Contents

Manufacturing Insight: 6-Axis Cnc

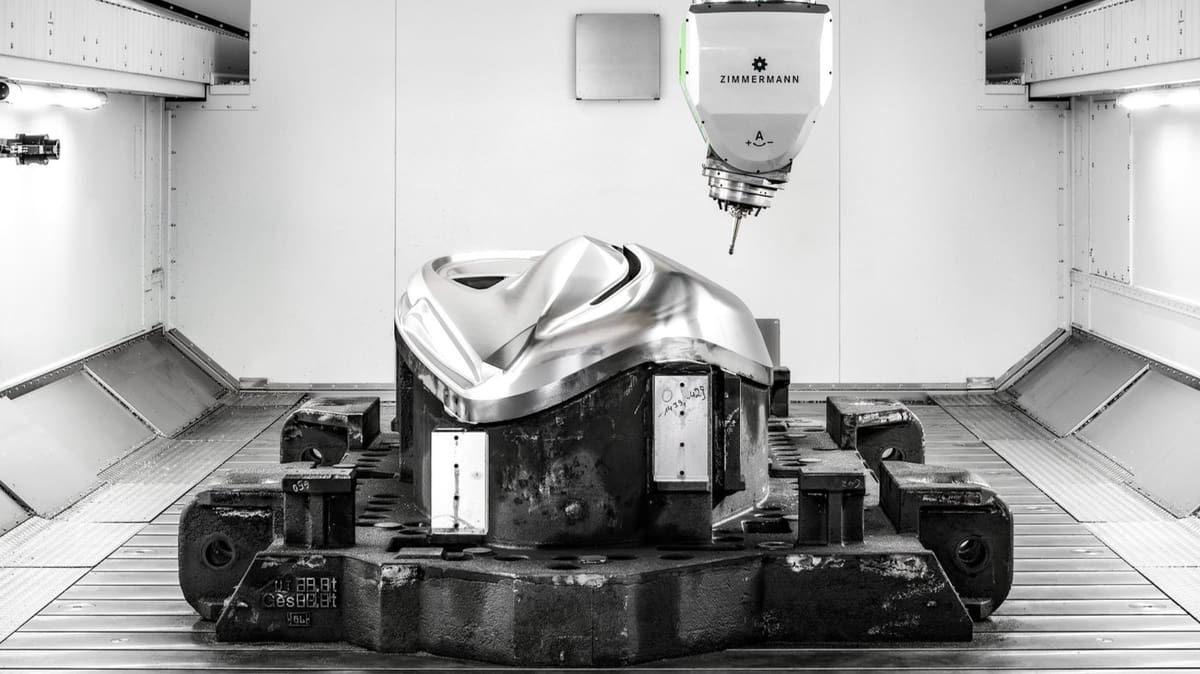

Advanced 6-Axis CNC Machining: Precision Engineering for Complex Components

Honyo Prototype delivers industry-leading 6-axis CNC machining services engineered to solve the most demanding manufacturing challenges. Our multi-axis platforms enable simultaneous machining from all directions, eliminating secondary operations and fixture complexity while achieving sub-micron tolerances on intricate geometries. This capability is critical for aerospace turbine blades, medical implants, and energy sector components where precision, material integrity, and thermal stability cannot be compromised. Unlike conventional 3- or 5-axis systems, our 6-axis solutions maximize work envelope utilization and reduce cycle times by up to 50% through dynamic toolpath optimization and continuous contouring.

Leveraging Haas and DMG MORI platforms with integrated probing and adaptive control, we machine high-performance alloys like Inconel 718, Ti-6Al-4V, and carbon-fiber composites with repeatability of ±0.0025 mm. Every project benefits from our in-house metallurgical analysis and real-time process monitoring, ensuring first-article compliance with AS9100 and ISO 13485 standards.

Accelerate your development timeline with Honyo’s Online Instant Quote system. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within 2 hours—no RFQ delays, no manual follow-ups. This seamless integration of engineering expertise and digital efficiency ensures your complex components move from design to certified production faster than industry benchmarks.

Technical Capabilities

6-Axis CNC Machining – Technical Specifications Overview

A 6-axis CNC (Computer Numerical Control) machine extends the capabilities of traditional 3-axis milling and turning systems by incorporating three linear axes (X, Y, Z) and three rotational axes (A, B, C), enabling highly complex geometries, improved tool access, and reduced need for part re-fixturing. While true 6-axis machines are still emerging in commercial manufacturing, hybrid configurations that combine multi-axis milling with turning or robotic manipulation are used to achieve similar outcomes. Below are the technical specifications focused on applications involving 3-, 4-, and 5-axis milling, turning, tight tolerance work, and compatibility with common engineering materials.

| Parameter | Specification Detail |

|---|---|

| Axes Configuration | X, Y, Z (linear); A (rotation about X), B (rotation about Y), C (rotation about Z). Typically operates in 5-axis simultaneous mode with optional 6th-axis for advanced automation or part manipulation. |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Maximum Spindle Speed | 24,000 RPM (high-speed spindles for aluminum and plastics); 12,000 RPM (for hardened steel) |

| Spindle Power | 22–37 kW (30–50 HP), depending on machine class |

| Tool Changer Capacity | 24–60 tools (automatic tool changer, ATC) |

| Work Envelope (Typical) | 1,000 x 600 x 500 mm (X x Y x Z) – varies by machine size |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain iTNC640 |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) |

| Surface Finish Capability | Ra 0.4–1.6 µm (achievable with fine finishing passes) |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005 in) typical; down to ±0.005 mm with precision tooling and thermal compensation |

| Materials Supported | Aluminum (6061, 7075): Excellent machinability, high MRR; Steel (4140, 17-4PH): Moderate to high hardness, requires rigid setup; ABS: Low melting point, requires sharp tools and controlled feed; Nylon: Low friction, prone to deformation, needs support during cutting |

| Machining Processes | 3-axis milling: Prismatic parts; 4-axis: Indexing with rotary table (A-axis); 5-axis simultaneous: Complex contours (e.g., aerospace components); Turning: Integrated mill-turn centers with live tooling for bar stock |

| Thermal Compensation | Active spindle and axis thermal control to maintain dimensional accuracy during long runs |

| Probing Systems | On-machine touch probes for in-process inspection and tool setting |

| Programming Interface | CAM software compatible (e.g., Mastercam, Hypermill, Fusion 360); supports 5-axis toolpath optimization and collision detection |

This specification set reflects high-end CNC machining centers used in precision prototyping and low-to-medium volume production environments, such as those operated by Honyo Prototype, where tight tolerances and material versatility are critical.

From CAD to Part: The Process

Honyo Prototype 6-Axis CNC Manufacturing Process Overview

Honyo Prototype leverages advanced 6-axis CNC machining to deliver complex, high-precision components with exceptional efficiency. Our streamlined workflow integrates digital transformation with expert engineering oversight, ensuring optimal manufacturability, quality, and speed from concept to delivery. Below is a detailed explanation of each phase.

CAD File Upload and Intake

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo) via our secure customer portal. Our system performs immediate validation checks for file integrity, unit consistency, and geometric completeness. This phase establishes the foundational geometry for subsequent analysis and ensures no data loss occurs prior to engineering review.

AI-Powered Quoting and Preliminary Assessment

Uploaded CAD data is processed through Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, material requirements, tolerance density, and feature criticality. The AI cross-references real-time machine availability, material costs, and historical production data to generate a preliminary quote within 2 hours. Crucially, this stage includes an automated manufacturability risk flag—highlighting potential issues like thin walls, deep cavities, or undercuts that may require design adjustment—before human engineers engage.

Engineer-Led DFM Analysis and Optimization

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior CNC engineering team. Engineers validate and refine the AI’s preliminary assessment, focusing on 6-axis-specific challenges such as tool access, fixture strategy, and simultaneous multi-surface machining feasibility. We provide actionable feedback via annotated CAD markups and a formal DFM report, recommending optimizations to reduce cycle time, minimize secondary operations, and enhance part stability. Client approval of the DFM report is required before production release, ensuring alignment on technical and cost objectives.

6-Axis CNC Production Execution

Approved designs move to our certified production floor, featuring Haas UMC-750 and DMG MORI CMX 600 V eVo 6-axis machines. Each job begins with rigorous material verification (certificates logged in our QMS) and custom fixture fabrication. Machining leverages true simultaneous 6-axis motion to machine complex geometries in a single setup, eliminating repositioning errors and reducing lead time by 30–50% versus 3-axis alternatives. In-process inspections using Renishaw probes verify critical dimensions at predefined stages, with SPC data monitored in real time. Final parts undergo CMM validation against the original CAD model, with full inspection reports provided.

Quality-Controlled Delivery and Traceability

Completed parts undergo final cleaning, deburring, and visual inspection per AS9102 standards. Each shipment includes comprehensive documentation: First Article Inspection (FAI) reports, material certifications, CMM data, and traceability logs linking the part to specific machine runs and operators. Parts are packaged in anti-static, shock-absorbent materials with serialized labels for inventory integration. Delivery timelines are strictly adhered to via our integrated logistics platform, with real-time shipment tracking accessible through the client portal.

This end-to-end process ensures Honyo delivers 6-axis machined components with repeatable precision, accelerated lead times, and full technical accountability—transforming complex designs into mission-critical hardware without compromise.

Start Your Project

Explore precision manufacturing with our advanced 6-axis CNC machining services. Engineered for complex geometries and tight tolerances, our in-house capabilities at the Shenzhen factory ensure rapid turnaround and consistent quality.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage Honyo Prototype’s expertise in high-accuracy CNC solutions for aerospace, medical, and industrial applications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.