Contents

Manufacturing Insight: 4X8 Cnc Router With Tool Changer

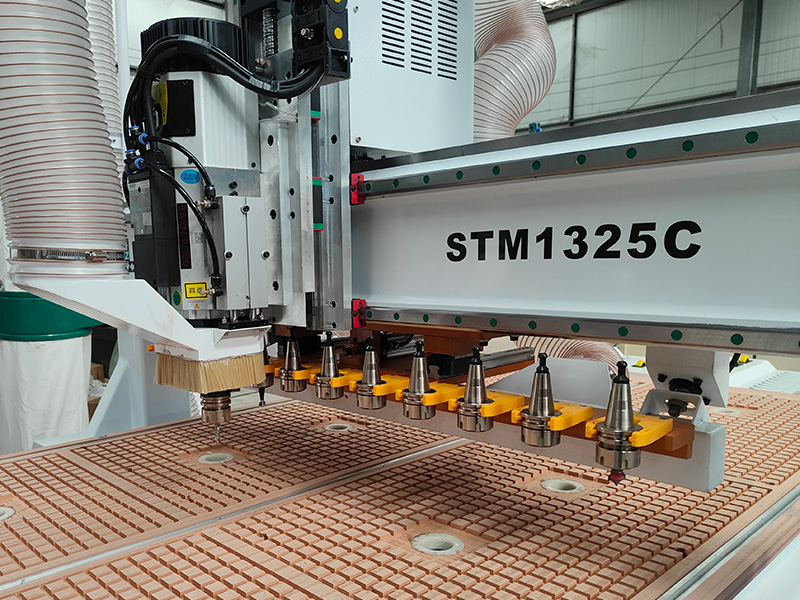

4×8 CNC Router with Automatic Tool Changer

Honyo Prototype delivers precision manufacturing solutions for demanding prototyping and low-to-mid volume production applications through our advanced 4×8 CNC routing platform equipped with a high-speed automatic tool changer (ATC). This system enables efficient machining of large-format substrates including aerospace composites, engineered woods, acrylics, and technical plastics with consistent accuracy up to ±0.001″. The integrated ATC eliminates manual tool changes, reducing cycle times by up to 40% while maintaining geometric tolerances critical for complex multi-operation parts. Our engineering team optimizes toolpaths and spindle parameters to maximize material yield and surface finish quality across diverse project requirements.

As a vertically integrated contract manufacturer, Honyo Prototype leverages this capability within a broader suite of CNC machining services—from rapid prototyping to certified production runs—ensuring seamless scalability from design validation to end-part fulfillment. Our facility maintains strict ISO 9001:2015 compliance with real-time process monitoring to guarantee repeatability for mission-critical components in aerospace, medical, and industrial sectors.

Transitioning from concept to manufactured part begins with our Online Instant Quote system. Upload CAD files to receive detailed manufacturability feedback and competitive pricing within minutes, backed by our engineering team’s expertise in optimizing designs for CNC router efficiency. This integrated workflow accelerates time-to-prototype while minimizing administrative friction for engineering procurement teams.

Technical Capabilities

Technical Specifications: 4×8 CNC Router with Automatic Tool Changer (ATC)

This high-performance 4×8 CNC router is engineered for precision 3-axis, 4-axis, and optional 5-axis milling operations, with integrated capabilities for light turning using rotary axis integration. Designed for tight-tolerance applications in prototyping and low-volume production, it supports a wide range of materials including aluminum, steel, ABS, and nylon. The automatic tool changer enables unattended multi-tool operations, enhancing efficiency and dimensional consistency.

| Specification | Detail |

|---|---|

| Work Envelope (Travel) | 48″ x 96″ x 6″ (X, Y, Z) – Custom Z-height options up to 12″ available |

| Control System | Fanuc 31i-B5, Siemens 840D, or Mach4/SmoothStepper (optional) |

| Spindle Motor | 15 HP (11 kW) ATC-compatible, ISO-30 or HSK-63 taper, variable speed 6,000–24,000 RPM |

| Positioning Accuracy | ±0.0005″ (12.7 µm) over full travel |

| Repeatability | ±0.0002″ (5 µm) |

| Axis Drive System | Precision ground ball screws with servo motors (optional linear motors on high-end models) |

| Tool Changer | Automatic Tool Changer (ATC) with 8–12 tool capacity, tool length measurement probe optional |

| Axes Configuration | Standard 3-axis (X, Y, Z); Optional 4th axis (rotary A-axis, ±360° indexing); Optional 5-axis (A/B or A/C trunnion table) |

| Turning Capability | Integrated 4th axis with live tooling support for light CNC turning (diameter up to 6″) |

| Maximum Material Tolerance | Capable of holding ±0.001″ (25 µm) on aluminum and ABS; ±0.0015″ (38 µm) on steel and nylon with proper fixturing and toolpath strategy |

| Materials Supported | Aluminum (6061, 7075), Mild and Stainless Steel (up to 4140), ABS, Nylon (including glass-filled grades), Delrin, and composites |

| Coolant System | Through-spindle coolant (optional) or flood coolant with mist collection |

| Vacuum Table | Multi-zone vacuum hold-down with pod system for sheet goods and fixtures |

| Rapid Traverse Rate | 1,200 IPM (X/Y), 800 IPM (Z) |

| Surface Finish Capability | <32 µin Ra on aluminum and plastics with fine finishing tools and optimized parameters |

| Machine Frame | Heavy-duty welded steel or cast iron base with vibration damping |

| Linear Guides | Hiwin or THK high-precision linear rails (size: 35 mm or 45 mm) |

| Software Compatibility | Compatible with Mastercam, Fusion 360, SolidWorks CAM, HyperMill, and Heidenhain |

| Probing System | Optional on-machine touch probe for tool setting, workpiece alignment, and in-process inspection |

This machine is ideal for high-mix, low-volume manufacturing environments requiring tight tolerances across diverse materials. With ATC and multi-axis capability, it supports complex 3D contouring, pocketing, drilling, and light turning—all within a single setup when configured with rotary or 5-axis components.

From CAD to Part: The Process

Honyo Prototype 4×8 CNC Router with Automatic Tool Changer Process Overview

Honyo Prototype utilizes a streamlined, technology-driven workflow for manufacturing parts via our 4×8-foot CNC routers equipped with automatic tool changers (ATC). This process ensures precision, efficiency, and rapid turnaround while maintaining rigorous quality standards. The workflow is structured into five distinct phases:

CAD File Upload

Clients initiate the process by uploading native CAD files (e.g., STEP, IGES, DWG, or native SolidWorks/Autodesk formats) through Honyo’s secure customer portal. Our system validates file integrity, checks for unit consistency, and confirms geometric completeness. Non-native formats undergo automated conversion with integrity verification to prevent data loss. Critical parameters such as material type, thickness, and finish requirements are specified during upload to inform downstream processes.

AI-Powered Quoting

Uploaded CAD data is processed by Honyo’s proprietary AI quoting engine, which performs preliminary manufacturability analysis. The system evaluates part geometry against machine capabilities (e.g., 4×8-foot bed size, 5HP spindle, 8–12 tool ATC capacity), material constraints, and standard operating procedures. Real-time cost estimation factors in material utilization, estimated machine runtime, toolpath complexity, and secondary operations. Quotes are generated within 2 business hours, including a preliminary DFM risk score. Complex geometries triggering high-risk flags are escalated to engineering for manual review before final quote issuance.

Engineering DFM Analysis

All projects undergo formal Design for Manufacturability (DFM) review by Honyo’s manufacturing engineering team. For 4×8 ATC routers, this phase focuses on: optimizing sheet nesting to maximize material yield, sequencing tool changes to minimize cycle time, validating toolpath strategies for thin/thick materials, and identifying potential vacuum table hold-down challenges. Engineers collaborate with clients to resolve conflicts—such as undercuts requiring specialized tooling or features exceeding the router’s 0.001-inch positional accuracy. Revised CAD files or process adjustments are documented, and final approval is obtained before production release.

CNC Production Execution

Approved jobs are scheduled on Honyo’s 4×8 CNC routers featuring 8–12 station ATCs, 5HP spindles (0–24,000 RPM), and high-precision linear guides. Key production steps include: material loading onto T-slot/vacuum tables, automated tool calibration via touch probes, and execution of optimized G-code with real-time tool wear monitoring. The ATC enables unattended multi-operation machining (e.g., roughing with compression bits, fine detailing with downcut spirals, and edge profiling), reducing manual intervention. All processes adhere to ISO 9001 traceability standards, with in-process inspections at critical stages using digital calipers and optical comparators.

Quality-Controlled Delivery

Completed parts undergo final inspection against client specifications, including dimensional verification (±0.005-inch tolerance standard), surface finish assessment, and deburring validation. Material certifications and process documentation (e.g., tooling logs, inspection reports) are compiled into a digital quality dossier. Parts are packaged with anti-scratch protection and shipped via client-preferred carriers, with tracking information and quality documentation shared through the customer portal. Standard lead time for ATC router projects is 3–5 business days post-DFM sign-off, with expedited options available.

Key Technical Specifications for 4×8 ATC Routers

| Parameter | Specification |

|————————-|—————————————-|

| Machine Bed Size | 48 x 96 inches (1220 x 2440 mm) |

| Spindle Power | 5 HP (3.7 kW), 0–24,000 RPM |

| Tool Changer Capacity | 8–12 tools (automated) |

| Positional Accuracy | ±0.001 inches (0.025 mm) |

| Standard Tolerance | ±0.005 inches (0.127 mm) |

| Supported Materials | Wood, MDF, acrylic, composites, aluminum (non-ferrous) |

This integrated process leverages automation for speed while retaining engineering oversight for complex challenges, ensuring clients receive production-ready parts with minimized lead times and zero non-conformances. Honyo’s focus on ATC optimization reduces per-part costs by 15–25% compared to single-tool setups for multi-operation jobs.

Start Your Project

Explore the precision and efficiency of our 4×8 CNC router with automatic tool changer—ideal for high-volume prototyping and production applications. Engineered for reliability and built with industrial-grade components, this machine delivers consistent performance for demanding manufacturing environments.

Manufactured in our Shenzhen facility, each unit undergoes rigorous quality control to ensure long-term durability and accuracy. Whether you’re in aerospace, automotive, or custom fabrication, this CNC router is designed to streamline your workflow and maximize uptime.

For detailed specifications, pricing, and lead times, contact Susan Leo at [email protected]. Let’s discuss how this machine can elevate your manufacturing capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.