Contents

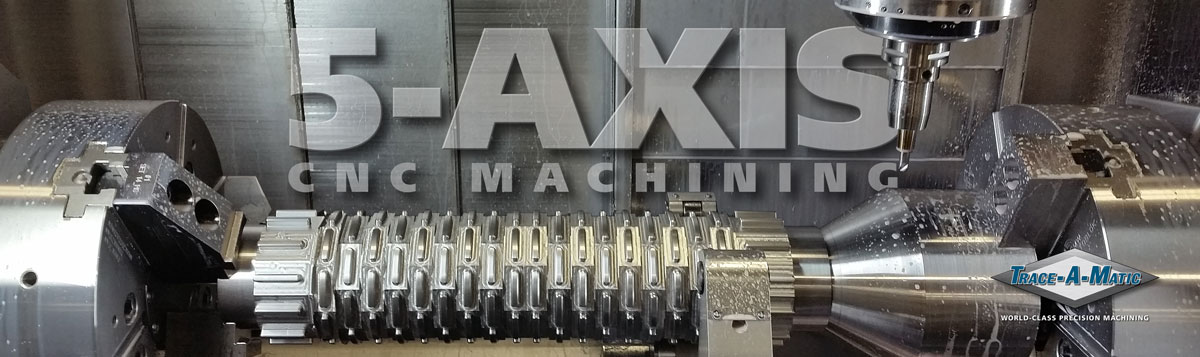

Manufacturing Insight: 5-Axis Machining

Precision Through Complexity: Honyo Prototype’s Advanced 5-Axis Machining Capability

Modern manufacturing demands components with intricate geometries, stringent tolerances, and superior surface finishes—requirements that traditional 3-axis CNC machining often struggles to meet efficiently. At Honyo Prototype, our state-of-the-art 5-axis CNC machining services eliminate these limitations by enabling simultaneous movement across five axes, allowing a single setup to machine complex contours, undercuts, and organic shapes from virtually any angle. This capability significantly reduces part handling, minimizes cumulative errors from multiple setups, and accelerates lead times for mission-critical components in aerospace, medical, and energy sectors.

Our engineering team leverages high-precision 5-axis mills equipped with advanced control systems to handle challenging materials—from titanium and Inconel to high-performance polymers—while maintaining micron-level accuracy and exceptional repeatability. By integrating dynamic toolpath optimization and real-time process monitoring, Honyo ensures optimal material removal rates without compromising dimensional integrity or surface quality. This approach directly translates to reduced scrap, lower total production costs, and faster time-to-market for your most demanding prototypes and low-volume production runs.

To streamline your procurement process, Honyo Prototype offers an Online Instant Quote platform. Simply upload your 3D CAD file, specify materials, quantities, and finishing requirements, and receive a detailed, transparent cost estimate within hours—not days. This digital efficiency, combined with our technical expertise in 5-axis complexity, positions Honyo as your strategic partner for turning ambitious designs into high-fidelity, functionally validated components.

Material & Process Performance Overview

| Parameter | Capability Range | Industry Impact |

|——————–|————————————–|——————————————|

| Tolerance Control | ±0.005 mm to ±0.025 mm | Ensures fit/function in precision assemblies |

| Max Work Envelope | 1,200 x 800 x 750 mm | Supports large-scale complex components |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (as machined) | Reduces need for secondary polishing |

| Lead Time Reduction| 30-50% vs. multi-setup 3-axis | Accelerates prototyping and NPI cycles |

Partner with Honyo Prototype to transform geometric complexity into competitive advantage—where engineering excellence meets operational agility.

Technical Capabilities

5-axis machining refers to the capability of a CNC machine to move a tool or workpiece along five different axes simultaneously—typically X, Y, Z, and two rotational axes (A and B or A and C, depending on configuration). This advanced machining method enables complex geometries, improved part accuracy, and reduced setup times compared to 3-axis or 4-axis systems. Honyo Prototype utilizes 5-axis milling and multitasking turning centers to achieve tight tolerances and high surface finishes across a range of engineering materials.

Below is a comparison of technical capabilities across 3-axis, 4-axis, and 5-axis CNC machining platforms, emphasizing precision, material compatibility, and application scope.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling / Mill-Turn |

|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) |

| Typical Tolerances | ±0.005″ (0.13 mm) | ±0.003″ (0.076 mm) | ±0.001″ (0.025 mm) or tighter |

| Surface Finish (Ra) | 32–125 μin | 32–63 μin | 16–32 μin (achievable with polishing) |

| Setup Complexity | High for complex parts | Moderate | Low (single-setup for complex parts) |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon, Titanium, PEEK |

| Aluminum Machinability | Excellent | Excellent | Excellent (high-speed capability) |

| Steel Machinability | Good (slower feeds) | Good | Good to Excellent (with hardened tooling) |

| ABS & Nylon Handling | Good (low melting point) | Good | Excellent (precise toolpath control) |

| Part Geometry Complexity | Low to Medium | Medium | High (organic shapes, undercuts) |

| Use Case Examples | Flat plates, simple brackets | Indexing features, cams | Aerospace impellers, medical implants, mold cores |

| Turning Integration | Not applicable | Limited | Full mill-turn capability (live tooling, C-axis) |

Honyo Prototype’s 5-axis machining centers support tight tolerance production down to ±0.0005″ (0.0127 mm) on critical features, with in-process metrology and thermal compensation systems ensuring dimensional stability. Materials such as 6061-T6 and 7075 aluminum, 4140 and 1018 steel, as well as engineering plastics like ABS and nylon, are routinely machined with high repeatability. The integration of turning with multi-axis milling allows for complete “done-in-one” manufacturing of complex rotational parts with off-center milling features.

From CAD to Part: The Process

Honyo Prototype executes 5-axis machining through a rigorously defined workflow designed for precision, efficiency, and manufacturability assurance. This integrated process minimizes iteration and ensures optimal outcomes for complex geometries.

CAD Upload and Initial Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and basic geometric validity. Invalid or corrupted files trigger instant notification to the client, preventing downstream delays. Validated CAD data feeds directly into the quoting engine, eliminating manual data re-entry errors.

AI-Powered Quoting with Engineering Oversight

Our proprietary AI engine analyzes the validated CAD geometry, extracting critical parameters including net part volume, feature complexity, surface area, and undercuts. It cross-references this against real-time material costs, machine availability, historical process times, and tooling requirements from our extensive production database. The AI generates a preliminary quote within 24-72 hours, including estimated lead time and material options. Crucially, complex geometries or non-standard requirements automatically flag the quote for review by our senior manufacturing engineering team, who validate the AI’s assessment and adjust parameters based on practical machining experience before client submission.

Collaborative DFM Analysis and Optimization

Upon quote acceptance, our engineering team conducts a comprehensive Design for Manufacturability (DFM) review. This is not a passive checklist but an active collaboration. We analyze tool access angles, identify potential thin-wall deflection or chatter risks, verify fixture requirements, and assess optimal workholding strategies for 5-axis simultaneous movement. Critical considerations include:

Minimum internal corner radii relative to available tooling

Achievable surface finishes on complex contours

Strategic stock placement to minimize repositioning

Identification of features better suited to alternative processes (e.g., EDM for deep cavities)

We provide specific, actionable feedback with annotated CAD markups and suggested modifications, often reducing cost by 15-30% while maintaining functional intent. Client approval of the DFM report is required before programming begins.

Precision 5-Axis Production Execution

Approved jobs enter production on our HAAS UMC-750 or DMG MORI CMX 600 V eco 5-axis vertical machining centers. Key production phases include:

CAM Programming: Using Mastercam and hyperMILL, our programmers generate optimized toolpaths leveraging full 5-axis simultaneous motion. Simulation verifies collision avoidance and material removal sequences.

Fixturing & Setup: Custom tombstones or modular fixturing is deployed. Setup technicians perform precise workpiece alignment using Renishaw probes, ensuring < 0.01mm positional accuracy across all rotational axes.

Machining: Operations utilize high-precision solid carbide tooling with through-coolant. In-process probing validates critical dimensions mid-run. All machines operate within temperature-controlled environments (±1°C).

Quality Control: First-article inspection uses Zeiss coordinate measuring machines (CMM) with 5-axis scanning capabilities. Critical dimensions, GD&T callouts, and surface finishes are verified against CAD nominal values per AS9102 standards.

Quality-Certified Delivery

Final parts undergo comprehensive cleaning, deburring, and visual inspection. Each shipment includes:

Dimensional inspection report (PDF and .dmis file)

Material certification (if applicable)

Process non-conformance report (if none, documented as zero defects)

Traceable job log with machine ID and operator

Parts are packaged using custom anti-corrosion materials and shipped via client-preferred carrier with real-time tracking. Expedited delivery options (including same-day for local clients) are available for qualified projects.

Typical Achievable Tolerances and Materials

| Parameter | Standard Capability | Tight Tolerance Option |

|——————–|———————|————————|

| Positional Accuracy | ±0.010 mm | ±0.005 mm |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

| Materials | Aluminum 6061/7075, Stainless 303/316, Titanium Grade 5, PEEK | Inconel 718, Tool Steels |

This structured workflow ensures that Honyo Prototype delivers complex 5-axis machined components with minimized risk, transparent communication, and documented quality, directly addressing the core challenges of precision prototyping and low-volume production.

Start Your Project

Discover precision with Honyo Prototype’s advanced 5-axis machining services. Our state-of-the-art facility in Shenzhen delivers complex, high-tolerance components with faster turnaround and superior surface finish. Ideal for aerospace, medical, and automotive applications.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in multi-axis CNC machining for prototypes and low-volume production—engineered to perform.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.