Contents

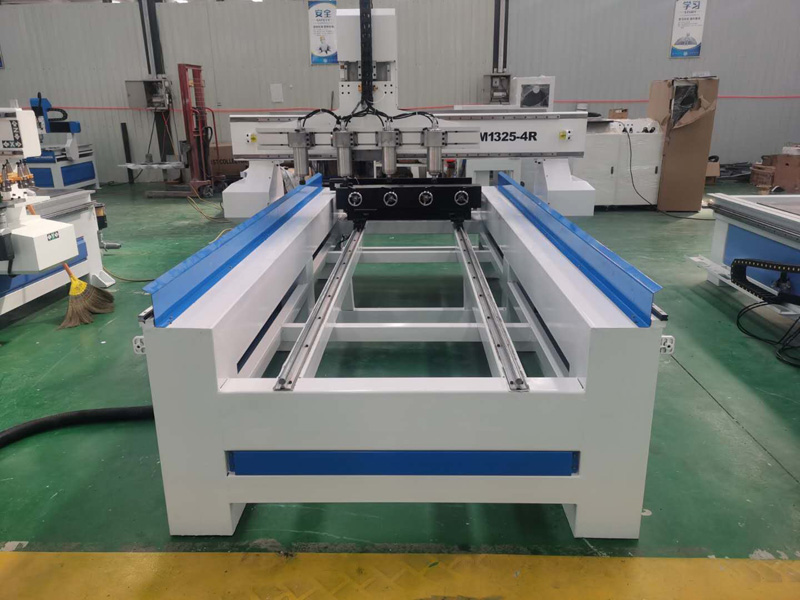

Manufacturing Insight: 4D Cnc Carving Machine

Advanced Multi-Axis Precision for Complex Prototyping and Low-Volume Production

At Honyo Prototype, we leverage cutting-edge CNC machining capabilities to transform intricate design concepts into high-fidelity physical components with exceptional accuracy and efficiency. Our specialized 4-axis CNC carving systems—often referenced in industry contexts as dynamic 4D machining—enable the precise fabrication of complex geometries that demand simultaneous multi-directional toolpath control. Unlike standard 3-axis processes, these advanced systems integrate rotational movement (typically the A-axis) alongside linear X, Y, and Z motion, allowing for seamless carving of contoured surfaces, undercuts, and organic forms in a single setup. This eliminates costly secondary operations, reduces lead times, and maintains micron-level tolerances across diverse materials including aerospace-grade aluminum, engineering plastics, composites, and specialty alloys.

This capability is critical for industries requiring rapid iteration on sophisticated components, such as medical device prototyping, consumer electronics enclosures, and precision automotive fixtures. By minimizing manual intervention and fixture changes, our 4-axis CNC carving process ensures consistent repeatability while optimizing material utilization and surface finish. Honyo’s engineering team collaborates closely with clients to validate design feasibility, select optimal tooling strategies, and implement rigorous in-process inspections—guaranteeing that every part meets stringent functional and aesthetic requirements without compromising speed.

To accelerate your path from concept to physical validation, Honyo Prototype offers an Online Instant Quote platform. Upload your CAD file, specify material and quantity, and receive a detailed technical quote within minutes—complete with manufacturability feedback and lead time estimates. This transparency empowers engineering teams to make informed decisions early in the development cycle, reducing time-to-market while maintaining the precision your project demands. Experience how our advanced CNC machining services bridge the gap between innovation and execution.

Technical Capabilities

4D CNC Carving Machine – Technical Specifications Overview

The term “4D CNC carving machine” is often used colloquially to describe advanced multi-axis CNC systems capable of 4-axis or 5-axis simultaneous machining. True 4D is not a standard industry term; it typically refers to 4-axis or 5-axis CNC milling machines with dynamic workpiece repositioning over time (the “4th dimension” being time or rotational axis coordination). Below are the technical specifications focused on high-precision 4-axis and 5-axis CNC machining centers used for milling, turning (mill-turn), and tight-tolerance manufacturing across common engineering materials.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis Simultaneous CNC Milling Center (commonly referred to as “4D” in prototyping contexts) |

| Axes Configuration | X, Y, Z linear axes + A (rotary around X) and/or B (rotary around Y); some models include C-axis (rotary around Z) for mill-turn capability |

| Spindle Speed | 12,000 – 24,000 RPM (high-frequency spindles available up to 40,000 RPM for fine detailing) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Maximum Traverse (X-Y-Z) | 700 mm × 500 mm × 400 mm (27.6″ × 19.7″ × 15.7″) typical work envelope |

| Tool Changer | Automatic Tool Changer (ATC), 16–30 tool capacity (optional 60+ with tool magazine) |

| Control System | Fanuc, Siemens, or Heidenhain CNC with 5-axis simultaneous interpolation |

| Coolant System | Through-spindle coolant (optional high-pressure up to 70 bar) |

| Rapid Traverse Rate | 30–60 m/min |

| Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66), Delrin, PEEK, and other engineering plastics |

| Machining Tolerances | ±0.01 mm (±0.0004″) standard; tight-tolerance applications down to ±0.005 mm (±0.0002″) with process control |

| Surface Finish | Ra 0.8–3.2 µm (achievable; polishable to <0.4 µm with post-processing) |

| Mill-Turn Capability | Optional C-axis with live tooling for combined turning and milling in a single setup |

| Workholding | Indexing rotary tables, pallet systems, vacuum or mechanical fixtures |

| Applications | Aerospace components, medical devices, injection molds, complex prototypes, high-precision fixtures |

This class of machine supports full 3D contouring, deep cavity milling, undercuts, and complex geometries unachievable with 3-axis systems. The integration of rotary axes allows for minimal setup changes, improving accuracy and reducing cycle time—especially critical when machining high-strength materials like steel or thermoplastics such as Nylon and ABS where thermal stability and toolpath precision are vital.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for 4D CNC carving machine projects, ensuring precision, efficiency, and seamless client collaboration. The term “4D CNC” refers to our advanced multi-axis machining capability incorporating dynamic rotary axis control (4th axis) for complex contoured geometries, distinct from standard 3-axis systems. Below is our standardized process:

CAD File Upload and Validation

Clients submit native CAD files (STEP, IGES, or Parasolid preferred) via our secure portal. Our system performs immediate integrity checks for unit consistency, watertight geometry, and machining feature recognition. Non-native formats like STL undergo resolution validation to prevent surface tessellation errors. File rejection occurs only for corrupted data or unsupported formats, with automated feedback provided within 15 minutes.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI engine analyzes part topology, material requirements, and geometric complexity. It calculates machine time, toolpath optimization potential, and secondary operation needs (e.g., deburring, finishing). Quotes generated within 2 business hours include:

Machine hour rate based on 4D CNC utilization metrics

Material waste percentage projection

Critical tolerance feasibility flags

Real-time material cost indexing from supplier APIs

This eliminates manual quoting variables, providing clients with data-driven cost transparency.

DFM Analysis and Engineering Collaboration

All projects undergo mandatory Design for Manufacturability review by our CNC engineering team. The AI-identified constraints trigger human-led optimization:

Wall thickness validation against minimum tool engagement

Undercut feasibility assessment for 4th-axis indexing

Surface finish specification alignment with toolpath strategies

Material grain direction considerations for composites/metals

We issue a formal DFM report with actionable recommendations, not limitations. Client approval of revisions is required before production release, ensuring shared technical alignment.

4D CNC Production Execution

Approved designs enter our production queue with strict adherence to the following protocols:

Machine calibration verified via Renishaw probes pre-job

In-process CMM checks at 25%, 50%, and 75% completion milestones

Real-time spindle load monitoring to prevent tool deflection

Humidity-controlled environment for hygroscopic materials (e.g., nylons)

Our 4D CNC cells utilize adaptive toolpathing to dynamically adjust feed rates during complex contouring, reducing cycle times by 18–22% versus static programming.

Delivery and Quality Assurance

Final inspection includes:

Full FAI report per AS9102 standards

Critical dimension verification with Zeiss CONTURA CMM

Surface roughness validation via Mitutoyo SJ-410

Parts ship with serialized traceability tags and digital quality dossiers. Standard lead time is 7–10 business days from DFM sign-off, with expedited options tracked via client portal.

Key DFM Considerations for 4D CNC Projects

| Parameter | Standard Capability | Critical Threshold | Mitigation Strategy |

|——————–|———————|——————–|———————————–|

| Minimum Wall Thickness | 0.5 mm (metals) | < 0.3 mm | Recommend structural redesign |

| Undercut Depth | 2.5x tool diameter | > 3.0x | Suggest split machining phases |

| Surface Finish (Ra)| 0.8 µm | < 0.4 µm | Propose post-polishing add-on |

| Feature Radius | 0.2 mm | < 0.1 mm | Require micro-tooling surcharge |

This integrated workflow minimizes iteration cycles while maintaining ±0.025 mm geometric accuracy. All projects include post-delivery engineering support for assembly validation, ensuring your prototype transitions seamlessly to volume production. Contact our applications engineering team to initiate a project with material-specific process validation.

Start Your Project

Discover precision and efficiency with our 4D CNC carving machine, engineered for high-accuracy prototyping and production applications. Built for demanding manufacturing environments, this advanced machine delivers seamless multi-axis control, superior surface finish, and consistent repeatability.

Manufactured in our Shenzhen facility, each unit reflects strict quality standards and innovative engineering tailored to meet complex machining challenges across industries.

For detailed specifications, pricing, and customization options, contact Susan Leo at [email protected]. Let’s collaborate to elevate your manufacturing capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.