Introduction: Navigating the Global Market for 5 axis lathe

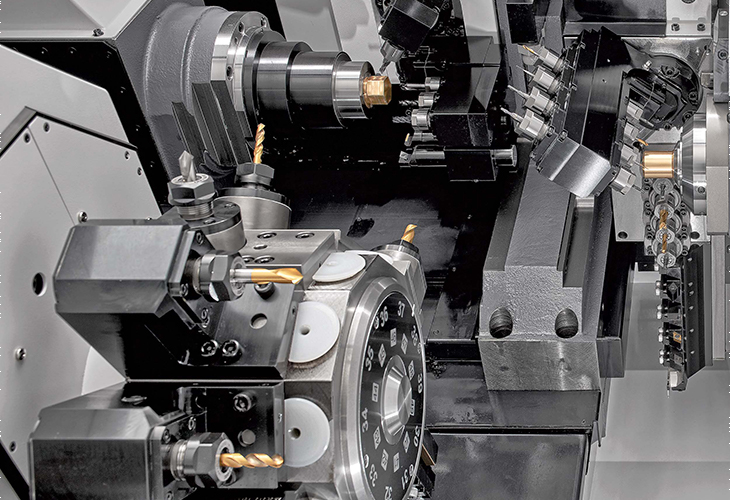

In today’s competitive manufacturing landscape, sourcing a reliable 5-axis lathe can be a daunting challenge for international B2B buyers. With the increasing demand for precision engineering and complex part machining, understanding the intricacies of these advanced CNC machines is crucial. This guide offers a comprehensive look into the world of 5-axis lathes, covering various types, applications, and the critical factors to consider when evaluating suppliers.

From the robust capabilities of leading brands to the nuances of operational efficiency, this resource is designed to empower buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil. You will find actionable insights on supplier vetting, cost analysis, and the latest technological advancements that can enhance your manufacturing processes.

By equipping you with the knowledge necessary to make informed purchasing decisions, this guide aims to streamline your sourcing process, ultimately leading to improved productivity and competitiveness in your operations. Whether you are looking to upgrade existing machinery or invest in new technology, understanding the full spectrum of 5-axis lathe options will help you navigate the global market with confidence.

Understanding 5 axis lathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Swiss Lathe | High precision, sliding headstock design | Medical, aerospace, and automotive | Pros: Excellent for small, complex parts; high accuracy. Cons: Higher upfront cost; requires skilled operators. |

| Vertical Lathe | Vertical spindle orientation, large workpieces | Heavy machinery, automotive components | Pros: Efficient for large parts; stable operation. Cons: Limited to specific part shapes; often requires additional tooling. |

| Horizontal Lathe | Horizontal spindle, versatile tooling options | General manufacturing, tool production | Pros: Flexible machining capabilities; ideal for various materials. Cons: Takes up more floor space; setup times can be longer. |

| Multi-Tasking Lathe | Combines turning, milling, and drilling | Complex assemblies in aerospace, automotive | Pros: Streamlines production processes; reduces handling time. Cons: Higher complexity may lead to maintenance challenges. |

| 5-Axis Mill-Turn | Integrates milling and turning in one setup | Aerospace, medical devices, and molds | Pros: High efficiency and accuracy; reduces cycle times. Cons: Higher initial investment; requires advanced programming skills. |

What are the Characteristics of CNC Swiss Lathes?

CNC Swiss lathes are designed for high-precision machining, particularly suitable for small, intricate parts. Their unique sliding headstock allows for the efficient production of long, slender components, which is essential in industries like medical and aerospace. Buyers should consider the initial investment and the need for skilled operators, as these machines demand advanced programming knowledge to fully leverage their capabilities.

How Do Vertical Lathes Function and Where are They Used?

Vertical lathes feature a vertical spindle orientation, making them ideal for machining large and heavy workpieces. They are commonly used in the production of heavy machinery and automotive components. Their stability during operation allows for efficient machining of large parts. However, buyers should note that vertical lathes are typically limited to specific shapes and may require additional tooling for varied applications.

What Makes Horizontal Lathes Versatile for Manufacturing?

Horizontal lathes are characterized by their horizontal spindle design, which allows for versatile tooling options. They are widely used in general manufacturing and tool production due to their adaptability to different materials and part shapes. While they offer flexible machining capabilities, buyers should be aware of their larger footprint and potentially longer setup times compared to other lathe types.

Why Choose Multi-Tasking Lathes for Complex Assemblies?

Multi-tasking lathes are engineered to combine turning, milling, and drilling operations within a single setup, significantly streamlining production processes. They are particularly beneficial in the aerospace and automotive industries, where complex assemblies are common. While they offer substantial efficiency gains, the complexity of these machines can lead to maintenance challenges and necessitate a higher level of programming skill.

What are the Benefits of 5-Axis Mill-Turn Machines?

5-axis mill-turn machines integrate both milling and turning operations, allowing for the machining of complex geometries in one setup. This capability is especially valuable in sectors like aerospace and medical device manufacturing, where precision and reduced cycle times are critical. However, the initial investment is typically higher, and the advanced programming required can be a barrier for some buyers.

Key Industrial Applications of 5 axis lathe

| Industry/Sector | Specific Application of 5 Axis Lathe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing for aircraft engines | High accuracy and reduced cycle times | Supplier certifications, quality control measures, and delivery timelines |

| Automotive | Production of complex engine parts and transmission components | Enhanced efficiency and reduced material waste | Machine reliability, after-sales service, and local support availability |

| Oil & Gas | Fabrication of specialized drilling and completion tools | Improved durability and performance in harsh conditions | Compliance with industry standards, tooling options, and part customization capabilities |

| Medical Devices | Manufacturing of intricate surgical instruments | Increased precision and reduced time-to-market | Regulatory compliance, precision engineering capabilities, and customization options |

| Electronics | Production of intricate housings and components for devices | Enhanced design flexibility and reduced assembly time | Technological compatibility, integration with existing systems, and vendor reliability |

How is a 5 Axis Lathe Used in Aerospace Manufacturing?

In the aerospace industry, 5 axis lathes are essential for producing high-precision components like turbine blades and engine casings. These components often require complex geometries and tight tolerances, which 5 axis machining can achieve in a single setup, minimizing the need for multiple setups and reducing cycle times. For international buyers, particularly from regions such as Africa and South America, sourcing lathes that meet stringent aerospace standards and offer robust after-sales support is crucial.

What Role Does a 5 Axis Lathe Play in Automotive Production?

Automotive manufacturers leverage 5 axis lathes to create intricate engine parts and transmission components. The ability to perform both turning and milling operations in one machine streamlines production processes and reduces waste, thereby enhancing efficiency. Buyers from Europe and the Middle East should prioritize suppliers that provide machines with proven reliability and strong local service networks to ensure minimal downtime and optimal performance.

Why is a 5 Axis Lathe Important in the Oil & Gas Sector?

In the oil and gas sector, 5 axis lathes are used to manufacture specialized drilling tools and completion equipment that must withstand extreme conditions. The precision and durability of components produced on these machines are vital for operational success and safety. International buyers should consider compliance with industry standards and the availability of customized tooling options when sourcing equipment to ensure that their production meets the specific demands of the sector.

How Do Medical Device Manufacturers Benefit from 5 Axis Lathes?

Medical device manufacturers utilize 5 axis lathes to produce intricate surgical instruments and components that require high precision and a quick turnaround. The ability to manufacture complex shapes in a single operation significantly reduces the time-to-market for new products. Buyers in this sector, especially from regions with developing medical industries, must ensure that their suppliers adhere to regulatory compliance and can offer customization to meet specific medical standards.

What Advantages Does a 5 Axis Lathe Offer Electronics Manufacturers?

Electronics manufacturers benefit from 5 axis lathes for producing intricate housings and components that require a high degree of design flexibility. The advanced capabilities of 5 axis machining allow for the integration of complex features that can reduce assembly time and improve overall product quality. Buyers should focus on sourcing machines that are technologically compatible with their existing systems and that come from reliable vendors, ensuring seamless integration and support.

3 Common User Pain Points for ‘5 axis lathe’ & Their Solutions

Scenario 1: Limited Machining Flexibility in Complex Projects

The Problem: Many B2B buyers in the manufacturing sector encounter significant limitations when using traditional lathes for complex machining tasks. The inability to handle intricate geometries often leads to multiple setups, which not only increases production time but also heightens the risk of errors during part handling. For companies looking to produce components with tight tolerances and complex features, this inefficiency can translate to lost contracts and increased operational costs.

The Solution: To address this issue, investing in a 5-axis lathe can dramatically enhance machining flexibility. B2B buyers should focus on sourcing machines that combine both turning and milling capabilities within a single setup. This dual functionality allows for the production of complex parts in one operation, significantly reducing cycle times and the potential for error. When selecting a 5-axis lathe, consider the machine’s software capabilities for advanced programming and simulation. It’s also vital to ensure that the machine’s tooling options support a wide variety of materials and cutting techniques. Partnering with reputable suppliers who offer robust training on programming and operation can further empower machinists, enabling them to maximize the machine’s capabilities for complex projects.

Scenario 2: High Operating Costs and Maintenance Challenges

The Problem: A common pain point for B2B buyers is the high operational costs associated with maintaining precision equipment like a 5-axis lathe. Frequent breakdowns, costly repairs, and inefficient power consumption can erode profit margins, especially for companies operating in highly competitive markets. Additionally, the complexity of these machines often requires specialized maintenance knowledge that in-house teams may lack.

The Solution: To mitigate these challenges, buyers should focus on acquiring equipment from manufacturers that offer comprehensive maintenance support and warranty options. Establishing a long-term relationship with a reputable service provider can ensure that any operational issues are addressed quickly, reducing downtime. Moreover, implementing a preventive maintenance schedule can help identify potential problems before they escalate into costly repairs. Investing in energy-efficient models can also be advantageous; these machines are designed to consume less power while maintaining high performance levels. Buyers should conduct a thorough analysis of their operational needs and seek out 5-axis lathe models that balance upfront costs with long-term savings in energy and maintenance.

Scenario 3: Difficulty in Skill Development and Training for Operators

The Problem: As 5-axis lathes incorporate advanced technology, many operators struggle to keep pace with the required skills for effective machine operation. This skill gap can lead to underutilization of the equipment, resulting in suboptimal productivity and diminished return on investment. Companies may find it challenging to recruit skilled labor, particularly in regions where technical training programs are limited.

The Solution: To overcome this challenge, companies should prioritize comprehensive training programs for their operators. This can include partnering with the machine manufacturer for specialized training sessions and utilizing online resources or simulation software to provide hands-on experience in a risk-free environment. Additionally, establishing a mentorship program where experienced machinists guide newer operators can facilitate knowledge transfer and boost confidence. Investing in ongoing education will not only enhance operator skills but also improve overall productivity and safety. Furthermore, buyers should seek out machines that are user-friendly and equipped with intuitive controls to ease the learning curve for new operators. By creating a culture of continuous learning and development, companies can ensure that their workforce is well-equipped to leverage the full capabilities of their 5-axis lathe.

Strategic Material Selection Guide for 5 axis lathe

What Are the Key Materials for 5 Axis Lathes?

When selecting materials for 5 axis lathes, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: Aluminum, Stainless Steel, Titanium, and Carbon Fiber Reinforced Polymer (CFRP). Each material offers unique benefits and challenges that can influence the performance and suitability of the final product.

How Does Aluminum Perform in 5 Axis Lathes?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It typically has a temperature rating of around 150°C and is suitable for applications requiring moderate strength. The primary advantages of aluminum include its low density, which facilitates faster machining speeds, and its cost-effectiveness compared to other metals.

However, aluminum has lower tensile strength than steel, making it less suitable for high-stress applications. Additionally, it can be prone to deformation under extreme conditions, which may impact precision. For international buyers, especially in regions with varying climates like Africa and South America, it is crucial to ensure compliance with local standards (e.g., ASTM) to guarantee material quality.

What About Stainless Steel in 5 Axis Lathe Applications?

Stainless steel is renowned for its high strength, durability, and corrosion resistance, making it an excellent choice for demanding applications. With a temperature rating exceeding 800°C, it can withstand extreme conditions. The material is versatile, suitable for various industries, including aerospace and automotive.

While stainless steel offers exceptional performance, it is more challenging to machine due to its toughness, which can lead to higher manufacturing costs. Moreover, its weight can be a disadvantage in applications requiring lightweight components. International buyers should consider compliance with standards like DIN or JIS to ensure material integrity and performance.

How Does Titanium Compare for 5 Axis Lathe Use?

Titanium is a high-performance material known for its strength-to-weight ratio and resistance to corrosion and heat. With a temperature rating of up to 600°C, it is ideal for aerospace and medical applications. The primary advantage of titanium is its durability, allowing components to withstand extreme conditions without significant wear.

However, titanium is one of the more expensive materials and poses challenges during machining due to its hardness. This can lead to increased tool wear and longer production times. For B2B buyers, especially in Europe and the Middle East, understanding the cost implications and ensuring compliance with relevant standards is vital for successful procurement.

What Role Does CFRP Play in 5 Axis Lathe Manufacturing?

Carbon Fiber Reinforced Polymer (CFRP) is gaining popularity in advanced manufacturing due to its lightweight and high-strength properties. It can withstand temperatures up to 120°C and offers excellent fatigue resistance. The key advantage of CFRP is its ability to produce lightweight components without sacrificing strength, making it ideal for industries like aerospace and automotive.

The challenges with CFRP include higher costs and complexity in manufacturing, as it requires specialized machining techniques. Additionally, international buyers must be aware of the varying standards and regulations concerning composite materials in their respective regions, particularly in Africa and South America.

Summary Table of Material Selection for 5 Axis Lathes

| Material | Typical Use Case for 5 Axis Lathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components | Lightweight and cost-effective | Lower tensile strength | Low |

| Stainless Steel | Automotive parts | High strength and durability | Difficult to machine | Medium |

| Titanium | Medical implants | Exceptional strength-to-weight ratio | High cost and machining challenges | High |

| Carbon Fiber Reinforced Polymer (CFRP) | Aerospace structures | Lightweight with high fatigue resistance | Higher manufacturing complexity | High |

This guide provides insights into the strategic selection of materials for 5 axis lathes, helping international B2B buyers make informed decisions tailored to their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 5 axis lathe

What Are the Main Stages of Manufacturing a 5 Axis Lathe?

The manufacturing of a 5 axis lathe involves several critical stages, each vital for ensuring the machine’s efficiency, precision, and durability. Understanding these stages can help B2B buyers make informed purchasing decisions.

Material Preparation: How Is Raw Material Processed for 5 Axis Lathes?

The first step in the manufacturing process is material preparation. High-quality steel, aluminum, or other alloys are typically selected based on the specific requirements of the lathe design. The raw materials undergo cutting and shaping to create components such as the bed, spindle, and tool holders. This process often involves CNC machining to achieve the necessary tolerances and surface finishes. It’s essential to verify that suppliers utilize materials that meet international standards for strength and durability.

Forming: What Techniques Are Used in Shaping Components?

After material preparation, the forming stage takes place. This involves advanced techniques like forging, casting, and machining. For instance, the main body of the lathe may be cast, while the spindle and other precision components are typically machined using CNC technology to ensure high accuracy. This dual approach allows manufacturers to balance cost-efficiency with the need for precision. Buyers should inquire about the forming techniques used by suppliers to ensure they align with their quality expectations.

Assembly: How Are Components Integrated into a Complete Machine?

The assembly stage is where individual components come together to form a complete 5 axis lathe. Skilled technicians and engineers meticulously assemble parts such as the headstock, tailstock, and carriage. This stage often involves alignment checks and initial calibration to ensure that all parts fit correctly and function as intended. B2B buyers should ensure that their suppliers have well-documented assembly protocols, as this can significantly impact the machine’s overall performance.

Finishing: What Processes Are Used to Enhance the Lathe’s Performance?

Finishing processes are crucial for enhancing the lathe’s performance and longevity. This can include surface treatments, coating applications, and final machining operations. Techniques such as anodizing or powder coating may be employed to improve corrosion resistance. Additionally, precision grinding may be used to achieve tight tolerances on critical surfaces. Buyers should verify that the finishing processes comply with industry standards to ensure the lathe’s durability in demanding environments.

What Quality Control Measures Are Essential for 5 Axis Lathes?

Quality control (QC) is a fundamental aspect of manufacturing 5 axis lathes, ensuring that each machine meets rigorous performance standards. Understanding the QC measures in place can help B2B buyers assess the reliability of their suppliers.

Which International Standards Should Be Followed in QC for 5 Axis Lathes?

Manufacturers often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that suppliers have processes in place for consistent quality, customer satisfaction, and continuous improvement. In addition, industry-specific certifications such as CE marking and API standards may be relevant, especially for lathes used in sectors like oil and gas or aerospace. B2B buyers should request certification documentation to confirm compliance.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of components at various stages. This can include dimensional checks and surface finish evaluations.

- Final Quality Control (FQC): Once assembly is complete, the entire lathe undergoes thorough testing. This may involve performance testing, calibration, and verification of tolerances.

Implementing these checkpoints helps identify and rectify issues early, ensuring that the final product meets all specifications.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed to ensure the quality of 5 axis lathes:

- Functional Testing: This assesses the overall performance of the machine, including its ability to execute programmed operations accurately.

- Dimensional Inspection: Precision measuring tools are used to verify that components meet specified dimensions and tolerances.

- Load Testing: This method evaluates the machine’s performance under maximum operational conditions to ensure it can handle the required workloads.

B2B buyers should inquire about the specific testing methods used by suppliers, as this can significantly influence the reliability and performance of the lathe.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. This can involve several strategies:

What Auditing Processes Can Be Conducted?

Conducting audits is an effective way to assess a supplier’s quality control practices. Buyers can perform on-site audits or request third-party audits to evaluate compliance with international standards and internal protocols. This not only helps verify the supplier’s commitment to quality but also builds trust in the partnership.

How Can Buyers Access Quality Control Reports?

Requesting detailed quality control reports can provide insights into a supplier’s performance. These reports should include information on inspection results, testing outcomes, and any corrective actions taken in response to identified issues. Regular reporting can indicate a supplier’s transparency and commitment to maintaining high standards.

What Role Do Third-Party Inspections Play in Supplier Verification?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspections can be arranged at various stages of production, ensuring that the lathe meets specifications before shipping. B2B buyers, especially those in regions like Africa and South America, may find third-party inspections particularly beneficial for mitigating risks associated with international sourcing.

What Nuances Should International Buyers Be Aware of in QC Practices?

International buyers must navigate various nuances when assessing quality control practices. Different regions may have distinct regulatory requirements, and it is crucial to understand these differences to ensure compliance. For instance, European buyers may prioritize CE marking, while buyers from the Middle East might focus on specific industry certifications relevant to their sectors.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear communication channels and expectations upfront can help mitigate misunderstandings and ensure that quality standards are met consistently.

Conclusion: Why Quality Assurance Is Crucial for 5 Axis Lathe Purchases

Investing in a 5 axis lathe is a significant decision for any business. Understanding the manufacturing processes and quality assurance measures in place can help B2B buyers make informed choices, ensuring they select suppliers that align with their quality expectations. By prioritizing quality at every stage, from material preparation to final testing, buyers can enhance their operational efficiency and achieve long-term success in their respective industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5 axis lathe’

Introduction

When sourcing a 5-axis lathe, B2B buyers must navigate a complex landscape of technical specifications, supplier reliability, and cost considerations. This guide provides a practical, step-by-step checklist to streamline your procurement process, ensuring you make informed decisions that align with your operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Before you begin contacting suppliers, it’s essential to have a clear understanding of your technical requirements. Specify the materials you will be machining, the types of parts you will produce, and the precision levels required.

- Considerations:

- Maximum workpiece size and weight.

- Required spindle speed and power.

- Tooling options compatible with your production needs.

Step 2: Research Potential Suppliers

Invest time in researching potential suppliers to identify those who specialize in 5-axis lathes. Look for companies with a strong reputation in the industry and a proven track record of delivering high-quality machines.

- Key Actions:

- Check online reviews and industry forums for feedback.

- Evaluate their experience with similar projects.

- Look for suppliers who can provide technical support and maintenance services.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify the certifications of potential suppliers to ensure they meet international quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management.

- What to Look For:

- Evidence of compliance with relevant industry standards.

- Certifications that demonstrate their machinery’s safety and reliability.

- Documentation of previous audits or inspections.

Step 4: Request Detailed Quotes

Once you have a shortlist of suppliers, request detailed quotes that break down costs transparently. This should include the price of the machine, shipping, installation, and any additional services.

- Considerations:

- Compare not just prices, but also the value offered in terms of warranties and service contracts.

- Ask for options on financing or leasing, which can affect your budget planning.

Step 5: Conduct Site Visits or Virtual Tours

If possible, arrange site visits or virtual tours of the suppliers’ facilities. Observing their operations can provide insights into their manufacturing processes and quality control measures.

- Benefits:

- Assess the condition of the machinery and the technology used.

- Meet with technical staff to discuss your specific needs and expectations.

- Evaluate the overall professionalism of the company.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to finalize terms and conditions. This includes delivery timelines, payment terms, and service agreements.

- Key Points to Address:

- Ensure clarity on warranty coverage and support options.

- Discuss penalties or remedies in case of delays or defects.

- Confirm post-purchase support for training and maintenance.

Step 7: Finalize the Purchase Agreement

Before concluding the purchase, review the contract thoroughly. Ensure that all agreed-upon terms are documented, and clarify any points that seem ambiguous.

- What to Ensure:

- Legal compliance with international trade regulations.

- Clear definitions of responsibilities for both parties.

- A structured timeline for delivery and installation.

By following this checklist, B2B buyers can enhance their sourcing strategy for 5-axis lathes, ensuring they select the right machine and supplier to meet their manufacturing goals.

Comprehensive Cost and Pricing Analysis for 5 axis lathe Sourcing

What Are the Key Cost Components in Sourcing a 5 Axis Lathe?

When considering the procurement of a 5-axis lathe, understanding the cost structure is crucial for making informed purchasing decisions. The primary components include:

-

Materials: The cost of raw materials such as high-quality steel and alloys significantly impacts the overall pricing. The choice of materials can also influence machine durability and performance, which are critical in high-stakes manufacturing environments.

-

Labor: Labor costs encompass both direct manufacturing labor and skilled technicians required for setup, maintenance, and operation. Countries with higher labor costs may see increased pricing, while regions with a more skilled workforce may offer better long-term value.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs associated with running production. Efficient manufacturing processes can help mitigate these costs, making it essential to evaluate suppliers on their operational efficiency.

-

Tooling: Specialized tooling is necessary for the functioning of 5-axis lathes. The cost can vary based on complexity and the need for custom tools, which can add to the initial investment.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring machine performance and reliability. Costs associated with quality inspections and certifications can be substantial, especially when sourcing from regions with varying standards.

-

Logistics: Transportation costs, including shipping and customs duties, can significantly affect the total cost of ownership, particularly for international buyers. Understanding Incoterms is essential to clarify who is responsible for shipping costs and risks.

-

Margin: Suppliers typically add a profit margin, which can vary based on market demand, competition, and the supplier’s positioning within the industry.

How Do Price Influencers Affect the Cost of 5 Axis Lathes?

Several factors can influence the pricing of 5-axis lathes:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes usually result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQ terms that align with their production needs.

-

Specifications and Customization: Custom features or specifications can lead to higher costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials and the need for specific quality certifications can substantially impact pricing. Buyers should ensure that the selected supplier meets the necessary industry standards, particularly in regulated markets.

-

Supplier Factors: Established suppliers with a reputation for quality and reliability may charge a premium. However, they often provide better service and warranty terms, which can justify the higher cost.

-

Incoterms: Understanding Incoterms can help buyers assess their total landed cost. Different terms can shift responsibility and costs between the buyer and seller, affecting overall pricing.

What Are the Best Buyer Tips for Sourcing 5 Axis Lathes?

To optimize your sourcing strategy for 5-axis lathes, consider the following tips:

-

Effective Negotiation: Engage suppliers in open discussions about pricing, especially concerning bulk orders or long-term contracts. Leverage competitive quotes to negotiate better terms.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the upfront price. Consider factors like energy consumption, maintenance costs, and expected lifespan when making comparisons.

-

Understand Pricing Nuances for International Buyers: International buyers, particularly from regions like Africa and South America, should be mindful of currency fluctuations, import duties, and regional economic conditions that may affect pricing.

-

Research and Due Diligence: Conduct thorough research on potential suppliers. Look for reviews, case studies, and testimonials from other businesses, particularly those in your region or industry.

-

Be Prepared for Variability in Pricing: Pricing can vary significantly based on market conditions and supplier capabilities. Always request detailed quotes that outline all cost components for transparency.

By taking these insights into account, international B2B buyers can navigate the complexities of sourcing 5-axis lathes more effectively, ensuring they receive optimal value for their investment.

Alternatives Analysis: Comparing 5 axis lathe With Other Solutions

When evaluating manufacturing solutions, it’s essential for B2B buyers to consider various alternatives that can deliver similar capabilities to a 5-axis lathe. While 5-axis lathes offer advanced machining capabilities, other technologies may also meet specific operational needs, depending on factors like cost, complexity, and required precision. This analysis compares the 5-axis lathe with two viable alternatives: 4-axis lathes and multi-tasking CNC machines.

| Comparison Aspect | 5 Axis Lathe | 4 Axis Lathe | Multi-Tasking CNC Machine |

|---|---|---|---|

| Performance | High precision and versatility | Good precision, limited axes | Excellent performance, multi-functionality |

| Cost | Higher initial investment | Lower cost | High cost due to complexity |

| Ease of Implementation | Moderate complexity | Easier to set up and operate | Complex setup and training required |

| Maintenance | Regular maintenance needed | Generally lower maintenance | Higher maintenance demands |

| Best Use Case | Complex geometries and tight tolerances | Simpler parts, less complex jobs | High production environments needing flexibility |

What Are the Benefits and Drawbacks of 4-Axis Lathes Compared to 5-Axis Lathes?

4-axis lathes represent a more cost-effective alternative for manufacturers focusing on less complex parts. They provide a fourth axis that allows for rotation around the workpiece, enabling more intricate designs than traditional 2 or 3-axis machines. The lower cost and simpler operation make them appealing for small to medium-sized enterprises. However, they fall short in handling complex geometries and tight tolerances that a 5-axis lathe can manage, limiting their application in high-precision industries.

Why Consider Multi-Tasking CNC Machines Over 5-Axis Lathes?

Multi-tasking CNC machines combine turning, milling, and other machining functions within a single setup. They excel in high-volume production environments where flexibility and efficiency are paramount. The ability to perform multiple operations in one machine reduces cycle times and increases throughput. However, the complexity of these machines translates to higher costs and more significant maintenance requirements, which can be a barrier for smaller businesses or those with limited budgets.

How Can B2B Buyers Select the Right Machining Solution for Their Needs?

Choosing the right machining solution involves assessing specific operational requirements, including the types of parts being produced, production volumes, and budget constraints. Buyers should consider the complexity of their projects; if they require intricate designs and high precision, investing in a 5-axis lathe may be worthwhile. Conversely, if the focus is on simpler components, a 4-axis lathe could suffice. For businesses seeking versatility and efficiency in high-volume production, multi-tasking CNC machines present a compelling option, albeit at a higher initial cost and maintenance commitment. Ultimately, a thorough analysis of these factors will guide buyers toward the most suitable solution for their manufacturing needs.

Essential Technical Properties and Trade Terminology for 5 axis lathe

What Are the Key Technical Properties of a 5 Axis Lathe?

When investing in a 5 axis lathe, understanding its technical properties is crucial for making informed purchasing decisions. Here are some of the most critical specifications to consider:

-

Material Grade

The material grade of a 5 axis lathe affects its durability, precision, and overall performance. Common materials include high-strength alloys and carbon steel, which offer excellent wear resistance and stability during operation. B2B buyers should prioritize high-grade materials to ensure longevity and reliability, especially in demanding production environments. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. In the context of a 5 axis lathe, tighter tolerances mean higher precision in machined parts. Typical tolerance levels can range from ±0.001 inches to ±0.0001 inches. For industries such as aerospace and automotive, where precision is paramount, investing in machines that can maintain stringent tolerances is essential. -

Spindle Speed

The spindle speed, usually measured in revolutions per minute (RPM), indicates how fast the cutting tool rotates. Higher spindle speeds allow for quicker material removal and can improve overall productivity. B2B buyers should evaluate the spindle speed options based on their specific machining requirements and the materials they intend to process. -

Axis Configuration

The axis configuration of a 5 axis lathe determines its machining capabilities. A typical configuration includes three linear axes (X, Y, Z) and two rotational axes (A, B). Understanding the axis configuration is vital for determining the complexity of parts that can be machined and the lathe’s suitability for specific applications. -

Feed Rate

The feed rate refers to the speed at which the cutting tool advances into the workpiece, typically measured in inches per minute (IPM). An optimal feed rate is crucial for achieving the desired surface finish and dimensional accuracy. Buyers should assess the feed rate capabilities in relation to their production goals, as it directly impacts machining efficiency. -

Tooling Compatibility

Tooling compatibility is another important property, as it affects the versatility of the lathe. A machine that supports a wide range of tools allows for more diverse applications and can adapt to various production needs. Buyers should consider the availability and cost of compatible tooling when making their purchasing decision.

Which Trade Terms Are Commonly Used in the 5 Axis Lathe Industry?

Understanding industry jargon can facilitate smoother negotiations and transactions. Here are several common trade terms relevant to 5 axis lathes:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of lathes, buyers often seek out OEMs for high-quality, reliable machinery and components. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For 5 axis lathes, understanding MOQ is crucial for budget planning and inventory management, especially for companies looking to scale their operations. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is essential for B2B transactions as it allows buyers to compare pricing, delivery times, and other terms from multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers engaged in global sourcing of 5 axis lathes. -

CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by a computer. Understanding CNC technology is crucial for buyers as it directly influences the precision, efficiency, and capabilities of a 5 axis lathe. -

Lead Time

Lead time is the time taken between the initiation of a process and its completion. In the context of purchasing a 5 axis lathe, lead time can affect production schedules and inventory levels, making it a critical factor for manufacturers.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when purchasing a 5 axis lathe, ultimately enhancing their operational efficiency and competitiveness in the market.

Navigating Market Dynamics and Sourcing Trends in the 5 axis lathe Sector

What Are the Current Market Dynamics and Key Trends Affecting the 5 Axis Lathe Sector?

The 5 axis lathe market is experiencing significant growth driven by the increasing demand for precision machining in various industries, including aerospace, automotive, and medical devices. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking advanced manufacturing technologies that offer enhanced efficiency and reduced operational costs. The integration of Industry 4.0 technologies, such as IoT and AI, is transforming traditional machining processes, allowing for real-time data analytics and predictive maintenance. This shift not only improves productivity but also minimizes downtime, making it an attractive proposition for B2B buyers.

Emerging trends in sourcing include a growing preference for used and refurbished machinery, which offers cost-effective solutions without compromising on quality. This trend is particularly relevant for buyers in developing markets, where budget constraints are significant. Furthermore, the increasing focus on automation and robotics in manufacturing is reshaping the landscape of 5 axis lathes, as buyers look for machines that can seamlessly integrate with automated systems to enhance production capabilities.

Additionally, sustainability is becoming a vital consideration in purchasing decisions. B2B buyers are more inclined to source from suppliers who demonstrate a commitment to environmentally friendly practices, including energy-efficient machinery and recyclable materials. As a result, manufacturers are innovating to meet these demands, leading to a more competitive market.

How Does Sustainability and Ethical Sourcing Impact B2B Purchasing in the 5 Axis Lathe Sector?

Sustainability and ethical sourcing have emerged as critical factors influencing B2B purchasing decisions in the 5 axis lathe sector. The environmental impact of manufacturing processes is under increasing scrutiny, prompting buyers to consider the lifecycle of machinery and its effects on the planet. This includes evaluating energy consumption, waste generation, and the potential for recycling at the end of a machine’s life.

Ethical supply chains are also gaining prominence, as businesses aim to align with suppliers who prioritize fair labor practices and transparency. Buyers are increasingly seeking suppliers with certifications that demonstrate compliance with environmental standards, such as ISO 14001, and those that utilize ‘green’ materials in their manufacturing processes. These certifications not only enhance a supplier’s credibility but also appeal to companies looking to improve their own sustainability profiles.

For B2B buyers in regions like Africa and South America, where environmental regulations may be less stringent, this trend presents both an opportunity and a challenge. Suppliers who proactively adopt sustainable practices can differentiate themselves in the market, potentially gaining a competitive advantage. As sustainability becomes a non-negotiable aspect of procurement, suppliers must adapt to meet these evolving expectations.

What Is the Brief Evolution and History of 5 Axis Lathes?

The evolution of 5 axis lathes traces back to the early 20th century, with the advent of CNC (Computer Numerical Control) technology revolutionizing machining capabilities. Initially, machining centers were limited to three axes, which constrained manufacturing flexibility and precision. The introduction of 5 axis machining in the 1990s marked a significant advancement, enabling manufacturers to produce complex geometries in a single setup.

This innovation drastically reduced cycle times and improved accuracy, making 5 axis lathes a game-changer in industries demanding high precision, such as aerospace and medical devices. Over the years, advancements in control systems and software have further enhanced the capabilities of 5 axis lathes, allowing for more intricate designs and automation integration. Today, these machines represent the pinnacle of machining technology, catering to a global market that increasingly values efficiency, precision, and sustainability.

In summary, the 5 axis lathe sector is evolving rapidly, influenced by technological advancements and shifting buyer expectations. For international B2B buyers, understanding these dynamics is essential for making informed purchasing decisions that align with their operational goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of 5 axis lathe

-

1. How do I choose the right 5-axis lathe for my business needs?

Selecting the appropriate 5-axis lathe involves assessing your specific production requirements, such as part complexity, material type, and volume. Start by defining the dimensions and tolerances of the parts you intend to manufacture. Research various models and their capabilities, focusing on features like spindle speed, tooling options, and automation compatibility. Consult with suppliers who can provide insights on machine performance and reliability. Additionally, consider the total cost of ownership, including maintenance and operational costs, to ensure the selected lathe aligns with your budget and productivity goals. -

2. What are the key features to look for in a 5-axis lathe?

When evaluating a 5-axis lathe, prioritize features such as simultaneous 5-axis machining capabilities, high-speed spindles, and advanced control systems for precision. Look for models that offer versatile tooling options, allowing for various operations like milling and turning in one setup. Ensure the machine has robust build quality to handle heavy-duty tasks and minimize vibrations. Additionally, consider user-friendly interfaces and software compatibility that can facilitate easier programming and operation, which is essential for improving production efficiency. -

3. What are the typical lead times for ordering a 5-axis lathe?

Lead times for 5-axis lathes can vary significantly based on the manufacturer, model, and customization level. Generally, standard machines may take anywhere from 8 to 12 weeks for delivery, while customized units could take several months. It’s crucial to communicate with your supplier about specific timelines and any potential delays that may arise due to supply chain issues or demand fluctuations. Planning your purchase well in advance of production needs can help mitigate any operational disruptions. -

4. How can I ensure the quality of the 5-axis lathe I am purchasing?

To ensure quality, work with reputable suppliers and manufacturers known for their reliability and customer service. Request detailed specifications, certifications, and performance records of the lathe models you are considering. It’s also beneficial to visit the manufacturer’s facility or request a factory acceptance test (FAT) to evaluate the machine’s performance firsthand. Additionally, consider reviews and testimonials from other businesses that have purchased similar machines, as they can provide insights into long-term reliability and support. -

5. What is the minimum order quantity (MOQ) for a 5-axis lathe?

The MOQ for a 5-axis lathe often depends on the supplier and the specific model. Generally, most suppliers offer individual machines, but bulk orders may qualify for discounts. In some cases, suppliers may have minimum purchase requirements for certain accessories or tooling packages. When negotiating with suppliers, inquire about flexibility in order quantities, especially if you are a smaller business or are looking to test the market with a single unit before committing to larger orders. -

6. What payment terms are typically offered for 5-axis lathe purchases?

Payment terms for 5-axis lathes can vary based on the supplier’s policies and the size of the order. Common arrangements include a deposit upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer financing options or installment payments, especially for larger purchases. Always clarify payment terms upfront and ensure they align with your cash flow management. Understanding these terms will help you budget effectively and avoid unexpected financial strain. -

7. How do I verify the credibility of a 5-axis lathe supplier?

To verify a supplier’s credibility, conduct thorough research, including checking their business credentials, industry experience, and customer reviews. Look for suppliers with established reputations and those who have been in business for several years. Request references from previous clients and, if possible, arrange visits to their facilities to assess operations. Certifications like ISO can also indicate a commitment to quality standards. Engaging with trade associations or industry groups can further help in identifying trustworthy suppliers. -

8. What logistics considerations should I keep in mind when importing a 5-axis lathe?

When importing a 5-axis lathe, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Ensure you understand the import duties applicable in your country, as these can significantly affect the overall cost. Work with logistics partners who specialize in heavy machinery to ensure safe transport and handling. Additionally, plan for installation and setup, as these may require specialized skills or tools. Clear communication with your supplier about shipping schedules and documentation is also essential to avoid delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 5 Axis Lathe Manufacturers & Suppliers List

1. CNC Machines – 5 Axis Lathe Machines

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: 50% Off Used 5 Axis Lathe Machines – CNCMachines.com. 5 Axis CNC lathes combine turning and milling operations in one machine, allowing for full machining capabilities and reduced cycle times. Various brands available including Haas, Mazak, Okuma, Doosan, and more. Categories include Vertical Mach Center, CNC Lathe, Horizontal Mach Center, Router, EDM, and Manual Machining. Options available: Chip…

2. Haas CNC – Simultaneous 5-Axis Motion

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: This company, Haas CNC – Simultaneous 5-Axis Motion, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. DMG MORI – 5-Axis CNC Machines

Domain: us.dmgmori.com

Registered: 2013 (12 years)

Introduction: 5-Axis CNC Machines – DMG MORI

– Universal milling machines marking DMG MORI’s 5-axis world market leadership.

– Capable of 5-sided milling and 5-axis simultaneous machining.

– Accuracy of less than 15 µm.

– Travel capabilities up to 6,000 mm.

– Machining of workpieces weighing up to 40 tons.

– Applications in aerospace, automotive, and tool/mold making.

– Mill-Turn (FD) technology for turning on …

4. Brother – Compact Machining Center

Domain: machinetool.global.brother

Registered: 2017 (8 years)

Introduction: {“products”: [{“name”: “Compact Machining Center”, “series”: [“S Series”, “W Series (Wide Travel)”, “R Series (Pallet Changer)”, “U Series (Universal)”]}, {“name”: “Horizontal Compact Machining Center”, “series”: [“H Series (Horizontal)”]}, {“name”: “Multi Tasking Series”, “series”: [“M Series (Multi-Tasking)”]}, {“name”: “5-Axis Special SPEEDIO Option”, “options”: [“Rotary Table T-200A/T-200Ad”, …

5. Ellison Technologies – 5-Axis CNC Machining Centers

Domain: ellisontechnologies.com

Registered: 2005 (20 years)

Introduction: 5-Axis CNC Machining Centers represent advanced multi-axis manufacturing solutions that enable precision machining of complex parts. Key advantages include single-setup machining, superior surface finish, faster cycle times, and enhanced precision. The product line includes several series: DNM 5AX Series for high-precision machining, DVF Series for simultaneous machining, VCF 5AX Series with a mov…

6. Tsugami – B075-III 5-Axis Swiss Type CNC Lathe

Domain: tsugamiamerica.com

Registered: 2020 (5 years)

Introduction: {“model”:”Tsugami B075-III”,”type”:”5-axis Swiss Type CNC Automatic Lathe”,”maximum_bar_stock”:”.275\” (7mm)”,”axes”:”5″,”sliding_headstock_guide_bushing”:”YES”,”max_headstock_stroke_with_guide_bushing”:”2.76\” (70mm)”,”tool_positions”:”21″,”live_tool_positions”:”4″,”control”:”FANUC 0i-TF”,”main_spindle_speed”:”15,000 rpm”,”max_sub_spindle_speed”:”12,000 rpm”,”main_spindle_motor”:”2hp (1.1/1.5kW)”…

7. Methods Machine – 5-Axis CNC Machining Centers

Domain: methodsmachine.com

Registered: 1996 (29 years)

Introduction: 5-Axis CNC Machining Centers minimize multiple setups and material handling, enabling the manufacturing of complex parts. Key features include:

– Faster machining and reduced part-handling

– Precision for various part shapes and sizes

– Improved throughput and cash flow for manufacturers

– Single setups for complex part shapes without moving across multiple workstations

– Higher productivity and q…

Strategic Sourcing Conclusion and Outlook for 5 axis lathe

The strategic sourcing of 5-axis lathes offers significant advantages for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. The integration of turning and milling operations in a single machine not only streamlines production processes but also minimizes handling times and reduces cycle times. This capability is crucial for businesses aiming to enhance efficiency and competitiveness in an increasingly global marketplace.

Buyers should prioritize partnerships with reputable suppliers who can provide quality machines, maintenance support, and training, ensuring that their investment yields optimal performance. Additionally, considering the availability of used machines can present cost-effective options without compromising on quality.

As the demand for precision machining continues to grow, embracing advanced technologies like 5-axis lathes will be vital for staying ahead in the industry. For businesses looking to innovate and expand their operational capabilities, now is the time to explore strategic sourcing options. Engage with trusted suppliers to secure the best machines that align with your production needs and future growth aspirations. Your commitment to leveraging advanced machinery will not only enhance your manufacturing prowess but also position you favorably in a competitive global landscape.