Introduction: Navigating the Global Market for 3d stone carving machine

In an increasingly competitive global market, sourcing a reliable 3D stone carving machine poses significant challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The complexity of selecting the right machinery—considering factors such as precision, versatility, and cost—can overwhelm even the most seasoned professionals. This guide aims to demystify the process by providing a comprehensive overview of 3D stone carving machines, covering essential aspects such as types, applications, and the intricacies of supplier vetting.

As the demand for custom stone products continues to grow, understanding the capabilities of various machines is crucial. From intricate tombstone designs to large-scale architectural applications, this guide will illuminate the diverse functionalities available in the market. Additionally, we will delve into critical considerations for evaluating suppliers, ensuring that buyers can confidently assess quality and reliability before making a purchase.

By equipping international B2B buyers with actionable insights, this guide empowers informed decision-making, helping businesses capitalize on the opportunities presented by advanced stone carving technology. Whether you are based in Germany, Nigeria, or elsewhere, you will find valuable information tailored to facilitate your sourcing journey, ultimately enhancing your operational efficiency and product offerings.

Understanding 3d stone carving machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3-Axis CNC Stone Carving Machine | Basic movement along X, Y, Z axes; suitable for simple designs | Tombstone engraving, basic signage | Pros: Affordable, easy to operate. Cons: Limited complexity in designs. |

| 4-Axis CNC Bridge Saw | Additional rotational axis for more intricate designs | Custom countertops, detailed carvings | Pros: Greater design flexibility. Cons: Higher cost, requires more skill. |

| 5-Axis CNC Stone Cutting Machine | Multi-directional movement allows for complex 3D shapes | Sculptures, architectural elements | Pros: High precision and versatility. Cons: Expensive, complex setup. |

| Desktop CNC Stone Carving Machine | Compact size, suitable for small-scale projects | Jewelry making, small crafts | Pros: Space-efficient, cost-effective. Cons: Limited work area and capabilities. |

| Laser Engraving Machine for Stone | Uses laser technology for detailed engraving | Fine art, intricate designs | Pros: High detail and speed. Cons: Limited to certain stone types. |

What Are the Characteristics of a 3-Axis CNC Stone Carving Machine?

The 3-Axis CNC Stone Carving Machine is the entry-level option for businesses looking to engage in stone carving. It operates along three axes—X, Y, and Z—allowing for straightforward carving and engraving tasks. This machine is particularly well-suited for applications such as tombstone engraving and basic signage production, making it ideal for small businesses or workshops entering the stone carving market. Buyers should consider its affordability and ease of use, although they should be aware of its limitations in creating complex designs.

How Does a 4-Axis CNC Bridge Saw Enhance Design Flexibility?

A 4-Axis CNC Bridge Saw expands upon the capabilities of a 3-axis machine by introducing an additional rotational axis. This enhancement allows for more intricate designs, making it suitable for custom countertops and detailed carvings. Businesses that focus on bespoke projects will find this machine particularly valuable. While it offers greater design flexibility, potential buyers must factor in the higher cost and the need for more skilled operators to maximize its capabilities.

What Makes the 5-Axis CNC Stone Cutting Machine Ideal for Complex Projects?

The 5-Axis CNC Stone Cutting Machine is engineered for high precision and versatility, capable of creating intricate 3D shapes and complex sculptures. This machine is favored by businesses involved in high-end architectural elements or artistic sculptures. Its ability to operate in multiple directions results in superior detail and finish quality. However, the investment is substantial, and the setup can be complex, requiring skilled personnel to operate effectively.

Why Consider a Desktop CNC Stone Carving Machine for Small Projects?

Desktop CNC Stone Carving Machines are compact and designed for small-scale projects, making them suitable for jewelry making and small crafts. These machines are ideal for businesses with limited space or those just starting in stone carving. They are cost-effective and easy to operate, but buyers should note that their limited work area restricts the size and complexity of projects.

How Does a Laser Engraving Machine for Stone Compare to Traditional CNC Machines?

Laser Engraving Machines utilize laser technology to achieve high-detail engravings on stone surfaces. They are particularly effective for fine art and intricate designs. This method is faster and can produce cleaner results compared to traditional CNC carving. However, it is essential for buyers to consider that laser machines are typically limited to specific stone types and may not be suitable for all carving applications.

Key Industrial Applications of 3d stone carving machine

| Industry/Sector | Specific Application of 3D Stone Carving Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Custom Stone Facades and Structures | Enhances aesthetic appeal and durability of buildings | Precision in design, availability of diverse stone types, and after-sales support |

| Memorial & Cemetery Services | Tombstone and Memorial Stone Carving | Offers personalized memorials, meeting client needs | Machine capabilities for intricate designs, ease of operation, and software compatibility |

| Interior Design | Decorative Stone Panels and Sculptures | Adds luxury and uniqueness to interior spaces | Material versatility, design flexibility, and maintenance requirements |

| Landscaping & Outdoor Design | Garden Features and Pathway Decorations | Improves outdoor aesthetics, increasing property value | Weather resistance of materials, customization options, and installation support |

| Signage & Advertising | Engraved Stone Signs and Markers | Provides a lasting and professional branding solution | Durability of the material, engraving precision, and cost-effectiveness |

How is a 3D Stone Carving Machine Used in Construction & Architecture?

In the construction and architecture sector, 3D stone carving machines are utilized to create custom stone facades and structural elements. These machines enable architects and builders to achieve precise designs that enhance the aesthetic appeal and durability of buildings. By automating the carving process, businesses can significantly reduce labor costs and time while ensuring high-quality finishes. For international buyers, sourcing machines that can handle various stone types and provide robust after-sales support is crucial for long-term success.

What Role Does a 3D Stone Carving Machine Play in Memorial & Cemetery Services?

In the memorial and cemetery services industry, 3D stone carving machines are essential for producing personalized tombstones and memorial stones. These machines allow for intricate designs and custom inscriptions that cater to individual client preferences, thus enhancing the emotional value of memorials. Buyers in this sector should prioritize machines with user-friendly software and high engraving precision to meet diverse customer demands effectively. Additionally, the ability to work with various stone materials can be a significant advantage.

How Does Interior Design Benefit from 3D Stone Carving Machines?

Interior designers leverage 3D stone carving machines to create decorative stone panels and sculptures that add luxury and uniqueness to spaces. These machines facilitate the production of custom designs that can transform ordinary interiors into extraordinary environments. For businesses in this sector, sourcing machines that offer flexibility in design and maintenance ease is vital, particularly when working with high-end clients who expect exceptional craftsmanship.

In What Ways Do Landscaping & Outdoor Design Utilize 3D Stone Carving Machines?

In landscaping and outdoor design, 3D stone carving machines are employed to create beautiful garden features and pathway decorations. These machines enable the production of intricate designs that enhance outdoor aesthetics, thus increasing property value. Buyers in this industry should consider the weather resistance of the materials used, as well as customization options to meet specific project requirements. Reliable installation support can also be a key factor in ensuring successful project execution.

How Are Signage & Advertising Enhanced by 3D Stone Carving Machines?

The signage and advertising sector benefits from 3D stone carving machines for creating engraved stone signs and markers. These machines provide a durable and professional branding solution that stands the test of time. Businesses must evaluate the durability of the materials used and the precision of the engraving process when sourcing these machines. Cost-effectiveness is also a critical consideration, as it impacts the overall return on investment for signage projects.

3 Common User Pain Points for ‘3d stone carving machine’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision and Quality in Stone Carvings

The Problem: Many B2B buyers in the stone fabrication industry face challenges when it comes to achieving the desired precision and quality in their carvings. This is particularly true for intricate designs, such as those required for high-end tombstones or decorative architectural elements. Traditional methods can lead to inconsistencies and quality issues, causing frustration and potential financial loss due to wasted materials or rework. Furthermore, buyers may struggle with the learning curve associated with operating sophisticated 3D stone carving machines, leading to inefficiencies in production and extended lead times.

The Solution: To overcome these challenges, B2B buyers should prioritize sourcing machines that come equipped with advanced features, such as multi-axis capabilities and high-quality diamond drill bits. These features enhance the machine’s ability to execute complex designs with precision. Additionally, investing in comprehensive training programs for operators can significantly improve the quality of output. Manufacturers often provide training sessions that cover machine operation, maintenance, and software usage. Engaging in these programs helps operators become proficient in utilizing the machine’s full capabilities, ultimately leading to improved quality and efficiency in production.

Scenario 2: High Operational Costs and Maintenance Issues

The Problem: Operating a 3D stone carving machine can result in significant overhead costs, which include energy consumption, tool wear, and maintenance. Many B2B buyers, especially those in emerging markets, find themselves struggling with unexpected maintenance issues that can halt production and incur additional costs. These operational challenges can be particularly detrimental for small to medium enterprises that rely on tight profit margins.

The Solution: To mitigate high operational costs, buyers should look for machines that offer energy-efficient features and require minimal maintenance. Researching and investing in machines with a robust warranty and reliable customer support can also alleviate long-term costs. Regular maintenance schedules should be established to avoid unexpected breakdowns, and using quality materials and tools can prolong the lifespan of the machine components. Moreover, implementing predictive maintenance techniques, such as monitoring machine performance and wear rates, can help anticipate issues before they become costly problems, ensuring smoother operations and reduced downtime.

Scenario 3: Limited Flexibility and Adaptability to Different Stone Types

The Problem: A common pain point for B2B buyers is the limited adaptability of certain 3D stone carving machines to handle various stone types, including granite, marble, and softer stones like soapstone. This limitation can restrict the range of projects a business can undertake, hindering growth and profitability. Buyers often find themselves needing multiple machines to accommodate different materials, which can lead to increased capital expenditure and operational complexity.

The Solution: To address this issue, buyers should consider investing in versatile 3D stone carving machines that are specifically designed to handle a wide variety of stone types. When sourcing a machine, look for models that offer adjustable settings for speed, pressure, and tool type, allowing for seamless transitions between materials. Additionally, consider machines with interchangeable tool heads that can be easily swapped out for different applications. Engaging with manufacturers who offer customization options can also provide tailored solutions to meet specific business needs. By choosing adaptable machines, businesses can expand their service offerings and respond more effectively to market demands, ultimately driving growth and profitability.

Strategic Material Selection Guide for 3d stone carving machine

What Are the Key Materials for 3D Stone Carving Machines?

When selecting materials for 3D stone carving machines, it is essential to consider the properties and performance of various stone types. Here, we analyze four common materials: granite, marble, quartz, and limestone, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Granite Perform in 3D Stone Carving Applications?

Granite is a highly durable igneous rock known for its hardness and resistance to weathering. It typically has a high temperature rating, making it suitable for various applications. The machine’s ability to carve granite allows for intricate designs and detailed finishes.

Pros: Granite’s durability ensures longevity and resistance to scratches and stains, making it ideal for high-traffic areas. Its aesthetic appeal adds value to the final product, particularly in architectural applications.

Cons: The hardness of granite can lead to higher wear on tools, increasing maintenance costs. Additionally, the initial cost of granite is generally higher than softer stones, which may deter some buyers.

Impact on Application: Granite is compatible with various CNC machines, including 3D routers, and is often used for countertops, sculptures, and memorials.

Considerations for International Buyers: Buyers should be aware of local sourcing capabilities and compliance with international standards, such as ASTM for stone quality. Countries like Germany and Nigeria may have specific regulations regarding the importation of stone materials.

What Advantages Does Marble Offer for 3D Stone Carving?

Marble is a metamorphic rock prized for its aesthetic qualities and workability. It has a moderate temperature rating and is relatively easy to carve, allowing for detailed and artistic designs.

Pros: Marble’s ability to achieve a high polish makes it suitable for decorative applications, such as sculptures and interior design elements. Its availability in various colors and patterns enhances its appeal.

Cons: Marble is softer than granite, which can lead to quicker wear and tear on tools. It is also more susceptible to staining and scratching, which may limit its use in certain environments.

Impact on Application: Marble is ideal for applications requiring intricate designs, such as statues and decorative panels, and is often used in luxury settings.

Considerations for International Buyers: Buyers should consider the availability of marble and its compliance with local standards. In Europe, for instance, marble quality is often regulated under DIN standards.

How Does Quartz Compare as a Material for 3D Stone Carving?

Quartz is an engineered stone made from natural quartz crystals and resins. It is known for its uniformity and durability, with a high resistance to scratches and stains.

Pros: The consistency of quartz allows for predictable machining results, making it easier to work with compared to natural stones. It is also available in a wide range of colors and finishes.

Cons: The manufacturing complexity of quartz can lead to higher costs compared to natural stones. Additionally, the presence of resins may limit its use in high-temperature applications.

Impact on Application: Quartz is commonly used for countertops and surfaces where durability and aesthetic appeal are paramount.

Considerations for International Buyers: Buyers should ensure that quartz products comply with local safety and quality standards, particularly in regions like South America, where regulations may vary.

What Role Does Limestone Play in 3D Stone Carving?

Limestone is a sedimentary rock that is softer and easier to carve than granite or marble. It is often used for architectural features and decorative elements.

Pros: Limestone’s workability allows for intricate designs and lower tool wear, making it cost-effective for detailed carvings. It is also readily available in many regions.

Cons: Its softness makes limestone more prone to damage and wear, limiting its use in high-traffic areas. Additionally, it may not achieve the same level of polish as harder stones.

Impact on Application: Limestone is suitable for outdoor applications, such as garden features and sculptures, where a rustic appearance is desired.

Considerations for International Buyers: Buyers should consider the local availability of limestone and any compliance with regional building codes, especially in the Middle East, where natural stone use is prevalent.

Summary Table of Strategic Material Selection

| Material | Typical Use Case for 3D Stone Carving Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Granite | Countertops, sculptures, memorials | High durability and scratch resistance | Higher tool wear and initial cost | High |

| Marble | Statues, decorative panels | Aesthetic appeal and polishability | Susceptible to staining and quicker wear | Medium |

| Quartz | Countertops, surfaces | Consistency and durability | Higher manufacturing costs | Medium |

| Limestone | Outdoor features, sculptures | Easy to carve and cost-effective | Prone to damage in high-traffic areas | Low |

This guide provides a comprehensive overview of material selection for 3D stone carving machines, aiding international B2B buyers in making informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d stone carving machine

What Are the Key Manufacturing Processes for 3D Stone Carving Machines?

The manufacturing of 3D stone carving machines involves several critical stages that ensure precision and functionality. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used?

The manufacturing process begins with the selection of high-quality materials. Common materials include robust metals like steel and aluminum for the frame, as well as specialized components such as high-grade bearings and motors. The choice of materials is crucial as it impacts the machine’s durability and performance.

Before fabrication, materials undergo strict quality checks to ensure they meet industry standards. This initial step involves testing for tensile strength, corrosion resistance, and dimensional accuracy.

2. How Is the Forming Process Carried Out?

Once materials are prepared, the forming process begins. This typically involves machining operations such as CNC milling, laser cutting, and bending. CNC technology is employed to create precise geometries that meet design specifications.

For 3D stone carving machines, it is essential that components like the gantry and bed are accurately shaped to provide stability during operation. Advanced techniques like water jet cutting may also be used for intricate designs, ensuring that even the most complex shapes can be produced with high fidelity.

3. What Happens During Assembly?

The assembly stage is where individual components come together to form the complete machine. This process often involves several sub-assemblies, including the control system, spindle assembly, and the motion system.

Precision is critical during assembly, as misalignment can lead to operational inefficiencies or inaccuracies in carving. Manufacturers often utilize jigs and fixtures to ensure that parts are positioned correctly. Furthermore, skilled technicians conduct multiple assembly checks to confirm that each component operates seamlessly with others.

4. How Is Finishing Performed?

Finishing is the final stage in the manufacturing process, which enhances both the aesthetics and functionality of the machine. This may involve surface treatments such as painting, anodizing, or powder coating to protect against corrosion and wear.

Additionally, manufacturers often conduct a final inspection to ensure that all surfaces are smooth and free from defects. This not only improves the machine’s appearance but also its performance during operation.

What Quality Assurance Measures Are Implemented?

Quality assurance (QA) is a critical component in the manufacturing of 3D stone carving machines. The goal of QA is to ensure that machines meet specified standards and function correctly.

1. What International Standards Should Buyers Be Aware Of?

For international buyers, understanding relevant quality standards is paramount. ISO 9001 is the most widely recognized quality management standard, ensuring that manufacturers meet customer and regulatory requirements consistently.

In addition, many manufacturers obtain CE certification, which indicates compliance with European health, safety, and environmental protection standards. This can be particularly important for buyers in Europe and the Middle East, where regulatory compliance is closely monitored.

2. What Are the Key QC Checkpoints?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. Typical checkpoints include:

-

Incoming Quality Control (IQC): This phase involves the inspection of raw materials and components upon arrival at the facility. It ensures that all materials meet the required specifications before production begins.

-

In-Process Quality Control (IPQC): Conducted during the various manufacturing stages, IPQC ensures that components are being fabricated correctly. This may involve dimensional checks and functional tests.

-

Final Quality Control (FQC): This is the last step before the machine is shipped. FQC includes comprehensive testing of the entire machine to verify that it operates correctly and meets performance specifications.

3. What Common Testing Methods Are Utilized?

Testing methods vary by manufacturer but typically include:

-

Functional Testing: Verifying that the machine operates according to design specifications.

-

Load Testing: Assessing how the machine performs under maximum operational loads.

-

Vibration Testing: Ensuring that the machine remains stable during operation, which is crucial for precision carving.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks and ensure product quality.

1. What Steps Can Buyers Take for Supplier Audits?

Buyers should conduct thorough supplier audits, which may involve:

-

Site Visits: Visiting the manufacturing facility to observe processes and practices firsthand. This allows buyers to assess the overall environment and quality control measures in place.

-

Documentation Review: Requesting documentation related to quality control processes, including inspection reports, certifications, and compliance records.

2. How Can Reports and Third-party Inspections Help?

Buyers can request detailed QC reports from suppliers, which should outline testing results and compliance with international standards. Additionally, third-party inspections can provide an unbiased assessment of the manufacturer’s quality control processes. Engaging reputable inspection agencies can offer additional assurance regarding product quality.

What Are the Quality Control Nuances for International Buyers?

Navigating quality control nuances can be challenging for international buyers, especially in regions with varying regulations and standards.

1. How Do Regional Standards Affect Quality Assurance?

Standards can differ significantly between regions. For instance, buyers in Europe may prioritize CE marking, while those in Africa or South America may focus on local certifications. Understanding these nuances is crucial for ensuring compliance and quality.

2. What Should Buyers Consider About Cultural Differences in Manufacturing?

Cultural differences can impact manufacturing practices and communication. Buyers should be aware of these differences and establish clear communication channels to ensure that quality expectations are understood and met.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for 3D stone carving machines can empower B2B buyers to make informed decisions. By focusing on material preparation, forming, assembly, finishing, and quality control, buyers can ensure they select reliable suppliers who deliver high-quality machines tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d stone carving machine’

In the competitive landscape of stone carving, sourcing a 3D stone carving machine requires careful consideration and a systematic approach. This guide provides a step-by-step checklist to ensure that you make informed purchasing decisions that align with your business needs and objectives.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of a successful procurement process. Consider factors such as the types of stone you will be working with (e.g., granite, marble, quartz), the complexity of the designs, and the desired output size. Additionally, determine whether you need features like automatic tool changers or multi-axis capabilities, as these can significantly impact your machine’s performance.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in CNC technology and market trends. This knowledge will help you identify machines that offer better efficiency, precision, and features. Look for innovations such as improved cooling systems or enhanced CAD/CAM compatibility, which can extend the lifespan of the tools and improve overall productivity.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request company profiles, product catalogs, and case studies from businesses in similar industries or regions. Assess their reputation by checking online reviews and seeking references. A reliable supplier should provide comprehensive support, including installation, training, and after-sales service.

- Look for Certifications: Ensure that the supplier’s machines comply with international safety and quality standards, which can vary by region.

- Assess Warranty and Support Options: A robust warranty and accessible customer support can safeguard your investment and minimize downtime.

Step 4: Request Demonstrations and Samples

Whenever possible, arrange for live demonstrations of the machines you are considering. This will allow you to see the machine’s capabilities firsthand and assess its performance on the types of stone you will be using. Additionally, request samples of previously carved items to evaluate the quality of work produced by the machine.

Step 5: Compare Pricing and Financing Options

Gather detailed quotes from multiple suppliers to compare pricing. Look beyond the initial purchase price; consider the total cost of ownership, which includes maintenance, operating costs, and potential upgrades. Explore financing options, as some suppliers may offer leasing or installment plans that can ease your cash flow concerns.

Step 6: Negotiate Terms and Conditions

Once you have selected a potential supplier, engage in negotiations to secure favorable terms. Discuss aspects such as delivery timelines, installation costs, and training provisions. Ensure that all agreements are documented clearly to avoid misunderstandings later.

Step 7: Finalize Your Purchase

After reaching an agreement, review the final contract thoroughly before signing. Confirm that all specifications, warranties, and support agreements are accurately reflected. Once the machine is delivered, conduct a thorough inspection to ensure it meets your expectations and operational requirements.

By following this checklist, you can navigate the complexities of sourcing a 3D stone carving machine with confidence, ensuring that your investment supports your business goals effectively.

Comprehensive Cost and Pricing Analysis for 3d stone carving machine Sourcing

What Are the Key Cost Components for 3D Stone Carving Machines?

When considering the sourcing of 3D stone carving machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The raw materials used in manufacturing these machines, such as high-quality steel for frames, advanced electronics, and durable components, significantly impact the overall cost. Machines designed for heavy-duty use will generally require more robust materials, leading to higher prices.

-

Labor: Skilled labor is essential in the manufacturing process, particularly for assembly and quality assurance. Labor costs can vary widely based on the region and the expertise required, influencing the final price of the machine.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads, leading to more competitive pricing.

-

Tooling: Specialized tooling is necessary for the precision required in stone carving. The cost of these tools, along with their maintenance, can add a significant amount to the overall cost.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that the machines meet industry standards. This may involve additional testing and inspection costs, which are reflected in the pricing.

-

Logistics: Shipping and handling costs are vital to consider, especially for international buyers. These costs can vary depending on the distance, shipping method, and any tariffs or customs duties involved.

-

Margin: Suppliers typically include a profit margin that reflects the market demand, competition, and perceived value of the machine.

What Factors Influence the Pricing of 3D Stone Carving Machines?

Several price influencers can significantly affect the cost of 3D stone carving machines:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often results in lower per-unit costs. Negotiating favorable terms for bulk purchases can yield significant savings.

-

Specifications and Customization: Machines tailored to specific needs or featuring advanced technology may come at a premium. Clearly defining your requirements can help in negotiating the best price.

-

Materials and Quality Certifications: Machines built with high-grade materials or those certified for quality (e.g., ISO standards) generally command higher prices. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer more consistent quality but at higher rates. It’s wise to compare multiple vendors.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can affect total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can lead to different liabilities and costs for the buyer.

How Can B2B Buyers Negotiate and Optimize Costs for 3D Stone Carving Machines?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Wisely: Engage in discussions about pricing and terms. Suppliers may have flexibility, especially for larger orders or long-term partnerships.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also operational costs, maintenance, and potential downtime. A cheaper machine may incur higher costs over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and additional costs related to import duties. Understanding local market conditions can provide leverage in negotiations.

-

Research and Compare: Take the time to research different suppliers and their offerings. Utilizing platforms that provide reviews and comparisons can help in making informed decisions.

Disclaimer on Indicative Prices

Prices for 3D stone carving machines can fluctuate based on market conditions, supplier changes, and currency variations. The figures provided in different sources are indicative and should be verified with suppliers for the most accurate and current pricing. Always request detailed quotes that outline all costs involved to ensure transparency and avoid unexpected expenses.

Alternatives Analysis: Comparing 3d stone carving machine With Other Solutions

Understanding Alternatives to 3D Stone Carving Machines

When considering investments in stone carving technologies, B2B buyers should evaluate various alternatives to the 3D stone carving machine. Each option has its own advantages and disadvantages, depending on factors such as operational needs, budget constraints, and specific applications within the stone fabrication industry.

| Comparison Aspect | 3D Stone Carving Machine | Laser Engraving Machine | Manual Stone Carving |

|---|---|---|---|

| Performance | High precision and versatility for intricate designs | Excellent for detailed engraving but limited to surface depth | Variable precision, highly dependent on skill |

| Cost | $5,000 – $40,000 depending on features | $2,000 – $15,000, generally lower | Low initial cost (tools) but high labor cost |

| Ease of Implementation | Requires software integration and training | Easier setup; often plug-and-play | Requires extensive training and experience |

| Maintenance | Regular maintenance needed for software and hardware | Minimal maintenance; often just lens cleaning | High wear and tear on tools; skilled labor needed |

| Best Use Case | Complex designs, large-scale projects | Fine engraving, detailed signage | Custom, artistic, and traditional pieces |

In-Depth Analysis of Alternatives

What are the Advantages and Disadvantages of Laser Engraving Machines?

Laser engraving machines offer a cost-effective solution for businesses focused on detailed surface work. They excel in creating intricate designs on polished stones like granite and marble, providing a clean finish without the need for extensive post-processing. However, they are limited in depth; while they can engrave fine details, they may not be suitable for applications requiring significant material removal or three-dimensional effects. Additionally, users must consider the initial investment in laser technology, which can vary based on the machine’s capabilities.

How Does Manual Stone Carving Compare?

Manual stone carving is a traditional method that allows for a high degree of artistic expression. It is often favored for custom, one-of-a-kind pieces that require a human touch. The initial investment in tools is relatively low; however, the labor costs can accumulate due to the time-intensive nature of the work. Furthermore, the quality of the final product heavily depends on the skill of the artisan, which can lead to variability in results. This method is best suited for small-scale operations or businesses focusing on bespoke artistic projects rather than high-volume production.

Making the Right Choice for Your Business Needs

When choosing the right stone carving solution, B2B buyers should assess their specific requirements, including the types of projects they plan to undertake and their budget. A 3D stone carving machine may be the ideal choice for businesses looking for high precision and versatility in large-scale applications. Conversely, companies focused on detailed engravings or custom artistic pieces may find that laser engraving machines or manual carving techniques better align with their operational goals. Ultimately, understanding the strengths and limitations of each option will enable businesses to make informed decisions that support their growth and production needs.

Essential Technical Properties and Trade Terminology for 3d stone carving machine

What Are the Key Technical Properties of a 3D Stone Carving Machine?

When investing in a 3D stone carving machine, understanding its technical specifications is crucial for ensuring it meets your business needs. Here are several critical properties to consider:

-

Material Grade

The material grade of the machine components, particularly the frame and spindle, affects durability and performance. Machines made from high-grade steel or aluminum alloys offer better stability and resistance to wear and tear, which is essential for long-term use. In a B2B context, this impacts operational costs, as a more durable machine reduces the need for frequent repairs or replacements. -

Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension. In stone carving, achieving tight tolerances (e.g., ±0.01 mm) is vital for precision work, particularly for intricate designs. Businesses that require high-quality finishes—such as in memorials or decorative panels—must prioritize machines with superior tolerance levels to meet customer expectations and reduce waste. -

Axis Configuration

Machines can have varying numbers of axes (typically 3, 4, or 5) that determine the complexity of the carving capabilities. A 5-axis machine allows for more intricate designs and the ability to carve from multiple angles, enhancing versatility. For companies aiming to offer diverse product ranges, investing in a multi-axis machine can be a strategic advantage. -

Spindle Power

The spindle power (measured in kW) is critical for determining the machine’s cutting efficiency and speed. Higher spindle power enables the machine to handle harder materials like granite or marble more effectively, reducing processing time. This can lead to increased productivity, making it a key consideration for B2B buyers looking to optimize their operations. -

Cooling System

A reliable cooling system, such as a bidirectional cooling mechanism, is essential to prolong tool life and maintain machine performance during prolonged operation. Effective cooling prevents overheating, which can lead to tool wear and subpar finishes. B2B buyers should consider machines with advanced cooling systems to ensure consistent production quality. -

Software Compatibility

Compatibility with CAD/CAM software is crucial for seamless design-to-production workflows. Machines that support popular design software enable easier integration into existing operations, allowing businesses to streamline processes. B2B buyers should look for machines that offer flexibility with various software options to enhance design capabilities.

What Are Common Trade Terms Associated with 3D Stone Carving Machines?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are several common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing a 3D stone carving machine, working with an OEM can ensure high-quality components tailored to specific requirements, enhancing performance and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory planning. Buyers should consider their production needs and negotiate MOQs that align with their operational capacity without incurring excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a company solicits price quotes from suppliers for specific products or services. In the context of 3D stone carving machines, issuing an RFQ allows buyers to compare prices, specifications, and delivery times, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms helps clarify who is responsible for shipping, insurance, and tariffs, enabling smoother transactions and reducing potential disputes. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. In the context of stone carving machines, shorter lead times can significantly impact project timelines, making it a critical factor for B2B buyers who require timely deliveries to meet customer demands. -

After-Sales Support

After-sales support encompasses the services provided after a purchase, such as installation, maintenance, and technical assistance. For buyers, robust after-sales support is crucial for minimizing downtime and ensuring that their machines operate efficiently over the long term.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting a 3D stone carving machine that meets their operational needs and enhances their competitive edge.

Navigating Market Dynamics and Sourcing Trends in the 3d stone carving machine Sector

What Are the Current Market Dynamics and Key Trends in the 3D Stone Carving Machine Sector?

The 3D stone carving machine market is witnessing significant growth, driven by a surge in demand for customized stone products across various industries, including construction, art, and memorial services. Global drivers such as urbanization, the rise of luxury homes, and an increasing inclination towards personalized decor are propelling market expansion. Moreover, advancements in technology, particularly in CNC (Computer Numerical Control) and CAD/CAM software, have made these machines more accessible and efficient, allowing for intricate designs and faster production times.

Emerging B2B tech trends include the integration of AI and machine learning in stone carving machines, enhancing precision and reducing human error. Additionally, the growing trend of automation is encouraging manufacturers to develop machines that can operate with minimal human intervention, thus optimizing labor costs. For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions. Germany, for instance, is experiencing a robust demand for high-quality machines, while Nigeria is seeing increased interest in affordable, durable options to boost local craftsmanship.

How Can Sustainability and Ethical Sourcing Impact the 3D Stone Carving Machine Industry?

Sustainability is becoming a cornerstone of the 3D stone carving machine industry, with increasing awareness of the environmental impact of stone extraction and processing. Ethical sourcing of materials is not just a trend but a necessity, as consumers and businesses alike are prioritizing sustainability in their purchasing decisions. B2B buyers should look for suppliers who adhere to sustainable practices, such as using recycled materials or sourcing stone from quarries that implement eco-friendly extraction methods.

Furthermore, certifications such as ISO 14001 for environmental management systems can serve as a benchmark for assessing the sustainability of suppliers. The integration of ‘green’ materials and processes in the manufacturing of stone carving machines is also gaining traction, with companies focusing on reducing waste and energy consumption. By prioritizing sustainability in their sourcing strategies, international buyers can not only enhance their brand reputation but also contribute to a more sustainable industry.

What Is the Evolution and Historical Context of 3D Stone Carving Machines?

The evolution of stone carving technology has significantly transformed the industry. Traditionally, stone carving was a labor-intensive process reliant on manual skills and rudimentary tools. The introduction of CNC technology in the late 20th century revolutionized this field, allowing for greater precision, speed, and the ability to create complex designs. Early machines were limited in capabilities, but advancements over the years have led to the development of multi-axis machines capable of intricate 3D carvings.

Today, 3D stone carving machines are equipped with advanced features such as automatic tool changers and real-time simulation capabilities, enabling users to visualize their designs before execution. This evolution reflects a broader trend in manufacturing toward automation and digital integration, making it essential for B2B buyers to stay informed about technological advancements to remain competitive in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d stone carving machine

-

How do I solve issues related to the precision of my 3D stone carving machine?

To address precision issues, first ensure that the machine is properly calibrated according to the manufacturer’s guidelines. Regular maintenance, including cleaning and lubrication of moving parts, is crucial. Additionally, using high-quality router bits and ensuring they are sharp can significantly enhance precision. Training your operators on the best practices for setup and operation can also minimize human error, leading to better overall results. -

What is the best type of 3D stone carving machine for intricate designs?

For intricate designs, a 5-axis CNC stone carving machine is often the best choice. This type of machine allows for greater flexibility and precision, enabling complex shapes and detailed patterns to be carved with ease. Additionally, consider machines that come with advanced CAD/CAM software compatibility, which can facilitate the design process and ensure that intricate details are accurately reproduced. -

How can I vet suppliers for 3D stone carving machines?

When vetting suppliers, start by researching their reputation in the industry. Look for reviews and testimonials from previous customers, and consider reaching out to them for insights. Verify the supplier’s certifications and compliance with international standards. It’s also advisable to request a demonstration of the machine’s capabilities and inquire about after-sales support and warranty conditions to ensure reliability. -

What are the common customization options available for 3D stone carving machines?

Customization options for 3D stone carving machines can vary widely, including modifications to the size of the worktable, the type of tooling used, and additional features such as automatic tool changers. Some manufacturers also offer tailored software solutions to meet specific design requirements. Discussing your specific needs with suppliers can help identify the most suitable options for your business. -

What is the minimum order quantity (MOQ) for 3D stone carving machines?

The minimum order quantity (MOQ) can differ significantly between suppliers. Some may offer machines as single units, while others might require bulk orders for competitive pricing. It’s essential to clarify the MOQ before proceeding with negotiations, especially if you are a smaller business. Additionally, inquire about the possibility of purchasing refurbished machines as an alternative if the MOQ is too high. -

What payment terms should I expect when purchasing a 3D stone carving machine?

Payment terms can vary by supplier but typically involve a deposit upfront (often 30-50% of the total cost) with the balance due upon delivery or installation. Some suppliers may offer financing options or payment plans, especially for larger orders. Ensure that you fully understand the payment schedule, including any potential fees for late payments, before finalizing your purchase. -

How do I ensure quality assurance (QA) for 3D stone carving machines?

Quality assurance can be ensured by thoroughly reviewing the supplier’s QA processes and certifications. Request documentation of quality control measures they implement during manufacturing. Additionally, consider arranging for a third-party inspection before shipment, which can provide an unbiased assessment of the machine’s quality. Establishing a clear return policy in case of defects is also advisable. -

What logistics considerations should I keep in mind when importing a 3D stone carving machine?

When importing a 3D stone carving machine, consider shipping costs, customs duties, and import taxes that may apply in your country. Choose a reliable logistics provider experienced in handling heavy machinery to ensure safe transportation. Additionally, review the shipping timeline and prepare for any potential delays at customs. Having all necessary documentation, such as invoices and certificates, ready can facilitate a smoother import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 3D Stone Carving Machine Manufacturers & Suppliers List

1. Style CNC – CNC Stone Router Machine

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: CNC stone router machine is a fully automatic computer-controlled machine tool capable of carving and cutting various stones including marble, granite, ceramics, ink-stone, jade, headstone, tombstone, artificial stone, glass, quartz, blue stone, and natural stone. It is compatible with CAD/CAM design software and equipped with professional router bits and a bidirectional tool cooling system to imp…

2. Omni CNC – 3D Stone Carving Machine

Domain: omni-cnc.com

Registered: 2009 (16 years)

Introduction: CNC Stone Carving Solution, 3D Stone Carving Machine, uses computer numerical control (CNC) technology, capable of engraving stone with repeated passes for depth, suitable for tombstone carving, sign carving, interior decoration, outdoor garden decorative panels, and interior pillar carving. Works with various stones including marble, granite, soapstone, limestone, and alabaster. Can also be custo…

3. JNIGolden – CNC Stone Carving Machine

Domain: jnigolden.com

Registered: 2014 (11 years)

Introduction: Product Name: Marble, Granite CNC Stone Carving Machine

Other Names: CNC stone carving machine, CNC stone engraving machine, CNC stone cutting machine, stone CNC router

Functions: Carving, engraving, cutting, polishing

Compatible Materials: Marble, granite, artificial stone, tombstone, ceramic tiles

Processing Speed: 2-3mm per second

Features: Independent spindles for engraving, cutting, milling; …

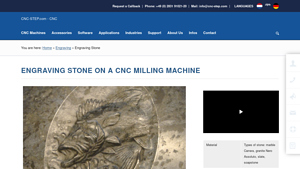

4. CNC-Step – Engraving Solutions for Stone

Domain: cnc-step.com

Registered: 2005 (20 years)

Introduction: Engraving stone with fonts, decorations, photos, and 3D reliefs. Suitable materials include marble (Carrara), granite (Nero Assoluto), slate, and soapstone. Applications include 2D milling, 3D milling, and engraving. Recommended machines: RaptorX-SL with special milling cutter. Software used: ConstruCAM 3D. Key features: High demands on CNC machine stability for deep machining of stone, need for h…

5. Ar – 5.5 kW CNC Stone Carving Machine

Domain: dir.indiamart.com

Registered: 1996 (29 years)

Introduction: This company, Ar – 5.5 kW CNC Stone Carving Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Jeesun – Vertical CNC 3D Stone Carving Router

Domain: jeesuncnc.com

Registered: 2022 (3 years)

Introduction: Vertical Type CNC 3D Stone Carving CNC Router Machine for Sculpture & Statues. Features: 1) Unique vertical structure design, welded by steel tubes for stability and rigidity. 2) 4th axis rotary attachment for stone plate and cylindrical products. 3) Maximum processing depth of 50mm, fast speed and high accuracy. 4) High quality parts from top-rated suppliers (Taiwan Guide, Japan servo motor & red…

7. CNC Stone Carving Machine – 5.5kw Water-Cooled Spindle

Domain: aliexpress.com

Registered: 2006 (19 years)

Introduction: This company, CNC Stone Carving Machine – 5.5kw Water-Cooled Spindle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. ELECNC – 2113ATC CNC Router

Domain: cncrouter-shop.com

Registered: 2018 (7 years)

Introduction: Model: ELECNC-2113ATC-4

Price: Negotiation

Effective Working Area: 2100*1300*600mm

Tool Magazine: 8 tools Carousel magazines

Working Voltage: 380V, 3Phase, 50Hz or option

Control System: Taiwan SYNTEC 6MB control system with 1.8m control box

Spindle: 5.5kw Chang sheng ATC water cooling spindle, 18000rpm, can rotate 180 degrees from -90 to 90

Inverter: 5.5kw Fuling inverter

Motor & Driver: 850w Jap…

9. RBM Actech – CNC Stone Router Machine

Domain: rbmactech.com

Registered: 2022 (3 years)

Introduction: CNC Stone Router Machine: A computer-controlled tool for precise cutting, carving, and engraving on stone surfaces. Suitable for materials like granite, marble, quartz, and sandstone. Key applications include 3D stone carving, stone CNC cutting, stone engraving, architectural stonework, and industrial use. Benefits include unmatched precision, time-saving, cost-efficiency, support for complex 3D d…

10. Blue Elephant – 1228 Stone CNC Router

Domain: elephant-cnc.com

Registered: 2013 (12 years)

Introduction: Blue Elephant Stone CNC Router is engineered for precision, stability, and durability in stone processing. Ideal for cutting and carving various stones, including marble and granite, it supports intricate detailing and heavy-duty production. Key models include 1228 Stone CNC Router with Horizontal Saw Spindle, 1325 Stone CNC Router, 2113 ATC-4A Stone CNC Router with Rotary Device, 1325 4×8 Stone C…

Strategic Sourcing Conclusion and Outlook for 3d stone carving machine

In the evolving landscape of stone carving technology, strategic sourcing of 3D stone carving machines presents a significant opportunity for international B2B buyers. The precision and efficiency offered by CNC machines not only enhance production capabilities but also enable businesses to meet the growing demands for custom stone products across various sectors, including construction, memorialization, and decorative arts. Investing in reliable and advanced machinery is crucial for maintaining competitive advantage, particularly in regions like Africa, South America, the Middle East, and Europe, where craftsmanship and personalization are highly valued.

As you embark on your sourcing journey, consider factors such as machine specifications, compatibility with design software, and the availability of after-sales support. Engaging with reputable manufacturers will ensure you receive quality machines tailored to your unique business needs.

Looking ahead, the demand for innovative stone carving solutions is expected to rise, driven by trends in architecture and interior design. Now is the ideal time to position your business for growth. Explore your options, leverage strategic partnerships, and invest in the future of stone carving technology to unlock new market opportunities and enhance your operational efficiency.