Guide Contents

Project Insight: 5 Axis Machining Centers

Why Speed and Precision Define Modern Product Development

Accelerating innovation requires rapid iteration and flawless execution—delays or dimensional inaccuracies can derail entire product launches.

For hardware startups and product engineers, precision isn’t optional; it’s the foundation of functional performance, reliability, and market competitiveness.

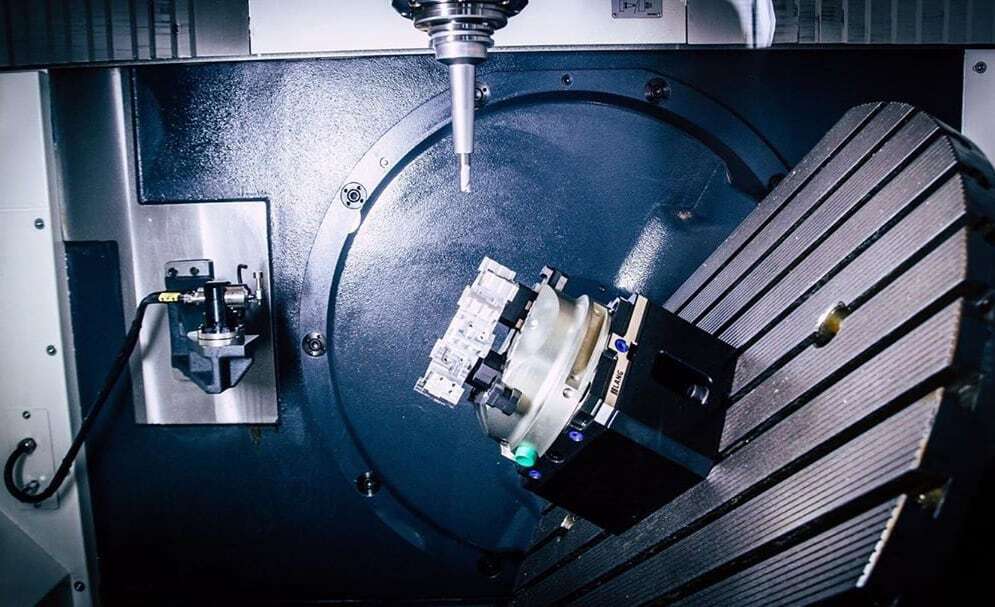

The Critical Role of 5-Axis Machining in Prototyping and Production

Complex Geometries in a Single Setup: Eliminate manual repositioning errors and machine intricate designs impossible with 3-axis systems.

Tight Tolerances (+/- 0.01mm): Achieve micron-level accuracy for critical features, ensuring parts function as intended in final assemblies.

Reduced Lead Times: Minimize setup steps and machining time, accelerating your path from CAD to physical prototype.

Honyo Prototype: Your Digital Manufacturing Partner

Precision Engineered for Innovation

Leverage our 5-axis machining centers with ±0.01mm tolerances to produce functional prototypes and end-use parts that meet the most demanding engineering specifications.

Shenzhen-based manufacturing ecosystem ensures access to advanced technology, skilled technicians, and rapid material sourcing—no compromise on quality or speed.

Streamlined Process from Design to Delivery

Online Instant Quote: Upload your CAD file and receive an AI-generated, transparent quote in seconds—no hidden fees, no delays.

Fast Turnaround: Industry-leading lead times through optimized workflows and in-house expertise—deliver precision parts 30–50% faster than traditional manufacturers.

End-to-End Transparency: Track your project in real-time via our digital platform, with proactive updates from quote to delivery.

At Honyo Prototype, we don’t just manufacture parts—we accelerate innovation. With AI-driven precision and seamless collaboration, your designs become reality faster, smarter, and with uncompromising quality.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

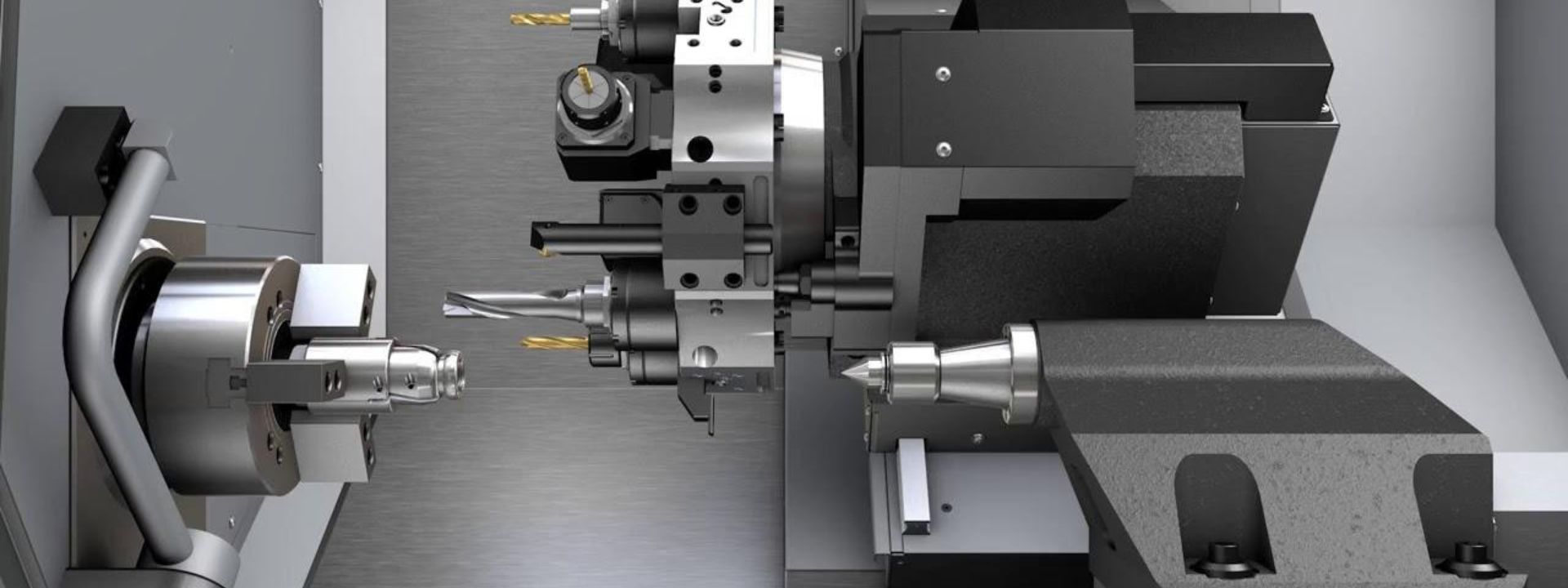

Precision 5-Axis Machining

±0.01mm Tight Tolerances: Achieve micron-level accuracy for functional prototypes and end-use parts, ensuring perfect fit, form, and function.

Full 5-Axis Simultaneous Machining: Eliminate multi-setup errors and tackle complex geometries (e.g., aerospace turbine blades, medical implants) in a single operation.

Multi-Axis Flexibility: Seamlessly switch between 3-axis, 4-axis, and 5-axis configurations to optimize efficiency for any design complexity.

Scalable Production from Prototype to Mass Manufacturing

No Minimums, No Limits: From 1 prototype to 10,000+ production parts—scale seamlessly as your product evolves.

Cost-Effective Scaling: Avoid capital investment in expensive machinery; leverage our industrial-grade equipment for agile, high-volume output.

Rapid Iteration Cycles: Accelerate time-to-market with quick turnaround times for design validation and production readiness.

Rigorous Quality Assurance

ISO 9001 Certified Processes: Consistent quality control across all stages, from material inspection to final delivery.

In-Process Monitoring: Real-time dimensional checks and surface finish verification to meet your exact specifications.

Material Expertise: Precision machining for aluminum, titanium, stainless steel, engineering plastics, and exotic alloys with minimal waste.

Streamlined Service Experience

AI-Powered Instant Quote: Upload your CAD file for an accurate, real-time price estimate—no manual quotes, no delays.

Fast Turnaround: Prototypes delivered in 3–5 days; production runs optimized for speed without compromising precision.

Dedicated Engineering Support: Our team collaborates with you from design review to delivery, ensuring manufacturability and cost efficiency.

“At Honyo Prototype, we empower innovators with precision manufacturing that accelerates time-to-market while eliminating the complexities of traditional machining.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes

Precision Materials for 5-Axis Machining

Our material portfolio is engineered for 5-axis complexity, balancing performance, machinability, and cost.

Aluminum 6061: The prototype favorite. Exceptional machinability for intricate geometries, corrosion resistance, and lightweight strength. Ideal for drone frames, aerospace brackets, and consumer electronics housings.

Aluminum 7075: High-strength aerospace-grade alloy. Delivers superior tensile strength for structural components. Our 5-axis capabilities handle its hardness with micron-level precision—perfect for military-grade parts and high-performance automotive components.

Stainless Steel 304: Corrosion-resistant workhorse. Ensures smooth internal channels and thread accuracy for medical devices, food processing equipment, and sanitary applications.

Stainless Steel 316: Marine-grade excellence. Withstands extreme chemical exposure and saltwater environments. Ideal for offshore equipment and pharmaceutical machinery where purity matters.

Brass: Electrical conductivity meets aesthetics. Precision-machined for connectors, valves, and decorative components. Maintains dimensional stability even in complex 5-axis toolpaths.

PEEK: Extreme-environment polymer. Used in medical implants, aerospace seals, and chemical-resistant parts. Specialized tooling ensures zero warpage and micron-level tolerances during high-temperature machining.

Surface Finishes That Elevate Performance

Enhance functionality, durability, and aesthetics with finishes tailored to your application.

Anodizing: Durable, customizable protection. Clear or colored coatings for aluminum parts with uniform thickness—even on complex 5-axis geometries. Ideal for branding, wear resistance, and electrical insulation.

Powder Coating: Seamless coverage for complex shapes. Electrostatic application ensures flawless adhesion and color consistency for outdoor enclosures, industrial equipment, and architectural components.

Precision Polishing: Mirror-like surfaces for critical applications. Manual and automated techniques eliminate micro-scratches, meeting ISO Class 1 standards for medical optics and high-end consumer products.

Passivation: Corrosion resistance for stainless steel. Removes surface contaminants to meet FDA/ISO standards for surgical instruments and food-grade components.

Electroplating: Conductive or decorative layers. Nickel, chrome, or gold plating for electrical contacts, automotive trim, or wear-resistant surfaces.

Optimizing Material Selection for Your Project

Maximize performance while minimizing cost and lead time with our expert guidance:

Function Meets Form: Match material properties to your application’s mechanical, thermal, and environmental demands—our engineers guide you from concept to final spec.

Cost-Efficiency Strategy: Balance performance needs with budget constraints. For example, 6061 aluminum often delivers 30% cost savings vs. 7075 while maintaining 90% of the strength for non-critical parts.

Regulatory Compliance: We ensure materials meet FDA, RoHS, or ISO standards for medical, aerospace, or automotive applications—no guesswork required.

Streamlined Service Experience

Innovation at your fingertips—no compromises, no delays.

Online Instant Quote: Upload your CAD file and receive real-time pricing, lead times, and DFMA feedback in under 60 seconds. No more back-and-forth emails—just actionable insights to accelerate your project.

AI-Powered Platform: Our proprietary algorithms optimize toolpaths for 5-axis machining, reducing cycle times by up to 25% while maintaining +/- 0.01mm tolerances. Every design is analyzed for manufacturability before production begins.

Fast Turnaround Without Compromise: From prototype to production, our Shenzhen facility delivers precision parts in as little as 3 days. With dedicated teams and automated workflows, we ensure your timeline aligns with innovation—not delays.

💡 Why Honyo Prototype?

We don’t just machine parts—we engineer solutions. Whether you’re a hardware startup scaling prototypes or a procurement manager sourcing end-use components, our 5-axis expertise ensures your vision is realized with unmatched precision, speed, and innovation. Get your quote today—your next breakthrough starts here.

From Quote to Part: Our Process

How It Works: From CAD to Part

Upload CAD File in Seconds

Upload your design files (STEP, IGES, STL, SolidWorks, etc.) via our secure cloud portal—no software required.

Instant validation checks ensure compatibility and flag potential upload issues before submission.

Get Real-Time AI-Powered Quote

Our proprietary AI engine analyzes your CAD in seconds, generating a precise cost breakdown with no hidden fees.

Compare material options, finishes, and lead times instantly—no waiting for manual quotes.

Transparent pricing: machine time, setup, materials, and shipping clearly itemized for full visibility.

Smart DFM Analysis & Optimization

Automated design for manufacturability checks highlight potential issues (e.g., tolerances, wall thickness, undercuts).

Receive actionable suggestions to optimize for cost and performance—before production starts.

Collaborate directly with our engineers to refine your design in real-time, eliminating costly rework.

Precision Production & Fast Delivery

Streamlined workflow from CNC programming to final inspection, ensuring ±0.01mm tolerances every time.

Real-time production tracking: monitor progress from machining to shipping with live updates.

Deliver high-quality functional prototypes or end-use parts in record time with end-to-end transparency.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Meets Innovation

Real-Time AI Quoting: Upload your CAD in seconds and receive an instant, transparent quote—no hidden fees, no delays. Our platform dynamically optimizes costs for material, machining time, and post-processing.

±0.01mm Tolerance Mastery: Achieve surgical precision on complex geometries for both functional prototypes and end-use parts—eliminating secondary operations and reducing assembly complexity.

50% Faster Turnaround: Prototype-to-delivery in 3–5 days, with seamless scaling from single units to high-volume production without retooling.

Your Partner in Manufacturing Excellence

Founder Susan Leo and our Shenzhen engineering team combine 15+ years of aerospace/medical-grade precision experience with cutting-edge 5-axis technology to solve your toughest challenges.

Collaborate hands-on at our Shenzhen/Dongguan facilities—where design reviews, quality checks, and rapid iteration happen under one roof.

Let’s build the future, together.

📧 [email protected] | 📞 +86 139 2843 8620

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.