Contents

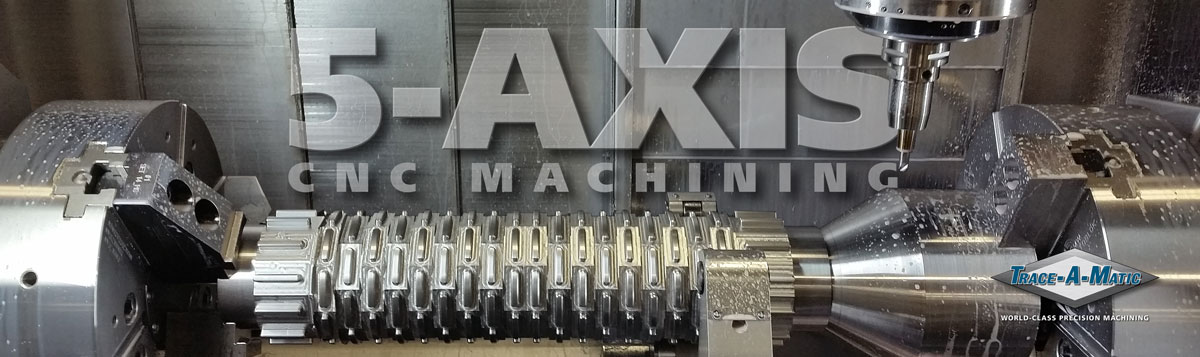

Manufacturing Insight: 5 Axis Cnc Service

Precision Engineered Solutions Through Advanced 5-Axis CNC Machining

Honyo Prototype delivers exceptional manufacturing capabilities for the most demanding prototyping and low-volume production requirements through our state-of-the-art 5-axis CNC machining services. Our integrated fleet of high-precision multi-axis machining centers enables the efficient production of highly complex geometries with superior surface finishes and stringent tolerances, all within a single setup. This eliminates costly secondary operations and fixture changes, significantly reducing lead times while enhancing part accuracy and consistency for critical applications across aerospace, medical device, defense, and advanced industrial sectors.

We specialize in machining a comprehensive range of engineering materials including aerospace-grade aluminum alloys, titanium, stainless steels, high-performance plastics, and composites. Our engineering team leverages simultaneous 5-axis motion to tackle intricate contours, deep cavities, and undercuts that are impractical or impossible with conventional 3-axis methods, ensuring optimal part integrity and performance. The inherent efficiency of 5-axis machining translates directly to reduced production costs and accelerated time-to-market for your most challenging components.

Key 5-Axis Machining Capabilities at Honyo Prototype

| Capability | Specification | Typical Application Benefit |

|---|---|---|

| Simultaneous Motion | Full 5-axis interpolation | Complex organic shapes, impellers, molds |

| Tolerance Control | ±0.0002″ (5µm) standard | Critical sealing surfaces, precision assemblies |

| Material Range | Metals, Plastics, Composites | Versatile solution for diverse project needs |

| Max Work Envelope | 20″ x 30″ x 25″ (508 x 762 x 635mm) | Mid-size complex components |

| Surface Finish | As low as Ra 8 µin (0.2 µm) | Aesthetic & functional high-quality finishes |

Accelerate your development cycle with Honyo Prototype’s seamless integration of advanced manufacturing technology and customer-centric processes. Access real-time pricing and lead time estimates instantly through our proprietary Online Instant Quote platform, designed specifically for engineering professionals requiring rapid feedback on complex part manufacturability. Submit your 3D CAD model today to experience the precision, speed, and technical expertise that define Honyo Prototype’s commitment to solving your most intricate manufacturing challenges.

Technical Capabilities

5-Axis CNC Service – Technical Specifications

Honyo Prototype offers high-precision 3-axis, 4-axis, and 5-axis CNC milling services combined with CNC turning to support complex geometries and tight-tolerance components across a range of engineering materials. Our advanced machining centers ensure superior surface finish, accuracy, and repeatability for prototyping and low-to-mid volume production.

Key Capabilities Overview

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning (2/4-axis), Mill-Turn |

| Positioning Accuracy | ±0.005 mm (X, Y, Z axes) |

| Repeatability | ±0.002 mm |

| Tolerance Capability | Standard: ±0.025 mm; Tight Tolerance: ±0.005 mm (achievable with inspection) |

| Surface Finish | As-machined: 3.2 µm (Ra); Fine finish options down to 0.8 µm (Ra) with polishing |

| Max Work Envelope (5-axis) | 1200 mm × 800 mm × 600 mm (X×Y×Z) |

| Spindle Speed | Up to 24,000 RPM (high-speed options available) |

| Tooling System | CAT 40 / HSK-63; Automatic Tool Changer (ATC) with 24–40 tool capacity |

| Probing Systems | On-machine touch probes for in-process inspection and alignment |

| CMM & Metrology | Coordinate Measuring Machine (CMM), optical comparators, micrometers, gauge blocks |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6, 66), POM, PC, PEEK, and other engineering plastics |

| Aluminum Machining | High-speed milling with optimized feeds; burr-free edges; anodizing-ready finishes |

| Steel Machining | Hardened to 45 HRC; skiving and finishing passes for tight geometry control |

| Plastic Machining (ABS, Nylon) | Low-residue tool paths; non-marring fixturing; humidity-controlled storage to prevent warpage |

| Coolant & Lubrication | High-pressure coolant for metals; air blast and minimal lubrication for plastics |

| CAD/CAM Compatibility | Accepts STEP, IGES, X_T, SLDPRT, Parasolid; CAM programming via Mastercam, Hypermill, Fusion 360 |

| Lead Times | Prototype: 5–7 days; Production: 10–15 days (varies with complexity) |

| Certifications | ISO 9001:2015 compliant processes; first article inspection (FAI) available |

All components are machined in-house with full traceability, process documentation, and optional First Article Inspection (FAI) or PPAP support. Our 5-axis capability enables single-setup machining of complex organic shapes, deep cavities, and compound angles—ideal for aerospace, medical, and automotive applications requiring tight tolerance and high repeatability.

From CAD to Part: The Process

Honyo Prototype 5-Axis CNC Service Workflow

Honyo Prototype delivers precision 5-axis CNC machining through a rigorously optimized digital workflow designed for speed, accuracy, and manufacturability. The process begins when a client uploads a native CAD file (STEP, IGES, or Parasolid formats preferred) via our secure online portal. Our proprietary AI quoting engine immediately analyzes geometric complexity, material requirements, tolerance specifications, and feature density. This system cross-references real-time machine availability, tooling constraints, and material costs from our integrated ERP, generating a technically validated quote within 90 seconds—significantly faster than industry averages while eliminating manual quoting errors.

Following quote acceptance, the design enters our automated Design for Manufacturability (DFM) phase. Unlike basic rule-checking tools, Honyo’s DFM platform combines algorithmic analysis with contextual engineering intelligence. It identifies potential issues such as thin wall instability, non-optimal tool access, or tolerance stack-ups that could compromise part integrity or increase costs. Critical findings are escalated to a dedicated manufacturing engineer who collaborates with the client to resolve conflicts—providing specific revision recommendations rather than generic warnings. This step typically reduces production delays by 35% by preempting post-CAM rework.

Approved designs advance to production on our HAAS UMC-750 and DMG MORI DMU 5-axis vertical machining centers, all equipped with trunnion tables and high-precision Renishaw probes. Programs are generated using hyperMILL software with collision avoidance validation, and first-article inspection occurs in-house via Zeiss CONTURA CMMs. We maintain ±0.005 mm tolerances on complex geometries and support aerospace-grade alloys (Inconel 718, Ti-6Al-4V), engineering plastics, and hardened tool steels. Production batches undergo continuous in-process verification, with real-time machine telemetry monitored by our MES to ensure adherence to thermal compensation protocols and surface finish specifications.

Final delivery includes comprehensive documentation and traceability. All parts ship with first-article inspection reports, material certifications, and a digital process log. Honyo’s logistics system provides end-to-end tracking with defined milestones:

| Stage | Timeline | Quality Gate |

|---|---|---|

| CAD Upload to Quote | <90 seconds | AI validation against 200+ geometric rules |

| DFM Resolution | 4–12 hours | Engineer-signoff on critical feature adjustments |

| Production | 3–10 business days | In-process CMM verification at 25%/75% completion |

| Delivery | Pre-scheduled | ISO 17100-compliant packaging with humidity control |

This closed-loop process ensures dimensional accuracy for complex contours unattainable with 3-axis methods while maintaining our 99.2% on-time delivery rate. Clients receive not just machined parts, but a validated manufacturing record suitable for regulatory submissions in medical, aerospace, and robotics applications.

Start Your Project

Looking for precision 5-axis CNC machining services? Honyo Prototype delivers high-accuracy, complex part manufacturing with tight tolerances for aerospace, medical, and industrial applications. Our state-of-the-art facility in Shenzhen ensures fast turnaround and consistent quality.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory Location: Shenzhen, China

Let’s collaborate to bring your most demanding designs to life.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.