Contents

Manufacturing Insight: 4 Axis Cnc Milling Machines

Advanced 4-Axis CNC Milling Capabilities at Honyo Prototype

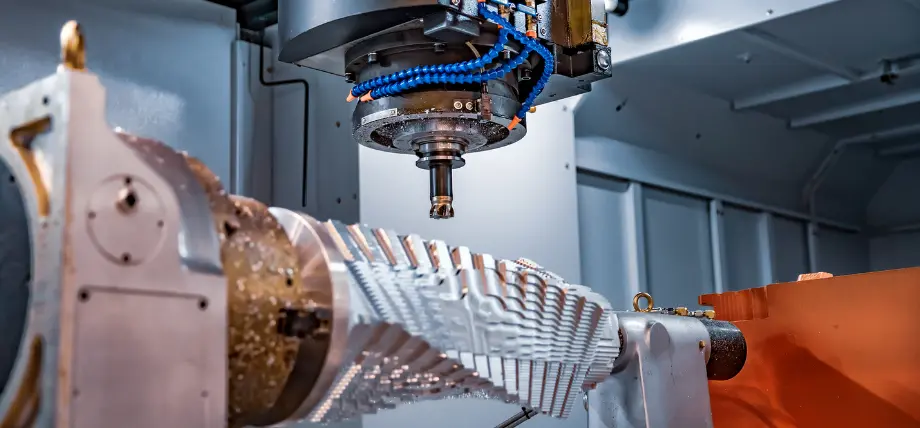

At Honyo Prototype, we leverage state-of-the-art 4-axis CNC milling technology to deliver precision-machined components that meet the exacting demands of complex geometries and tight-tolerance applications. Unlike conventional 3-axis systems, our 4-axis milling machines integrate a rotary axis (typically the A-axis) to enable continuous or indexed rotation of the workpiece. This capability eliminates the need for multiple manual setups, significantly reducing lead times while enhancing accuracy for intricate features such as undercuts, helical contours, and multi-sided profiles.

Our fleet of high-performance 4-axis CNC mills supports a broad spectrum of engineering-grade materials, including aerospace aluminum alloys, titanium, stainless steel, and high-temperature plastics. Each machine is operated by certified manufacturing engineers who optimize toolpaths, spindle speeds, and fixturing to ensure repeatability within ±0.005 mm tolerances. This expertise is critical for industries where failure is not an option—such as medical device prototyping, defense subsystems, and fluid dynamics components—where Honyo consistently delivers first-article approval on complex builds.

Beyond machining, Honyo Prototype streamlines your procurement workflow with our Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical assessment and competitive pricing within hours—not days. This digital efficiency, combined with our in-house metrology lab and rapid-turnaround prototyping, ensures your project transitions seamlessly from design validation to production-ready parts.

For mission-critical components requiring the versatility of 4-axis milling, trust Honyo Prototype to execute with engineering rigor and responsive service. Initiate your project today through our Online Instant Quote system for accelerated time-to-part.

Technical Capabilities

4-Axis CNC Milling Machines – Technical Specifications Overview

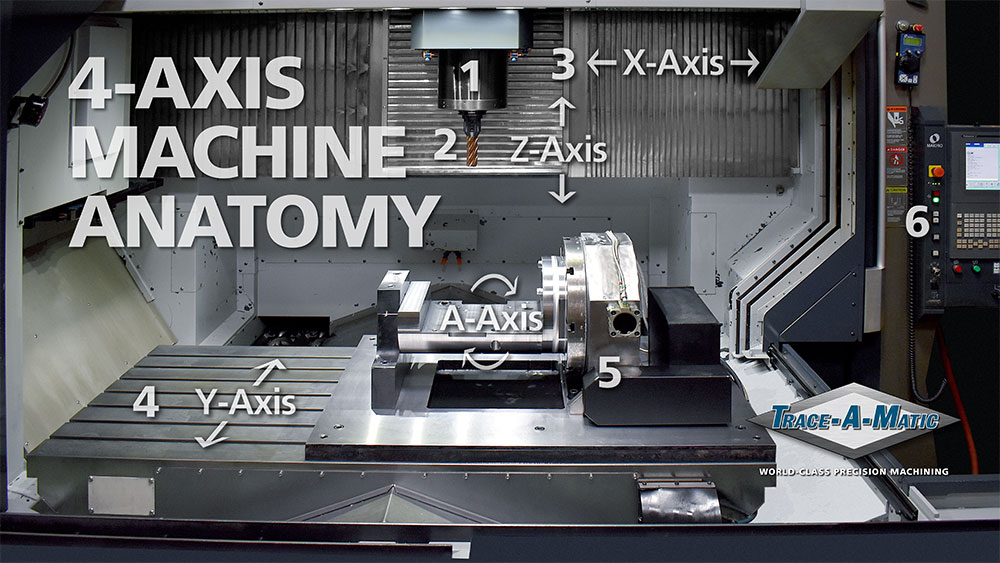

4-axis CNC milling machines extend the capabilities of standard 3-axis systems by adding a rotational A-axis (rotation around the X-axis), enabling the cutting tool to access multiple sides of a workpiece without manual repositioning. This enhances precision and efficiency for complex geometries. When compared to 3-axis and 5-axis systems, 4-axis machines offer a balance between cost and functionality for parts requiring angular features or contouring on multiple faces.

These machines are commonly used for tight-tolerance applications in industries such as aerospace, automotive, and medical devices. They support a wide range of materials including aluminum, steel, ABS, and nylon, each requiring specific spindle speeds, feed rates, and tooling strategies to maintain dimensional accuracy.

Below is a comparison of key technical aspects across 3-axis, 4-axis, and 5-axis CNC milling, with relevance to turning, tight tolerance capabilities, and material compatibility.

| Feature | 3-Axis CNC Milling | 4-Axis CNC Milling | 5-Axis CNC Milling | CNC Turning (Turning Centers) |

|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotational around X) | X, Y, Z, A, B (or C) | X, Z (rotational C-axis optional) |

| Simultaneous Axis Control | 3 | Typically 4-axis indexed or simultaneous | Full simultaneous 5-axis contouring | 2-axis (X, Z); optional C-axis milling |

| Typical Spindle Speed | 8,000 – 15,000 RPM | 8,000 – 18,000 RPM | 10,000 – 20,000 RPM | 3,000 – 10,000 RPM (varies by diameter) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.002 mm |

| Tight Tolerance Capability | Up to ±0.01 mm | Up to ±0.005 mm | Up to ±0.002 mm | Up to ±0.005 mm (diametrical) |

| Common Tooling | End mills, drills, taps | End mills, rotary indexers, probing systems | High-precision end mills, tilting spindles | Turning inserts, boring bars, drills |

| Materials – Aluminum | Excellent | Excellent (high-speed machining supported) | Excellent (complex contours) | Excellent (bar stock) |

| Materials – Steel | Good (with proper tooling) | Good (hardened steels with cooling strategies) | Excellent (incl. hardened tool steels) | Excellent (alloy and stainless steels) |

| Materials – ABS | Good (low melting point) | Good (requires reduced speed and cooling) | Good (for detailed prototypes) | Limited (not typical) |

| Materials – Nylon | Fair (tendency to melt/deform) | Fair (needs sharp tools and low heat input) | Fair (precision machining possible) | Fair (for custom bushings, gears) |

| Typical Applications | Flat parts, slots, simple holes | Multi-face parts, cams, indexing features | Aerospace impellers, molds, organic shapes | Shafts, pins, threaded components |

| Integration with Turning | No | No (separate machine type) | No (mill-turn centers combine both) | Yes (primary function) |

Notes on Tight Tolerance Machining:

Achieving tight tolerances on 4-axis CNC milling machines depends on machine rigidity, thermal stability, spindle precision, and tool path optimization. High-quality linear guides, ball screws with preload, and in-process probing are often employed to maintain tolerances within ±0.005 mm. Materials like aluminum and steel respond well to high-precision machining, while plastics such as ABS and nylon require careful parameter selection to avoid deformation due to heat and cutting forces.

For hybrid operations combining milling and turning, mill-turn centers (often with Y-axis and C-axis live tooling) are preferred, allowing complete machining in a single setup. However, standard 4-axis milling machines remain ideal for prismatic or moderately complex parts requiring rotational indexing without the full complexity of 5-axis motion.

From CAD to Part: The Process

Honyo Prototype employs a rigorously optimized workflow for 4-axis CNC milling projects, designed to maximize precision, minimize lead times, and ensure manufacturability from initial concept to final delivery. Our process leverages proprietary AI tools and deep manufacturing expertise specifically calibrated for multi-axis capabilities, where the fourth axis (typically a rotary A-axis) enables complex contouring and reduced setup requirements compared to 3-axis machining. Below is a detailed explanation of each phase.

Upload CAD

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via our secure customer portal. For 4-axis projects, we specifically require models indicating rotational features or complex geometries suitable for continuous 4-axis machining. Our system automatically validates file integrity and checks for critical 4-axis considerations such as rotational axis alignment, potential tool collisions during rotation, and minimum feature accessibility. Incomplete or ambiguous rotational intent triggers immediate client notification to prevent downstream delays.

AI-Powered Quoting

Uploaded CAD data feeds directly into our proprietary AI quoting engine, which performs real-time manufacturability analysis against Honyo’s 4-axis machine parameters (e.g., Haas UMC-750 with 11-inch rotary table capacity, max swing diameter 300mm). The AI evaluates material utilization, estimated machine hours including rotary positioning time, fixture requirements, and toolpath complexity. Crucially, it identifies early-stage 4-axis specific risks like excessive part repositioning needs or non-continuous rotational surfaces. Within minutes, clients receive a detailed quote including DFM insights, material cost breakdowns, and a preliminary timeline, with options to adjust tolerances or surface finishes for cost optimization.

DFM Analysis and Engineering Review

All 4-axis projects undergo mandatory DFM review by our senior manufacturing engineers. This phase focuses on resolving geometric conflicts inherent in rotational machining. Engineers verify rotational axis centering, assess thin-wall stability during rotation, validate tool clearance throughout the 360-degree sweep, and optimize stock orientation to minimize secondary operations. Common issues addressed include:

| Potential Issue | Honyo’s Resolution Approach |

|---|---|

| Undercuts requiring multiple setups | Redesign for single-setup 4-axis machining using adaptive toolpaths |

| Thin features prone to vibration during rotation | Recommend material-specific RPM/feed adjustments or support structures |

| Non-continuous rotational surfaces | Propose hybrid 3+1 axis strategy or fixture modification |

| Collision risks with vise/rotary table | Generate verified toolpath simulations in Mastercam |

Clients receive a formal DFM report with actionable recommendations, revised tolerance callouts, and a collaborative engineering sign-off before proceeding. This phase typically concludes within 3-5 business days.

Production Execution

Approved designs move to our dedicated 4-axis cell featuring Haas UMC-750 and DMG MORI NTX 1000 machines with integrated Renishaw probing. Production includes:

Workholding optimization using custom tombstone fixtures or zero-point systems to maintain CMM-verified part orientation throughout rotation.

In-process inspections via on-machine probing to validate rotational accuracy (typically ±0.005mm positional tolerance per rotation).

Real-time spindle load monitoring to detect anomalies during extended rotational cuts.

All 4-axis toolpaths undergo virtual simulation in NCSIMUL prior to machine deployment to eliminate collisions. Complex geometries utilize high-speed machining strategies with tapered end mills to access deep cavities during rotation.

Delivery and Documentation

Final inspection includes full CMM reporting with rotational feature verification (e.g., concentricity of rotated bores, profile tolerances on contoured surfaces). Parts ship with comprehensive documentation:

Dimensional inspection report per AS9102

Material certification with lot traceability

Toolpath simulation video for critical rotational features

Packing list with humidity indicators for moisture-sensitive materials

Standard lead time for 4-axis projects ranges from 7-12 business days post-DFM approval, with expedited options available. All deliveries include digital as-built models for client validation against original CAD.

This integrated workflow ensures Honyo consistently achieves ±0.010mm geometric tolerances on rotational features while reducing typical 4-axis project lead times by 25% compared to industry benchmarks through proactive DFM resolution and AI-driven process optimization.

Start Your Project

Explore precision manufacturing with our advanced 4-axis CNC milling machines, engineered for complex geometries and high repeatability. Ideal for prototyping and low to high-volume production runs.

All machines are operated and maintained in our Shenzhen factory, ensuring strict quality control and rapid turnaround times. Built for accuracy and efficiency, our 4-axis systems support a wide range of materials including aluminum, steel, plastics, and composites.

For technical specifications, pricing, or to schedule a factory tour, contact Susan Leo at [email protected]. Let’s discuss how our CNC capabilities can support your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.