Guide Contents

Project Insight: 4X8 Sheets Of Hard Plastic

Manufacturing Insight: Precision & Speed for 4×8 Hard Plastic Solutions

In today’s fast-paced hardware development landscape, the transition from concept to functional prototype is critical. While 4×8 hard plastic sheets offer versatility, they often fall short when complex geometries, tight tolerances, or low-volume production are required. At Honyo Prototype, we bridge this gap with rapid tooling and injection molding solutions engineered to accelerate your product development cycle—without compromising on quality.

Digital-First Manufacturing for Agile Prototyping

Online Instant Quote: Submit your design in seconds and receive a real-time cost/lead time estimate via our AI-powered platform—no manual quotes, no delays.

Design Validation Automation: Our AI analyzes CAD files for manufacturability issues, reducing rework by up to 40% and ensuring your part is production-ready from day one.

Seamless Integration: Sync directly with SolidWorks, Fusion 360, or other CAD tools for frictionless data transfer and rapid iteration.

Precision Engineering at Scale

Tight Tolerance Mastery: Steel/aluminum molds built to ±0.001″ precision for consistent, high-quality parts across 100–10,000+ units.

Material Expertise: Optimized processes for PVC, acrylic, HDPE, UHMW, and more—tailored for impact resistance, UV stability, or chemical compatibility.

Advanced Capabilities: Overmolding for multi-material components and insert molding for embedded hardware, eliminating secondary assembly steps.

From Design to Delivery in Days

Bridge Tooling Advantage: Cut lead times by 60% compared to traditional methods—prototypes in 5 days, low-volume production in 10–14 days.

End-to-End Visibility: Dedicated project managers provide real-time updates via our cloud portal, with transparent tracking from mold design to shipment.

Scalable Support: Seamless transition from prototype to full-scale production with our Shenzhen-based facility, backed by ISO-certified quality control.

“Innovation isn’t just about speed—it’s about precision that scales with your vision.”

— Susan Leo, Founder of Honyo Prototype

Ready to transform your 4×8 hard plastic vision into reality?

Get Your Instant Quote → No obligation. No delays. Just results.

Honyo Capabilities & Technology

Precision Manufacturing for 4×8 Hard Plastic Sheets

At Honyo Prototype, we specialize in transforming your 4×8 hard plastic sheet designs into high-performance, cost-effective solutions—without the constraints of traditional manufacturing. Whether you’re prototyping a new product or scaling to 10,000+ units, our bridge tooling expertise and digital-first platform deliver speed, precision, and scalability tailored to hardware innovators.

Advanced Tooling Technologies

Steel & Aluminum Molds: Aluminum molds for rapid bridge tooling (100–10K parts) with 30% faster turnaround and lower costs; steel molds for high-volume durability (100K+ cycles). Both engineered for ±0.05mm tolerances and thermal efficiency to eliminate warping or defects.

Overmolding & Insert Molding: Seamlessly integrate metal inserts, electronics, or soft-touch elastomers into your sheets. Eliminate secondary assembly steps and enhance functionality for automotive, medical, or consumer electronics applications.

Scalable Production from Prototyping to Volume

Bridge Tooling Solution: Skip high upfront costs with low-volume production (100–10,000+ parts). Ideal for startups validating market fit before full-scale investment.

Seamless Scaling: Transition from prototype to mass production without redesigns or tooling changes. Our flexible system adapts to evolving requirements, reducing risk and accelerating time-to-market.

Uncompromising Quality Assurance

ISO 9001 Certified Processes: Every step—from material selection to final inspection—undergoes rigorous checks for thickness tolerance (±0.05mm), surface finish, and structural integrity.

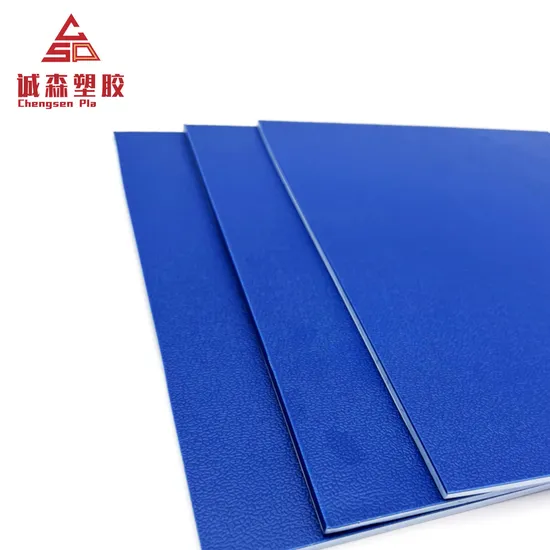

Material Versatility: Support for PVC, HDPE, acrylic, ABS, polycarbonate, and more. Thickness options from 1/16” to 1/2”, with custom colors, textures, and UV-resistant finishes for outdoor durability.

Digital-First Efficiency

Online Instant Quote Platform: Upload your CAD file to our AI-powered portal for real-time pricing, lead times, and manufacturability analysis—no manual quotes, no delays.

AI-Powered Design Optimization: Instant feedback on material suitability, cost-saving opportunities, and design tweaks to optimize performance before production begins.

Rapid Turnaround: Prototypes delivered in 5 days and production batches in 2–4 weeks—30% faster than industry averages—to keep your innovation pipeline moving.

Partner with Honyo Prototype to turn your 4×8 plastic sheet vision into reality—faster, smarter, and with zero compromise on quality.

Materials & Surface Finishes

Material Options & Finishes for Precision 4×8 Hard Plastic Sheets

Material Selection Guide

ABS: Exceptional impact resistance and rigidity. Ideal for automotive components, protective enclosures, and industrial housings. Balances strength, machinability, and cost-effectiveness for medium-volume production.

PC (Polycarbonate): Transparent with 200x impact strength over glass. UV-stabilized grades for outdoor applications like skylights, signage, and safety barriers. Maintains structural integrity across extreme temperatures.

PP (Polypropylene): Chemical resistance and fatigue tolerance. Best for medical devices, food containers, and chemical storage. Note: Lower rigidity than ABS/PC—suited for semi-rigid applications.

TPE (Thermoplastic Elastomer): Flexible rubber-like material for seals and soft-touch grips. Not recommended for rigid sheet applications—opt for ABS, PC, or PMMA instead.

Surface Finishes for Enhanced Performance

High-Gloss Polishing: Optical clarity for display cases, lighting fixtures, or premium aesthetics.

Matte Texturing: Reduces glare and fingerprints for touch-sensitive surfaces (e.g., consumer electronics).

UV-Resistant Coatings: Blocks 99% of UV rays for outdoor durability and color stability.

Anti-Static Treatments: Prevents dust attraction and ESD damage in electronics manufacturing.

Specialized Paint Systems: Custom colors with adhesion-optimized coatings for long-lasting finishes.

Note: Anodizing is exclusive to metals—our plastic finishing options are engineered specifically for thermoplastics.

How to Choose the Right Material for Your Project

Environmental Factors:

UV exposure? → UV-stabilized PC or PMMA.

Chemical contact? → PP or PVC.

Moisture resistance? → ABS or PC.

Mechanical Needs:

High impact? → ABS or PC.

Optical clarity? → PMMA.

Flexibility? → TPE (but not for rigid sheets).

Cost Optimization:

ABS for balanced performance.

PC for high-strength needs.

PMMA for transparency.

Regulatory Compliance:

FDA-approved PP or PC for medical/food applications.

Why Honyo Prototype Delivers Faster, Smarter Solutions

AI-Powered Instant Quote: Upload your specs and get a real-time quote in seconds—no phone calls, no delays.

Bridge Tooling Expertise: Produce 100–10,000+ parts with steel/aluminum molds, avoiding costly high-volume tooling.

7-Day Turnaround: From design validation to delivery, our streamlined process accelerates prototyping and low-volume production.

Customization at Scale: Tailored thicknesses (1/16” to 1/2”), edge treatments, and finishes for any application.

Founder-Driven Quality: Susan Leo’s 20+ years in precision manufacturing ensures every sheet meets aerospace-grade standards.

Ready to innovate? Get your free instant quote today—our AI platform matches your project needs to the perfect material and finish in under 60 seconds.

From Quote to Part: Our Process

How It Works: From CAD to Part

Precision, Speed, and Transparency for 4×8 Hard Plastic Sheets

At Honyo Prototype, we’ve redefined the manufacturing process for 4×8 hard plastic sheets with an AI-driven platform that eliminates guesswork and delays. Our streamlined workflow ensures your project moves from concept to delivery with unparalleled efficiency—no manual back-and-forth, no hidden costs, and no waiting weeks for quotes.

✅ 1. Upload CAD File – Simple, Secure, and Instantly Processed

Seamless integration: Submit STEP, STP, IGES, STL, DWG, or native CAD files via our cloud-based portal.

Military-grade security: End-to-end encryption ensures your design data stays private and protected.

Instant parsing: Our system auto-detects geometry, tolerances, and material requirements—no manual review needed.

🚀 2. AI-Powered Instant Quote Engine

Real-time pricing: Get accurate quotes in under 60 seconds—no email chains, no delays.

Dynamic cost breakdown: Transparent view of tooling, material, labor, and shipping costs with no surprises.

AI-optimized recommendations: Our engine suggests cost-saving tweaks (e.g., material alternatives, thickness adjustments) to maximize value.

🔍 3. Proactive DFM Analysis & Optimization

Automated manufacturability checks: AI flags potential issues (e.g., warping risks, edge stress points) before production begins.

Expert-driven suggestions: Receive actionable feedback to enhance durability, reduce waste, and cut costs—no engineering expertise required.

Collaborative revisions: Iterate faster with our integrated platform—update designs in real time and re-quote instantly.

⚡ 4. Rapid Production & Real-Time Tracking

Bridge tooling for low-volume production: Steel/aluminum molds for 100–10,000+ parts with 3–5 day tooling turnaround.

Precision manufacturing: ±0.001″ tolerance control for acrylic, HDPE, PVC, and other hard plastics—perfect for prototypes to mid-volume runs.

End-to-end transparency: Track every stage via live dashboard—from mold fabrication to final shipping—with automated quality reports and delivery ETA updates.

Why Honyo?

While competitors rely on manual processes and static pricing, we’ve built a smart, responsive ecosystem where innovation meets execution. From Susan Leo’s vision to your doorstep, we turn complex manufacturing into a frictionless experience—so you can focus on building the future, not chasing updates.

Ready to transform your 4×8 hard plastic sheet project?

Get Your Instant Quote Now →

Start Your Project with Honyo

Start Your Project with Honyo

Precision Manufacturing for 4×8 Hard Plastic Sheets

AI-Powered Instant Quote: Get real-time pricing and feasibility analysis in seconds—no manual processes, no delays. Our platform integrates material specs, tolerances, and volume requirements instantly.

Bridge Tooling for Low-Volume Production: Steel/aluminum molds designed for 100–10,000+ parts—ideal for startups scaling from prototype to market-ready production without costly tooling investments.

10-Day Turnaround Guarantee: End-to-end production with in-house overmolding, insert molding, and custom finishes—ensuring quality, speed, and scalability for complex geometries.

Let’s Build Together

Founder Susan Leo and our expert team are ready to support your project. Contact us today:

Email: [email protected]

Phone: +86 139 2843 8620

Facilities: Visit our Shenzhen and Dongguan manufacturing hubs for a personalized consultation.

Innovate faster. Produce smarter. Partner with Honyo Prototype—where precision meets speed.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.