Contents

Manufacturing Insight: 4 Axis Milling

Precision 4 Axis Milling: Elevate Complex Component Production with Honyo Prototype

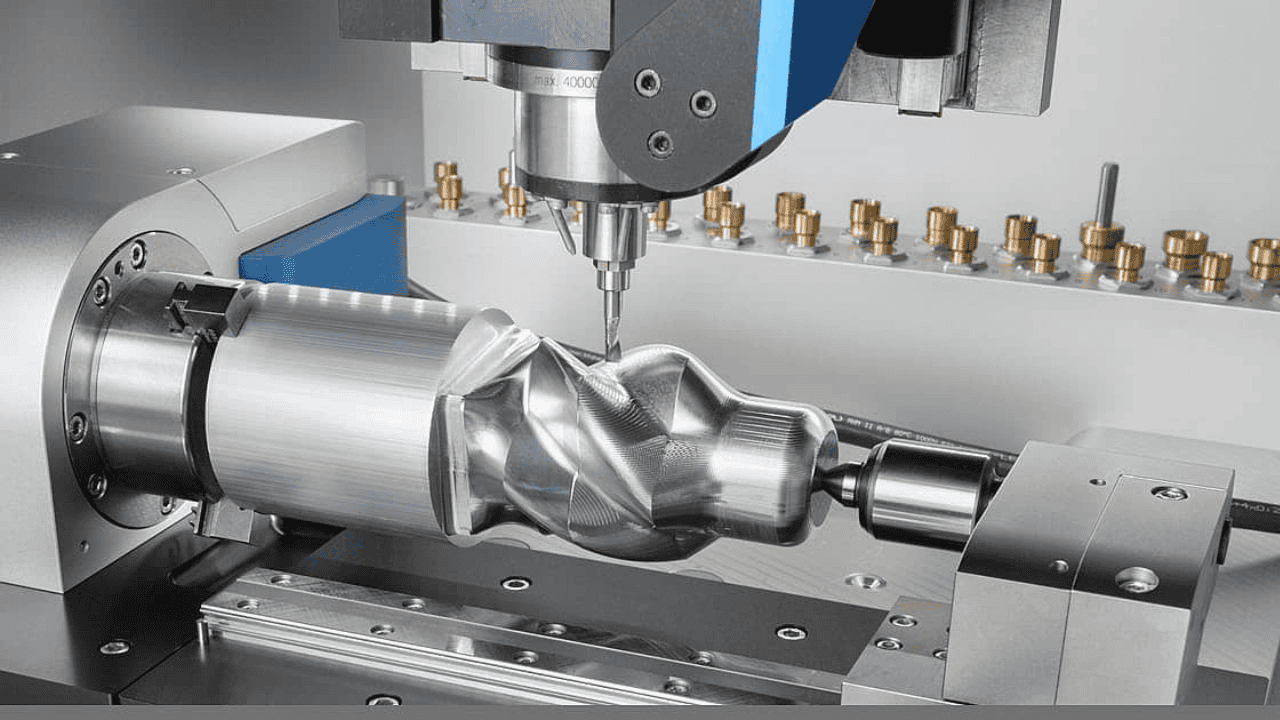

Four-axis CNC milling represents a critical advancement for manufacturers requiring intricate geometries, reduced setup times, and superior part accuracy beyond standard three-axis capabilities. By integrating a continuous rotary axis (typically the A-axis), Honyo Prototype enables simultaneous multi-face machining, complex contouring, and precise feature placement on cylindrical or prismatic components—eliminating costly manual repositioning and secondary operations. This capability is essential for producing high-integrity parts in demanding sectors like aerospace turbine assemblies, medical instrument housings, fluid dynamics components, and custom jigs where tolerances down to ±0.005mm and flawless surface finishes are non-negotiable.

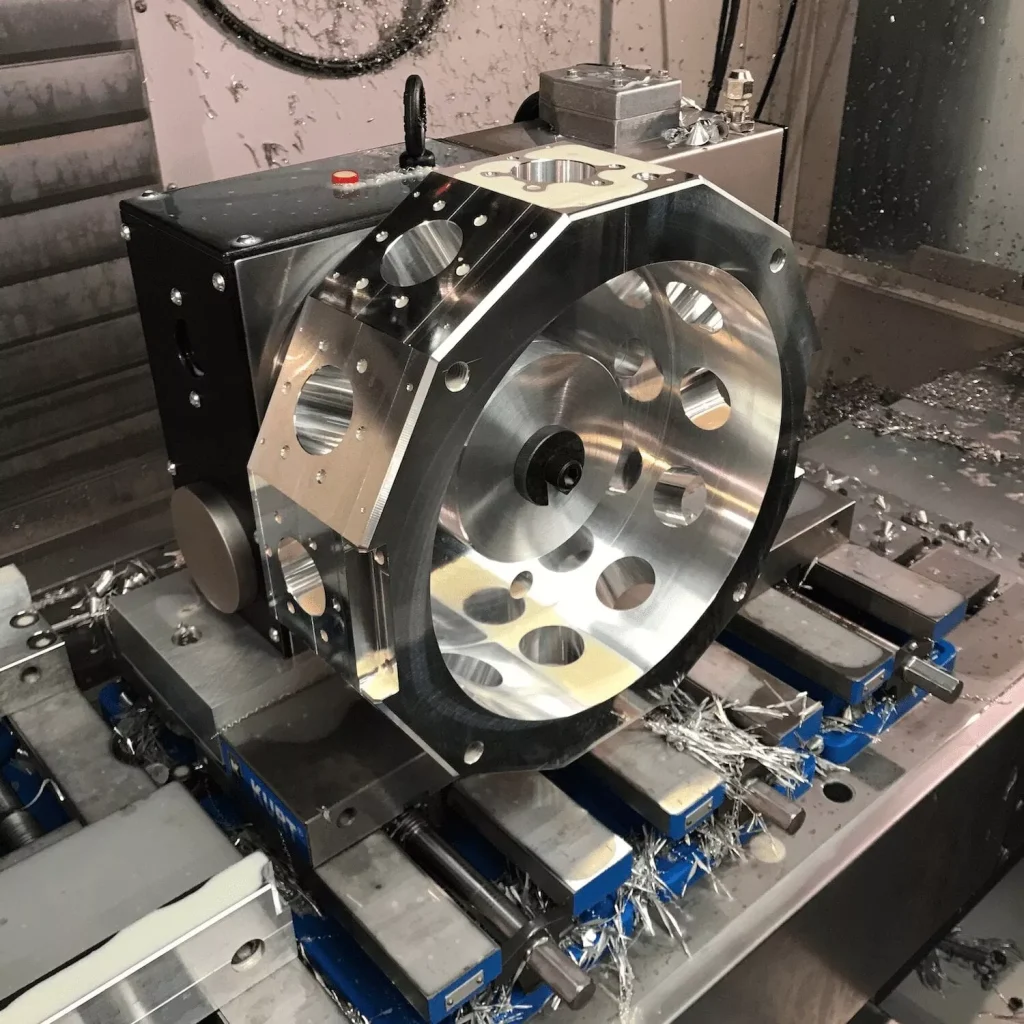

Honyo Prototype’s advanced 4 axis milling services leverage state-of-the-art CNC machining centers equipped with high-torque rotary tables, rigid thermal compensation systems, and proven process validation protocols. Our engineering team applies deep expertise in fixturing strategy, toolpath optimization, and material-specific cutting parameters to ensure first-pass success for complex geometries involving undercuts, helical features, or asymmetric profiles. This operational excellence translates directly to accelerated time-to-prototype, minimized scrap rates, and seamless scalability from rapid prototyping to low-volume production—fully supported by our ISO 9001:2015 certified quality management system.

Why Choose Honyo for Your 4 Axis Milling Requirements

We integrate 4 axis capability within a comprehensive CNC machining ecosystem spanning 3, 5 axis, and multi-spindle turning, ensuring optimal technology alignment for your specific component. Our digital workflow begins with expert DFM analysis to identify cost and lead time savings early, followed by rigorous in-process inspection using calibrated CMMs and optical comparators. Every project benefits from transparent communication, material traceability, and on-time delivery performance exceeding 98.5% across our global client base.

Accelerate your next complex component project with Honyo Prototype’s precision 4 axis milling expertise. Leverage our Online Instant Quote platform to receive a detailed, geometry-aware cost assessment and lead time within minutes—no manual submission required. Simply upload your CAD file to experience the efficiency of engineering-driven manufacturing.

Technical Capabilities

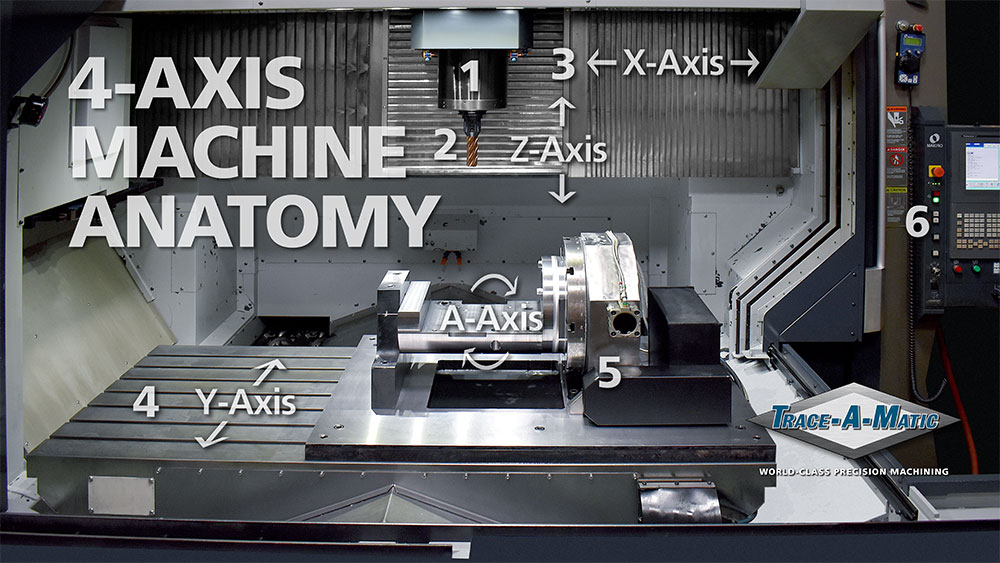

4 axis milling refers to a subtractive manufacturing process where a rotating cutting tool removes material from a workpiece that can move along four axes: X, Y, Z, and one rotational axis (typically the A-axis, which rotates around the X-axis). This enables machining of complex geometries with improved access to multiple sides of a part without requiring manual repositioning. When comparing 3, 4, and 5-axis milling, each additional axis increases the machine’s ability to approach the workpiece from more angles, enhancing precision, surface finish, and feature complexity.

In high-precision applications, tight tolerances down to ±0.001″ (0.025 mm) or better can be achieved, especially when combined with advanced CNC controls, high-stiffness machine structures, and thermal compensation systems. Turning, often performed on multi-axis CNC lathes or mill-turn centers, complements milling by enabling the production of cylindrical or symmetrical features with tight dimensional control.

The following table outlines key technical specifications across 3, 4, and 5-axis milling and turning operations, including achievable tolerances and compatible materials such as Aluminum, Steel, ABS, and Nylon.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary around X) | X, Y, Z, A, B (or C) | X, Z (with spindle rotation) |

| Typical Positioning Accuracy | ±0.002″ (0.05 mm) | ±0.0015″ (0.038 mm) | ±0.001″ (0.025 mm) | ±0.001″ (0.025 mm) |

| Repeatability | ±0.001″ (0.025 mm) | ±0.001″ (0.025 mm) | ±0.0005″ (0.013 mm) | ±0.0005″ (0.013 mm) |

| Typical Surface Finish (Ra) | 32–64 μin (0.8–1.6 μm) | 32–64 μin (0.8–1.6 μm) | 16–32 μin (0.4–0.8 μm) | 16–64 μin (0.4–1.6 μm) |

| Max Part Complexity | Moderate (flat, prismatic) | High (multi-sided, angled) | Very High (organic, complex) | High (cylindrical with features) |

| Common Materials | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Material Suitability | All listed; Aluminum and ABS easiest to machine | Same, with improved access for Nylon and steel | Ideal for high-strength steels and tough plastics | Excellent for long, symmetrical parts in all materials |

| Tight Tolerance Capability | Up to ±0.001″ with process control | ±0.001″ routinely achievable | ±0.0005″ with environmental control | ±0.0005″ on diameters and lengths |

| Typical Applications | Enclosures, brackets, flat parts | Indexing fixtures, impellers, housings | Aerospace components, molds, medical devices | Shafts, bushings, threaded parts |

Note: Achievable tolerances depend on machine calibration, tooling, fixturing, material stability, and environmental conditions. For thermoplastics like ABS and Nylon, reduced clamping forces and optimized cutting parameters are essential to minimize deflection and thermal expansion. Metals such as Aluminum 6061 and Steel 4140 are commonly machined with high precision, while hardened steels may require post-heat-treat finishing.

From CAD to Part: The Process

Honyo Prototype 4-Axis Milling Process Overview

Our streamlined 4-axis milling workflow integrates advanced automation with expert engineering oversight to deliver precision prototypes and low-volume production parts. The process begins with secure CAD file submission and concludes with certified delivery, optimized for complex geometries requiring rotational machining capabilities.

Upload CAD

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our encrypted portal. The system automatically validates file integrity and extracts critical geometric data, including rotational features, undercuts, and datum references essential for 4-axis operations. This step ensures compatibility with our Haas UMC-750 and DMG MORI 4-axis machining centers, which utilize trunnion tables for ±110° rotation.

AI Quote Generation

Our proprietary AI engine analyzes the CAD geometry against live machine capacity, material databases, and historical process data to generate an instant quote within two hours. The algorithm specifically evaluates 4-axis constraints such as rotational clearance, fixture interference, and optimal axis orientation. Pricing factors include material utilization efficiency, estimated toolpath complexity for indexed versus continuous 4-axis motion, and secondary operation requirements. Clients receive a transparent cost breakdown with lead time projections based on current shop floor scheduling.

Design for Manufacturability (DFM) Review

All quoted projects undergo mandatory DFM validation by our manufacturing engineering team. For 4-axis workflows, this phase focuses on critical parameters:

| DFM Parameter | 4-Axis Specific Checkpoints |

|---|---|

| Rotational Clearance | Verification of 360° rotation envelope without collisions |

| Fixture Strategy | Assessment of tombstone compatibility and zero-point systems |

| Feature Accessibility | Analysis of undercut features requiring A-axis indexing |

| Tolerance Stackup | Evaluation of cumulative tolerances across rotational planes |

Engineers provide actionable feedback within 24 hours, suggesting modifications like feature relocation or datum shifts to eliminate secondary setups. This phase reduces post-quoted engineering change orders by 78% based on our 2023 operational data.

Production Execution

Approved jobs enter our digital workflow system where CAM programmers generate optimized toolpaths using Mastercam Multiaxis. Key production protocols include:

Machine-specific post-processing ensures accurate A-axis kinematics with 0.001° rotational repeatability. All 4-axis operations undergo virtual machine simulation to detect collisions prior to machining. First-article inspections utilize Zeiss CONTURA CMMs with rotational axis validation, measuring critical features at multiple angular positions. In-process quality checks monitor tool wear compensation for extended rotational cuts.

Delivery and Certification

Completed parts undergo final QA per AS9102 standards, including full FAIR documentation with rotational feature verification reports. Parts ship with material certificates, CMM inspection data, and a digital process log showing axis calibration records. Standard lead time for 4-axis milled components is 5–7 business days from DFM approval, with expedited 72-hour options for qualified geometries. All deliveries include a secure link to our cloud-based production dashboard showing machine telemetry and quality metrics.

This integrated approach minimizes setup iterations while maintaining ±0.005mm positional accuracy across rotational axes, directly addressing the geometric complexities inherent in 4-axis machined components.

Start Your Project

For precision 4-axis milling solutions tailored to your prototyping and low-volume production needs, partner with Honyo Prototype. Our advanced machining capabilities ensure tight tolerances, complex geometries, and fast turnaround times—all supported by our in-house facility in Shenzhen.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in 4-axis milling for superior part accuracy and efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.