Introduction: Navigating the Global Market for 5 axis cnc mill desktop

In the fast-evolving landscape of manufacturing, sourcing a reliable 5-axis CNC mill desktop can pose significant challenges for international B2B buyers. With the complexity of precision engineering and the diverse material requirements across industries, decision-makers must navigate a multitude of options while ensuring they meet their operational needs. This guide provides an in-depth exploration of 5-axis CNC mill desktops, detailing various types available on the market, their applications in sectors such as aerospace, medical, and jewelry, and the critical aspects of supplier vetting.

The comprehensive scope of this guide empowers businesses, particularly those in Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Saudi Arabia, to make informed purchasing decisions. By understanding the specifications, potential applications, and cost considerations, buyers can confidently evaluate which machines align best with their production goals.

Additionally, the guide addresses the importance of compliance with international regulations and export controls, ensuring that buyers are equipped to navigate these complexities efficiently. Ultimately, this resource aims to streamline the procurement process, helping businesses enhance their operational capabilities and drive innovation in their respective industries.

Understanding 5 axis cnc mill desktop Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

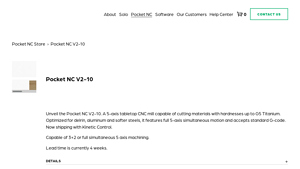

| Pocket NC V2-10 | Compact design, full 5-axis simultaneous motion, Kinetic Control | Prototyping, small batch production | Pros: Affordable, versatile for small parts. Cons: Limited travel size. |

| TN5-V6-TC8 | High-speed spindle, automatic tool changer, high precision | Aerospace, medical devices, jewelry | Pros: High accuracy, suitable for complex machining. Cons: Higher cost, larger footprint. |

| MDA Precision 5-Axis Mill | Brushless servo motors, dynamic work offsets, modular design | Microfluidics, micro-machining | Pros: Excellent for detailed work, adaptable. Cons: Requires skilled operation. |

| Desktop CNC 5-Axis Mill | User-friendly interface, compact, entry-level pricing | Educational purposes, hobbyist projects | Pros: Accessible for beginners, low investment. Cons: May lack advanced features for industrial use. |

| High-Performance CNC Mill | Robust construction, advanced cooling systems, large travel | Heavy-duty machining, industrial applications | Pros: High durability, suitable for large-scale production. Cons: Expensive, requires significant space. |

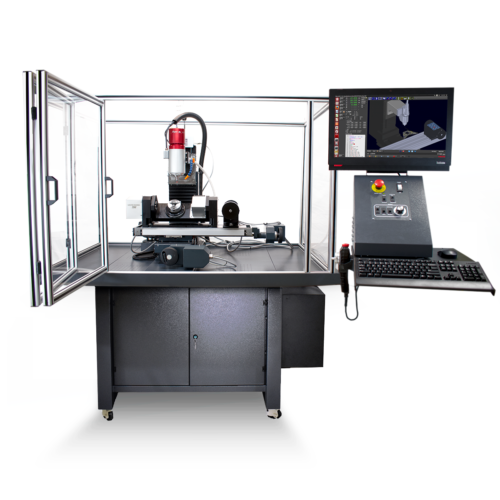

What are the Key Characteristics of the Pocket NC V2-10?

The Pocket NC V2-10 is designed for compactness without sacrificing performance. It features full 5-axis simultaneous motion, making it ideal for prototyping and small batch production. The Kinetic Control software enhances usability, allowing users to program with standard G-code. Buyers should consider its limited travel size, which may restrict its application to smaller components.

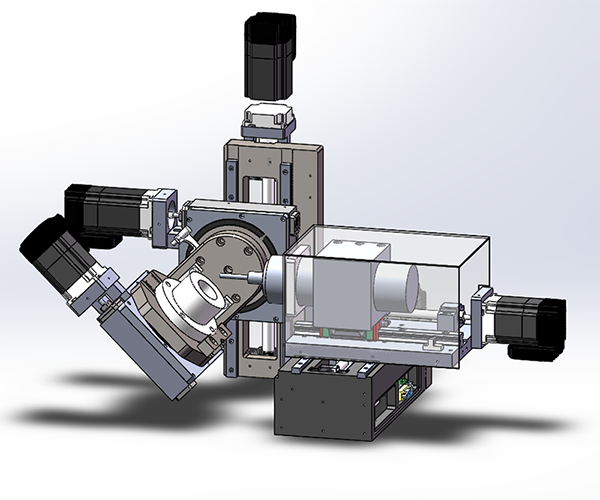

How Does the TN5-V6-TC8 Stand Out in Precision Machining?

The TN5-V6-TC8 is distinguished by its high-speed spindle and automatic tool changer, making it suitable for high-precision applications like aerospace and medical device manufacturing. With a travel capacity that supports complex designs, this mill is designed for high-volume production. However, its higher cost and larger footprint may deter smaller operations.

Why Choose MDA Precision 5-Axis Mill for Micro-Machining?

The MDA Precision 5-Axis Mill is engineered with brushless servo motors and dynamic work offsets, making it perfect for micro-machining tasks. It excels in applications requiring fine detail, such as microfluidics and intricate jewelry designs. Businesses should weigh the need for skilled operation against its adaptability and precision capabilities.

What Are the Benefits of a Desktop CNC 5-Axis Mill for Beginners?

Desktop CNC 5-Axis Mills are designed to be user-friendly, making them a great entry point for educational purposes and hobbyist projects. With accessible pricing, these mills provide an excellent introduction to CNC machining. However, they may lack the advanced features necessary for more complex industrial applications, which could limit their long-term utility for serious manufacturers.

How Do High-Performance CNC Mills Cater to Industrial Needs?

High-performance CNC mills are built for durability and efficiency, featuring advanced cooling systems and larger travel capacities. These machines are ideal for heavy-duty machining and industrial applications, allowing for large-scale production. While they offer significant advantages in terms of robustness, their higher price point and space requirements may pose challenges for smaller operations.

Key Industrial Applications of 5 axis cnc mill desktop

| Industry/Sector | Specific Application of 5 axis cnc mill desktop | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | High precision and reduced cycle times for complex parts | Ensure compliance with aerospace standards and certifications |

| Medical Devices | Custom surgical instruments and implants | Tailored solutions that meet stringent medical regulations | Look for machines with biocompatible material capabilities |

| Jewelry | Intricate design and prototyping | Ability to create detailed designs with high-quality finishes | Verify capabilities for precious metals and gem settings |

| Automotive | Production of prototypes and custom parts | Enhanced design flexibility and rapid prototyping | Consider machine size and material compatibility |

| Microfluidics | Fabrication of micro-scale components | Precision manufacturing for advanced applications | Assess the machine’s capability for micro-machining |

How Is 5 Axis CNC Milling Used in Aerospace Manufacturing?

In the aerospace sector, 5-axis CNC mills are essential for creating highly intricate components such as turbine blades and structural frames. These machines allow manufacturers to achieve superior precision and reduce production time for complex geometries, which is crucial in an industry where safety and performance are paramount. International buyers should consider sourcing machines that comply with aviation standards and regulations, ensuring they can meet the rigorous demands of aerospace applications.

What Role Does 5 Axis CNC Milling Play in Medical Device Production?

5-axis CNC mills are increasingly used in the medical device industry to produce custom surgical instruments and implants tailored to individual patient needs. These machines provide the precision required to meet strict medical regulations while enabling rapid prototyping and production of complex geometries. Buyers from regions like Africa and South America should prioritize sourcing mills that can handle biocompatible materials, ensuring that their products meet health and safety standards.

How Can Jewelry Manufacturers Benefit from 5 Axis CNC Mills?

In the jewelry industry, 5-axis CNC milling machines enable artisans to create intricate designs and prototypes with high-quality finishes. These machines are capable of working with various precious metals and offer the flexibility needed for custom designs. When sourcing a 5-axis CNC mill, businesses should focus on the machine’s ability to handle fine details and its compatibility with specialized tools for gem settings, which are critical for producing high-value jewelry pieces.

Why Is 5 Axis CNC Milling Important for Automotive Prototyping?

Automotive manufacturers utilize 5-axis CNC mills for rapid prototyping of parts, allowing for enhanced design flexibility and faster time-to-market. These machines can produce both functional prototypes and custom components, which are essential for testing and validation processes in automotive design. Buyers should consider the machine’s size and material compatibility, particularly for lightweight materials like aluminum, which are increasingly used in modern vehicle manufacturing.

What Advantages Does 5 Axis CNC Milling Offer in Microfluidics?

In the field of microfluidics, 5-axis CNC milling is used for the fabrication of micro-scale components essential for lab-on-a-chip devices and other advanced applications. The precision offered by these machines allows manufacturers to create intricate channel designs and features that are critical for fluid manipulation at the microscale. International buyers should assess the machine’s capabilities for micro-machining, ensuring it can produce the high-precision components required for cutting-edge microfluidic technologies.

3 Common User Pain Points for ‘5 axis cnc mill desktop’ & Their Solutions

Scenario 1: Difficulty in Material Compatibility and Machining Precision

The Problem: Many B2B buyers encounter challenges when selecting a 5-axis CNC mill desktop that can handle a range of materials, especially those with varying hardness levels. For instance, manufacturers in industries such as aerospace or medical devices often require precision machining of materials like titanium or high-grade aluminum. However, not all machines are optimized for these materials, leading to issues like tool wear, poor surface finish, or even machine breakdowns. This can cause significant downtime and increased operational costs, especially for businesses that rely heavily on tight tolerances and high-quality finishes.

The Solution: To overcome material compatibility issues, buyers should thoroughly assess the specifications of potential CNC mills, focusing on spindle power, RPM ranges, and the machine’s capability to handle specific materials. When sourcing a 5-axis CNC mill desktop, consider models like the Pocket NC V2-10, which can effectively cut materials up to G5 titanium and is optimized for softer materials like delrin and aluminum. Additionally, investing in quality cutting tools specifically designed for the materials being machined can enhance performance and reduce wear. Regular training for operators on best practices for material handling and tool selection will also ensure optimal performance and longevity of the machine.

Scenario 2: Complexity of Programming and Operation

The Problem: Another common pain point for B2B buyers is the complexity involved in programming and operating 5-axis CNC mills. Many businesses, especially startups or smaller manufacturers, may not have staff with extensive CNC programming experience. This can lead to programming errors, inefficient machining processes, and ultimately, increased costs. Buyers often find themselves in a steep learning curve, which can hinder productivity and slow down project timelines.

The Solution: To address these programming challenges, companies should prioritize machines that offer user-friendly software and comprehensive training resources. For example, the TN5-V6-TC8 comes with PC-based control software that supports standard FANUC G-code, making it easier for operators to adapt. Furthermore, manufacturers should consider investing in CAM software that is compatible with their CNC mill, as this can streamline the programming process. Providing in-house training sessions or partnering with the machine supplier for training can also significantly reduce the learning curve. Lastly, maintaining a library of programming templates for common tasks can enhance efficiency and reduce the likelihood of errors.

Scenario 3: Limited After-Sales Support and Maintenance Resources

The Problem: Many B2B buyers express concerns regarding the availability of after-sales support and maintenance resources for their 5-axis CNC mills. Especially in regions like Africa or South America, where access to technical expertise and replacement parts may be limited, machine owners can face prolonged downtime due to maintenance issues or lack of support. This can lead to frustration and financial losses, as production schedules are disrupted.

The Solution: To mitigate these risks, buyers should conduct due diligence on the manufacturer’s after-sales support reputation before making a purchase. Opting for suppliers who offer robust support packages, including remote assistance, maintenance training, and readily available spare parts, is crucial. Additionally, establishing a maintenance schedule based on the manufacturer’s guidelines and training staff on routine checks can prevent unexpected breakdowns. Buyers should also consider forming relationships with local service providers or training employees in basic troubleshooting techniques to ensure that minor issues can be resolved quickly. This proactive approach can significantly reduce downtime and enhance overall productivity.

Strategic Material Selection Guide for 5 axis cnc mill desktop

What are the Key Properties of Common Materials for 5 Axis CNC Milling?

When selecting materials for a 5-axis CNC mill desktop, it’s essential to consider the specific properties that will influence performance, durability, and application suitability. Below, we analyze four common materials: Aluminum, Delrin, Titanium, and Steel, providing insights tailored for international B2B buyers.

Aluminum: A Versatile Choice for Precision Machining

Aluminum is widely used in CNC milling due to its excellent machinability and lightweight characteristics. Key properties include a high strength-to-weight ratio, good corrosion resistance, and thermal conductivity, making it suitable for various applications, including aerospace and automotive components.

Pros: Aluminum is durable yet easy to machine, leading to lower manufacturing complexity and faster production times. It is also relatively cost-effective compared to other metals.

Cons: While it is resistant to corrosion, it may not withstand high-temperature applications as effectively as other materials. Additionally, softer grades can be prone to deformation under heavy loads.

Impact on Application: Aluminum is compatible with various media, making it ideal for parts requiring precision and light weight.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is crucial. Buyers from regions like Africa and South America should ensure the availability of specific aluminum grades that meet local industry requirements.

Delrin: Ideal for Low-Friction Applications

Delrin, a type of acetal resin, is favored for its low friction properties and excellent dimensional stability. It can withstand temperatures up to 100°C and is resistant to chemicals, making it suitable for applications in medical devices and automotive components.

Pros: Delrin is easy to machine and offers a smooth finish, reducing the need for secondary operations. Its resistance to wear makes it long-lasting in applications involving moving parts.

Cons: Delrin is not as strong as metals and may not be suitable for high-load applications. It can also be more expensive than some metals.

Impact on Application: Its compatibility with various fluids makes it ideal for applications in microfluidics and other precision engineering fields.

Considerations for International Buyers: Buyers should check for compliance with relevant safety and environmental standards, particularly in the medical sector, where regulations can be stringent.

Titanium: High Strength with Excellent Corrosion Resistance

Titanium is known for its exceptional strength and corrosion resistance, making it a preferred choice for high-performance applications, including aerospace and medical implants. It has a high melting point and can withstand harsh environments.

Pros: Titanium is incredibly durable and lightweight, providing excellent performance in demanding applications. Its biocompatibility also makes it suitable for medical uses.

Cons: The primary downside is its high cost and the complexity of machining, which can lead to longer production times and higher manufacturing expenses.

Impact on Application: Titanium’s unique properties make it ideal for applications requiring high strength and low weight, particularly in aerospace and defense.

Considerations for International Buyers: Compliance with international standards such as ASTM and JIS is crucial, especially in industries like aerospace where safety is paramount.

Steel: The Workhorse of Manufacturing

Steel is a staple material in CNC machining due to its strength and versatility. It comes in various grades, offering different properties such as hardness and corrosion resistance.

Pros: Steel is highly durable and can withstand significant stress, making it suitable for heavy-duty applications. It is also widely available and generally more affordable than titanium.

Cons: Steel can be more challenging to machine compared to aluminum and Delrin, leading to longer processing times. Additionally, certain grades may be susceptible to corrosion if not properly treated.

Impact on Application: Steel is ideal for applications requiring high strength and durability, such as in the automotive and construction industries.

Considerations for International Buyers: Buyers should be aware of the specific steel grades that meet local standards and regulations, particularly in regions with stringent quality control measures.

Summary Table of Material Selection for 5 Axis CNC Mill Desktop

| Material | Typical Use Case for 5 Axis CNC Mill Desktop | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Excellent machinability and lightweight | Limited high-temperature performance | Medium |

| Delrin | Medical devices, microfluidics | Low friction and wear resistance | Less strength than metals | Medium |

| Titanium | Aerospace, medical implants | High strength and corrosion resistance | High cost and machining complexity | High |

| Steel | Heavy-duty machinery, automotive applications | High durability and stress resistance | More difficult to machine | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on the properties, advantages, and limitations of each material.

In-depth Look: Manufacturing Processes and Quality Assurance for 5 axis cnc mill desktop

What Are the Key Stages in the Manufacturing Process of 5-Axis CNC Mill Desktops?

The manufacturing process for 5-axis CNC mill desktops involves several critical stages, each designed to ensure precision, reliability, and performance. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step involves selecting high-quality raw materials, typically aluminum, titanium, or polymer composites. The choice of material is crucial as it affects the machine’s performance, durability, and capability to withstand high-speed operations. Once selected, materials undergo processes such as cutting, milling, and surface treatment to achieve the required dimensions and surface quality.

Advanced CNC machining techniques are often employed at this stage to ensure that the raw materials are accurately shaped according to the specifications. This may involve initial rough machining followed by precision machining to achieve tight tolerances.

Forming: What Techniques Are Used to Shape the Components?

Forming processes for 5-axis CNC mills may include casting, forging, and machining. The most common method is CNC machining, where computer-controlled tools precisely remove material to create complex geometries.

In 5-axis mills, the ability to machine from multiple angles simultaneously allows for intricate designs that would be challenging or impossible with traditional 3-axis milling. This capability is essential for producing components like trunnion tables and spindle housings, which require high precision.

Assembly: How Are Components Brought Together?

Once all components are machined, the assembly stage begins. This involves integrating various parts such as the spindle, tool holder, and control systems. Attention to detail is critical during assembly, as any misalignment can lead to significant performance issues.

Automated assembly techniques, including robotic arms and precision jigs, are often utilized to enhance consistency and reduce human error. Furthermore, during this stage, manufacturers conduct initial checks to ensure that each component fits correctly and functions as intended.

Finishing: What Processes Ensure a Quality Surface?

The finishing stage involves polishing and coating processes that enhance the aesthetic and functional properties of the CNC mill. Techniques such as anodizing or powder coating are commonly used to improve corrosion resistance and surface hardness.

Precision measuring tools are employed to verify that the final dimensions meet specifications. This is crucial for ensuring that the finished product performs optimally in demanding applications.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is vital in the manufacturing of 5-axis CNC mill desktops. B2B buyers should look for compliance with international standards such as ISO 9001, which focuses on effective quality management systems. Additionally, certifications like CE mark for products sold in Europe, and API standards for specific applications in the oil and gas sector, can be indicators of a manufacturer’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) encompasses several checkpoints throughout the manufacturing process, ensuring that products meet established standards:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified requirements before they enter the production line.

-

In-Process Quality Control (IPQC): Regular checks are performed during the manufacturing process. This includes monitoring machining tolerances and dimensions, ensuring that any deviations are addressed immediately.

-

Final Quality Control (FQC): Once the assembly is complete, a comprehensive inspection is conducted. This includes functional tests, performance evaluations, and dimensional checks to confirm that the finished product adheres to specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should actively verify the quality control processes of potential suppliers to ensure they align with their own quality standards. Here are several methods to achieve this:

-

Audits: Conducting on-site audits allows buyers to assess the manufacturing processes firsthand. This can provide insights into the supplier’s adherence to quality standards and manufacturing practices.

-

Quality Reports: Requesting detailed quality reports can reveal the supplier’s testing methods, quality metrics, and results from previous production runs.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s QC processes. These organizations can conduct thorough assessments and report their findings back to the buyer.

-

Certifications and Documentation: Reviewing certifications related to quality standards, as well as documentation of processes and procedures, helps buyers understand how a supplier manages quality.

What Are the Specific QC Considerations for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of additional QC considerations. These include:

-

Export Compliance: Ensure that the supplier complies with international export regulations. This is particularly important for products like CNC mills that may require export licenses.

-

Cultural and Regulatory Differences: Understanding the cultural and regulatory landscape of the supplier’s country can help buyers navigate potential challenges in quality assurance. This includes recognizing local standards and practices that may differ from international norms.

-

Logistical Challenges: International shipping can introduce variables that affect product quality. Buyers should work closely with suppliers to ensure proper handling and packaging during transport.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for 5-axis CNC mill desktops is essential for B2B buyers. By focusing on the key stages of manufacturing, adhering to international quality standards, and actively verifying supplier QC processes, buyers can make informed decisions that enhance their operational efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5 axis cnc mill desktop’

In this guide, we aim to equip B2B buyers with a practical checklist for sourcing a 5-axis CNC mill desktop. This technology is increasingly essential for precise machining in various industries, including aerospace, medical, and jewelry. By following this checklist, you can ensure a successful procurement process tailored to your specific needs and regional considerations.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. Consider factors such as material compatibility (e.g., aluminum, titanium), machining tolerances, and the intended applications. This step is critical as it guides your discussions with suppliers and helps filter options that do not meet your needs.

- Material Hardness: Ensure the mill can handle the hardness levels of the materials you plan to work with.

- Machining Capabilities: Decide whether you need full simultaneous 5-axis machining or if 3+2 indexing is sufficient.

Step 2: Research and Shortlist Potential Suppliers

Begin by compiling a list of manufacturers and suppliers specializing in 5-axis CNC mills. This research is vital to understanding the market landscape and identifying reputable companies.

- Supplier Reputation: Look for suppliers with a strong track record in your region or industry.

- Product Reviews: Read customer testimonials and case studies to gauge product performance and support.

Step 3: Evaluate Supplier Certifications and Compliance

Ensuring that suppliers have the necessary certifications is crucial for quality assurance and compliance with international standards. This step protects your investment and ensures reliable operation.

- ISO Certification: Verify if the supplier is ISO-certified, which indicates adherence to quality management standards.

- Export Compliance: Confirm that the supplier can legally export to your country, especially if you are in regions with strict trade regulations.

Step 4: Request Detailed Quotations

Once you have narrowed down your list, request detailed quotations from potential suppliers. A comprehensive quote will help you compare pricing, included features, and warranties.

- Inclusions: Ensure that the quote outlines all components, including tooling, software, and any necessary accessories.

- Payment Terms: Clarify payment options, financing availability, and any upfront costs.

Step 5: Assess After-Sales Support and Warranty Options

After-sales support can significantly impact your operational efficiency. Evaluate what support services are available and the terms of the warranty.

- Technical Support: Check if the supplier offers remote assistance or on-site training for your team.

- Warranty Coverage: Understand the duration and scope of the warranty provided, as well as any conditions that may void it.

Step 6: Visit the Supplier’s Facility (If Possible)

If feasible, arrange a visit to the supplier’s manufacturing facility. This allows you to inspect the production processes and quality control measures firsthand.

- Production Quality: Observe the machining process and the equipment used to ensure they meet your standards.

- Employee Expertise: Engage with the engineering team to assess their knowledge and ability to support your specific requirements.

Step 7: Finalize the Purchase Agreement

Once you’ve selected a supplier, finalize the purchase agreement. Ensure that all negotiated terms are documented clearly to avoid misunderstandings later.

- Delivery Timelines: Confirm expected lead times for delivery and installation.

- Contract Clauses: Review clauses regarding cancellations, returns, and liability to protect your interests.

By following this structured checklist, B2B buyers can confidently navigate the procurement of a 5-axis CNC mill desktop, ensuring that they make informed decisions that align with their operational goals.

Comprehensive Cost and Pricing Analysis for 5 axis cnc mill desktop Sourcing

What Are the Key Cost Components in Sourcing a 5 Axis CNC Mill Desktop?

Understanding the cost structure of a 5 axis CNC mill desktop is crucial for international B2B buyers. The primary components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the price. High-performance materials, such as aerospace-grade aluminum or G5 titanium, will increase costs compared to softer materials like Delrin or standard aluminum. Buyers should assess the material requirements based on their specific machining applications to optimize their investment.

-

Labor: Labor costs vary by region and can influence the overall pricing. Regions with higher labor costs may result in more expensive machines. In contrast, sourcing from countries with lower labor costs can provide more competitive pricing but may raise concerns about quality and reliability.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturers often pass savings to buyers, so understanding the supplier’s operational efficiency can help in negotiating better prices.

-

Tooling: Tooling costs are essential for CNC operations, encompassing everything from tool holders to specialized end mills. Buyers should consider whether the package includes essential tooling or if additional purchases will be necessary, as these can add to the total cost.

-

Quality Control: High-quality CNC mills usually come with rigorous QC processes, which can increase manufacturing costs. However, investing in quality assurance can reduce long-term operational costs by minimizing failures and maintenance.

-

Logistics: Shipping costs, particularly for international buyers, can be significant. Factors such as freight charges, insurance, and customs duties need to be included in the total cost assessment. Understanding Incoterms can help buyers negotiate better shipping terms and manage costs effectively.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary widely based on the supplier’s brand reputation, market demand, and the uniqueness of the machine.

How Do Price Influencers Affect the Cost of 5 Axis CNC Mills?

Several factors influence the pricing of 5 axis CNC mills, which international buyers should consider:

-

Volume/MOQ: Purchasing in larger quantities often leads to reduced per-unit costs. Buyers should assess their needs and consider bulk orders when possible to achieve better pricing.

-

Specifications and Customization: Custom features, such as enhanced spindle power or unique tooling options, can significantly increase costs. Buyers must clearly define their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Machines built with certified materials often command higher prices. However, investing in certified equipment can lead to better performance and longevity, thus reducing total ownership costs.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a strong track record may charge a premium, but they often provide better support and warranty services.

-

Incoterms: The chosen Incoterms can affect the total landed cost. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for buyers to manage shipping risks and costs effectively.

What Are the Best Practices for Negotiating and Managing Costs?

B2B buyers should adopt several strategies to enhance cost-efficiency and ensure a favorable purchasing experience:

-

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may offer discounts for upfront payments or longer contract commitments.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, operational efficiency, and potential downtime costs. A lower upfront cost may lead to higher operational costs over time.

-

Research and Compare: Gather quotes from multiple suppliers and assess their offerings critically. This can provide leverage in negotiations and help identify the best overall value.

-

Stay Informed About Market Trends: Understanding market dynamics in regions like Africa, South America, and the Middle East can help buyers anticipate pricing changes and make informed purchasing decisions.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better service, priority in order fulfillment, and potential cost reductions in future transactions.

By leveraging these insights, international B2B buyers can make informed decisions when sourcing 5 axis CNC mills, ensuring they achieve both quality and cost-effectiveness in their purchases.

Alternatives Analysis: Comparing 5 axis cnc mill desktop With Other Solutions

Introduction to Alternative Solutions for 5 Axis CNC Mill Desktops

In the landscape of precision machining, the 5 axis CNC mill desktop presents a powerful solution for intricate manufacturing tasks. However, buyers must consider alternative technologies that may offer similar capabilities or advantages depending on specific operational needs. This section explores viable alternatives, allowing B2B buyers to make informed decisions based on performance, cost, and application suitability.

Comparison Table of 5 Axis CNC Mill Desktop and Alternatives

| Comparison Aspect | 5 Axis CNC Mill Desktop | Alternative 1: 3 Axis CNC Mill | Alternative 2: CNC Router |

|---|---|---|---|

| Performance | High precision for complex shapes | Good for simpler geometries | Efficient for flat materials |

| Cost | Moderate (e.g., $6,900) | Lower (e.g., $3,000) | Variable (e.g., $2,000 – $5,000) |

| Ease of Implementation | Requires advanced setup | Easier setup and operation | User-friendly with less training |

| Maintenance | Higher due to complexity | Lower, fewer moving parts | Generally low, but depends on usage |

| Best Use Case | Aerospace, medical, jewelry | Prototyping, basic machining | Sign-making, cabinetry, soft materials |

Detailed Breakdown of Alternatives

Alternative 1: 3 Axis CNC Mill

The 3 axis CNC mill is a cost-effective alternative that is suitable for simpler machining tasks. It operates on three axes—X, Y, and Z—allowing for efficient machining of flat and moderately complex parts. While the performance may not match that of a 5 axis mill in terms of intricate designs, its lower cost and ease of implementation make it attractive for startups and small businesses focused on prototyping and basic manufacturing. However, its limitations in handling complex geometries can lead to additional machining steps, potentially increasing overall production time.

Alternative 2: CNC Router

CNC routers are versatile tools designed primarily for woodworking and soft materials. They can handle large sheets and are known for their speed and efficiency in cutting flat surfaces. While they are less suited for high-precision tasks compared to a 5 axis CNC mill, their lower price point and user-friendly operation make them appealing for businesses focused on sign-making, cabinetry, or similar applications. The trade-off lies in their limited capability to perform intricate or detailed work, which could necessitate additional tooling or processes for certain projects.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right machining solution hinges on specific business requirements, including the complexity of parts, budget constraints, and operational capabilities. The 5 axis CNC mill desktop excels in precision for complex applications, making it ideal for industries such as aerospace and medical. However, for businesses focused on simpler projects or those with tighter budgets, 3 axis CNC mills or CNC routers may present more viable options. By evaluating the unique demands of their operations and considering the pros and cons of each alternative, B2B buyers can make a strategic investment that aligns with their production goals.

Essential Technical Properties and Trade Terminology for 5 axis cnc mill desktop

What Are the Essential Technical Properties of a 5-Axis CNC Mill Desktop?

Understanding the key technical specifications of a 5-axis CNC mill desktop is crucial for B2B buyers, especially when making investment decisions. Here are several critical properties that define the performance and suitability of these machines for various applications.

1. Material Capability

The material capability of a CNC mill indicates the types of materials it can effectively machine. For instance, models like the Pocket NC V2-10 can cut materials up to the hardness of G5 Titanium, making them suitable for industries requiring high-strength components. Buyers should assess their specific material needs, as some machines excel with softer materials like aluminum or plastics, while others are designed for harder alloys.

2. Travel Dimensions

Travel dimensions refer to the maximum distances the machine’s cutting tool can move along the X, Y, and Z axes. For example, the TN5-V6-TC8 offers travel distances of 500mm in the X-axis, 200mm in the Y-axis, and 280mm in the Z-axis. This is vital for determining whether the machine can accommodate the size of the parts you intend to manufacture. Selecting a machine with appropriate travel dimensions can enhance productivity and reduce setup times.

3. Tolerance and Accuracy

Tolerance defines the permissible limit of variation in a physical dimension, while accuracy refers to how close a machine’s output is to the desired measurement. High-precision machines, such as those with a rotational accuracy of 0.002mm, are essential in industries like aerospace and medical device manufacturing, where precision is paramount. For B2B buyers, understanding the required tolerances for their products can guide them in selecting a machine that meets quality standards.

4. Spindle Speed and Power

Spindle speed, measured in RPM (revolutions per minute), affects the machine’s ability to perform different types of cuts efficiently. A spindle speed range of 5,000 to 30,000 RPM, as found in some models, allows for both high-speed machining and the ability to handle tougher materials. Buyers should evaluate their machining requirements to ensure the spindle power and speed align with their production goals.

5. Control Software Compatibility

Many CNC mills operate using industry-standard G-code, which is essential for interoperability with various CAM (Computer-Aided Manufacturing) software. Understanding the control software used by a CNC mill is crucial for ensuring compatibility with existing systems and workflows. For international buyers, it’s also important to consider whether additional training or software licenses are necessary for effective operation.

What Are Common Trade Terms Related to 5-Axis CNC Mill Desktop?

Familiarity with industry terminology can help buyers navigate the complexities of purchasing a 5-axis CNC mill desktop. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC mills, knowing the OEM can help buyers assess the quality and reliability of the machine.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it can influence inventory costs and purchasing strategies, especially for businesses looking to scale.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request a price quote for specific goods or services. It is a standard practice in B2B transactions and helps buyers compare pricing and terms among different suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms can help buyers understand shipping costs, risk management, and delivery responsibilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is crucial for planning production schedules and ensuring timely delivery to customers.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when investing in 5-axis CNC mill desktops, aligning their purchases with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the 5 axis cnc mill desktop Sector

What Are the Key Trends Driving the 5 Axis CNC Mill Desktop Market?

The market for 5-axis CNC mill desktops is experiencing significant growth, driven by advancements in manufacturing technology and increasing demand for precision engineering across various sectors. One primary driver is the surge in industries such as aerospace, medical devices, and jewelry, where high precision and intricate designs are crucial. Additionally, the growing trend of digital fabrication and prototyping is pushing manufacturers to adopt 5-axis machining capabilities that allow for complex geometries and reduced setup times.

Another notable trend is the integration of smart technologies, such as IoT and AI, into CNC milling machines. This integration enables real-time monitoring and predictive maintenance, enhancing operational efficiency and minimizing downtime. Furthermore, the demand for compact and user-friendly machines is growing, particularly among small and medium-sized enterprises (SMEs) and educational institutions in regions like Africa and South America, where budget constraints are common.

International buyers, especially from regions like Nigeria and Saudi Arabia, should also consider lead times and export regulations when sourcing these machines. As manufacturers streamline their supply chains, understanding the logistics and compliance requirements will be essential for effective procurement.

How Is Sustainability and Ethical Sourcing Shaping the B2B Landscape for 5 Axis CNC Mills?

Sustainability and ethical sourcing are increasingly becoming focal points for B2B buyers in the 5-axis CNC mill desktop market. The environmental impact of manufacturing processes is under scrutiny, leading companies to seek machines that minimize waste and energy consumption. Many manufacturers are now prioritizing eco-friendly practices, such as using recyclable materials and energy-efficient components in their machines.

Buyers should also be aware of certifications that indicate a manufacturer’s commitment to sustainable practices. Certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as indicators of a company’s dedication to sustainability. Additionally, sourcing from suppliers who demonstrate transparency in their supply chains can help ensure that ethical practices are upheld throughout the manufacturing process.

Moreover, the push for greener technologies is leading to innovations in materials used for CNC milling. Companies are increasingly developing biodegradable or recyclable materials that can withstand the rigors of machining while reducing environmental footprints. For international buyers, especially those in regions facing stringent environmental regulations, aligning with suppliers who prioritize sustainability can enhance brand reputation and compliance.

What Is the Evolution of the 5 Axis CNC Mill Desktop Technology?

The evolution of 5-axis CNC mill desktop technology has been marked by significant advancements over the past few decades. Initially, CNC machines were primarily 3-axis systems, limiting their ability to produce complex geometries. However, as industries demanded greater precision and flexibility, manufacturers began developing 5-axis systems that allow for simultaneous movement across multiple axes.

The introduction of compact desktop models has democratized access to this technology, enabling smaller manufacturers and educational institutions to harness advanced machining capabilities. Early models were often expensive and required extensive training to operate, but recent innovations have focused on user-friendly interfaces and training resources, making them more accessible to a broader audience.

As technology continues to advance, the future of 5-axis CNC milling looks promising, with ongoing developments in automation, materials science, and software integration poised to further enhance the capabilities and applications of these machines in the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of 5 axis cnc mill desktop

-

How do I choose the right 5-axis CNC mill desktop for my business needs?

Choosing the right 5-axis CNC mill depends on several factors, including the materials you intend to work with, the size of the components, and your desired precision. Consider mills that offer flexibility, such as those capable of handling various materials like aluminum and titanium. Evaluate the machine’s specifications, such as travel distances, spindle speed, and tooling options. Additionally, assess software compatibility with your existing systems and whether the manufacturer provides adequate support and training. -

What is the typical lead time for ordering a 5-axis CNC mill desktop?

Lead times can vary significantly based on the manufacturer and the specific model. Generally, you can expect a lead time ranging from 2 to 8 weeks after placing an order. Factors influencing lead time include the complexity of the machine, customization options, and shipping logistics. It’s advisable to confirm the estimated shipping date with the supplier during your procurement process to plan your production schedules accordingly. -

What payment options are available for purchasing a 5-axis CNC mill desktop?

Most suppliers offer various payment methods, including credit cards, bank transfers, and financing options. Some manufacturers may provide financing plans specifically for businesses, which can be beneficial if you lack immediate capital. Ensure to inquire about payment terms and any potential discounts for bulk orders. Additionally, verify if the supplier accepts international payments, especially if you’re purchasing from regions like Africa or South America. -

Are there minimum order quantities (MOQs) for 5-axis CNC mills?

Many manufacturers have MOQs, especially for custom orders or when purchasing accessories. However, for standard models, you may often be able to order just one unit. It’s essential to discuss your needs directly with the supplier to determine any applicable MOQs and whether they can accommodate smaller orders, particularly if you’re testing the market or starting a new project. -

How can I vet suppliers of 5-axis CNC mills?

To vet suppliers, start by researching their reputation within the industry. Look for customer reviews, case studies, and testimonials to gauge the quality of their machines and service. Verify their certifications and compliance with international standards, particularly if you’re importing. Engaging in direct communication can also help assess their responsiveness and support capabilities. Additionally, consider requesting references from other businesses that have purchased similar equipment. -

What are the shipping options for 5-axis CNC mills, especially for international orders?

Shipping options for international orders typically include air freight, sea freight, or a combination of both. The choice depends on your budget, urgency, and the size of the equipment. Be sure to discuss shipping terms with your supplier, including who is responsible for customs clearance and potential tariffs. It’s also wise to confirm the estimated delivery time and whether the supplier provides tracking information. -

How do I ensure quality assurance for my 5-axis CNC mill purchase?

Quality assurance can be ensured by selecting suppliers who provide detailed specifications and warranties for their machines. Requesting factory inspection reports and certifications can also be beneficial. Additionally, consider suppliers that offer post-purchase support, including training and maintenance services. Engaging in a comprehensive pre-purchase evaluation, such as a demo or trial run, can further help confirm the machine meets your quality standards. -

Can I customize my 5-axis CNC mill desktop?

Yes, many manufacturers offer customization options to meet specific business needs. Customizations may include modifications to the machine’s size, tooling capabilities, or software integration. When discussing your requirements with suppliers, be clear about your intended applications and any unique features you may need. Keep in mind that customizations may affect lead times and pricing, so it’s important to clarify these details upfront.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 5 Axis Cnc Mill Desktop Manufacturers & Suppliers List

1. Pentamachine – Pocket NC V2-10

Domain: pentamachine.com

Registered: 2020 (5 years)

Introduction: {“product_name”: “Pocket NC V2-10”, “price”: “$6,900.00”, “description”: “A 5-axis tabletop CNC mill capable of cutting materials with hardnesses up to G5 Titanium. Optimized for delrin, aluminum and softer steels, it features full 5-axis simultaneous motion and accepts standard G-code. Now shipping with Kinetic Control.”, “capabilities”: “Capable of 3+2 or full simultaneous 5 axis machining.”, “t…

2. PocketNC – Key Product

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Two miniature CNC milling machines mentioned: PocketNC and DesktopNC. PocketNC is noted for hobbyist use with soft metals and wood, but requires expensive software for full 5-axis machining. DesktopNC comes with free software that can generate simultaneous 5-axis G-code. Key considerations include machine strength, spindle power (noted as 800 watts), and the impact of vibration on machining qualit…

3. MDA Precision – TN5-V6-TC8 High Precision 5-Axis CNC Mill

Domain: mdaprecision.com

Registered: 2003 (22 years)

Introduction: This company, MDA Precision – TN5-V6-TC8 High Precision 5-Axis CNC Mill, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. 5AXISMAKER – Desktop CNC Machines

Domain: 5axismaker.co.uk

Registered: 2022 (3 years)

Introduction: 5AXISMAKER offers desktop CNC machines that provide both 5-axis milling and 3D printing capabilities. These machines are designed for various applications including dental aligners, product design, architecture, aerospace, automotive, sculpture, and more. They allow for complex designs to be created affordably and efficiently, with the ability to control milling in two additional rotating axes com…

5. Haas – Universal Machining Centers

Domain: haascnc.com

Registered: 1996 (29 years)

Introduction: This company, Haas – Universal Machining Centers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. CNC Cookbook – Pocket NC 5-Axis Desktop Mill

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: Pocket NC: 5-Axis Desktop Mill, Kickstarter project with 280 backers pledging $355,833, high-speed spindle, trunion table, designed for better rigidity, target price of $3500, capable of machining aluminum, attention to detail from a team of machinists and engineers, promising early signs of success.

Strategic Sourcing Conclusion and Outlook for 5 axis cnc mill desktop

The landscape of 5-axis CNC mills is evolving rapidly, offering significant opportunities for international B2B buyers seeking precision and versatility in manufacturing. Key takeaways highlight the machines’ capabilities in handling various materials, including titanium and aluminum, making them suitable for diverse applications such as aerospace, medical, and micro-machining. The strategic sourcing of these desktop mills not only facilitates cost-effective production but also enhances operational efficiency and product quality.

As manufacturers in Africa, South America, the Middle East, and Europe continue to invest in advanced technologies, the importance of selecting the right equipment cannot be overstated. A well-informed purchasing decision can lead to improved production cycles and a competitive edge in the marketplace.

Looking ahead, businesses are encouraged to leverage the latest advancements in 5-axis CNC technology to optimize their manufacturing processes. By engaging with reputable suppliers and exploring financing options, companies can ensure they are well-equipped to meet the demands of an increasingly competitive global market. Now is the time to take action and invest in the future of your manufacturing capabilities.