Guide Contents

Project Insight: 5 Axis Cnc Service

Manufacturing Insight: 5-Axis CNC Service – Accelerating Innovation with Unmatched Precision

In today’s hyper-competitive product development landscape, speed and precision aren’t just advantages—they’re existential requirements. For hardware startups and product engineers, every day of delay risks market share, while tolerance errors can derail entire projects. Honyo Prototype redefines manufacturing as a strategic accelerator, leveraging 5-axis CNC technology to transform complex designs into high-precision parts with unmatched efficiency.

Why Speed & Precision Are Non-Negotiable in Modern Prototyping

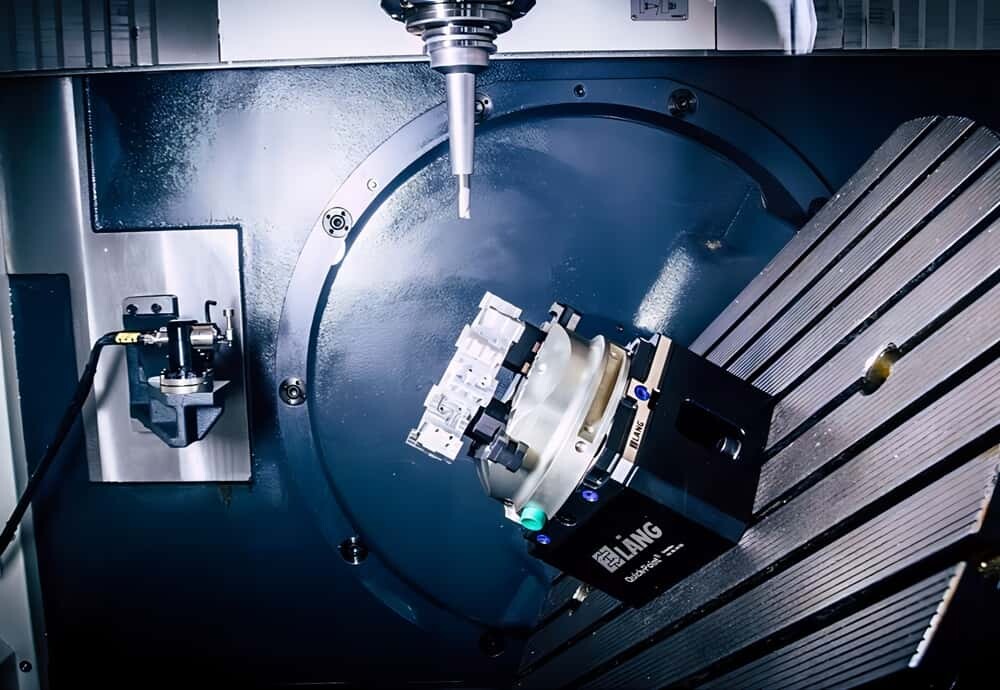

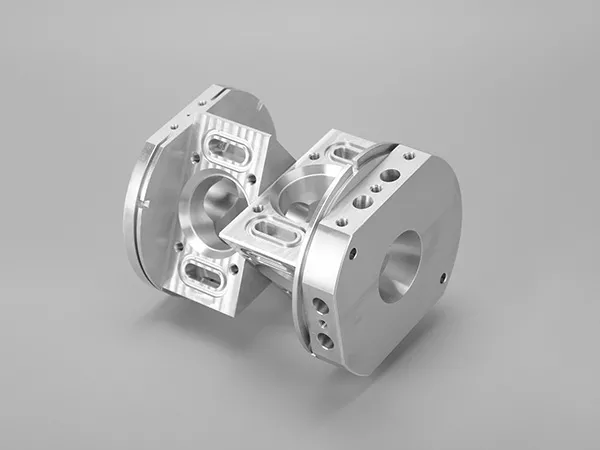

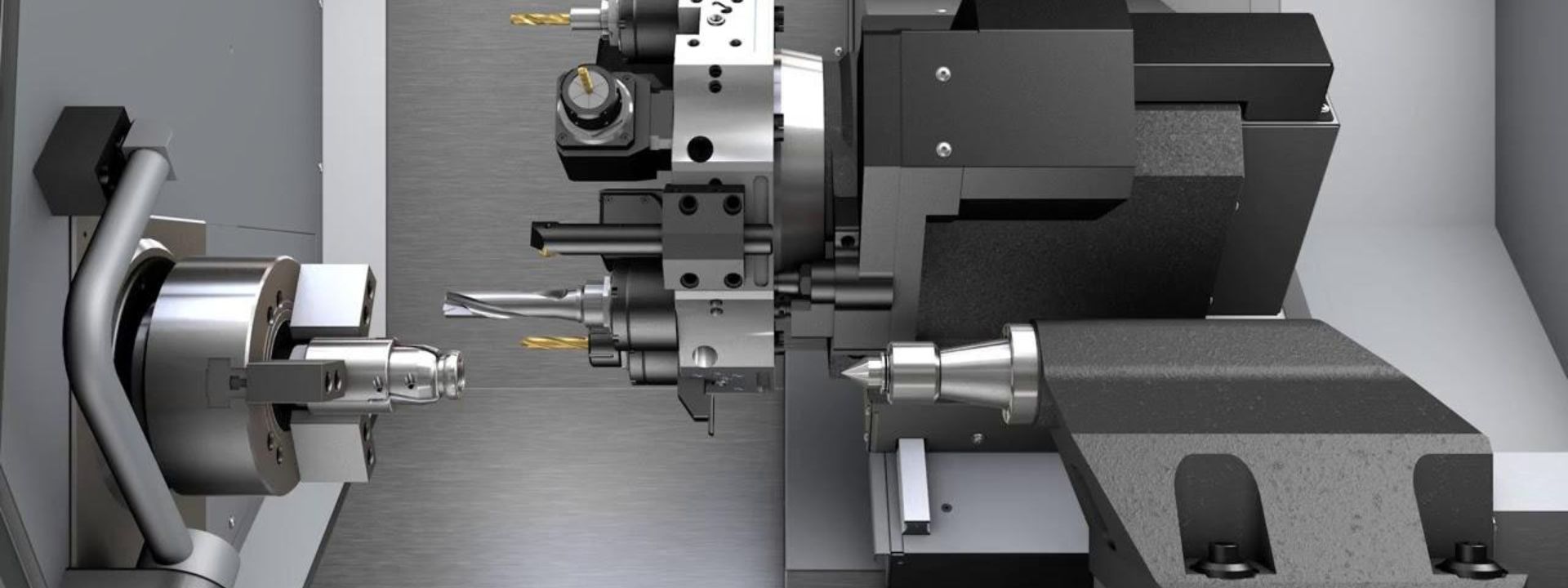

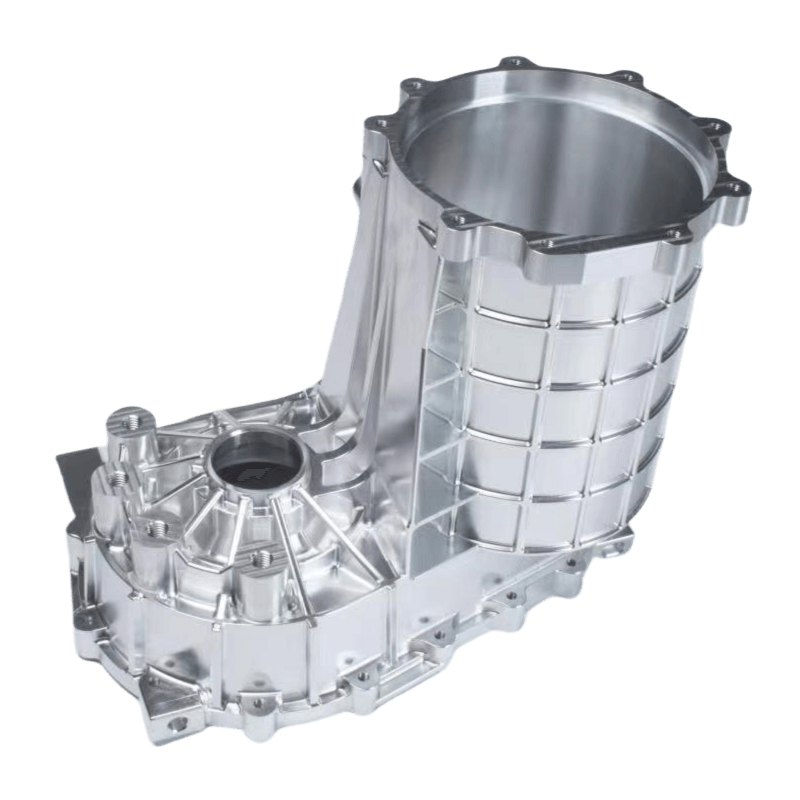

Complex geometries demand multi-axis precision: Traditional 3-axis machining often requires multiple setups, increasing error risk and lead times. 5-axis CNC eliminates secondary operations, ensuring intricate features are machined in a single setup.

Tight tolerances = functional reliability: ±0.01mm accuracy ensures prototypes behave like final production parts, reducing costly design iterations and validation failures.

Time-to-market pressure: Startups face razor-thin windows to capture market opportunities. Delayed prototypes mean delayed revenue – and lost competitive edge.

How Honyo Prototype Delivers: Digital Manufacturing Partner for Next-Gen Prototyping

✨ Online Instant Quote: Our AI-powered platform provides real-time pricing and DFM feedback within seconds – no more waiting days for quotes. Simply upload your CAD file, and get actionable insights instantly.

⚡️ AI-Optimized Process Planning: Machine learning algorithms analyze your design to optimize toolpaths, minimize setup time, and maximize material efficiency – cutting lead times by up to 30% while maintaining ±0.01mm tolerances.

🚀 72-Hour Prototype Turnaround: From CAD to certified parts, our Shenzhen-based facility leverages 5-axis automation for rapid, error-free production. Scale seamlessly to full production runs without compromising quality.

🔧 End-to-End Precision Engineering: Whether you need functional prototypes or end-use components, our 5-axis CNC service ensures consistent quality across all stages – no secondary operations, no rework costs.

Founded by Susan Leo, Honyo Prototype merges deep manufacturing expertise with cutting-edge digital innovation to turn your ideas into reality – faster, smarter, and more precisely than ever before.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Multi-Axis Precision Engineering

3/4/5-Axis Simultaneous Machining: Eliminate manual repositioning errors and reduce lead times by up to 40% with seamless multi-axis control for complex geometries.

Tight Tolerances (±0.01mm): Consistently achieve sub-10-micron precision for functional prototypes and end-use parts in aerospace, medical, and industrial applications.

Scalable Production from Prototyping to Mass Production

Flexible MOQs: Start with a single prototype and scale to 10,000+ parts without additional setup costs—perfect for startups iterating rapidly.

Rapid Changeover Technology: Minimize downtime between projects with automated tooling and optimized workflows for faster turnaround.

ISO-Certified Quality Assurance

ISO 9001:2015 Certified: Rigorous quality control from raw material inspection to final part verification, ensuring compliance with global standards.

Advanced Metrology: Utilizing CMM, laser scanning, and in-process monitoring to guarantee every dimension meets exact specifications.

AI-Powered Service Experience

Instant Online Quoting: AI-driven cost estimates in seconds with transparent, no-hassle quotes—no hidden fees, no delays.

AI-Driven DFM Optimization: Proactive suggestions to reduce costs and improve manufacturability before production begins.

Expedited Turnaround: Prototypes delivered in 24-48 hours, with express options for critical deadlines—precision without compromise.

Materials & Surface Finishes

Material Options & Finishes for Precision 5-Axis Machining

At Honyo Prototype, our 5-axis CNC services combine precision engineering with versatile material and finish options to deliver functional prototypes and end-use parts tailored to your exact specifications. Leverage our AI-powered platform for instant quotes and expert guidance on material selection—ensuring optimal performance, cost-efficiency, and rapid production.

Premium Material Selection for Every Application

Aluminum 6061: Lightweight, excellent corrosion resistance, and superior machinability. Ideal for aerospace components, automotive parts, and structural prototypes where weight savings are critical.

Aluminum 7075: High-strength alloy with exceptional fatigue resistance. Perfect for high-load applications like military equipment, drone frames, and high-performance sporting goods.

Stainless Steel 304: Corrosion-resistant, non-magnetic, and FDA-compliant. Best for medical devices, food processing equipment, and outdoor hardware requiring durability.

Stainless Steel 316: Enhanced chloride/acid resistance for marine environments and chemical processing. Used in biomedical implants and offshore engineering components.

Brass: Outstanding electrical conductivity and aesthetic appeal. Common in electrical connectors, valve components, and decorative fixtures.

PEEK: High-temperature stability (250°C+), chemical inertness, and biocompatibility. Critical for aerospace, automotive, and medical implants requiring extreme durability.

Surface Finishes to Elevate Performance & Aesthetics

Anodizing: Enhances aluminum’s wear resistance and electrical insulation. Offers vibrant color customization (black, blue, red) for aerospace and consumer electronics housings.

Painting: Custom color matching and UV-resistant coatings for metals/plastics. Ideal for visual prototypes and consumer-facing products requiring brand-specific aesthetics.

Polishing: Mirror-like surface finish (Ra ≤ 0.1μm) for optical instruments, medical devices, and luxury product prototypes where precision and smoothness are non-negotiable.

How to Choose the Right Material for Your Project

Mechanical Requirements: Prioritize strength-to-weight ratio (Al 7075) or flexibility (PEEK) based on functional demands.

Environmental Exposure: Marine/chemical environments? Opt for SS 316 or PEEK. General use? SS 304 or Al 6061.

Electrical Needs: Conductive parts? Brass or aluminum. Insulating needs? PEEK is the gold standard.

Cost vs. Performance: Balance budget with technical specs—our AI platform analyzes your design to recommend cost-optimized materials without compromising quality.

Regulatory Compliance: Medical or food-grade applications? SS 316 or PEEK ensure FDA/ISO certification.

💡 Ready to optimize your design?

Get an instant quote online in seconds—our AI-powered platform cross-references material properties, finish costs, and lead times to deliver a tailored solution. All projects ship in 3–5 business days, even with complex finishes. No fixed asset investment. Zero compromise on precision.“Precision isn’t just a metric—it’s our promise.”

— Susan Leo, Founder of Honyo Prototype

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined precision manufacturing with a seamless, AI-driven workflow that delivers functional prototypes and end-use parts faster than traditional methods. Here’s how:

1. Upload Your CAD File

Drag-and-drop simplicity: Submit STEP, STL, or IGES files instantly—no technical expertise required.

AI-powered preprocessing: Our platform analyzes geometry and tolerances in seconds, preparing for precise quoting and production planning.

2. Get Instant, Transparent Quote

Real-time pricing: AI engine calculates cost breakdown within 10 seconds—no hidden fees or manual delays.

Customizable options: See live pricing for materials, finishes, and lead times to optimize your budget before production begins.

3. Proactive DFM Analysis

Automated design checks: Identify potential manufacturing issues (e.g., undercutting, wall thickness) before production begins.

Expert collaboration: Our engineers provide actionable feedback to enhance part functionality and reduce costs—ensuring first-time-right manufacturing.

4. Precision Production & Real-Time Tracking

Shenzhen-based 5-axis CNC: Achieve ±0.01mm tolerances with state-of-the-art machining for functional prototypes and end-use parts.

Full visibility: Track your order from machining to delivery via our customer portal—no surprises, just results.

Ready to accelerate your product development?

Honyo’s AI-powered workflow delivers high-precision parts with unmatched speed and transparency—no compromises. Start your project today.

Start Your Project with Honyo

Start Your Project with Honyo: Precision CNC Machining, Simplified

Engineer your next breakthrough with Honyo’s cutting-edge 5-axis CNC solutions—where innovation meets precision, speed, and unmatched reliability.

Instant, AI-Powered Quoting

Get real-time pricing in seconds with our AI-driven online platform—no waiting, no guesswork

Transparent cost breakdowns tailored to your project specs, eliminating hidden fees

Uncompromising Precision

Achieve ±0.01mm tolerances for functional prototypes and end-use parts

5-axis machining for complex geometries, reducing assembly steps and enhancing part integrity

Speed That Keeps You Competitive

Prototype to production in as little as 3 days

Agile workflow designed for hardware startups’ fast-paced development cycles

Meet Susan Leo & Our Expert Team

Founder-led specialists with decades of precision manufacturing experience

Dedicated support from initial design review to final delivery

Contact Us Today:

Email: [email protected]

Phone: +86 139 2843 8620

Facilities: Shenzhen & Dongguan (visits available by appointment)

Ready to accelerate your product development? Let’s build the future—faster, smarter, and with precision that sets the standard.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.