Contents

Manufacturing Insight: 3D Printing Services Metal

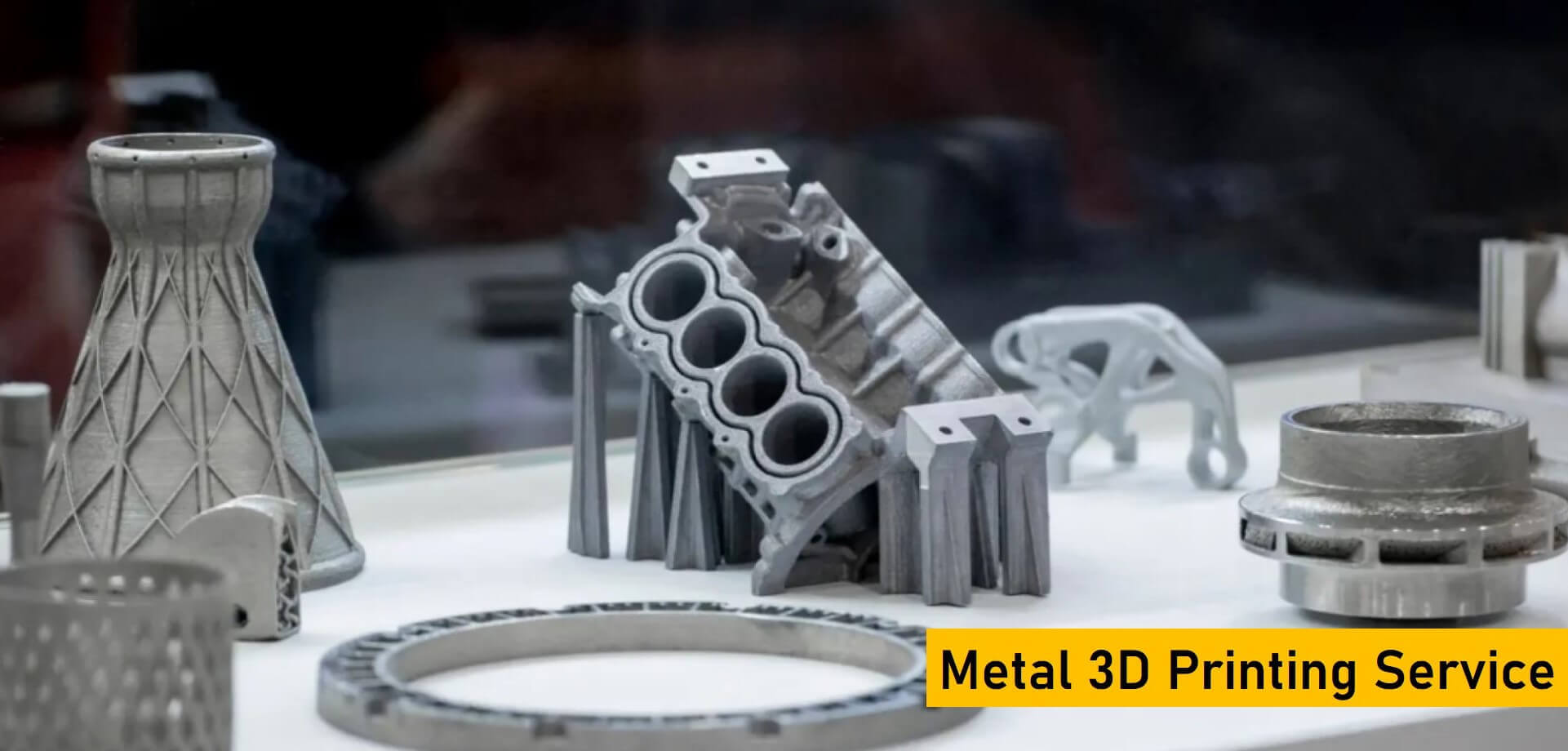

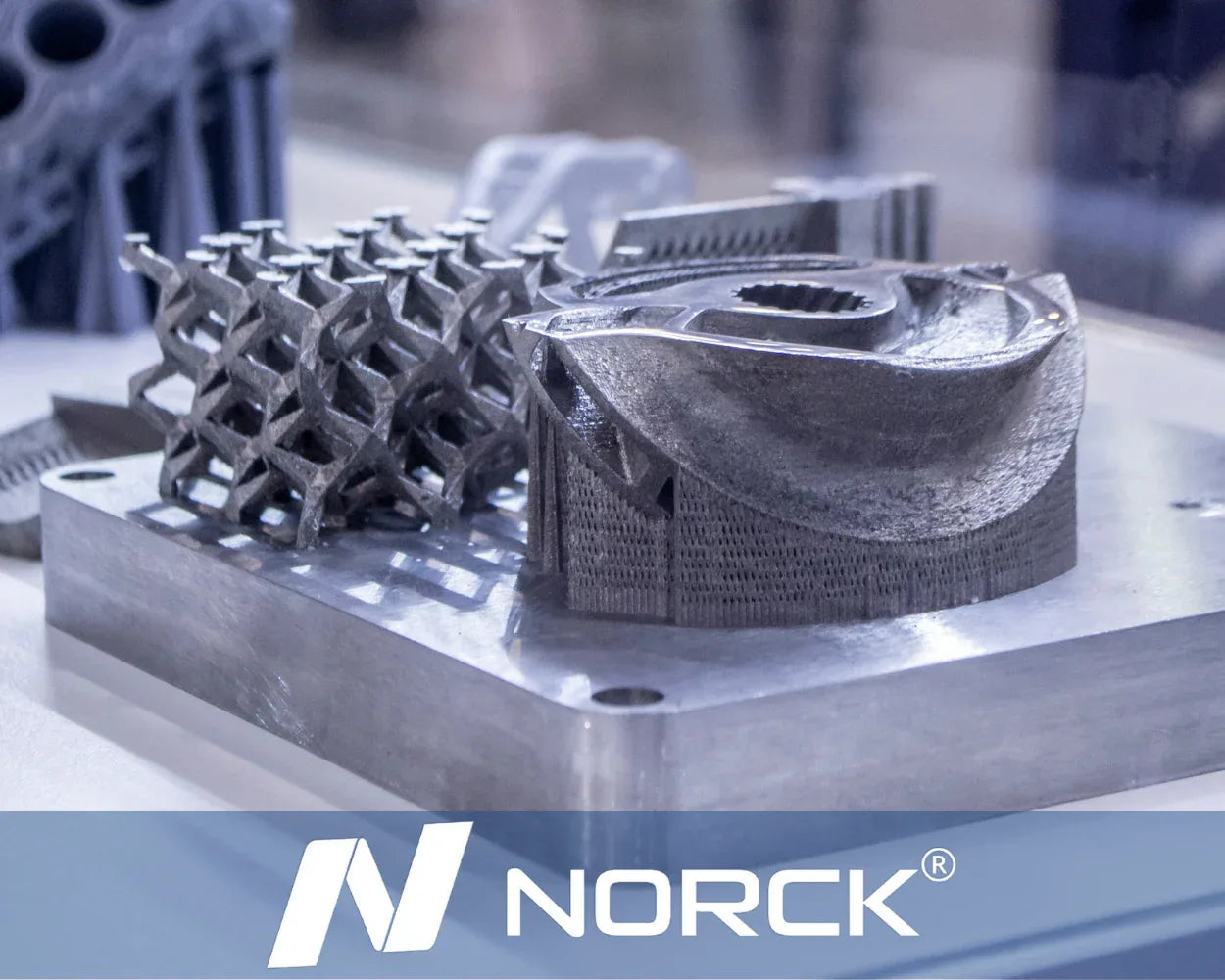

Industrial Metal 3D Printing Services Engineered for Production Reality

Honyo Prototype delivers precision industrial metal additive manufacturing solutions, transforming complex design concepts into functional, production-grade components. Our advanced Direct Metal Laser Sintering (DMLS) capabilities support demanding applications across aerospace, medical device, and industrial equipment sectors, utilizing certified materials including Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, and Stainless Steels 17-4PH and 316L. We prioritize dimensional accuracy, material integrity, and repeatability, ensuring parts meet stringent industry standards for performance-critical use. Our integrated workflow encompasses design validation, build optimization, precision post-processing, and comprehensive metrology, providing a seamless transition from prototype to low-volume production.

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your CAD file directly to our secure portal and receive a detailed, transparent project evaluation including manufacturability feedback and competitive pricing within minutes, not days. This eliminates traditional quoting delays, empowering engineering and procurement teams to make rapid, data-driven decisions. Partner with Honyo Prototype for metal AM services where engineering rigor meets operational speed, delivering components that perform under real-world conditions. Initiate your project evaluation today through our instant quoting platform.

Technical Capabilities

The requested technologies—SLA, SLS, MJF, and DMLS—are commonly used in advanced additive manufacturing. However, it is important to clarify that Stereolithography (SLA) and Multi Jet Fusion (MJF) are primarily polymer-based processes and are not typically used for metal 3D printing. Selective Laser Sintering (SLS) is also mainly employed for nylon and other thermoplastics, though metal variants exist in research or hybrid systems. Direct Metal Laser Sintering (DMLS) is the only fully established metal additive manufacturing process among the four.

Below is a technical specification table outlining the capabilities and material compatibility for each process, with accurate alignment to industry standards:

| Process | Technology Type | Primary Materials | Compatible Metals | Compatible Polymers | Layer Resolution Range | Build Volume (Typical Max) | Surface Finish (Ra) | Key Applications |

|---|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymerization | Photopolymer resins | Not applicable | ABS-like, Tough, Flexible, Castable resins | 25–100 μm | 1450 x 800 x 500 mm (large format) | 0.8–2.0 μm | Prototyping, molds, visual models |

| SLS (Selective Laser Sintering) | Powder Bed Fusion (Polymer) | Nylon (PA11, PA12), Glass-filled Nylon | Not standard | Nylon (PA11, PA12), TPU | 80–120 μm | 700 x 380 x 580 mm | 10–20 μm (as-printed) | Functional prototypes, end-use parts, complex geometries |

| MJF (Multi Jet Fusion) | Powder Bed Fusion (Polymer) | PA12, PA11, TPU | Not applicable | ABS-like (HP proprietary), Nylon (PA12), TPU | 80–100 μm | 380 x 280 x 380 mm | 5–15 μm (as-printed) | High-volume end-use parts, mechanical components |

| DMLS (Direct Metal Laser Sintering) | Powder Bed Fusion (Metal) | Metal alloys | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Tool Steel (Maraging), Titanium (Ti6Al4V) | Not applicable | 20–50 μm | 250 x 250 x 325 mm (typical) | 10–25 μm (as-printed), improved with post-processing | Aerospace, medical implants, tooling, high-stress components |

Notes:

SLA does not support metal printing; it is exclusively for photopolymer resins, including engineering-grade materials that simulate ABS properties.

SLS and MJF are polymer-centric technologies. While metal-infused powders or hybrid post-processing (e.g., infiltration) exist, they do not achieve full-density metal parts like DMLS.

DMLS is the preferred method for producing fully dense, high-strength metal components from aluminum, steel, and titanium alloys.

Materials such as ABS are not directly printable via SLS or MJF in standard forms but are emulated through nylon-based composites with similar mechanical behavior.

For metal 3D printing services, DMLS remains the industry-standard solution for functional, load-bearing metal components. SLS, MJF, and SLA serve critical roles in polymer additive manufacturing and are often used in parallel for non-metal prototypes, jigs, and fixtures.

From CAD to Part: The Process

Honyo Prototype Metal 3D Printing Service Workflow

Our end-to-end metal additive manufacturing process is engineered for precision, efficiency, and technical rigor. Below is a detailed explanation of each phase, reflecting our commitment to industrial-grade outcomes and seamless B2B integration.

CAD File Submission

Clients initiate the process by uploading native CAD files via our secure customer portal. We exclusively accept industry-standard formats including STEP AP203/214, IGES, and Parasolid (.x_t, .x_b). STL files are accepted only when accompanied by the original parametric CAD model to ensure geometric integrity. File validation checks for watertight geometry, minimum feature resolution (≥0.4mm), and adherence to build envelope constraints (max 500 x 500 x 500mm for SLM systems). Incomplete or non-compliant files trigger automated notifications with specific failure diagnostics before proceeding.

AI-Powered Quoting Engine

Upon file validation, our proprietary AI engine generates a preliminary quote within 90 minutes. This system analyzes 37 distinct parameters: bounding box volume, support structure density, layer thickness requirements, material utilization efficiency, and machine-specific build time algorithms. Quotes include material cost (based on real-time powder market rates for Inconel 718, Ti-6Al-4V, AlSi10Mg, etc.), post-processing labor estimates, and geometric complexity surcharges. Critical tolerances specified in the CAD model (e.g., ±0.1mm on critical datums) automatically adjust pricing tiers. Clients receive a downloadable PDF report detailing all cost variables.

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Metal Additive (DFM) review by our ASQ-certified manufacturing engineers. This phase combines automated simulation (using Materialise Magics and ANSYS Additive Prep) with human expertise to address:

Support structure optimization for thermal stress mitigation

Build orientation analysis to minimize residual stress (via finite element modeling)

Critical surface identification requiring post-machining

Powder evacuation channel validation for internal cavities

Heat treatment requirements based on material and geometry

Clients receive a formal DFM report with actionable recommendations, including risk assessments for features below 0.5mm thickness or overhangs exceeding 45°. Revisions are collaboratively managed via the portal with version-controlled CAD markups.

Production Execution

Approved designs enter our certified production environment operating under ISO 9001:2015 and NADCAP standards. Key production stages include:

Machine calibration: Laser power verification (±2W tolerance) and build plate leveling (±5μm flatness)

Build process: Layer-by-layer fabrication using 20-50μm layer thickness on EOS M 400-4 or SLM Solutions SLM®500 systems with inert argon atmosphere (O₂ < 100ppm)

In-situ monitoring: Coaxial melt pool sensors and thermal imaging capture 1,200+ data points per layer

Post-processing: Stress relief annealing, support removal via wire EDM, HIP (if specified), and precision machining per AS9100-compliant work instructions

Quality-Controlled Delivery

Final parts undergo stringent verification before shipment:

Dimensional inspection: CMM validation against original CAD (report includes GD&T analysis per ASME Y14.5)

Material certification: Full traceability from powder lot to finished part with test coupons meeting AMS 7000 standards

Surface finish validation: Ra measurements via profilometry (typical as-built Ra 8-12μm)

Non-destructive testing: X-ray CT scanning for internal defects (per ASTM E1000) when specified

All deliverables include a comprehensive quality package: first article inspection report (FAIR), material test report (MTR), and process parameter log. Parts ship in anti-static, humidity-controlled packaging with real-time GPS tracking. Typical lead time from DFM approval to delivery is 7-12 business days for standard builds.

Process Technology Matrix

| Parameter | SLM (Selective Laser Melting) | DMLS (Direct Metal Laser Sintering) |

|——————–|——————————-|————————————-|

| Primary Materials | Ti-6Al-4V, Inconel 718, 17-4PH | Stainless Steels (17-4PH, 316L), CoCr |

| Laser Source | Fiber laser (1kW) | Fiber laser (700W) |

| Layer Thickness | 20-50 μm | 30-50 μm |

| Typical Build Rate | 50-80 cm³/hr | 40-60 cm³/hr |

| Surface Roughness | Ra 8-12 μm (as-built) | Ra 10-15 μm (as-built) |

| Key Applications | Aerospace brackets, fluid manifolds | Medical implants, tooling inserts |

This structured workflow ensures technical transparency, minimizes iteration cycles, and delivers production-ready metal components meeting aerospace, medical, and industrial performance criteria. All process data remains accessible to clients through our digital thread platform for full lifecycle traceability.

Start Your Project

Looking for high-precision metal 3D printing services? Honyo Prototype delivers advanced metal additive manufacturing solutions with rapid turnaround and strict quality control. Our Shenzhen-based factory is equipped with state-of-the-art technology to support your prototyping and low-volume production needs.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.