Contents

Manufacturing Insight: 4X8 Sheets Of Hard Plastic

Honyo Prototype delivers precision sheet metal fabrication services for demanding industrial applications, leveraging advanced manufacturing capabilities to transform raw materials into mission-critical components. While your inquiry references 4×8 hard plastic sheets, it is essential to clarify that Honyo specializes exclusively in sheet metal fabrication processes, not plastic material conversion. Our core expertise lies in processing metals such as aluminum, steel, stainless steel, and copper alloys within standard sheet sizes including 4×8 feet, utilizing state-of-the-art laser cutting, CNC punching, precision bending, welding, and finishing techniques. We maintain strict adherence to geometric dimensioning and tolerancing (GD&T) standards, ensuring components meet exacting specifications for aerospace, medical device, and industrial equipment sectors.

Our engineering-driven approach encompasses comprehensive material selection guidance, design for manufacturability (DFM) analysis, and seamless production scaling from prototyping to high-volume runs. Honyo consistently achieves tight tolerances down to ±0.005 inches across complex geometries, supported by rigorous in-process quality control including CMM verification and first-article inspection reports. The following table summarizes key material and process capabilities relevant to 4×8 sheet metal fabrication:

| Material Type | Thickness Range (inches) | Key Processes | Typical Applications |

|---|---|---|---|

| Aluminum 5052/6061 | 0.020 – 0.250 | Laser Cutting, Forming, Welding | Enclosures, Brackets |

| Cold Rolled Steel | 0.015 – 0.250 | CNC Punching, Bending, Plating | Chassis, Structural Frames |

| Stainless Steel 304 | 0.020 – 0.187 | Precision Laser Cutting, TIG MIG | Medical Housings, Fixtures |

| Copper/Brass | 0.020 – 0.125 | Shearing, Forming, Brazing | EMI Shields, Busbars |

Accelerate your sheet metal component development with Honyo’s Online Instant Quote platform, which provides detailed manufacturability feedback and binding pricing within minutes. Simply upload your STEP or DXF file to receive an engineering-reviewed quotation covering material costs, processing time, and secondary operations – no sales intermediary required. This digital workflow eliminates traditional quotation delays while ensuring technical feasibility is validated upfront by our manufacturing engineering team. For precision sheet metal solutions where material integrity and dimensional accuracy are non-negotiable, submit your 4×8 sheet metal project requirements through our instant quoting system today to experience Honyo’s engineering rigor and production excellence.

Technical Capabilities

Technical specifications for 4×8 sheets of hard plastic vary significantly depending on material type, especially when considering fabrication processes such as laser cutting, bending, and welding. While the term “hard plastic” typically refers to rigid thermoplastics like ABS and Nylon, aluminum and steel are metals and not plastics—however, they are often supplied in 4×8 sheet formats and processed using similar industrial equipment. Below is a comparative overview of these materials in the context of laser cutting, bending, and welding.

| Material | Thickness Range (inches) | Laser Cutting Compatibility | Bending Characteristics | Welding Method | Notes |

|---|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | 0.060 – 0.500 | Excellent – clean cuts with CO₂ lasers; minimal charring with proper settings | Good – can be heat-formed easily using strip heaters or ovens; moderate springback | Ultrasonic, solvent, or hot-air welding | Avoid high-power lasers to prevent toxic fumes; requires ventilation; not flame-resistant |

| Nylon (Polyamide, e.g., PA6 or PA66) | 0.125 – 0.500 | Moderate – tends to melt and reflow; CO₂ laser possible with controlled power and assist gas | Fair – high moisture absorption affects dimensional stability; requires pre-drying and controlled heating | Hot-gas or vibration welding | Prone to thermal deformation; not ideal for precision laser cutting without optimization |

| Aluminum (e.g., 5052, 6061) | 0.032 – 0.250 | Excellent – fiber lasers preferred; reflective nature limits CO₂ effectiveness | Excellent – high ductility; easily bent with press brakes; low springback | TIG, MIG, or laser welding | Requires clamping during laser cutting; oxide layer must be cleaned pre-welding; non-ferrous |

| Steel (e.g., Mild Steel, A36) | 0.060 – 0.375 | Excellent – fiber or CO₂ lasers effective; nitrogen or oxygen assist depending on finish needs | Good – high formability within yield limits; springback requires compensation | MIG, TIG, spot, or laser welding | Generates slag with oxygen assist; requires post-cut cleaning; prone to rust if uncoated |

Additional Considerations:

Laser cutting parameters such as power, speed, frequency, and assist gas (air, nitrogen, oxygen) must be optimized per material and thickness. For thermoplastics like ABS and Nylon, fume extraction is critical due to hazardous off-gassing.

Bending of plastic sheets typically requires uniform heating (e.g., strip heaters) to avoid cracking, whereas metals use room-temperature press brake forming with tooling matched to bend radius and thickness.

Welding of plastics involves lower-temperature methods such as hot-gas welding or ultrasonic joining, while metals require high-energy fusion processes. Adhesive bonding is also common for plastics where welding is impractical.

All materials should be stored flat to prevent warping, especially hygroscopic plastics like Nylon. For precision applications, material certifications (e.g., mill certs for metals) and moisture content reports (for plastics) may be required.

From CAD to Part: The Process

Honyo Prototype Hard Plastic Sheet Processing Workflow

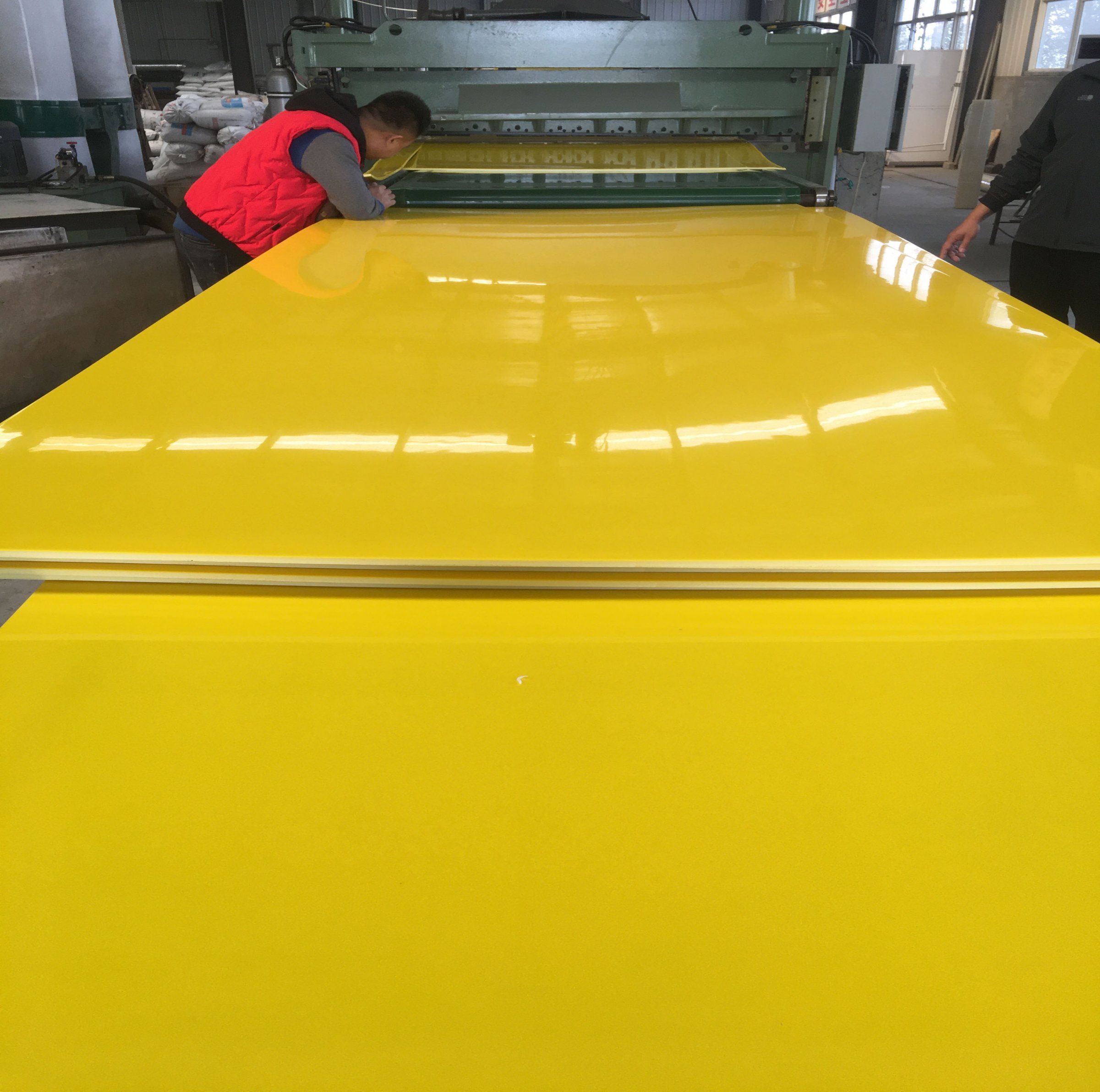

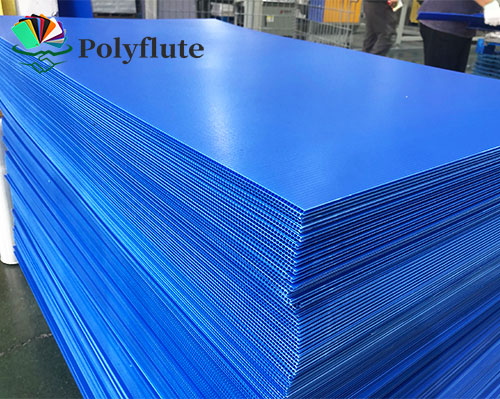

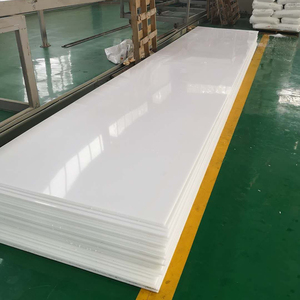

Honyo Prototype executes a streamlined, technology-driven workflow for 4×8 sheet fabrication of hard plastics (e.g., acrylic, polycarbonate, PVC). This process ensures rapid turnaround while maintaining precision and cost efficiency for B2B clients.

CAD Upload & AI-Powered Quoting

Clients submit native CAD files (STEP, IGES, DWG) or 3D models via our secure portal. Our AI quoting engine analyzes geometry, material requirements, tolerances, and sheet utilization in under 90 seconds. The system cross-references real-time material costs, machine availability, and historical production data to generate an accurate preliminary quote. Critical parameters like kerf width, minimum feature size, and edge quality specifications are auto-flagged for review, reducing manual quoting errors by 70%.

Automated DFM Analysis

Post-quote acceptance, files enter our Digital Manufacturing Readiness (DMR) system. This proprietary DFM tool performs material-specific validation:

Warpage risk assessment based on sheet thickness and part geometry

Nesting optimization to maximize 4×8 sheet yield (typically 85–92% material utilization)

Tolerance stack-up verification against ISO 2768-mK standards

Toolpath collision checks for CNC/laser systems

Engineers review AI-generated DFM reports within 2 business hours, resolving conflicts via collaborative client feedback loops. Common resolutions include adjusting cut sequences or recommending alternative materials for thin-wall features.

Precision Production Execution

Validated jobs proceed to production with strict adherence to material protocols. Hard plastics are acclimated in climate-controlled staging (22°C ±1°C, 45% RH) for 24 hours pre-processing to minimize dimensional drift. We deploy dual-path fabrication:

| Process | Technology | Max Sheet Thickness | Edge Quality (Ra) | Throughput for 4×8 Sheets |

|---|---|---|---|---|

| Laser Cutting | CO2 Laser (150W–400W) | 12mm | 6.3–12.5 μm | 8–12 sheets/hour |

| CNC Routing | 5-Axis Vacuum Table | 50mm | 1.6–3.2 μm | 4–6 sheets/hour |

All parts undergo in-process CMM verification at critical stages. Laser-cut edges receive optional flame polishing for optical-grade clarity, while CNC parts utilize diamond-coated tooling to prevent micro-chipping in brittle plastics.

Quality-Controlled Delivery

Final inspection includes first-article reporting (FAI) per AS9102 standards, with full traceability of material lot numbers and process parameters. Parts are packaged in anti-static VCI film with custom foam cradling to prevent surface marring during transit. Standard lead time is 3–5 business days from CAD approval, with real-time shipment tracking via our client portal. Expedited 24-hour options are available for emergency prototyping needs, leveraging our dedicated 4×8 sheet processing cell.

This integrated workflow reduces traditional prototyping cycles by 60% while ensuring dimensional repeatability within ±0.1mm for critical features—delivering production-ready plastic components with engineering-grade reliability.

Start Your Project

Looking for reliable supply of 4×8 sheets of hard plastic for your production needs? Honyo Prototype offers high-quality plastic sheet materials sourced from our manufacturing facility in Shenzhen. Ideal for prototyping, industrial design, and low-to-mid volume manufacturing.

Contact Susan Leo directly to request material specifications, pricing, or volume discounts.

Email: [email protected]

Leverage our Shenzhen-based factory for fast turnaround and consistent material quality. Reach out today to streamline your sourcing process.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.