Introduction: Navigating the Global Market for 5 axis cnc router for sale

In today’s competitive landscape, sourcing the right 5 axis CNC router for sale can be a daunting challenge for international B2B buyers. With the rapid evolution of technology and varying manufacturing standards across regions, navigating this complex market requires a strategic approach. This guide serves as a comprehensive resource, addressing critical aspects such as machine types, applications, supplier vetting processes, and cost considerations.

By exploring the diverse functionalities of 5 axis CNC routers, buyers can discover how these machines enhance precision, efficiency, and versatility in manufacturing processes across various industries. From woodworking and aerospace to automotive and metalworking, understanding the specific applications of these routers is crucial for making informed purchasing decisions.

This guide is tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Germany. By equipping decision-makers with actionable insights and best practices, we aim to empower them to identify reliable suppliers, negotiate favorable terms, and ultimately invest in machinery that aligns with their business goals. Whether you’re looking to upgrade your production capabilities or expand into new markets, our guide provides the knowledge necessary to navigate the global landscape of 5 axis CNC routers confidently.

Understanding 5 axis cnc router for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SmartShop 5 Axis | Robust steel frame, automatic tool changer, versatile material handling | Woodworking, cabinetry, sign making | Pros: Economical, versatile, strong support. Cons: Limited to specific materials. |

| DMS Essentials | Customizable design, heavy-duty, compact footprint | Aerospace, automotive, composites | Pros: Highly adaptable, space-efficient. Cons: Initial investment can be high. |

| Glacier 5 | Fully enclosed design, high precision, advanced controls | Aerospace components, complex parts | Pros: Excellent accuracy, continuous operation. Cons: May require specialized training. |

| Denali 5 | Mid-range trim center, quick-change fixture system | Wood, foam, composites processing | Pros: Efficient for small to medium batches. Cons: Limited heavy-duty capabilities. |

| Redwood 5 | Open architecture, customizable, high-speed performance | Diverse manufacturing sectors | Pros: Flexibility, robust design. Cons: Larger footprint may require more space. |

What Are the Key Characteristics of the SmartShop 5 Axis CNC Router?

The SmartShop 5 Axis CNC router is designed for versatility and precision, featuring a robust all-steel frame and an automatic tool changer. It excels in woodworking, cabinetry, and sign-making applications, allowing businesses to handle various materials efficiently. Buyers appreciate its economical price point and strong customer support, though it may be limited to specific material types, which could restrict some applications.

How Does the DMS Essentials 5-Axis Router Stand Out in Customization?

DMS Essentials routers are known for their heavy-duty construction and customizable designs, making them ideal for high-production environments in sectors like aerospace and automotive. The compact footprint allows for efficient use of floor space, which is crucial for manufacturers with limited room. While they offer excellent adaptability, the initial investment can be substantial, necessitating careful budget planning.

Why Choose the Glacier 5 for High-Precision Manufacturing?

The Glacier 5 is engineered for precision and versatility, featuring a fully enclosed architecture that enhances safety and minimizes contamination. It is particularly suited for intricate aerospace components and complex automotive parts. This machine provides unmatched accuracy and speed, making it a top choice for industries requiring high-quality output. However, users may need specialized training to fully utilize its advanced capabilities.

What Benefits Does the Denali 5 Offer for Smaller Operations?

The Denali 5 is a mid-range CNC router designed as a “Trim Center,” allowing for efficient processing of light materials like wood and foam. Its quick-change fixture system enhances productivity, making it suitable for small to medium-sized operations. While it is efficient for various applications, its limitations in handling heavy-duty materials may deter some buyers looking for more robust options.

How Does the Redwood 5 Cater to Diverse Manufacturing Needs?

The Redwood 5 combines high-speed performance with an open architecture design that allows for flexibility across various industries. Its robust construction ensures durability for continuous operations, while customizable options make it adaptable to specific production needs. Although it offers significant advantages, its larger footprint may require additional space, which is an essential consideration for potential buyers.

Key Industrial Applications of 5 axis cnc router for sale

| Industry/Sector | Specific Application of 5 axis cnc router for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | Enhanced accuracy and reduced material waste | Need for high-speed capabilities and compatibility with composites |

| Furniture and Cabinetry | Custom furniture design and production | Increased design flexibility and reduced lead times | Demand for versatility in materials and ease of operation |

| Automotive | Production of complex parts and prototypes | High precision and ability to handle diverse materials | Robust construction and support for continuous operation |

| Signage and Display | Creation of intricate signage and promotional displays | Ability to achieve detailed designs and faster outputs | Requirements for software compatibility and high-speed cutting |

| Art and Sculptures | Artistic carving and intricate designs | Unique product offerings and enhanced creativity | Need for custom tooling options and support for various materials |

How is a 5 Axis CNC Router Used in Aerospace Manufacturing?

In the aerospace sector, 5-axis CNC routers are utilized for manufacturing precision components, such as brackets and housings that require intricate designs and high tolerances. These machines can handle complex geometries that traditional routers cannot, reducing material waste and improving production efficiency. International buyers must consider the machine’s compatibility with advanced materials like composites and its ability to operate at high speeds, which is critical for meeting stringent aerospace standards.

What Role Does a 5 Axis CNC Router Play in Furniture and Cabinetry?

In the furniture and cabinetry industry, a 5-axis CNC router is essential for custom furniture design and production. It allows manufacturers to create intricate joinery and detailed carvings that enhance the aesthetic appeal of furniture pieces. The flexibility of these machines helps businesses reduce lead times and adapt to changing customer demands. Buyers should prioritize sourcing machines that can process various materials, including hardwoods and softwoods, while ensuring ease of use for operators.

How is a 5 Axis CNC Router Beneficial in Automotive Production?

The automotive industry leverages 5-axis CNC routers for producing complex parts and prototypes, including brackets, panels, and molds. These routers deliver high precision, accommodating the diverse range of materials used in automotive manufacturing, from plastics to metals. For international buyers, it’s vital to consider the machine’s durability and support for continuous operation, as well as its ability to integrate with existing production lines to enhance efficiency.

How Does a 5 Axis CNC Router Enhance Signage and Display Production?

In the signage and display sector, 5-axis CNC routers are employed to create intricate signage and promotional displays that require detailed designs. The capability to cut, carve, and engrave with precision allows businesses to produce high-quality products that stand out in a competitive market. Buyers should focus on sourcing routers that offer fast cutting speeds and compatibility with various materials, including acrylics and woods, to maximize production efficiency.

Why is a 5 Axis CNC Router Ideal for Artistic Carving?

For artists and sculptors, a 5-axis CNC router provides the tools necessary to create intricate carvings and sculptures with unmatched detail. These machines enable the production of unique art pieces that can be customized according to client specifications, enhancing creative possibilities. Buyers should seek routers that offer customizable tooling options and support for various materials, ensuring that their artistic vision can be fully realized.

3 Common User Pain Points for ‘5 axis cnc router for sale’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right 5-Axis CNC Router for Specific Needs

The Problem: B2B buyers often struggle with selecting the right 5-axis CNC router that meets their specific production needs. Given the wide range of applications—from woodworking to metal fabrication—buyers are frequently overwhelmed by the technical specifications and features of various models. They may worry about investing in a machine that won’t perform optimally for their intended tasks, leading to wasted resources and potential production delays.

The Solution: To effectively select the appropriate 5-axis CNC router, buyers should first conduct a thorough needs assessment. This includes identifying the primary materials they will be working with (e.g., wood, plastics, metals) and the specific types of operations they plan to perform (e.g., cutting, milling, engraving). Once this is established, buyers can consult with manufacturers or distributors to discuss their needs and get tailored recommendations. It’s also advisable to request demonstrations or trial periods for machines under consideration, allowing buyers to assess performance in real-world conditions. Additionally, reviewing case studies or testimonials from similar businesses can provide insights into how specific models have performed in comparable applications.

Scenario 2: Concerns Over Maintenance and Downtime of CNC Routers

The Problem: Many buyers worry about the maintenance requirements and potential downtime associated with 5-axis CNC routers. Concerns about the complexity of repairs, availability of spare parts, and the skills required for regular maintenance can lead to anxiety over operational continuity. For companies in high-demand industries, even a small amount of downtime can lead to significant financial losses.

The Solution: To mitigate these concerns, it is crucial to choose a 5-axis CNC router from a reputable manufacturer that offers robust support services, including maintenance packages and readily available spare parts. Buyers should inquire about the warranty options and service agreements that include routine maintenance checks. Additionally, investing in operator training can empower staff to perform basic troubleshooting and maintenance tasks, reducing reliance on external service providers and minimizing downtime. Establishing a proactive maintenance schedule can further enhance machine longevity and performance, ensuring that the router remains a reliable asset in the production process.

Scenario 3: High Initial Investment and Financing Options

The Problem: The high initial cost of purchasing a 5-axis CNC router can be a significant barrier for many B2B buyers, especially smaller manufacturers or startups. The pressure to make a large capital investment can lead to hesitation, as buyers weigh the potential return on investment (ROI) against their current financial situation.

The Solution: To address the financial aspect, buyers should explore flexible financing options that manufacturers often provide. Many CNC router suppliers offer leasing or financing plans that spread the cost over time, making it more manageable. Buyers should also conduct a detailed ROI analysis that considers not only the direct cost of the machine but also the efficiency gains and increased production capabilities it will bring. Engaging with financial advisors who specialize in manufacturing equipment can provide further clarity on the best financing strategies. Additionally, buyers can look into potential grants or government incentives available for investing in advanced manufacturing technology, which can alleviate some of the financial burdens associated with the initial purchase.

Strategic Material Selection Guide for 5 axis cnc router for sale

What Are the Key Properties of Common Materials for 5-Axis CNC Routers?

When selecting materials for a 5-axis CNC router, it is essential to consider their properties, advantages, and limitations. This ensures optimal performance and suitability for various applications. Below are analyses of four common materials used in conjunction with 5-axis CNC routers.

How Does Aluminum Perform in 5-Axis CNC Routing?

Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. Its excellent machinability allows for high-speed cutting, making it ideal for intricate designs and components. Aluminum typically has a temperature rating of around 660°C, which is sufficient for most machining applications.

Pros: Aluminum is durable, has a good strength-to-weight ratio, and is relatively inexpensive compared to other metals. It is also non-toxic and recyclable, making it an environmentally friendly choice.

Cons: While aluminum is resistant to corrosion, it can be prone to scratching and denting. Additionally, the cost can vary based on alloy composition, which may complicate budgeting for projects.

Impact on Application: Aluminum is suitable for applications like aerospace components, automotive parts, and consumer electronics. Its compatibility with various media types allows for diverse product offerings.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions. In regions like Europe and South America, specific alloy grades may be preferred based on local manufacturing practices.

What Are the Benefits of Using Wood in CNC Routing?

Wood is a traditional material that remains highly popular for CNC routing due to its aesthetic appeal and ease of machining. It is available in various species, each with unique properties. Wood typically has a lower density, making it easier to cut and shape.

Pros: Wood is readily available and cost-effective, especially in regions with abundant forestry. It offers excellent durability and can be finished in numerous ways to enhance its appearance.

Cons: Wood is susceptible to moisture and can warp or swell if not properly treated. Additionally, it may require more frequent maintenance compared to metals.

Impact on Application: Wood is ideal for furniture making, cabinetry, and decorative items. Its compatibility with various finishes allows for a wide range of end products.

Considerations for International Buyers: Compliance with local regulations regarding sustainable forestry practices is crucial. In Europe, for example, buyers may need to adhere to the EU Timber Regulation (EUTR).

How Does Composite Material Compare for CNC Applications?

Composite materials, such as fiberglass or carbon fiber, are increasingly popular in high-performance applications. They offer excellent strength-to-weight ratios and can withstand high temperatures, making them suitable for demanding environments.

Pros: Composites are lightweight, highly durable, and resistant to corrosion. They can be engineered to meet specific performance requirements, making them versatile for various applications.

Cons: The cost of composite materials can be significantly higher than traditional materials like wood or aluminum. Additionally, machining composites can be more complex and may require specialized tools.

Impact on Application: Composites are commonly used in aerospace, automotive, and marine industries. Their unique properties allow for innovative designs that would be impossible with traditional materials.

Considerations for International Buyers: Buyers should be aware of the specific standards for composite materials, such as ASTM D3039 for tensile properties. Understanding local market preferences for composites is also essential, particularly in regions with advanced manufacturing sectors like Germany.

What Role Does Steel Play in CNC Routing Applications?

Steel is renowned for its strength and durability, making it a preferred choice for heavy-duty applications. It can withstand high pressures and temperatures, with various grades available for different applications.

Pros: Steel is incredibly strong and can handle demanding machining tasks. It is also widely available and can be sourced at competitive prices.

Cons: The weight of steel can complicate handling and transportation. Additionally, it is susceptible to rust if not properly coated or treated.

Impact on Application: Steel is commonly used in manufacturing machinery, automotive components, and structural applications. Its robustness allows for precise machining of complex parts.

Considerations for International Buyers: Compliance with international standards such as ASTM A36 for structural steel is vital. Buyers in the Middle East and Africa should also consider the availability of specific steel grades and their local sourcing options.

Summary Table of Material Selection for 5-Axis CNC Routers

| Material | Typical Use Case for 5 axis cnc router for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Prone to scratching and denting | Medium |

| Wood | Furniture making, cabinetry | Readily available and cost-effective | Susceptible to moisture and warping | Low |

| Composite | Aerospace, automotive, marine applications | Excellent strength-to-weight ratio | High cost and complex machining requirements | High |

| Steel | Machinery manufacturing, automotive components | Incredibly strong and durable | Heavy and susceptible to rust | Medium |

This strategic material selection guide provides valuable insights for B2B buyers considering 5-axis CNC routers, ensuring informed decisions based on material properties, advantages, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 5 axis cnc router for sale

What Are the Main Stages in the Manufacturing Process of 5-Axis CNC Routers?

The manufacturing of 5-axis CNC routers involves several critical stages, each designed to ensure that the final product meets the necessary precision and quality standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage involves selecting high-grade materials such as high-strength steel or aluminum alloys, which provide the necessary durability and stability for CNC routers. Materials are often pre-cut to size, ensuring they meet specific dimensional requirements before moving on to forming. Advanced techniques like laser cutting or water jet cutting may be employed to achieve precise shapes with minimal waste.

Forming

During the forming stage, the prepared materials undergo various processes to create the components of the CNC router. Techniques such as CNC machining, welding, and bending are commonly utilized. For instance, the frame and gantry components are typically welded together to form a rigid structure capable of withstanding significant operational stresses. Precision machining ensures that all parts fit together seamlessly, which is crucial for the machine’s accuracy.

Assembly

Once the individual components are formed, the assembly process begins. This stage involves integrating various elements, including the spindle, control systems, and the vacuum table. Each component must be aligned and calibrated to ensure optimal performance. Advanced robotic systems may assist in this stage, promoting consistency and reducing human error. Furthermore, manufacturers may implement modular designs, allowing for easier upgrades or repairs.

Finishing

The final stage of manufacturing involves applying protective coatings and conducting surface treatments. This step not only enhances the aesthetic appeal of the CNC router but also increases its resistance to corrosion and wear. Additionally, manufacturers may perform final quality checks during this stage, ensuring that each machine meets all specifications before shipping.

How is Quality Assurance Implemented in the Manufacturing of 5-Axis CNC Routers?

Quality assurance (QA) is paramount in the manufacturing of 5-axis CNC routers, as it directly impacts the machine’s reliability and performance. Manufacturers adhere to international standards, such as ISO 9001, and industry-specific certifications, which guide their QA processes.

International Standards and Certifications

ISO 9001 provides a framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. In addition, compliance with CE marking indicates that the product meets European safety and environmental protection standards. For manufacturers targeting markets in Africa or South America, understanding local regulatory requirements is also essential, as these can vary significantly.

Quality Control Checkpoints

Quality control is typically segmented into three main checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet predefined standards before they enter the manufacturing process. This step often includes material testing and certification to verify quality.

-

In-Process Quality Control (IPQC): During assembly and forming, ongoing inspections are crucial. This includes dimensional checks and functional tests to ensure that components are manufactured correctly and fit together as intended. Advanced measurement tools and techniques, such as laser scanners and coordinate measuring machines (CMM), are often employed for precise evaluations.

-

Final Quality Control (FQC): Before shipping, finished machines undergo comprehensive testing to validate their performance. This stage may include operational tests to verify cutting precision, speed, and overall functionality. Manufacturers may also simulate real-world conditions to ensure reliability under various operating scenarios.

What Testing Methods Are Commonly Used for 5-Axis CNC Routers?

Testing methods employed in the QA process of 5-axis CNC routers are diverse and tailored to assess different aspects of machine performance. Common methods include:

-

Functional Testing: This involves running the machine through a series of programmed tasks to evaluate its operational capabilities, such as speed, accuracy, and response to commands.

-

Load Testing: Manufacturers often perform load testing to ensure that the machine can operate under maximum capacity without failure. This helps in identifying any potential weaknesses in the structure or components.

-

Vibration Testing: This method assesses how well the machine can withstand operational vibrations, which can affect precision and longevity. Machines are subjected to controlled vibrations to monitor their response and durability.

-

Environmental Testing: For machines intended for use in various climates, environmental testing ensures that the CNC router can operate effectively in conditions ranging from extreme temperatures to high humidity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring reliable machinery. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, production processes, and adherence to quality standards firsthand. This can be instrumental in evaluating the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QA processes. These reports should outline testing methods, results, and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial assessment of the manufacturing process and the quality of the final product. These inspections can validate the supplier’s claims and ensure compliance with industry standards.

-

Certifications Verification: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE marking. This verification process can often be conducted online through certification bodies.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances, particularly when sourcing from manufacturers in different regions. Understanding local regulations, cultural differences, and logistical challenges is crucial. For instance, while European standards may emphasize environmental sustainability, other regions may prioritize cost-effectiveness.

Furthermore, the shipping process can introduce additional quality concerns, such as damage during transit. Buyers should ensure that suppliers have robust packaging and handling protocols to mitigate these risks. Establishing clear communication channels and expectations regarding quality standards is also vital for ensuring satisfaction and minimizing disputes.

In summary, understanding the manufacturing processes and quality assurance practices for 5-axis CNC routers is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring that they invest in high-quality machinery that meets their production needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5 axis cnc router for sale’

Introduction

Sourcing a 5-axis CNC router is a critical investment for businesses looking to enhance their machining capabilities. This guide provides a step-by-step checklist to help B2B buyers navigate the procurement process effectively. By following these steps, you can ensure that you select the right machine and supplier to meet your operational needs.

Step 1: Define Your Technical Specifications

Before exploring the market, establish clear technical specifications for your 5-axis CNC router. Consider factors such as the materials you will process (wood, metal, composites), the desired cutting speeds, and the size of the work area. This clarity will streamline your search and help you compare options more effectively.

- Material Compatibility: Ensure the machine can handle the materials relevant to your production.

- Size Requirements: Determine the maximum dimensions of the components you will be machining.

Step 2: Set Your Budget

Establishing a budget is essential before beginning your search. This includes not just the purchase price of the CNC router, but also installation, maintenance, and training costs. A well-defined budget will help you filter options and avoid overspending.

- Consider Financing Options: Many suppliers offer financing plans that can ease the initial financial burden.

- Account for Total Cost of Ownership: Factor in long-term operational costs, including energy consumption and maintenance.

Step 3: Research Potential Suppliers

Thoroughly research suppliers to understand their offerings and reputation in the market. Look for companies with a proven track record in manufacturing 5-axis CNC routers and check their customer reviews and case studies.

- Supplier Credentials: Verify certifications and industry standards compliance (ISO, CE, etc.).

- Experience: Prioritize suppliers with extensive experience in your specific industry.

Step 4: Evaluate Machine Features

When comparing different models, focus on the features that will directly impact your production efficiency. Look for advanced functionalities such as automatic tool changers, integrated vacuum tables, and user-friendly control systems.

- Customization Options: Assess if the machine can be tailored to fit your unique operational requirements.

- Technology Integration: Consider how well the CNC router integrates with your existing systems.

Step 5: Request Demonstrations and Samples

Before making a final decision, request demonstrations of the machines you are considering. This will give you a firsthand look at the machine’s capabilities and performance. Additionally, ask for sample parts produced by the machine to evaluate quality.

- On-Site Demonstrations: If possible, visit the supplier’s facility to see the machine in action.

- Sample Quality: Review the finish and precision of sample parts to ensure they meet your standards.

Step 6: Verify Warranty and Support Services

Check the warranty terms and after-sales support offered by the supplier. A robust warranty and ongoing technical support are crucial for minimizing downtime and ensuring long-term satisfaction with your investment.

- Warranty Duration: Look for comprehensive coverage that includes parts and labor.

- Availability of Support: Ensure that technical support is readily accessible, ideally with options for remote assistance.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and machine, review the purchase agreement carefully. Ensure that all specifications, pricing, and support terms are clearly outlined and understood.

- Payment Terms: Clarify payment schedules and any contingencies related to financing.

- Delivery and Installation: Confirm delivery timelines and the details of installation services provided.

By following this checklist, you can make a well-informed decision when sourcing a 5-axis CNC router, ultimately enhancing your manufacturing capabilities and operational efficiency.

Comprehensive Cost and Pricing Analysis for 5 axis cnc router for sale Sourcing

What Are the Key Cost Components for 5 Axis CNC Routers?

When evaluating the cost structure of 5 axis CNC routers, several key components must be considered. These include:

-

Materials: The quality and type of materials used in manufacturing the CNC routers significantly impact costs. High-grade steel frames, precision motors, and durable electronics contribute to a higher initial investment but often result in better performance and longevity.

-

Labor: Skilled labor is essential for the assembly and calibration of CNC machines. Labor costs can vary significantly by region, which is particularly relevant for international buyers. For instance, labor-intensive regions in Europe may have higher costs compared to South American or African counterparts.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs, leading to competitive pricing.

-

Tooling: The cost of tooling—such as cutting tools, fixtures, and jigs—adds to the overall expense. Custom tooling can further increase costs but may be necessary for specialized applications.

-

Quality Control (QC): Rigorous QC processes ensure that each machine meets industry standards, which can add to the cost but is essential for maintaining performance and reliability.

-

Logistics: Shipping costs vary based on distance and the chosen method of transportation. Additionally, international shipping can incur customs fees and import taxes that must be factored into the total cost.

-

Margin: Supplier margins can vary widely based on brand reputation, service offerings, and market demand. Understanding the margin structure can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of 5 Axis CNC Routers?

Several factors influence the pricing of 5 axis CNC routers, which are crucial for buyers to understand:

-

Volume/MOQ: Minimum order quantities (MOQ) and volume purchases can lead to significant discounts. Buyers looking to acquire multiple units should negotiate bulk pricing to optimize their investment.

-

Specifications and Customization: Custom features, such as specialized tooling or enhanced software capabilities, can substantially increase costs. Buyers should weigh the necessity of these features against their specific operational needs.

-

Materials and Quality Certifications: Machines built with superior materials and backed by quality certifications (ISO, CE, etc.) typically come at a premium. However, they often provide greater reliability and lower maintenance costs in the long run.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge more but often offer superior after-sales support and warranty services.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) is essential for international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final landed cost of the equipment.

What Tips Can Help International Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, and the Middle East, effective negotiation and understanding of total costs can lead to significant savings:

-

Conduct Market Research: Familiarize yourself with pricing benchmarks in your region and the specific features you require. This knowledge empowers you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also maintenance, operational efficiency, and potential downtime. A lower initial price may lead to higher long-term costs.

-

Leverage Currency Fluctuations: Monitor currency exchange rates and negotiate terms that allow you to benefit from favorable fluctuations.

-

Seek Long-term Partnerships: Building relationships with suppliers can lead to better pricing, support, and service. Consider establishing contracts that reflect ongoing business rather than one-off purchases.

-

Be Aware of Pricing Nuances: Understand that different regions may have varying pricing structures due to local economic conditions, tariffs, and supply chain logistics. This insight can help you negotiate more effectively.

Disclaimer

Prices for 5 axis CNC routers can vary widely based on specifications, market conditions, and supplier terms. The information provided is for indicative purposes only and should be verified with suppliers for precise quotes tailored to specific needs.

Alternatives Analysis: Comparing 5 axis cnc router for sale With Other Solutions

Introduction: What Are the Alternatives to 5 Axis CNC Routers?

When evaluating manufacturing technologies, B2B buyers must consider not only the primary product—such as a 5-axis CNC router—but also viable alternatives that can fulfill similar objectives. These alternatives may vary in performance, cost, and application suitability. Understanding these options allows buyers to make informed decisions tailored to their unique operational needs.

Comparison Table

| Comparison Aspect | 5 Axis CNC Router For Sale | Alternative 1: 3 Axis CNC Router | Alternative 2: Manual Machining |

|---|---|---|---|

| Performance | High precision with complex geometries; suitable for intricate designs. | Good for simpler shapes; limited in complexity. | Variable; depends on operator skill and tools used. |

| Cost | Higher initial investment; financing options available. | Generally lower cost; more accessible for startups. | Low upfront costs; however, labor costs can accumulate. |

| Ease of Implementation | Requires training and setup; often needs skilled technicians. | Easier to set up and operate; less training required. | Simple setup but requires extensive training for skilled labor. |

| Maintenance | Regular maintenance needed; parts can be expensive. | Lower maintenance costs; fewer complex components. | High variability; depends on tools and materials used. |

| Best Use Case | Ideal for industries requiring precision, such as aerospace and automotive. | Suitable for woodworking and basic metal fabrication. | Best for custom jobs where precision is less critical. |

Detailed Breakdown of Alternatives

Alternative 1: 3 Axis CNC Router

3-axis CNC routers are simpler machines that operate along three linear axes (X, Y, and Z). They are often favored for their lower cost and ease of use, making them a practical choice for small to medium-sized businesses entering the CNC world. While 3-axis routers can efficiently handle basic cutting and engraving tasks, they lack the ability to execute complex angles and curves that a 5-axis machine can manage. This limitation can hinder innovation and design capabilities in sectors demanding high precision.

Alternative 2: Manual Machining

Manual machining utilizes traditional tools operated by skilled workers. This method can be cost-effective, particularly for small-scale operations or bespoke projects. However, the quality and precision of the output heavily depend on the machinist’s experience and skill level. Manual machining is less efficient for mass production and can lead to longer turnaround times. While it may serve well for prototyping or custom jobs, it often falls short in the fast-paced environments of modern manufacturing where speed and precision are paramount.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right manufacturing technology requires a thorough assessment of your specific operational needs, budget constraints, and production goals. A 5-axis CNC router is an excellent choice for businesses focused on high precision and complex designs, particularly in industries such as aerospace and automotive. Conversely, if cost and ease of use are more critical, a 3-axis CNC router may suffice for simpler tasks. For companies emphasizing customization and manual craftsmanship, traditional manual machining could be an appropriate alternative. By aligning your choice with your operational requirements and growth trajectory, you can optimize your manufacturing capabilities and drive your business forward.

Essential Technical Properties and Trade Terminology for 5 axis cnc router for sale

What Are the Key Technical Properties of a 5-Axis CNC Router?

Understanding the technical specifications of a 5-axis CNC router is essential for B2B buyers to ensure they select a machine that meets their production needs. Here are some critical specifications to consider:

-

Material Grade: The material grade of the CNC router’s frame and components, typically steel or aluminum, influences durability and performance. A robust steel frame, for instance, enhances stability, reducing vibrations during operation, which is crucial for precision machining. This is particularly important for industries such as aerospace and automotive, where tolerances are critical.

-

Tolerance Levels: Tolerance refers to the permissible limit or limits of variation in a physical dimension. For CNC routers, tighter tolerances lead to higher precision in manufacturing parts. A tolerance of ±0.001 inches is often standard for high-precision applications. Understanding tolerance requirements helps businesses ensure that their production processes meet industry standards and customer expectations.

-

Spindle Power and Type: The spindle power, usually measured in horsepower (HP), directly affects the cutting capabilities of the CNC router. A higher HP allows for the machining of harder materials and can improve efficiency in production. Additionally, the type of spindle (e.g., HSD or ISO) can impact the range of tooling options available and the overall versatility of the machine.

-

Rapid Travel Speed: This specification indicates how quickly the machine can move between cuts, measured in inches per minute (IPM). Higher rapid travel speeds, such as 2,500 IPM, can significantly reduce cycle times, enhancing productivity. For manufacturers, this means faster turnaround and increased throughput, which can lead to improved profitability.

-

Control System: The control system, often from renowned manufacturers like FANUC or Siemens, dictates the machine’s operational capabilities. A user-friendly interface and advanced programming options are essential for optimizing machining processes. Buyers should consider systems that offer robust support and extensive features for complex machining tasks.

-

Vacuum Table and Fixturing: A universal vacuum table is a common feature that enhances the machine’s ability to hold down various materials securely during the machining process. Understanding the table’s design and capacity is vital for ensuring it can accommodate the intended workpieces, minimizing setup times and improving machining accuracy.

What Are Common Trade Terms in the 5-Axis CNC Router Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, understanding whether a CNC router is an OEM product can impact decisions regarding warranty, support, and replacement parts.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for businesses to understand as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their production schedules and budget constraints.

-

RFQ (Request for Quotation): An RFQ is a formal document that buyers use to solicit price quotes from suppliers. This process helps businesses compare pricing and terms from different manufacturers, ensuring they receive the best value for their investment.

-

Incoterms (International Commercial Terms): Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is critical for managing shipping costs, responsibilities, and risks in cross-border purchases.

-

Lead Time: This refers to the time taken from placing an order to delivery. In the context of CNC routers, shorter lead times can significantly impact a business’s ability to meet customer demands and production schedules.

-

Customization Options: Many CNC routers offer customization options to cater to specific business needs. Understanding the extent of customization available can help buyers tailor machines to their production processes, enhancing efficiency and effectiveness.

By grasping these technical specifications and trade terminologies, B2B buyers can make informed decisions when investing in a 5-axis CNC router, ensuring that they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 5 axis cnc router for sale Sector

What are the Current Market Dynamics and Key Trends in the 5 Axis CNC Router Sector?

The global market for 5 axis CNC routers is experiencing significant growth, driven by advancements in manufacturing technologies and increasing demand for precision machining across various industries. Key drivers include the rising need for automation in production processes and the growing trend towards customization in manufacturing. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality, versatile CNC routers that can handle complex tasks with efficiency.

Emerging trends include the integration of Industry 4.0 technologies, such as IoT connectivity and AI-driven analytics, which enhance operational efficiency and predictive maintenance capabilities. Moreover, the shift towards digital manufacturing is prompting businesses to invest in CNC machinery that can seamlessly integrate into their existing workflows. Buyers are also prioritizing suppliers that offer comprehensive support services, including installation, training, and ongoing technical assistance, which are critical for maximizing the return on investment.

Market dynamics are also influenced by regional factors. For instance, in Europe, stringent regulations on manufacturing processes are pushing companies to adopt more precise and efficient technologies. In contrast, emerging markets in Africa and South America are witnessing rapid industrialization, leading to increased demand for affordable yet high-performance CNC solutions. Understanding these dynamics is essential for international buyers to make informed sourcing decisions that align with their operational goals.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the 5 Axis CNC Router Market?

Sustainability is becoming a cornerstone of modern manufacturing, and its importance cannot be overstated in the context of sourcing 5 axis CNC routers. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to seek machines that minimize waste and energy consumption. B2B buyers are increasingly looking for suppliers that prioritize eco-friendly practices, such as using sustainable materials and implementing energy-efficient technologies in their CNC routers.

Ethical sourcing is equally critical, as buyers want assurance that their suppliers adhere to fair labor practices and responsible supply chain management. Certifications like ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming vital benchmarks for evaluating potential suppliers. Additionally, using ‘green’ materials in the manufacturing of CNC routers, such as recycled metals and eco-friendly coatings, can significantly enhance a company’s brand reputation and appeal to environmentally conscious customers.

Investing in sustainable and ethically sourced CNC routers not only helps businesses comply with regulations but also fosters customer loyalty and enhances market competitiveness. For international buyers, particularly in regions where environmental standards are becoming increasingly stringent, sourcing from suppliers with robust sustainability credentials is not just a trend but a strategic necessity.

What is the Evolution of 5 Axis CNC Routers in the B2B Landscape?

The evolution of 5 axis CNC routers has been marked by rapid technological advancements and an increasing focus on automation and precision. Initially, CNC technology was primarily utilized for basic machining tasks. However, over the past few decades, the introduction of advanced controls, high-speed spindles, and sophisticated software has transformed these machines into powerful tools capable of executing complex geometries and intricate designs.

As industries such as aerospace, automotive, and woodworking demanded higher precision and versatility, manufacturers responded by developing 5 axis CNC routers that could accommodate a wider range of materials and applications. Today, these machines are equipped with features like advanced tool changers, automated vacuum systems, and integrated software solutions that streamline production processes.

This evolution reflects a broader trend in manufacturing towards increased efficiency and customization, allowing businesses to meet the diverse needs of their clients while maintaining competitive pricing. For B2B buyers, understanding the historical development of 5 axis CNC routers provides valuable insights into their capabilities and the potential for future advancements in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 5 axis cnc router for sale

-

How do I choose the right 5-axis CNC router for my business needs?

Selecting the right 5-axis CNC router involves assessing your specific applications, material types, and production volume. Start by evaluating the machine’s capabilities, such as its cutting speed, precision, and compatibility with various materials like wood, plastics, or metals. Consider the machine’s size and footprint to ensure it fits your operational space. Additionally, look for features like automatic tool changers and advanced control systems that can enhance efficiency. Consulting with suppliers and reviewing customer testimonials can also provide insights into the machine’s performance in real-world applications. -

What are the typical lead times for purchasing a 5-axis CNC router?

Lead times for acquiring a 5-axis CNC router can vary significantly based on the manufacturer, model, and any customization required. Generally, standard machines may be available for shipment within 4 to 12 weeks, while custom configurations could extend this timeline to several months. It’s advisable to discuss timelines with your supplier upfront and factor in additional time for installation and training, especially if you are sourcing from international suppliers. Planning ahead can help mitigate any disruptions to your production schedule. -

What customization options are available for 5-axis CNC routers?

Most manufacturers offer various customization options for 5-axis CNC routers to meet specific operational needs. Customizations can include adjustments to the machine’s size, spindle type, tool holders, and additional features like advanced vacuum systems or automated loading/unloading systems. It’s crucial to communicate your production requirements and material specifications to the supplier, who can then recommend suitable modifications. Always request detailed specifications and ensure that any customizations are backed by adequate warranties and support. -

What is the minimum order quantity (MOQ) for 5-axis CNC routers?

The minimum order quantity for 5-axis CNC routers varies by manufacturer and can depend on factors like machine type and specifications. Some suppliers may have a MOQ of one unit, while others may require multiple machines to secure favorable pricing or terms. When sourcing internationally, consider the total landed cost, including shipping and tariffs, as this can affect the overall investment. It’s advisable to inquire about bulk purchase discounts or financing options that may be available for larger orders. -

What payment terms are commonly offered for international purchases of CNC routers?

Payment terms for international purchases of CNC routers typically vary by supplier but often include options such as upfront payments, letter of credit, or installments. Many suppliers require a deposit to initiate production, with the balance due upon delivery or installation. It’s essential to clarify payment methods and terms before finalizing your order, ensuring they align with your cash flow and budget. Additionally, consider using secure payment platforms that offer buyer protection to mitigate risks associated with international transactions. -

How can I verify the credibility of a CNC router supplier?

Verifying the credibility of a CNC router supplier involves several steps. Start by researching the company’s history, reputation, and customer reviews. Request references from previous clients, especially those in your industry or region. Check for certifications or memberships in industry organizations, which can indicate compliance with quality standards. Additionally, visiting the supplier’s facility or attending trade shows can provide firsthand insight into their operations and product quality. Engaging with them directly through discussions about your specific needs can also reveal their expertise and customer service capabilities. -

What should I consider regarding logistics when importing a 5-axis CNC router?

When importing a 5-axis CNC router, logistics considerations are critical to ensure a smooth delivery process. Evaluate shipping options, including freight forwarders and customs brokers, to handle international transportation and customs clearance. Understand the associated costs, such as duties, taxes, and insurance, which can impact your total investment. Additionally, confirm the machine’s shipping dimensions and weight to arrange suitable transportation and unloading equipment. Planning ahead for installation and training on-site is also vital to minimize downtime once the machine arrives. -

What quality assurance practices should I expect from suppliers of CNC routers?

Reputable suppliers of CNC routers should have robust quality assurance practices in place. This includes adherence to international standards such as ISO certifications, regular quality checks during production, and comprehensive testing of machines before shipment. Inquire about the warranty and after-sales support, which should cover parts and service for a defined period. Suppliers should also provide documentation, such as compliance certificates and user manuals, to support machine operation and maintenance. Establishing clear communication regarding these practices can enhance your confidence in their products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 5 Axis Cnc Router For Sale Manufacturers & Suppliers List

1. Laguna Tools – SmartShop® 5 Axis CNC Router

Domain: lagunatools.com

Registered: 1996 (29 years)

Introduction: Product Name: SmartShop® 5 Axis CNC Router

Weight: 8600 lbs.

Frame: All Welded Steel Frame & Gantry

Design: Fixed Table, Moving Gantry for unrestricted access

Tool Changer: Standard 12-Position, Automatic Rotary Tool Changer

Control System: FANUC 31i-B5 Industrial Control with 1,500-Watt Servo Package

Vacuum Table: Universal Vacuum Table, Pod Ready with Adjustable Pop-Up Pins

Spindle: HSD 2-Axis 9…

2. EX-FACTORY – CNC Routers

Domain: exfactory.com

Registered: 1995 (30 years)

Introduction: EX-FACTORY CNC ROUTERS – 5 – AXIS – Woodworking Machinery

3. CNC Multi-Axis Machining Centers – Affordable Used Machines

Domain: machinestation.us

Registered: 2013 (12 years)

Introduction: Used CNC Multi-Axis Machining Centers for Sale | 3, 4 & 5-Axis Ready. Brands include Daewoo, Doosan, DMG Mori, Haas, Hyundai, Matsuura, Mazak, Mighty Viper, Mori Seiki, Nakamura, Okuma, Sharp, SNK, Star, Takisawa, Toyoda, Tsugami, Yama Seiki, YCM. Machines under $25k available. Features include CNC Milling Machines like Bridge Mills and Gantry Mills for large-scale parts machining, CNC Boring Mill…

4. CNC PD – 5 Axis CNC Routers

Domain: cncpd.com

Registered: 2003 (22 years)

Introduction: 5 Axis CNC Routers offer superior performance, accuracy, and control for machining complex surfaces, deep cavities, and intricate components. Ideal for high-end prototyping, aerospace, automotive, composites, and advanced woodworking. Available models include:

– Motionmaster 5 Axis CNC Router Dual 5×5 Moving Table [USED]: 1999 model, dual 5×5 moving tables, 48 in. stroke, Perske dual-ended spindl…

5. CNC Machines – 5 Axis Mills

Domain: cncmachines.com

Registered: 1997 (28 years)

Introduction: 5 Axis CNC Mill, 50% Off Used 5 Axis Mill For Sale, rotates on A and B axis, moves across X, Y, and Z in linear direction, capable of milling complex parts, top brands include Haas, Mazak, Hurco, DMS, SCM, various models and capacities available, options include chip conveyor, probe, coolant thru spindle, programmable coolant, 360 deg. indexing table, delivery options, year range, price filters.

6. Used 5 Axis CNC Routers – Various Brands

Domain: plastimach.com

Registered: 1995 (30 years)

Introduction: Used 5 Axis CNC Routers for Sale from brands such as THERMWOOD, MULTICAM, DMS, MOTION MASTER, QUINTAX, FLOW, NORTHWOOD, NORWOOD, ROUTECH. Previously sold listings are also available.

7. KD Capital – Used CNC Routers

Domain: kdcapital.com

Registered: 2003 (22 years)

Introduction: Used CNC Routers for Sale – KD Capital Equipment offers a variety of used CNC routers, with 105 models available. The inventory includes brands such as AXYZ, AccTek, Anderson, Baileigh, Biesse, CAMaster, CMS, CR Onsrud, and many others. The machines are suitable for cutting materials like wood, metal, glass, foam, and plastics, enhancing quality and productivity in various applications such as doo…

8. STYLECNC – Industrial 5 Axis CNC Router Machine

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: {“Product Name”: “Industrial 5 Axis CNC Router Machine for 3D Milling”, “Brand”: “STYLECNC”, “Model”: “STM2040-5A”, “Price”: {“Standard Edition”: “$110,000”, “Pro Edition”: “$150,000”}, “Stock Availability”: “360 Units in Stock Available for Sale Every Month”, “Warranty”: “One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)”, “Money Back Guarantee”: “30-Day…

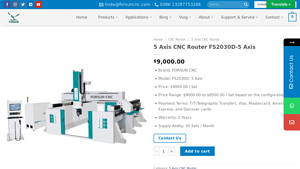

9. FORSUN CNC – 5 Axis CNC Router FS2030D

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: Product Name: 5 Axis CNC Router FS2030D-5 Axis

Brand: FORSUN CNC

Price: $9,000.00 / Set

Price Range: $9,000.00 to $9,500.00 / Set based on configuration

Payment Terms: T/T, Visa, Mastercard, American Express, Discover

Warranty: 2 Years

Supply Ability: 30 Sets / Month

Model Name: 5 Axis CNC Router FS2030D-5 Axis

X, Y-Axis Travel: 4800*2800*2000mm

A and C Axis Travel: A: ±120°, C: ±245°

Spindle Powe…

Strategic Sourcing Conclusion and Outlook for 5 axis cnc router for sale

As international B2B buyers navigate the complex landscape of sourcing 5-axis CNC routers, understanding the key factors influencing purchasing decisions is critical. The advanced capabilities of these machines—such as their precision, versatility, and efficiency—provide significant competitive advantages across various industries, from woodworking to aerospace manufacturing. Strategic sourcing not only facilitates access to high-quality equipment but also enables companies to optimize costs, enhance productivity, and ensure alignment with specific operational requirements.

Buyers should prioritize suppliers that offer robust support, including installation and training, as well as flexible financing options to accommodate different budgets. It’s essential to evaluate machines based on their adaptability to various materials and the potential for customization to meet unique production needs.

Looking ahead, the demand for innovative manufacturing solutions is set to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Investing in a 5-axis CNC router can be a transformative step for businesses aiming to elevate their production capabilities and stay ahead of the competition. We encourage buyers to explore their options, engage with reputable suppliers, and take proactive steps toward enhancing their operational efficiency.