Contents

Manufacturing Insight: 4X8 Abs Sheet

Precision ABS Sheet Fabrication for Demanding Applications

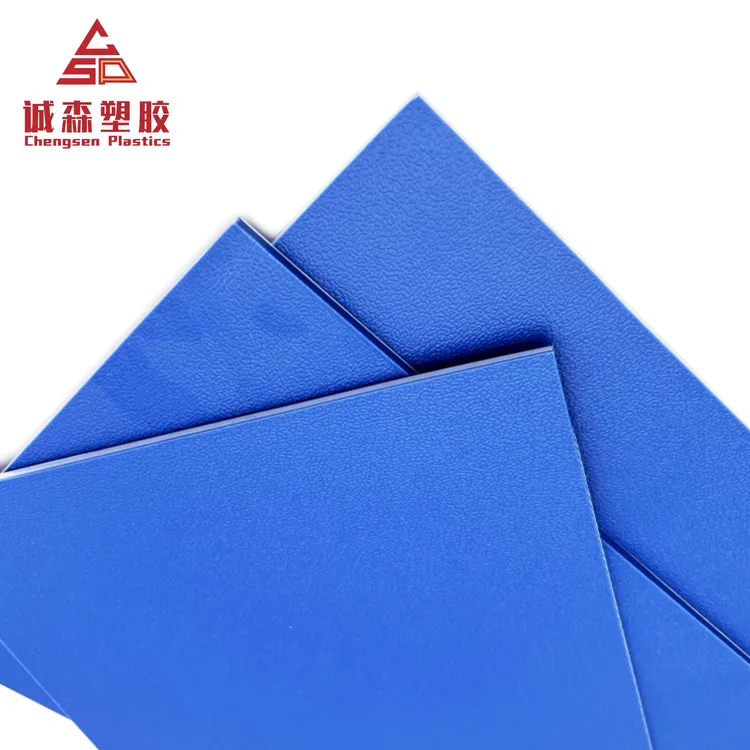

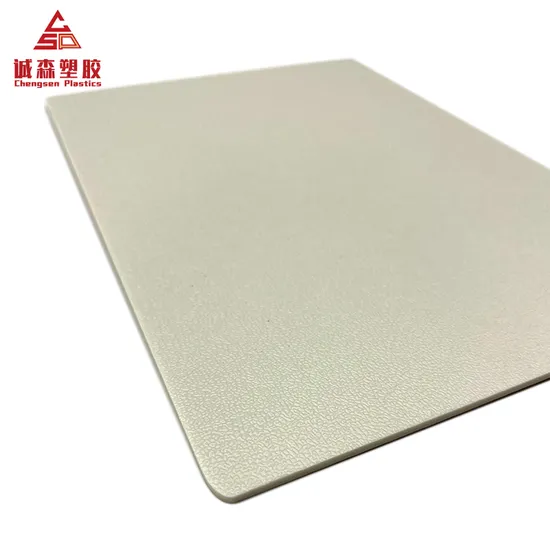

Honyo Prototype delivers engineered solutions for 4×8 ABS sheet material, leveraging decades of sheet metal fabrication expertise to ensure dimensional accuracy, structural integrity, and accelerated time-to-market. While ABS thermoplastic sheets fall outside traditional metal categories, our specialized forming, cutting, and finishing processes—refined through rigorous metal fabrication standards—translate seamlessly to high-tolerance plastic component production. This capability is critical for prototyping enclosures, jigs, and low-volume production parts where impact resistance, chemical stability, and thermal performance are non-negotiable.

Our integrated sheet metal fabrication services extend to ABS with the same ISO-certified quality controls, advanced CNC routing, and custom bending techniques applied to aluminum or steel. Clients benefit from material-agnostic precision, whether fabricating 1.5mm thin ABS housings or 10mm structural panels, with strict adherence to ±0.005″ tolerances. Crucially, Honyo eliminates quotation delays through our Online Instant Quote platform, providing real-time cost and lead-time feedback for 4×8 ABS sheet projects within minutes—not days. Submit DXF/DWG files directly to receive actionable pricing validated by our engineering team, streamlining procurement for R&D and production cycles alike.

For engineering teams requiring rapid iteration without sacrificing manufacturability, Honyo Prototype bridges material versatility with fabrication excellence. Begin your project with confidence by accessing our Online Instant Quote system today.

Technical Capabilities

The term “4×8 ABS sheet” typically refers to a thermoplastic sheet made of Acrylonitrile Butadiene Styrene (ABS) with dimensions of 4 feet by 8 feet (approximately 1219 mm × 2438 mm). While the name specifies ABS, similar sheet sizes are used across other materials like aluminum, steel, and nylon in fabrication processes. Below is a technical comparison focused on laser cutting, bending, and welding characteristics for each material in a 4×8 sheet format.

| Material | Thickness Range (typical) | Laser Cutting Compatibility | Bending Characteristics | Welding Method | Notes |

|---|---|---|---|---|---|

| ABS | 1 mm – 10 mm | Excellent – cuts cleanly with CO₂ lasers; minimal charring with proper settings | Good – can be heat-bent using strip heaters or ovens; prone to cracking if cold-formed | Not weldable with traditional methods; solvent or ultrasonic welding required | Thermoplastic; avoid high heat exposure; flammable – requires ventilation |

| Nylon (PA6/PA66) | 2 mm – 12 mm | Moderate – possible with CO₂ lasers but may melt or degrade; better suited for mechanical cutting | Good – high impact and abrasion resistance; can be heat-formed | Limited – friction or ultrasonic welding possible; not suitable for arc welding | Hygroscopic – must be dried before processing; excellent chemical resistance |

| Aluminum (e.g., 5052, 6061) | 0.5 mm – 12 mm | Excellent – fiber lasers preferred; reflective material requires proper beam control | Excellent – high formability; commonly bent on press brakes with radius ≥ material thickness | TIG or MIG welding; requires clean, oxide-removed surfaces | Lightweight; corrosion-resistant; reflective – safety precautions needed during laser cutting |

| Steel (Mild Steel, e.g., A36) | 0.8 mm – 12 mm | Excellent – fiber lasers provide precise, clean cuts | Good – bendable on press brakes; minimum bend radius ~0.5–1× thickness depending on grade | MIG, TIG, or spot welding; requires post-weld finishing for corrosion protection | Prone to rust; often powder-coated or painted after fabrication |

Application Notes:

Laser cutting is highly effective for all listed materials when the correct laser type and parameters are used. ABS and nylon require lower power and controlled speeds to prevent melting or toxic fumes. Aluminum and steel are best processed with fiber lasers due to reflectivity and thermal conductivity concerns.

For bending, aluminum offers the best combination of ductility and springback control, while ABS requires careful heating to avoid fractures. Steel provides structural rigidity but demands higher tonnage equipment.

Welding is primarily applicable to metals; thermoplastics like ABS and nylon rely on alternative joining methods such as fastening, adhesives, or specialized welding techniques.

All processes should follow manufacturer guidelines and safety protocols, particularly regarding ventilation (for plastics) and personal protective equipment (for metalworking).

From CAD to Part: The Process

Honyo Prototype delivers precision fabrication for 4×8 ABS sheet projects through a streamlined, technology-driven workflow designed for speed and manufacturability assurance. Our process begins with secure CAD file submission via the Honyo Portal, where clients upload native or neutral formats (STEP preferred). This triggers immediate validation against geometric and material constraints specific to ABS sheet processing, including maximum flatness tolerances and minimum feature size checks for routing or laser cutting.

The validated CAD model feeds our proprietary AI Quoting Engine, which analyzes part geometry, sheet utilization, and process parameters against live machine availability and material inventory. Within 120 seconds, clients receive a detailed digital quote specifying cost, lead time, and critical process notes—such as recommended ABS grade (e.g., MC-901 for machining, LGX for thermoforming) and edge finish options. All quotes undergo secondary validation by a manufacturing engineer to ensure accuracy.

Next, our Design for Manufacturability (DFM) phase executes automatically. Honyo’s DFM system performs 27 material-specific checks for ABS, including wall thickness validation (minimum 0.060″ for structural stability), draft angle verification (1.5° minimum for formed parts), and thermal stress risk assessment during cutting. Clients receive a comprehensive DFM report within 24 hours highlighting potential issues like unsupported thin sections or features prone to warpage. We provide actionable alternatives, such as suggested kerf adjustments for laser cutting or tab recommendations for nested parts to minimize sheet distortion.

Upon client approval, production initiates in our climate-controlled facility. 4×8 ABS sheets are quarantined for 48 hours at 72°F/50% RH to stabilize prior to processing. CNC routing uses diamond-coated tools at optimized spindle speeds (12,000–18,000 RPM) with through-spindle coolant to prevent melting, while laser systems employ nitrogen assist gas for clean edges. All parts undergo first-article inspection per AS9102 standards, with critical dimensions verified using calibrated CMMs. Typical production lead time is 3–5 business days from DFM sign-off.

Final delivery adheres to strict packaging protocols: parts are interleaved with anti-static film, secured in custom foam-lined crates, and shipped with material certs and FAI reports. We provide real-time logistics tracking through our client portal.

Standard Lead Time Breakdown for 4×8 ABS Sheet Projects

| Process Stage | Typical Duration | Key Dependencies |

|—————|——————|——————|

| CAD Upload to AI Quote | 2 minutes | Valid STEP/IGES file, complete material specification |

| AI Quote to DFM Completion | 24 hours | Client responsiveness to DFM feedback loops |

| DFM Approval to Shipment | 3–5 business days | Sheet thickness (≤0.250″ processes fastest), finishing requirements |

| Total Typical Turnaround | 4–6 business days | Excludes client revision cycles; expedited options available |

This integrated workflow reduces traditional prototyping timelines by 60% while ensuring ABS parts meet dimensional and cosmetic requirements for functional testing or low-volume production. Our system guarantees traceability from digital model to delivered part through blockchain-verified process logs accessible to clients.

Start Your Project

Looking for high-quality 4×8 ABS sheets for your next project? Contact Susan Leo at [email protected] to request a quote or inquire about material specifications. With our factory based in Shenzhen, we offer fast production and reliable delivery for prototyping and low-volume manufacturing needs. Reach out today to streamline your sourcing process with precision-engineered thermoplastic solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.