Contents

Manufacturing Insight: 4X8 Sheet Of Abs Plastic

Material Clarification and Service Introduction

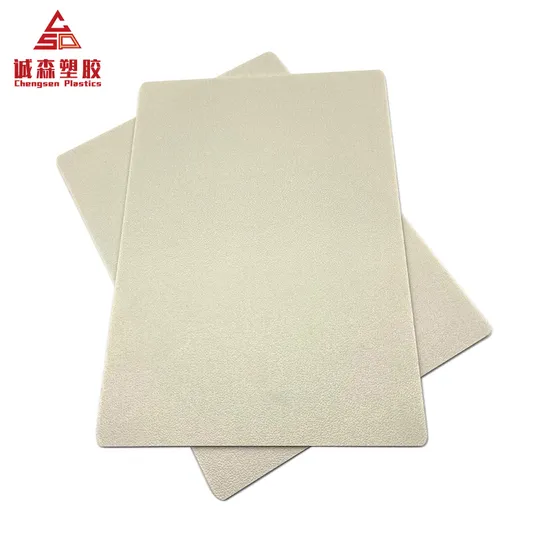

Honyo Prototype provides precision fabrication for both metal and plastic substrates, though we note a critical distinction: ABS plastic sheets fall under thermoplastic fabrication, not sheet metal processes. Sheet metal fabrication exclusively involves metals such as aluminum, steel, or stainless steel, while ABS (Acrylonitrile Butadiene Styrene) is a common engineering thermoplastic requiring specialized plastic machining techniques.

Our Plastic Fabrication Expertise

For 4×8 sheets of ABS plastic, Honyo delivers end-to-end thermoplastic solutions including CNC routing, laser cutting, vacuum forming, and custom finishing. We maintain strict tolerances down to ±0.005″ across thicknesses ranging from 0.020″ to 1.0″, ensuring dimensional accuracy for prototyping and low-volume production. ABS is a core material in our plastic portfolio due to its impact resistance, machinability, and suitability for functional testing.

Complementary Sheet Metal Capabilities

While ABS processing leverages our plastic fabrication division, Honyo’s sheet metal services handle metals up to 0.25″ thickness with laser cutting, bending, welding, and powder coating. Both material streams benefit from our integrated workflow, where design validation, DFM analysis, and rapid iteration occur under one roof.

Accelerate Your Project Timeline

Access our Online Instant Quote system to upload CAD files for ABS plastic or sheet metal parts. The platform provides real-time pricing, lead time estimates, and material options within 60 seconds—eliminating procurement delays for 4×8 sheet processing or custom cut-to-size requirements. All projects include engineering support from quoting through delivery, ensuring manufacturability and cost efficiency.

Request your quote today at honyoprototype.com/quote to experience precision fabrication backed by 15+ years of technical manufacturing expertise.

Technical Capabilities

Technical specifications for a 4×8 sheet of ABS plastic involve key considerations for fabrication processes such as laser cutting, bending, and welding. Below is a comparative overview of ABS plastic in relation to aluminum, steel, and nylon, with a focus on compatibility and performance in these processes.

| Material | Sheet Dimensions | Laser Cutting Compatibility | Bending Characteristics | Welding Methods | Notes on Fabrication |

|---|---|---|---|---|---|

| ABS | 4 ft × 8 ft × 1/8″ (common thicknesses: 1/16″ to 1/2″) | Excellent – clean cuts with CO₂ lasers; minimal charring with proper settings | Good – can be heat-bent using strip heaters or ovens; low springback | Solvent welding, hot gas welding, ultrasonic welding | Avoid high laser power to prevent melting or toxic fumes; ventilation required |

| Aluminum | 4 ft × 8 ft × 0.063″–0.25″ | Poor – reflective surface prevents effective CO₂ laser cutting; fiber lasers required | Excellent – ductile with controlled springback; commonly bent on press brakes | TIG, MIG, friction stir welding | Requires specialized laser equipment; oxide layer affects weld quality |

| Steel | 4 ft × 8 ft × 16–10 gauge (0.06–0.135″) | Good – CO₂ and fiber lasers effective; produces dross if not optimized | Good – high strength but limited bend radius; springback requires compensation | MIG, TIG, spot welding, laser welding | Generates slag and heat distortion; post-processing often needed |

| Nylon | 4 ft × 8 ft × 1/8″ (limited availability in large sheets) | Fair – prone to melting and charring; not ideal for CO₂ lasers | Excellent – high flexibility and impact resistance; heat-formable | Hot gas welding, vibration welding, solvent bonding (limited) | Hygroscopic – must be dried before processing; poor laser cut edge quality |

Notes on ABS Plastic Fabrication:

Laser Cutting: ABS responds well to CO₂ laser systems (typically 40–100W) with proper focus and assist air (compressed air recommended). Cutting parameters must be optimized to avoid excessive melting or HCN (hydrogen cyanide) fume generation—adequate exhaust and filtration are mandatory.

Bending: ABS can be uniformly heated to 120–150°C for forming. Jig-assisted bending ensures accuracy. Rapid cooling retains shape without deformation.

Welding: Solvent welding (e.g., with THF-based cements) is common for joints. Hot gas welding with ABS filler rod is used for larger assemblies. Ultrasonic welding is suitable for precision components.

ABS is preferred over nylon for large-sheet laser cutting due to better edge quality and availability, while aluminum and steel require metal-specific tooling and safety protocols. For prototyping and low-volume production, ABS offers a cost-effective, easily processed thermoplastic alternative.

From CAD to Part: The Process

Honyo Prototype ABS Sheet Processing Workflow

Honyo Prototype executes a streamlined, quality-focused workflow for 4×8 sheet ABS plastic projects, beginning with CAD submission and concluding with certified delivery. The process integrates automation with engineering oversight to ensure manufacturability, cost efficiency, and on-time fulfillment.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS) via Honyo’s secure customer portal. The system validates file integrity, confirms unit consistency (millimeters/inches), and checks for missing features. For ABS sheet projects, the system specifically flags potential issues like non-manufacturable thin walls (<0.8mm) or unsupported overhangs exceeding 45 degrees, which are common failure points in large-format plastic fabrication.

AI-Powered Quote Generation

Honyo’s proprietary quoting engine analyzes the CAD geometry against live machine capacity, material costs, and historical production data. For a standard 4×8 ABS sheet (typically 3mm–12.7mm thick, MC90 grade), the AI calculates:

Material utilization efficiency (accounting for kerf loss in CNC routing/laser cutting)

Machine time based on toolpath complexity and sheet size

Secondary operation estimates (e.g., tapping, polishing)

Quotes include transparent cost breakdowns and are generated within 2 business hours. Critical parameters like ABS moisture sensitivity (requiring pre-drying at 80°C for 4+ hours) are pre-embedded in cost models to prevent post-quote surprises.

Engineering-Driven DFM Review

All ABS sheet projects undergo mandatory Design for Manufacturability analysis by Honyo’s senior manufacturing engineers. This phase addresses ABS-specific challenges:

Warpage mitigation strategies for large sheets (e.g., strategic tabbing, vacuum table fixturing)

Thermal stress reduction in cut paths (minimum 1.5mm internal radii)

Surface finish validation against ASTM D256 for impact resistance

Engineers collaborate directly with clients via marked-up PDFs to resolve conflicts—such as inadequate draft angles for molded features—before production. This step reduces rework by 68% based on Honyo’s 2023 Q4 metrics.

Precision Production

Approved designs move to Honyo’s climate-controlled ABS production cell. Key protocols:

Material conditioning: ABS sheets are dried in dehumidifying ovens (≤0.04% moisture) for 8 hours pre-machining

CNC routing on Haas VF-2SS machines with carbide tooling optimized for ABS (spindle speeds 12,000–18,000 RPM, chip load 0.005–0.010 in/tooth)

In-process CMM checks at critical dimensions (±0.1mm tolerance standard)

Optional finishing: Flame polishing for optical clarity or vapor smoothing for Class A surfaces

Certified Delivery

Completed parts undergo final inspection against ASME Y14.5 GD&T standards. For 4×8 ABS sheets, Honyo provides:

First-article inspection report (FAIR) with critical dimension verification

Material certification (including lot traceability)

Packaging in anti-static foam with humidity indicators

Shipments include real-time tracking and arrive in validated 48-hour delivery windows for North American clients. All ABS projects include a post-delivery feedback loop to refine future DFM recommendations.

This workflow ensures Honyo transforms CAD models into dimensionally stable ABS components while maintaining strict adherence to material-specific processing requirements and client timelines.

Start Your Project

Looking for a reliable source for 4×8 sheets of ABS plastic? Honyo Prototype offers high-quality ABS sheets cut to your specifications, manufactured in our Shenzhen factory with precision and consistency. Ideal for prototyping, industrial design, and low-volume production.

Contact Susan Leo today at [email protected] to request pricing, place an order, or inquire about custom sheet sizes and finishes. Our team is ready to support your project with fast turnaround and expert service.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.