a rigorously optimized workflow designed for precision, speed, and technical validation. This process eliminates traditional bottlenecks while ensuring manufacturability and compliance with aerospace, medical, and industrial standards.

CAD Submission

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system validates geometric integrity, unit consistency, and topology completeness. For 6-axis work, we specifically check for undercuts, complex contours, and features requiring simultaneous multi-axis interpolation. Incomplete or ambiguous geometry triggers immediate client feedback to prevent downstream delays.

AI-Powered Quoting

Uploaded CAD data feeds into Honyo’s proprietary AI quoting engine, which analyzes over 200 parametric variables including material utilization, toolpath complexity, setup requirements, and machine kinematics. The AI cross-references real-time shop floor data (machine availability, tooling inventory, labor rates) and historical performance metrics for 6-axis operations. Within 2 hours, clients receive a detailed quote with cost breakdown, lead time, and preliminary feasibility flags—no manual engineering review required for standard geometries.

DFM Analysis

All 6-axis projects undergo mandatory Design for Manufacturability (DFM) by our senior CNC engineering team. This phase focuses on:

Collision avoidance validation for rotary axes and complex workholding

Optimization of fixturing to minimize setups (leveraging 6-axis capabilities to machine 5 faces in 1 setup)

Material-specific strategy adjustments (e.g., titanium chatter reduction, aluminum high-speed parameters)

Tolerance stack-up analysis for multi-axis feature relationships

Verification of achievable surface finishes on non-orthogonal surfaces

DFM reports include actionable recommendations with annotated CAD visuals, typically completed within 24 business hours. Client approval is required before production release.

Production Execution

Approved jobs enter our climate-controlled 6-axis production cell featuring DMG MORI CMX 600 V eVo and Hermle C400 U milling centers with HSD spindles (max 24,000 RPM). Key protocols:

Workpieces secured via custom-designed tombstones accommodating ±180° B-axis rotation

In-process probing for on-machine verification of critical datums

Real-time vibration monitoring to maintain sub-5µm tolerances on complex geometries

Full traceability via RFID tags tracking material lot numbers, machine parameters, and operator certifications

Typical cycle times for 6-axis jobs are 30–50% faster than segmented 3+2 axis approaches due to eliminated repositioning.

Delivery and Documentation

Finished parts undergo CMM validation against original CAD with full GD&T reporting. Delivery includes:

First-article inspection report (FAIR) with 3D deviation maps

Material certification and heat-treat documentation

Machining process log (tooling used, spindle loads, coolant parameters)

Packaging compliant with AS9100 shock/vibration standards

Standard lead time from DFM approval to shipment is 7–12 business days for prototypes, with expedited 72-hour options for qualified geometries.

Process Advantages Summary

The integration of AI-driven quoting with human-led DFM for 6-axis machining delivers measurable client benefits:

| Metric | Traditional 3+2 Axis | Honyo 6-Axis Process | Improvement |

|---|---|---|---|

| Setup Changes | 3–5 | 1–2 | 60% reduction |

| Critical Feature Tolerance | ±0.025mm | ±0.005mm | 80% tighter |

| Lead Time (Prototype) | 14–21 days | 7–12 days | 40% faster |

| Scrap Rate | 8–12% | 2–4% | 65% lower |

This workflow ensures technically complex 6-axis components achieve first-pass yield rates exceeding 95% while maintaining full compliance with ISO 9001:2015 and NADCAP requirements. Clients receive production-ready parts with validated process documentation for seamless integration into their assembly pipelines.

Start Your Project

Discover precision with our 6-axis CNC machining services, engineered for complex geometries and tight tolerances. Ideal for aerospace, medical, and automotive prototyping and production.

Our advanced machining capabilities are powered by state-of-the-art equipment and expert programming, ensuring superior accuracy and surface finish in every part.

Located in Shenzhen, our modern facility supports rapid turnaround and high repeatability for both prototypes and large-volume orders.

Contact Susan Leo to discuss your project requirements or request a quote.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.