Contents

Manufacturing Insight: 5-Axis Cnc Machining Services

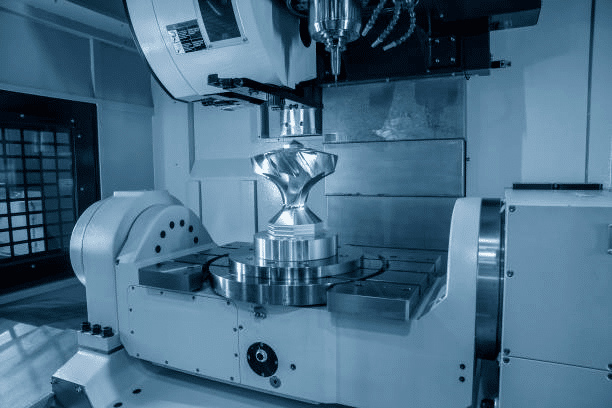

Precision 5-Axis CNC Machining Services for Complex Engineering Challenges

Honyo Prototype delivers advanced 5-axis CNC machining services engineered to transform intricate designs into high-precision components with exceptional repeatability. Our state-of-the-art facility utilizes DMG MORI and HAAS multi-axis machining centers, capable of achieving tolerances down to ±0.005 mm while handling complex geometries that demand simultaneous five-axis motion. This capability eliminates costly secondary operations, reduces lead times, and ensures superior surface finishes for mission-critical parts across aerospace, medical device, and defense sectors. We machine a comprehensive range of materials including titanium alloys, Inconel, aluminum 7075, PEEK, and engineered plastics, adhering to stringent AS9100 and ISO 13485 quality standards.

For design engineers and procurement teams requiring rapid validation of manufacturability and cost, Honyo Prototype provides an industry-leading Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed technical assessment and competitive pricing within hours—not days—accelerating your path from concept to certified production. Our engineering team collaborates proactively to optimize designs for manufacturability, ensuring your project achieves both technical excellence and cost efficiency from the first machining run.

Technical Capabilities

5-axis CNC machining services provide advanced precision manufacturing capabilities for complex geometries and high-tolerance components. These services include 3-axis, 4-axis, and full 5-axis milling, as well as CNC turning, enabling versatile production across a range of engineering materials such as aluminum, steel, ABS, and nylon. The integration of multi-axis motion allows for reduced setup times, improved accuracy, and the ability to machine intricate features in a single operation.

| Feature | Specification Detail |

|---|---|

| Machining Types | 3-axis milling, 4-axis indexing milling, 5-axis simultaneous milling, CNC turning |

| Axis Configuration | XYZ linear axes with A/C or B/C rotary axes for full 5-axis simultaneous movement |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.003 mm (±0.0001″) |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005″) typical; down to ±0.005 mm (±0.0002″) for critical features |

| Surface Finish | As low as 0.8 µm Ra (32 µin); polishable to <0.4 µm Ra with post-processing |

| Maximum Work Envelope | Up to 1200 x 600 x 500 mm (47 x 24 x 20 in) depending on machine configuration |

| Spindle Speed | Up to 24,000 RPM (high-speed options available for aluminum and plastics) |

| Tool Changer Capacity | 20–30 tool automatic tool changers (ATC) standard on 5-axis machines |

| Control System | Fanuc, Siemens, or Heidenhain with advanced CAM integration (e.g., Mastercam, Hypermill) |

| Material Type | Common Grades | Machinability Notes |

|---|---|---|

| Aluminum | 6061-T6, 7075-T6, 2024-T3, 5052 | Excellent machinability; high material removal rates; ideal for aerospace and prototyping |

| Steel | 4140, 4340, 1018, A2, D2, Stainless 303/316 | Moderate to difficult; requires rigid setup; tight tolerances achievable with proper tooling |

| ABS | Industrial-grade ABS (e.g., PA-765) | Easy to machine; low melting point; ideal for functional prototypes and jigs |

| Nylon | Nylon 6, Nylon 6/6, Glass-filled options | Low friction; prone to deflection; requires sharp tools and light cuts for precision |

These machining services are optimized for industries requiring high precision and repeatability, including aerospace, medical, robotics, and automotive. Multi-axis capabilities eliminate the need for multiple fixtures, reduce lead times, and maintain geometric accuracy across complex parts. Tight tolerance machining is supported by in-process probing, thermal compensation, and post-process CMM inspection to ensure conformance to technical drawings and GD&T requirements.

From CAD to Part: The Process

Honyo Prototype 5-Axis CNC Machining Service Workflow

Our end-to-end 5-axis CNC machining process is engineered for precision, speed, and manufacturability assurance. The sequence begins when a client uploads a CAD model through our secure portal. Supported formats include STEP, IGES, and native SOLIDWORKS files, with automatic validation for geometric integrity and unit consistency. This initial upload triggers immediate data ingestion into our production ecosystem.

AI-Powered Quoting Engine

The uploaded CAD model undergoes rapid analysis via our proprietary AI quoting system. This engine evaluates part geometry, material requirements, tolerance specifications, and surface finish criteria against real-time shop floor data—including machine availability, tooling costs, and labor rates. The output is a detailed, transparent quote within 2 business hours, inclusive of NRE charges, material costs, and expedited lead time options. Crucially, this is a preliminary quote; final pricing requires DFM validation to eliminate unforeseen complexities.

Engineering-Led DFM Analysis

Upon quote acceptance, our manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) review. This is not an automated checkpoint but a collaborative engineering assessment focusing on:

Eliminating impractical undercuts or inaccessible features for 5-axis toolpaths

Optimizing stock material dimensions to minimize waste

Refining tolerances where GD&T over-specification increases cost without functional benefit

Verifying fixturing strategy feasibility for thin-wall or delicate geometries

Recommending cost-saving material substitutions where permissible

The DFM report includes annotated CAD markups, cost-impact analysis, and alternative design suggestions. Client feedback is integrated within 24 hours to lock the final manufacturing plan. Below summarizes critical DFM evaluation criteria:

| DFM Focus Area | Key Checks | Typical Resolution Time |

|---|---|---|

| Geometric Feasibility | Collision avoidance, tool reach, step-over | 2-4 hours |

| Tolerance Rationalization | GD&T alignment with part function | 1-2 hours |

| Material Utilization | Billet size optimization, nesting potential | 1-3 hours |

| Surface Finish | Toolpath strategy for critical features | 2-4 hours |

Precision Production Execution

Approved designs move to production on our DMG MORI and MAZAK 5-axis vertical machining centers. Each run includes:

Pre-machining CMM verification of raw stock

In-process probing for workpiece alignment and tool wear compensation

Real-time SPC monitoring of critical dimensions

Dedicated machine cells for aluminum, titanium, and engineering plastics to prevent cross-contamination

All operations adhere to ISO 9001:2015 protocols, with first-article inspection reports generated per AS9102 standards for aerospace clients. Complex assemblies undergo sub-assembly validation before final machining.

Certified Delivery & Documentation

Completed parts undergo final QA per the client’s inspection plan, including full FAI documentation where required. Shipments include:

Material test reports (MTRs) with traceable heat numbers

Dimensional conformance certificates (COC)

Process validation records for critical features

Packaging certified for ESD-sensitive or high-polish finishes

Standard lead time from DFM approval to delivery is 5-7 business days for single-part prototypes, scalable to 10-12 days for complex assemblies. All shipments include digital access to as-machined 3D scan data for client validation.

This integrated workflow ensures first-pass yield rates exceeding 98.5% while compressing traditional prototyping timelines by 40%. We maintain rigorous change control between phases to prevent scope creep, guaranteeing cost and schedule adherence without compromising precision.

Start Your Project

Discover precision and reliability with our 5-axis CNC machining services at Honyo Prototype. Engineered for complex geometries and tight tolerances, our advanced machining solutions ensure superior part accuracy and faster turnaround times.

Our state-of-the-art facility in Shenzhen is equipped with the latest 5-axis technology, supported by a team of expert engineers dedicated to delivering high-quality prototypes and production components for aerospace, medical, automotive, and industrial applications.

Partner with us for seamless manufacturing excellence.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Honyo Prototype – Precision Machining from Shenzhen to the World.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.