Introduction: Navigating the Global Market for 3d stl files for cnc

In a rapidly evolving landscape, sourcing high-quality 3D STL files for CNC machining has become a critical challenge for businesses looking to enhance productivity and innovation. The ability to access precise and optimized digital models is vital for manufacturers and creators alike, especially in regions like Africa, South America, the Middle East, and Europe, where diverse markets are continuously demanding specialized products. This guide seeks to empower B2B buyers by offering comprehensive insights into the types and applications of 3D STL files, effective supplier vetting processes, cost considerations, and best practices for maximizing the value of these digital assets.

Navigating through a plethora of options can be daunting, yet understanding the key factors influencing the global market for 3D STL files can greatly simplify decision-making. From decorative art pieces to functional components, various categories of STL files cater to different industry needs. Moreover, knowledge surrounding compatibility with CNC machines, software requirements, and licensing agreements is crucial to avoid costly misunderstandings.

This guide is designed to equip international buyers with actionable intelligence, thereby facilitating informed purchasing decisions that align with their specific operational requirements. Whether you’re a small artisan shop in Nigeria, a large manufacturing firm in Saudi Arabia, or an innovative design studio in Europe, our insights will help clarify the complexities of acquiring 3D STL files for CNC, paving the way for successful projects and sustainable growth.

Understanding 3d stl files for cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

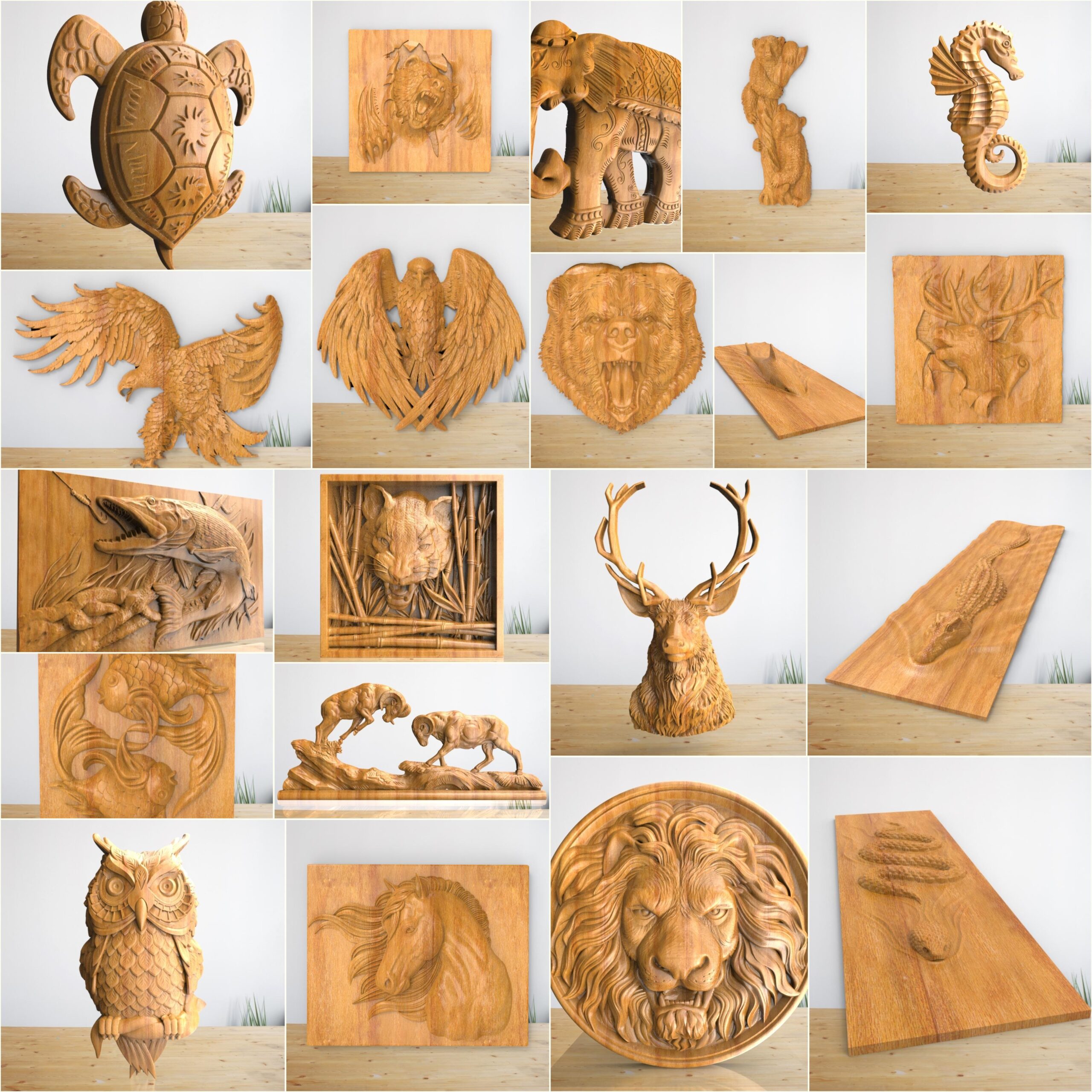

| Decorative STL Files | Highly detailed, often intricate designs suitable for aesthetic purposes. | Interior design, gifts, signage manufacturing. | Pros: Eye-catching, unique designs. Cons: Higher complexity can lead to longer machining times. |

| Functional STL Files | Models designed for practical use, often focusing on fitting and assembly. | Product prototypes, mechanical parts, tooling. | Pros: High utility, often designed for specific applications. Cons: May require customization for specific needs. |

| Relief STL Files | Typically two-dimensional with varying depths, creating a sculptural effect. | Art installations, memorials, heritage projects. | Pros: Provides a dramatic visual impact. Cons: Requires careful craftsmanship to ensure quality. |

| Engraving STL Files | Specifically designed for engraving applications, with flat surfaces. | Personalized products, awards, corporate gifts. | Pros: Versatile for various materials. Cons: Limited to specific engraving technologies. |

| Hybrid STL Files | Combines elements of decorative and functional designs. | Unique product offerings, arts and crafts. | Pros: Flexibility in application. Cons: Can be challenging to machine effectively if overly complex. |

What Are Decorative STL Files and Their B2B Applications?

Decorative STL files are characterized by their intricate designs and high level of detail, making them suitable for aesthetic applications like interior decoration, gifting, and signage production. These models often serve businesses that aim to create visually impressive products that stand out. When purchasing decorative files, businesses should consider the complexities involved in machining, as detailed designs may result in longer production times and higher costs.

How Do Functional STL Files Serve B2B Needs?

Functional STL files are crafted for practical use, focusing on fit and assembly. They are essential for producing product prototypes, mechanical components, and tooling for various industries. Buyers should prioritize the accuracy and material specifications of these models to ensure that they fulfill their intended purpose. While usually straightforward, any customization needed for specific applications can add to the financial investment.

What Are Relief STL Files Used For in Business?

Relief STL files create visual depth through varying surface levels, lending themselves to artistic applications like sculptures or memorial pieces. They are increasingly sought after for art installations and heritage projects. Businesses considering these models should account for the craftsmanship required for high-quality output, as a poor execution can detract significantly from their intended aesthetic impact.

How Are Engraving STL Files Different?

Engraving STL files are tailored for flat surfaces intended for marking or engraving, making them popular for personalized products including awards and corporate gifts. Their versatility allows for usage across different materials, which is attractive to B2B clients. However, businesses must note that these files are limited to certain engraving technologies, potentially narrowing their application scope.

What Advantages Do Hybrid STL Files Offer?

Hybrid STL files incorporate both decorative elements and functional designs, providing unique product offerings for arts and crafts or other specialized applications. The flexibility of these files allows businesses to distinguish their products in competitive markets. However, their often complex nature may lead to challenges in machining, requiring an assessment of the technical capabilities of buyers’ CNC equipment.

Key Industrial Applications of 3d stl files for cnc

| Industry/Sector | Specific Application of 3D STL Files for CNC | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Production of custom tooling and machine parts | Improves efficiency by reducing lead times and costs | Quality of STL files, compatibility with existing CNC machinery |

| Home Décor | Creation of intricate decorative items and furniture | Enhances product differentiation and unique offerings | Design detail, aesthetics, and material compatibility |

| Automotive | Fabrication of prototype components | Accelerates product development cycles | Precision of models, adaptability for rapid prototyping processes |

| Medical Devices | Development of custom implants and surgical tools | Increases patient-specific solutions and operational efficiency | Compliance with medical standards and biocompatibility of materials |

| Educational Institutions | Fabrication of teaching aids and prototypes | Provides hands-on learning experiences for students | Variety of designs, ease of use with educational CNC equipment |

How Are 3D STL Files for CNC Utilized in the Manufacturing Sector?

In the manufacturing industry, 3D STL files play a pivotal role in producing custom tooling and machine parts. These digital models allow manufacturers to create intricate components with high precision, reducing both lead times and production costs. For international B2B buyers, particularly in emerging markets like Nigeria or Saudi Arabia, ensuring compatibility with existing CNC machines is crucial. Additionally, the quality of STL files must be scrutinized to ensure they meet the specific requirements of the manufacturing process, preventing delays in production.

What Are the Advantages of Using 3D STL Files for CNC in Home Décor?

The home décor sector effectively leverages 3D STL files to create unique decorative items and furniture pieces. These digital models enable businesses to differentiate their products in a saturated market by offering custom designs that appeal to various aesthetic preferences. For B2B buyers in regions such as Europe and South America, sourcing high-quality, detailed designs is essential, as they significantly impact the final product’s appeal and marketability. Additionally, compatibility with diverse materials ensures that manufacturers can adapt designs for different customer demands.

How Do Automotive Companies Benefit from 3D STL Files for CNC?

Automotive companies utilize 3D STL files primarily for fabricating prototype components, which is vital for accelerating product development cycles. The ability to quickly produce and test new designs helps minimize time-to-market for new vehicles and parts. International B2B buyers from regions like the Middle East require models that maintain rigorous standards of precision due to the critical role each component plays in vehicle safety and performance. Therefore, sourcing STL files that meet stringent quality benchmarks is paramount.

In What Ways Are 3D STL Files for CNC Transforming Medical Device Development?

In the medical sector, 3D STL files are instrumental in developing custom implants and surgical tools tailored to individual patient needs. This personalization enhances the efficacy and safety of medical interventions. B2B buyers in this field must prioritize compliance with established medical standards and the biocompatibility of materials used in production. Partnering with suppliers who understand these technical requirements is crucial to ensuring successful and ethical implementations.

How Do Educational Institutions Leverage 3D STL Files for CNC?

Educational institutions harness the power of 3D STL files to fabricate teaching aids and prototypes, enriching the learning experience for students. These applications provide hands-on learning opportunities, allowing students to engage with practical applications of engineering and design. For B2B buyers in this sector, the variety and ease of use of these designs must be considered, ensuring they are suitable for educational CNC equipment and capable of fostering an engaging learning environment.

3 Common User Pain Points for ‘3d stl files for cnc’ & Their Solutions

Scenario 1: Complexity in File Compatibility and Integration Issues

The Problem: B2B buyers often face the challenge of ensuring that the 3D STL files they purchase or download are fully compatible with their existing CNC machinery and software systems. This issue is compounded by the variety of CNC machines available across different regions, each potentially requiring different file formats or specific configurations. As a result, clients may find themselves spending significant time and resources on troubleshooting rather than focusing on productive output.

The Solution: To navigate these compatibility issues, businesses should prioritize sourcing STL files from reputable vendors that provide detailed specifications about file compatibility. Before purchasing, buyers should confirm that the files are compatible with their CNC software and discuss with vendors regarding any configuration requirements. It’s also advisable to maintain a dialogue with machine operators and CAD technicians to ensure that the chosen models meet their operational needs. For added reliability, buyers may consider suppliers who offer technical support or service agreements to address any compatibility concerns proactively.

Scenario 2: Limited Options for Niche Applications

The Problem: Companies in specialized sectors—such as medical device manufacturing, automotive part production, or artistic design—often struggle to find 3D STL files tailored to their specific applications. Off-the-shelf models may lack the intricate details or functionalities required for precision work, leading to frustration and delays in production schedules.

The Solution: To overcome this limitation, businesses should engage with custom design services or platforms that allow for bespoke STL file creation. By collaborating directly with experienced designers, companies can develop models that meet their exact specifications. Additionally, buyers should invest time in community engagement—such as forums or networks—where they can share their unique needs and perhaps find designers willing to create tailored STL files. This proactive approach not only ensures access to niche designs but also opens up opportunities for innovative cooperation within the industry.

Scenario 3: Quality and Detailing Concerns

The Problem: The quality of downloaded STL files can often vary significantly, which poses a substantial risk for B2B buyers. Poorly optimized models may result in manufacturing defects, wasted materials, and time lost in production processes. This is especially critical in industries where precision is key, such as metalworking or custom furniture.

The Solution: To guarantee the quality of STL files, businesses should implement a rigorous vetting process before purchasing. This includes analyzing customer reviews and checking ported details about previous buyer experiences to determine the reliability of the files. Moreover, buyers should seek vendors who provide preview options, allowing for initial assessments of detail and precision. It can also be beneficial to demand test runs with low-cost materials before full-scale production. By taking these precautions, buyers can ensure their files meet high standards for performance and reduce the risk of costly errors during machining.

Strategic Material Selection Guide for 3d stl files for cnc

When selecting materials for 3D STL files intended for CNC machining, understanding the unique properties and applications of various materials is crucial for achieving optimal results. Here, we explore four common materials utilized in this context: MDF (Medium Density Fiberboard), acrylic, metal, and wood – focusing on their properties, advantages, and inherent limitations.

What Are the Key Properties of Medium Density Fiberboard (MDF) for CNC Machining?

MDF is a versatile composite material made from wood fibers combined with adhesives under heat and pressure. With a density typically ranging from 600 to 800 kg/m³, it provides a smooth surface that’s ideal for detailed carving. MDF offers moderate resistance to pressure and is not particularly high in load-bearing capacity. It has no natural grain, allowing for consistent finishes in intricate designs.

Pros: The key advantages of MDF include its low cost and excellent machining properties. It can be easily cut, shaped, and painted, making it suitable for decorative and functional components.

Cons: However, its primary limitations include a lower durability compared to solid wood and susceptibility to moisture, which may lead to warping. For applications requiring robust endurance, MDF is less suited.

In international contexts, buyers must consider local compliance regarding sustainability practices, as MDF can be manufactured with formaldehyde. Standards such as those from the European Union (EU) can influence material sourcing and procurement strategies.

How Does Acrylic Stand Out as a Material for CNC Projects?

Acrylic, or PMMA (Polymethyl Methacrylate), is a popular thermoplastic known for its clarity and weather resistance. It has a temperature resistance of approximately 80°C and is lightweight, making it adaptable for various designs.

Pros: Acrylic can be easily engraved and cut with high precision, producing polished edges. It is commonly used for signage, displays, and fixtures due to its aesthetic appeal and versatility.

Cons: One downside is its tendency to crack under high impact and stress. Although available in various colors and thicknesses, acrylic can sometimes be more expensive than MDF.

For international buyers, certifications such as ISO 1183 ensure the quality and performance of acrylic products, making it a reliable choice across different markets.

What Are The Advantages of Using Metal for CNC Machining?

Metal materials, including aluminum and stainless steel, are renowned for their strength and resilience. They can withstand high temperatures and mechanical stresses, making them ideal for functional parts and fixtures requiring precise tolerances.

Pros: Metal parts exhibit excellent durability and longevity, making them suitable for high-performance applications. They can also be used in conjunction with various finishes and coatings to enhance corrosion resistance and aesthetic qualities.

Cons: The primary downside of metal materials is their higher cost and the increased complexity in machining processes. Metals require specialized tools and expertise that may significantly raise the manufacturing cost and duration of projects.

For international B2B transactions, adhering to standards such as ASTM for metals is crucial. This ensures that all products meet global performance and safety benchmarks, especially in regulated industries.

How Is Wood Used Effectively Within CNC Projects?

Wood remains a timeless material for CNC applications, offering diverse aesthetic choices from hardwoods to softwoods. Each type exhibits unique properties, generally presenting high strength-to-weight ratios.

Pros: Wood can be easily shaped and carved, allowing for both intricate designs and structural parts. It’s also often favored for environmentally-friendly projects when sourced sustainably.

Cons: However, wood’s limitations include susceptibility to warping, cracking, and surface blemishes. Additionally, it requires careful finishing to achieve desired aesthetics without compromising durability.

B2B buyers must consider regulations regarding imported timber products to ensure compliance with local laws, such as the Forestry Stewardship Council (FSC) certifications, particularly in Europe and North America.

Summary Markdown Table

| Material | Typical Use Case for 3D STL Files for CNC | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| MDF | Decorative pieces, detailed carvings | Smooth surface, low cost | Not moisture resistant, lower durability | Low |

| Acrylic | Signage, displays, fixtures | High clarity, precision machining | Prone to cracking under impact | Medium |

| Metal | Functional parts and fixtures | High strength and durability | Higher manufacturing complexity and cost | High |

| Wood | Furniture, artistic designs | Aesthetic appeal, easy to work | Susceptible to warping and blemishes | Medium |

By carefully weighing these materials’ properties, benefits, and compliance requirements, international B2B buyers can make informed decisions that enhance their CNC projects’ quality and functionality.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d stl files for cnc

What Are the Key Stages in the Manufacturing Process of 3D STL Files for CNC?

The production of 3D STL files for CNC machining involves a specific set of stages, essential for ensuring that the final digital designs meet industry requirements for quality and precision. Here is an overview of the main stages involved.

Material Preparation: How Are 3D Models Designed and Optimized?

The initial phase in the manufacturing of STL files begins with design and modeling. Engineers and designers utilize Computer-Aided Design (CAD) software to create detailed 3D models, considering factors such as dimension specifications, compatibility with various CNC machines, and the intended use of the final piece (be it functional or decorative).

During this stage, optimization techniques are applied to ensure that files are not only easy to machine but also minimize potential wastage of materials. This includes generating models that facilitate effective tool paths and reduce machining errors. For international B2B buyers, understanding the design capabilities of suppliers can help ensure that the models will fit seamlessly into your existing CNC workflows.

Forming: What Techniques Are Employed in File Generation?

Once the model is prepared, the next step involves generating the STL files from the CAD formats. Here, various export settings must be used to convert the designs accurately to the STL format, maintaining high fidelity and resolution. This stage commonly employs techniques like tessellation, where mesh generation ensures that the model’s surfaces are appropriately representational in the STL file.

B2B buyers should ensure that their suppliers use best practices in file generation to prevent issues during CNC machining, such as inaccuracies or failed jobs due to poorly constructed STL files. Confirming that suppliers keep up-to-date with software updates and industry advancements can also contribute to improved file quality.

Assembly: Are STL Files Verified Before Final Delivery?

While STL files are not assembled in a physical sense, they must be checked for integrity and precision prior to being delivered. Many companies implement robust verification processes, including simulation checks, where the models are imported into CNC simulation software to verify machining paths and realistic performance outcomes.

For B2B buyers, requesting proof of this verification process can provide added assurance that the files received will work as expected. This step is crucial for buyers looking to engage in large-scale production, where the cost of errors can escalate significantly.

Finishing: How Is Quality Achieved in the Final STL Files?

In the finishing stage, quality assurance is paramount. Suppliers should perform checks on STL files to ensure that they adhere to both internal and external quality standards. This stage may include final refinements to the digital model and checking accuracy related to the original design specifications.

It is important for B2B buyers to inquire about the quality assurance processes followed by suppliers. Buyers should look for detailed reports that document the steps taken during the quality checks, ensuring that the files produced fulfill the desired standards.

What Quality Assurance Methods Are Commonly Used for 3D STL Files?

Maintaining high-quality standards in the manufacturing of STL files is integral for supplier reliability. This section outlines relevant international standards and best practices employed by suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is one of the most recognized international standards applicable to any organization, covering quality management systems. This standard emphasizes continual improvement and customer satisfaction, making it a reputable measure for assessing suppliers.

Specific industries may require further compliance, such as CE marking in Europe for safety and environmental standards, or ISO/TS 16949 for organizations involved in automotive supply chains. As buyers from diverse regions (like Africa, South America, and the Middle East) engage in international procurement, having a good understanding of these standards can facilitate smoother operations and help mitigate risks.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality Control (QC) checkpoints are crucial at various stages during the manufacturing process. Typically, these include:

- Incoming Quality Control (IQC): Assessment of raw data integrity before commencing the file generation process.

- In-Process Quality Control (IPQC): Evaluation during file generation, particularly to catch any discrepancies early in the design phase.

- Final Quality Control (FQC): Comprehensive final checks on the STL files to ensure they meet specifications before delivery.

B2B buyers should request details regarding these QC checkpoints and any documentation or certifications that come as part of the verification process.

What Testing Methods Are Used to Validate STL Files?

Common testing methods can include running CNC simulations, which simulate how the generated STL files will perform in real-world machining conditions. Physical tests may also be used, where a sample is machined from the STL file to validate accuracy and performance before mass production.

B2B purchasers can benefit from insisting that their suppliers adhere to these testing methodologies. A reliable supplier should readily provide test results or validation reports to affirm the quality of the files produced.

How Can B2B Buyers Verify Supplier Quality Controls?

For international users acquiring STL files for CNC applications, ensuring quality assurance at every step can significantly impact operational efficiency and end-product quality. Here are strategies to validate supplier QC practices:

What Should Buyers Request During Supplier Audits?

Buyers must conduct proper supplier audits, requesting documentation that outlines the supplier’s manufacturing processes, adherence to international standards, and any quality certifications. This can include:

- Documentation of previous quality audits and certifications.

- Verification of quality management systems in place.

- Evidence of completed QC processes for previous orders.

Performing audits not only builds trust but also establishes a framework for long-term collaborative relationships.

How Can Third-party Inspections Be Used?

Engaging third-party inspectors to review suppliers can provide an additional layer of assurance. Independent inspection services can assess the supplier’s facilities, evaluate their processes, and provide unbiased reports regarding quality compliance and performance.

By leveraging third-party inspections, B2B buyers can fearlessly move forward with assured confidence in their supplier’s capabilities, creating compelling partnerships across regions like Europe, Africa, and the Middle East.

Conclusion: Ensuring Quality in STL Files for CNC Machining

Understanding the manufacturing processes and quality assurance measures associated with 3D STL files is crucial for B2B buyers operating in international markets. By emphasizing structured processes, quality standards, and effective validation techniques, companies can significantly enhance their production outcomes and foster sustainable supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d stl files for cnc’

Introduction

In the competitive landscape of CNC machining, sourcing high-quality 3D STL files is vital for optimizing production efficiency and ensuring design precision. This guide serves as a comprehensive checklist for B2B buyers seeking to procure STL files suitable for CNC applications. By following these steps, you can enhance supplier relationships, mitigate risks, and guarantee the quality of your virtual designs.

Step 1: Define Your Technical Specifications

Having a clear understanding of your technical needs is crucial in ensuring the 3D STL files you source are compatible with your CNC machinery. Consider factors like file size, complexity of the design, and material compatibility. This will also help in communicating effectively with suppliers.

- Include requirements: Specify features such as the intended material, size, and detail level for the STL files.

- Provide examples: If possible, share design samples or references to clarify your expectations to potential suppliers.

Step 2: Research and Identify Potential Suppliers

Before making any commitments, it’s critical to research suppliers who specialize in STL files for CNC. Look for providers with established credibility and industry experience.

- Check online platforms: Use reputable marketplaces like Cults3D or 3DWAVE to find a range of suppliers, and look for those with positive reviews or ratings.

- Assess their portfolio: Evaluate the diversity and quality of their previous work to ensure they meet your specific design requirements.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Verify experience: Inquire about their experience with CNC-related STL files, especially in your sector.

- Request samples: Consider asking for a small sample design to assess their output quality.

Step 4: Confirm Compatibility with Your CNC Machines

Every CNC machine has unique software and compatibility requirements. Ensure that the STL files you are considering are compatible with your existing systems.

- Check file formats: While STL is a common format, confirm that the supplier can deliver files in the format that matches your CNC software.

- Look for optimization: Ensure that files are optimized for smooth machining processes to minimize errors and downtime during production.

Step 5: Discuss Licensing and Use Rights

Understanding the licensing agreements attached to STL files is essential to avoid future legal complications. This ensures compliance with usage rights and protection of your investment.

- Clarify usage: Ensure you understand whether the files are for personal use only, commercial resale, or if they allow modifications.

- Negotiate terms: If necessary, discuss and negotiate licensing terms to suit your business needs.

Step 6: Request After-Sales Support and Services

Inquire about the support services offered post-purchase. This can be critical for resolving technical issues or obtaining updates for designs.

- Consider added value: Providers offering support can significantly ease the implementation of the STL files in your operations.

- Evaluate training resources: Check if suppliers provide tutorials or customer service to assist in the integration of their designs with your CNC processes.

Step 7: Finalize Your Selection and Place Orders

Once you have assessed and chosen the right supplier, proceed to finalize your order. Ensure all terms are well-documented to avoid future misunderstandings.

- Review quotations: Compare prices, terms, and service levels before making a decision.

- Keep clear communication: Maintain open lines of communication with the supplier to facilitate a smooth transaction.

Following these steps will not only streamline your procurement process for 3D STL files for CNC applications but also enhance overall operational efficiency in your manufacturing endeavors.

Comprehensive Cost and Pricing Analysis for 3d stl files for cnc Sourcing

What Are the Key Cost Components for Acquiring 3D STL Files for CNC Machining?

When sourcing 3D STL files for CNC fabrication, understanding the cost structure is paramount for effective budgeting and decision-making. Each file’s pricing incorporates multiple components:

-

Materials: Since STL files are digital assets, traditional materials costs like wood or metal are not applicable. However, higher-quality models or specialized designs may command a premium due to the artist’s skill or design intricacies.

-

Labor: The cost of labor primarily involves the design and modeling phases. Skilled designers may charge more for their expertise, influencing the overall cost. Additionally, if modifications or customizations are required, this will add to the labor cost.

-

Manufacturing Overhead: This includes costs related to software licenses needed for creating or manipulating STL files, as well as tools that enhance design quality—such as 3D software subscriptions.

-

Tooling for Custom Designs: If buyers need tailored files not available in standard catalogs, the investment in tooling for custom designs can be considerable.

-

Quality Control (QC): Ensuring that the STL files meet specific machining standards requires QC measures, which can add to the final cost. This may include testing compatibility with different CNC machines or ensuring high precision.

-

Logistics: Although logistics are less of a burden for digital products, issues like bandwidth for downloading large files could be a consideration in regions with slower internet speeds.

-

Margin: Suppliers typically apply a margin to cover their overhead and profit incentives. The complexity and novelty of a design can increase this margin.

How Do Price Influencers Affect the Cost of 3D STL Files for CNC?

Numerous factors influence the pricing strategies employed by suppliers:

-

Volume and Minimum Order Quantity (MOQ): Buying in bulk often results in reduced unit costs. For established manufacturers, supplier negotiations can lead to cost savings at higher volumes.

-

Specifications and Customization Needs: Custom STL files significantly increase costs due to the labor and time involved in creating unique designs tailored to specific project requirements.

-

Materials Used and Quality Certifications: Models requiring advanced design tools or higher resolutions will be priced accordingly. Files certified for high precision or functional use often carry a higher price tag.

-

Supplier Factors: The experience level of the supplier, along with their reputation and the location of their operations, can affect pricing. Suppliers with extensive industry experience may charge more for their services but offer added assurance of quality.

-

Incoterms: International shipping terms can have implications for buyers, especially in terms of VAT and import duties, which can affect the overall purchasing cost even for digital products.

What Buyer Strategies Enhance Cost Efficiency When Sourcing 3D STL Files?

International buyers, especially those from Africa, South America, the Middle East, and Europe, can optimize their purchasing strategy using the following tips:

-

Negotiation Techniques: Always aim for discussions around price flexibility and volume discounts. Suppliers may be willing to adjust prices based on long-term commitments or larger purchase orders.

-

Understanding Total Cost of Ownership (TCO): Beyond the initial acquisition cost, consider factors like the longevity and versatility of the STL files. A slightly higher investment in a well-designed model can save money in the long run through reduced machining issues or a longer operational lifespan.

-

Navigating Pricing Nuances for International Transactions: Be mindful of fluctuations in currency exchange rates and additional banking fees that can alter the final cost. Establishing payments in a local currency can sometimes mitigate risks associated with currency value changes.

-

Market Research: Stay updated on market trends regarding STL files, variations in supplier pricing, and emerging technologies that may present new opportunities or significant cost-saving options.

By thoughtfully considering these factors, B2B buyers can make informed decisions when sourcing 3D STL files for CNC applications, ensuring they maximize value while minimizing unnecessary costs.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier offers.

Alternatives Analysis: Comparing 3d stl files for cnc With Other Solutions

Introduction: Understanding Alternative Solutions for CNC Applications

In the realm of CNC machining, businesses are often confronted with a myriad of tools and technologies that help translate digital designs into precise physical products. While 3D STL files specifically designed for CNC are a popular choice, there are viable alternatives worth considering. This analysis highlights how these alternatives stack up against traditional STL files in terms of performance, cost, ease of implementation, maintenance, and best use cases. By examining these aspects closely, B2B buyers can make more informed purchasing decisions tailored to their operational needs.

| Comparison Aspect | 3D STL Files for CNC | Alternative 1: G-code | Alternative 2: DXF Files |

|---|---|---|---|

| Performance | High-quality, precise detail | Excellent for machine control, but requires more knowledge | Good for 2D and 3D, but less detail than STL |

| Cost | Typically low; $5-$50 per file | Varies; can be generated from free software | Often lower, especially for simple designs |

| Ease of Implementation | User-friendly, instant downloads from various platforms | Requires software that can interpret G-code | Easy to open in CAD software with a conversion tool |

| Maintenance | Low; requires file organization | Medium; iterative updates may be necessary | Low; mostly stable file formats |

| Best Use Case | Detailing complex designs, artistic projects | Precise machining operations requiring intricate controls | Simpler, geometric designs or flat cuts |

What are the advantages of G-code as an alternative to STL files for CNC?

G-code is the language used by CNC machines to perform specific functions like cutting, milling, and drilling. While STL files offer detailed 3D models, G-code excels in controlling the machinery for efficient operation. Its primary advantage is the precision it delivers during machining. However, producing G-code typically requires specialized software and a deeper understanding of machine operations, making it less straightforward for beginners. Additionally, any modifications to the design necessitate regenerating the G-code, which complicates maintenance.

How do DXF files compare to STL files in CNC applications?

DXF (Drawing Exchange Format) files are primarily utilized for 2D designs but can also represent 3D geometries. They have a lower cost barrier, especially suitable for companies looking to create simpler designs without engaging with complex 3D modelling. They easily integrate into most CAD software, making implementation seamless. However, DXF files may not convey the intricate details and textures achievable with STL files, limiting their effectiveness for applications requiring high levels of detail.

Conclusion: How Can B2B Buyers Choose the Right CNC Solution for Their Needs?

When selecting the most suitable solution for CNC applications, B2B buyers should clearly define their project requirements. If high precision and intricate designs are paramount, 3D STL files are advantageous, especially for custom and artistic applications. Meanwhile, G-code offers unmatched control over CNC machines for users familiar with operating complexities. DXF files serve as a cost-effective option for simpler geometric designs but do not provide the depth of information contained in STL files. Ultimately, the choice hinges on project complexity, budget constraints, and the technical expertise available within the organization, guiding buyers toward the solution that best aligns with their operational objectives.

Essential Technical Properties and Trade Terminology for 3d stl files for cnc

What Are the Key Technical Properties of 3D STL Files for CNC?

When dealing with 3D STL files for CNC machining, it’s essential to understand specific technical properties that impact the efficiency and outcome of your projects. Here are some critical specifications relevant to B2B purchasing decisions:

1. File Format and Compatibility

STL (Stereolithography) is the most widely used file format for 3D printing and CNC machining. It is essential to ensure that your chosen STL files are compatible with your CNC software to avoid delays or errors during production. Many CNC machines require specific file versions, so obtaining files compatible with both your hardware and software is crucial for seamless operations across different platforms.

2. Resolution and Detail Level

The resolution of an STL file determines the level of detail that can be achieved in the final product. Higher resolution files contain more polygons and thus more detailed geometry, which is vital for intricate designs. However, higher resolutions require more processing power and time in CNC machining. Understanding your projects’ requirements allows you to strike a balance between detail and efficiency.

3. Units of Measurement

STL files can be based on various units of measurement—most commonly metric or imperial. If the measurements in the STL file do not match the settings in your CNC machine or software, it can lead to significant production errors. B2B buyers must ensure that the STL files specify their units of measurement clearly to avoid costly mistakes.

4. Mesh Integrity and Error Checking

Before using STL files, it is critical to confirm the integrity of the mesh. Mesh errors, such as non-manifold edges or holes, can result in production failures. Many CNC software platforms include functionalities to repair mesh issues prior to machining. Ensuring the STL file is error-free enhances operational efficiency and ensures product quality.

5. Orientation and Assembly Requirements

The way a model is oriented in the STL file can affect machining efficiency as well as the strength of the final product. It is essential to understand how to orient your models for optimal machining. Additionally, for complex assemblies, files that include assembly instructions can be beneficial, increasing productivity and reducing labor costs.

6. Physical Properties

While STL files primarily focus on geometry, understanding the intended material for the final product—such as wood, metal, or plastic—is vital. Different materials have unique characteristics that may affect the design parameters within the STL file. Familiarity with material properties ensures that the digital design will successfully translate into a physically viable product post-manufacturing.

What Are Common Trade Terms Associated with 3D STL Files for CNC?

In the world of B2B transactions, specific jargon and terms are frequently used. Familiarity with these can streamline communication and enhance negotiation processes:

1. OEM (Original Equipment Manufacturer)

An OEM produces designs and components that are then marketed by another company. In CNC machining, businesses often work with OEMs who provide standardized components that fit perfectly with specific designs, ensuring compatibility and reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQs is essential for buyers when assessing whether a supplier aligns with their production needs and budgets, particularly when sourcing STL files in bulk for large manufacturing runs.

3. RFQ (Request for Quotation)

An RFQ is a business document that outlines the specifications for OEM products or services a company seeks and requests pricing from suppliers. Knowing how to draft an RFQ can result in better pricing and faster procurement of STL files and CNC machining services.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms used globally in international transactions to clearly define the responsibilities of buyers and sellers. Understanding these terms is crucial for managing logistics and ensuring smooth delivery of STL files and other related components in a B2B context.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is received. In the context of CNC machining, understanding the expected lead time for prototyping or final product delivery is critical for keeping your production schedule on track.

Familiarizing yourself with these technical properties and trade terminology will enable you to make informed decisions and enhance your procurement process for 3D STL files and CNC machining, leading to more efficient and successful projects.

Navigating Market Dynamics and Sourcing Trends in the 3d stl files for cnc Sector

What Are the Key Market Trends Driving the 3D STL Files for CNC Sector?

The global market for 3D STL files tailored for CNC applications is witnessing robust growth, influenced by several key drivers. Increasing demand for customized manufacturing and rapid prototyping across diverse industries—including woodwork, crafting, and industrial production—has led to a surge in sourcing these digital assets. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are not only seeking high-quality designs but also looking for files that ensure compatibility with various CNC machines and software.

Emerging technology trends like cloud-based design platforms and collaboration tools are transforming how businesses procure and utilize these files. For instance, integration with CAD software allows for real-time modifications and iterative design processes, enhancing efficiency. Furthermore, the rise of e-commerce for digital goods facilitates instant access to vast libraries of STL files, allowing buyers to quickly adapt to market demands.

As more companies adopt CNC strategies for production, the expectations for file accuracy, detailing, and ease of use are rising. This shift is increasing the competition among suppliers to offer premium, well-optimized STL files. Key trends include the shift towards subscription models for file access and the increasing prevalence of specialized vendors catering to niche markets, promoting a wide array of customizable options.

How Is Sustainability Shaping Supply Chain Strategies for 3D STL Files?

In the ever-evolving landscape of B2B, sustainability and ethical sourcing are becoming crucial considerations. As environmental concerns escalate, businesses are compelled to prioritize sustainable practices in sourcing their 3D STL files. This encompasses the use of eco-friendly materials in files intended for CNC manufacturing and the adoption of practices that minimize waste.

The importance of ethical supply chains cannot be overstated, particularly for international buyers who want to ensure that their sourcing practices align with global sustainability goals. Many suppliers now offer digital products that come with certifications indicating their environmental impact. For example, STL files that are compatible with materials such as reclaimed wood or biodegradable composites enable businesses to produce more sustainable end products, reducing negative ecological footprints.

Moreover, the growing trend for ‘green’ certifications in digital files promotes responsible sourcing and affirms commitment to sustainability among businesses. Suppliers who prioritize environmentally friendly practices are likely to find favor with B2B buyers looking to enhance their corporate social responsibility profile. In this context, sustainability not only answers consumer demand but also serves as a competitive differentiator in the marketplace.

What Is the Historical Context of the 3D STL Files for CNC Sector?

The development of 3D STL files for CNC applications can be traced back to the advent of rapid prototyping technologies in the late 20th century. Initially, STL (Standard Tessellation Language) was created as a simple means of representing three-dimensional shapes for 3D printing, primarily for industrial applications. However, as CNC technology grew more accessible, the use of STL files found foothold in various sectors including woodworking, design, and manufacturing.

Over time, the market evolved, driven by enhancements in software capabilities and the democratization of CNC technology. Today, it encompasses a vibrant online ecosystem where B2B buyers can easily access thousands of pre-designed STL files. The shift from traditional manufacturing methods to CNC machining has not only revolutionized production processes but has also fostered the emergence of diverse niches, allowing for tailored 3D designs that cater to specific market needs. This historical backdrop informs present sourcing strategies, highlighting the importance of staying abreast of advancements in technology and market expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d stl files for cnc

-

How do I choose the right STL files for my CNC projects?

Selecting the right STL files involves considering the type of materials you’ll be working with, the CNC machine compatibility, and the purpose of the project. Look for files that are optimized for CNC machining, which typically feature clean geometry and are easily scalable. Check for detailed descriptions, customer reviews, and sample renderings to help ensure that they meet your quality standards. Lastly, verify that the models’ design complexity aligns with your machine’s capabilities to prevent operational issues. -

What are the payment terms for purchasing 3D STL files?

Payment terms may vary by supplier but commonly include options like upfront payments, split payments, or payment upon delivery. When engaging with suppliers, always inquire about accepted payment methods—credit cards, bank transfers, and digital wallets are common. It’s advisable to use secure payment platforms and establish clear invoicing details. Familiarize yourself with cancellation or refund policies should any issues arise after the purchase. -

What is the typical lead time for obtaining STL files for CNC?

Lead times can vary based on the supplier and file complexity. Generally, digital files are available for instant download upon payment confirmation, which means you can start working immediately. However, if you request customized files, the lead time may extend to several days or weeks, depending on the supplier’s workload and the level of customization. Establish a clear timeline with your supplier to avoid project delays. -

Can I customize STL files to fit my specific project needs?

Many suppliers offer customization options for STL files, allowing you to modify designs according to your project’s specifications. It’s essential to communicate your requirements clearly, such as dimensions, design changes, or material considerations, when requesting customization. Be aware that custom modifications may incur additional costs and change the delivery timelines. Always confirm the feasibility of the changes with your supplier before proceeding. -

How do I verify the quality of STL files from suppliers?

Quality verification can be conducted through a combination of reviews and sample testing. Look for suppliers with positive customer ratings and testimonials that emphasize their file quality and service reliability. You may also request sample STL files to test on your CNC machine to ensure that the designs operate smoothly and meet your specifications. Consider establishing quality assurance agreements with your suppliers to further safeguard your interests. -

What are the common logistical aspects to consider when acquiring STL files internationally?

Since STL files are digital products, logistics largely pertain to data security and internet bandwidth. Ensure that your internet connection can handle large file sizes, which may be relevant depending on the complexity of the STL files. Check the supplier’s delivery methods for digital files, ensuring secure methods of file transfer. Furthermore, consider data protection laws and intellectual property rights, especially if the designs could be used commercially. -

Are there minimum order quantities (MOQs) when purchasing STL files?

Most suppliers do not enforce MOQs for digital STL files as they are often available for individual purchase. However, some might offer discounts on bulk orders, which can benefit businesses looking to acquire multiple designs simultaneously. Always verify if there are any bundled offerings or promotional packages that could provide better pricing, particularly for B2B transactions. -

What intellectual property rights do I have with purchased STL files?

When buying STL files, it’s crucial to review the licensing agreements associated with your purchase. Most vendors provide files for personal and commercial use but restrict selling or redistributing the files. Ensure you understand your rights to modify or use the designs commercially. Always communicate with the supplier to clarify any uncertainties regarding usage rights to prevent potential legal issues down the line.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 3D Stl Files For Cnc Manufacturers & Suppliers List

1. 3D Wave – STL Models & Laser-Ready Files

Domain: 3dwave.us

Registered: 2021 (4 years)

Introduction: 3D STL Models for CNC Router and 3D Illusion Laser-ready files. Available categories include: American, Canadian, Angels, Animals, Australian & NZ, Bundle Badges, British, Birds, Crosses & Crucifixes, Celtics, Clocks, Crests, Farm, Food & Drink, Flowers & Plantlife, Furniture & Decorations, Frames & Picture Frames, Fantasy, German, Guns, Cars & Equipment, Insects & Reptiles, Religious, Skulls & Bi…

2. Carbide 3D – 3D Models for CNC Machines

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: Carbide 3D offers 3D models for CNC machines like the Shapeoko CNC Router and Nomad Desktop CNC, which both support full 3D projects. STL files are the most common format for 3D models, preferred for their compatibility with CNC machines, while OBJ files are less favored for CNC use due to limited compatibility with CAM software. DXF files can also store 3D models but are not as commonly available…

3. Cults – Cnc STL Files

Domain: cults3d.com

Registered: 2013 (12 years)

Introduction: Cults offers 30.3k Cnc STL files for 3D printers with prices ranging from US$3.51 to US$45.99. Some notable products include: ‘BARREL WITH GRAPE’ for US$5.84, ‘HORSE HEAD’ for US$15.20, ‘NEVER FORGET FALLEN SOLDIERS’ for US$9.35, ‘Eagle and Sacred Heart of Jesus’ for US$11.69, and ‘Saint Maria Goretti Relief’ for US$17.53. The platform supports file formats such as STL, OBJ, STEP, 3MF, SCAD for 3D…

4. Inventables – 8 Best STL File Websites for 3D Carving

Domain: inventables.com

Registered: 2001 (24 years)

Introduction: Title: 8 Best Sites to Download STL Files (For 3D Carving)

Key Product Details:

1. STL File Format: Used for 3D carving and CNC routing applications; file size up to 100 MB.

2. Best File Types: STL files with flat faces or flat bottoms are recommended for 3D carving.

3. Recommended Websites for STL Files:

– STLFinder: Search engine for STL files; offers both paid and free options.

– Free3D:…

5. Etsy – CNC Files Mega Bundle

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Cnc Stl Files – Over 5,000 items available. Popular listings include digital downloads of CNC files such as: 1. MEGA BUNDLE CNC Files For Router Machines – Sale Price: $9.90 (Original Price: $19.80, 50% off) 2. Panno & Bas-Reliefs 3D CNC Router STL Pack – Sale Price: $14.90 (Original Price: $29.80, 50% off) 3. CNC 3D Panel Design Bundle – Sale Price: $28.40 (Original Price: $37.86, 25% off) 4. Ent…

6. 3Axis – Laser-Cut STL Files and Plans

Domain: 3axis.co

Registered: 2017 (8 years)

Introduction: STL Files available for laser-cut tools, including boxes and generators. Formats: CDR, DXF, PDF, SVG, AI, EPS, BMP, STL, DWG. Product categories include 3D puzzles (animals, vehicles), woodworking plans (gift boxes, jewelry boxes, tool boxes), decor items (clocks, lamps, photo frames), kids learning tools, and office supplies. Offers 148 free STL files for download, specifically designed for CNC r…

7. All3DP – Free STL Files for CNC Routers

Domain: all3dp.com

Registered: 2013 (12 years)

Introduction: Best sites for free STL files for CNC routers.

8. STL24 – Custom 3D Models for CNC

Domain: stl24.com

Registered: 2018 (7 years)

Introduction: This company, STL24 – Custom 3D Models for CNC, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 3d stl files for cnc

In conclusion, the strategic sourcing of 3D STL files for CNC machining represents a pivotal opportunity for businesses looking to enhance their production capabilities. By leveraging high-quality, precise STL files tailored for various applications—ranging from decorative art to functional components—buyers can significantly streamline their workflows. Emphasizing attributes such as instant accessibility, compatibility with diverse CNC software, and continuous updates of model designs can provide a competitive edge in rapidly evolving markets.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are encouraged to explore options that not only meet their immediate requirements but also align with their long-term goals of innovation and efficiency. Investing in a well-rounded sourcing strategy will ensure that your business remains agile and responsive to market demands while achieving higher productivity and quality.

As you embark on this journey, consider collaborating with reputable suppliers and platforms that can provide both variety and reliability in their offerings. The future of CNC machining lies in the hands of those who can adeptly utilize these resources, paving the way for groundbreaking developments in manufacturing. Take the step today towards sourcing excellence and watch your projects take flight!