Introduction: Navigating the Global Market for 3d printing service china

In the rapidly evolving landscape of global manufacturing, sourcing reliable 3D printing services in China presents a significant challenge for international B2B buyers. As businesses strive to innovate and meet market demands, the need for high-quality, cost-effective 3D printed parts becomes paramount. This guide delves into the complexities of navigating the Chinese 3D printing market, offering insights into various printing technologies, applications across diverse industries, and strategies for supplier vetting.

Understanding the nuances of 3D printing services—from Stereolithography (SLA) to Selective Laser Sintering (SLS)—is crucial for making informed purchasing decisions. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany, with actionable knowledge on pricing structures, lead times, and material options. By providing a comprehensive overview of the market, this resource empowers businesses to streamline their sourcing processes, ensuring they select the right partners to meet their specific needs.

In an era where efficiency and quality are non-negotiable, this guide serves as a vital tool for international buyers seeking to leverage the advanced capabilities of Chinese 3D printing services, ultimately enhancing their competitive edge in the global marketplace.

Understanding 3d printing service china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Stereolithography (SLA) | Uses UV light to cure liquid resin, high precision, smooth finish | Prototyping, Jewelry, Dental Models | Pros: High detail, smooth surface. Cons: Slower speed, limited material options. |

| Fused Deposition Modeling (FDM) | Melts thermoplastic filament, cost-effective, versatile | Functional Prototypes, Consumer Products | Pros: Affordable, widely available materials. Cons: Lower resolution than SLA. |

| Selective Laser Sintering (SLS) | Uses laser to fuse powdered materials, strong parts | Aerospace, Automotive, Industrial Parts | Pros: Durable parts, complex geometries possible. Cons: Higher cost, post-processing required. |

| Direct Metal Laser Sintering (DMLS) | Metal 3D printing, high strength, precision | Tooling, Aerospace Components, Medical Devices | Pros: High strength, intricate designs. Cons: Expensive setup, longer lead times. |

| Multi Jet Fusion (MJF) | Uses inkjet technology and heat, faster than SLS | Functional Prototypes, Low-Volume Production | Pros: Fast production, excellent detail. Cons: Limited material types compared to others. |

What are the Characteristics of Stereolithography (SLA) for B2B Buyers?

Stereolithography (SLA) is renowned for its ability to produce exceptionally detailed and smooth parts. This technology employs UV light to cure liquid resin layer by layer, making it ideal for applications requiring intricate designs, such as dental models and jewelry. While SLA parts exhibit high precision, the process is relatively slower and typically limited to a narrower range of materials compared to other methods. B2B buyers should consider SLA when high surface quality and fine details are paramount, especially in industries like healthcare and luxury goods.

How Does Fused Deposition Modeling (FDM) Benefit Businesses?

Fused Deposition Modeling (FDM) is a widely used 3D printing technology that extrudes melted thermoplastic filament to create parts layer by layer. It is particularly cost-effective and offers a broad selection of materials, making it suitable for producing functional prototypes and consumer products. However, while FDM is affordable and accessible, it generally provides lower resolution compared to SLA. Businesses looking for budget-friendly prototyping solutions or low-volume production runs will find FDM a valuable option.

Why Choose Selective Laser Sintering (SLS) for Strong Parts?

Selective Laser Sintering (SLS) employs a laser to fuse powdered materials, resulting in parts that are strong and durable. This method is particularly advantageous for industries such as aerospace and automotive, where components often require complex geometries and high strength. While SLS offers superior mechanical properties, it can be more costly and may require additional post-processing steps. B2B buyers should evaluate SLS for applications where durability and design complexity are critical.

What Advantages Does Direct Metal Laser Sintering (DMLS) Offer?

Direct Metal Laser Sintering (DMLS) is a cutting-edge technology for metal 3D printing, allowing for the creation of parts with intricate designs and high strength. DMLS is particularly beneficial for applications in tooling, aerospace components, and medical devices, where precision and material properties are essential. However, the setup costs can be high, and lead times may be longer than other methods. Businesses should consider DMLS when they require high-performance metal parts that conventional manufacturing cannot achieve.

How is Multi Jet Fusion (MJF) Transforming Production Efficiency?

Multi Jet Fusion (MJF) utilizes inkjet technology and heat to produce parts quickly and with excellent detail. This method is particularly efficient for functional prototypes and low-volume production, offering faster turnaround times than traditional methods like SLS. While MJF provides high-quality parts, it currently has a more limited range of material options. B2B buyers should consider MJF when speed and detail are critical, particularly in industries requiring rapid prototyping and iterative design processes.

Key Industrial Applications of 3d printing service china

| Industry/Sector | Specific Application of 3D Printing Service China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom engine components and lightweight parts | Reduces weight, improves fuel efficiency, and accelerates R&D | High precision requirements, compliance with aviation standards |

| Automotive | Prototyping and manufacturing of complex components | Shortens development time and allows for rapid iteration | Material selection for durability and performance |

| Consumer Electronics | Custom housings and prototypes for devices | Enhances product design flexibility and reduces time-to-market | Need for aesthetic finishes and functional designs |

| Healthcare | Medical implants and surgical tools | Customization for patient-specific needs and faster production | Compliance with medical regulations and biocompatibility |

| Architecture | Scale models and detailed prototypes | Facilitates client presentations and design iterations | High-quality finishes and accurate scaling |

How is 3D Printing Service in China Beneficial for the Aerospace Industry?

In the aerospace sector, 3D printing service in China is utilized for producing custom engine components and lightweight parts. By leveraging advanced materials and manufacturing techniques, businesses can significantly reduce the weight of their products, leading to improved fuel efficiency and performance. Additionally, rapid prototyping capabilities allow for quicker R&D cycles, enabling companies to innovate faster. International buyers must prioritize suppliers who meet stringent aviation standards and ensure high precision in their manufacturing processes.

What Role Does 3D Printing Play in the Automotive Sector?

The automotive industry benefits from 3D printing services in China through the prototyping and production of complex components. This technology accelerates the development process by allowing engineers to create and test prototypes swiftly, ultimately shortening time-to-market for new vehicles. Buyers in this sector should consider material selection carefully, ensuring that parts can withstand the rigors of automotive use while adhering to industry regulations.

How Can Consumer Electronics Companies Leverage 3D Printing Services?

For consumer electronics, 3D printing services in China are invaluable for creating custom housings and prototypes for devices. This flexibility in design allows companies to iterate quickly and adapt to changing market demands. The ability to produce aesthetically pleasing and functional designs in low volumes can also significantly enhance product offerings. When sourcing, businesses should focus on suppliers who can provide high-quality finishes that meet consumer expectations.

In What Ways Does 3D Printing Enhance Healthcare Solutions?

In the healthcare sector, 3D printing services are revolutionizing the production of medical implants and surgical tools. Customization enables the creation of patient-specific solutions, which can lead to better outcomes in surgical procedures. Furthermore, faster production times help meet urgent medical needs. Buyers should ensure that their suppliers comply with stringent medical regulations and that materials used are biocompatible, ensuring safety for patients.

How is 3D Printing Transforming Architectural Design?

Architects and builders are increasingly using 3D printing services in China for creating detailed scale models and prototypes. This technology allows for precise representations of designs, facilitating better client presentations and design iterations. High-quality finishes and accurate scaling are essential for these applications, making it crucial for international buyers to select suppliers that can deliver on these requirements to effectively communicate their vision.

3 Common User Pain Points for ‘3d printing service china’ & Their Solutions

Scenario 1: Delays in Production Timelines

The Problem: One of the most pressing challenges faced by international B2B buyers when sourcing 3D printing services from China is the potential for delays in production timelines. Many companies rely on timely delivery for their product launches, and any hold-up can lead to missed market opportunities. Buyers may experience frustration when initial timelines provided by the service providers do not align with their urgent needs, especially when prototypes or parts are critical for upcoming projects or presentations.

The Solution: To mitigate this risk, buyers should establish clear communication regarding timelines from the outset. When selecting a 3D printing service in China, request a detailed project timeline that includes production, quality checks, and shipping. Utilize services that offer real-time tracking and updates on your order. Additionally, consider partnering with companies that provide DFM (Design for Manufacturability) analysis to identify potential bottlenecks before production begins. This proactive approach can help ensure that any issues are addressed early, reducing the likelihood of delays.

Scenario 2: Inconsistent Quality Control

The Problem: Quality assurance is a significant concern for B2B buyers, especially when outsourcing manufacturing to another country. Variations in production quality can lead to discrepancies in the final product, affecting the functionality and appearance of components. Buyers may worry about receiving parts that do not meet their specifications or industry standards, resulting in wasted resources and potential reputational damage.

The Solution: To address quality concerns, buyers should prioritize working with ISO-certified 3D printing services that have a proven track record of quality assurance. Before placing a large order, consider requesting a sample or prototype to evaluate the quality firsthand. Additionally, engage in thorough discussions about the materials and processes used in production, ensuring they align with your requirements. Establishing a strong partnership with the provider, including regular feedback loops and quality audits, can further enhance the consistency of the output. Utilizing companies that offer buyer protection guarantees can also provide peace of mind, ensuring recourse if the delivered parts do not meet the agreed-upon standards.

Scenario 3: Complex Design Requirements

The Problem: B2B buyers often have intricate design specifications that require advanced 3D printing capabilities. However, many buyers may find that not all service providers can accommodate complex geometries or specific materials required for their projects. This limitation can hinder innovation and result in suboptimal product performance if the buyer has to compromise on design to fit the capabilities of the 3D printing service.

The Solution: To overcome this challenge, buyers should conduct thorough research on potential 3D printing service providers before making a commitment. Look for companies that specialize in the materials and processes that align with your project needs, such as SLA, SLS, or metal printing. It’s crucial to engage in preliminary discussions about your design requirements and request a DFM analysis from the service provider to ensure manufacturability. This analysis can highlight any design issues early on, allowing for adjustments before production begins. Additionally, collaborating with providers that offer comprehensive support throughout the design and production phases can facilitate the successful realization of complex projects. This strategic partnership will enable buyers to leverage the full capabilities of advanced 3D printing technologies while maintaining design integrity.

Strategic Material Selection Guide for 3d printing service china

What Are the Key Properties of Common 3D Printing Materials in China?

When selecting materials for 3D printing services in China, international B2B buyers must consider various factors, including the properties of the materials, their suitability for specific applications, and compliance with industry standards. Here, we analyze four commonly used materials: PLA, ABS, Nylon, and Metal (specifically stainless steel).

How Does PLA Perform in 3D Printing Applications?

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources like corn starch. It has a relatively low melting temperature, making it easy to print. Key properties include good tensile strength and a low warping tendency. However, it has lower temperature resistance compared to other materials, making it unsuitable for high-heat applications.

Pros: PLA is cost-effective and environmentally friendly. It is ideal for prototyping and applications where aesthetic quality is paramount.

Cons: Its lower heat resistance limits its use in functional parts exposed to elevated temperatures. Additionally, it may not be as durable as other materials.

Impact on Application: PLA is compatible with various media, but its lower heat tolerance restricts its use in automotive or aerospace components.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer PLA due to its eco-friendly nature, aligning with sustainability goals. Compliance with ASTM standards can enhance marketability.

What Are the Advantages and Disadvantages of Using ABS?

Acrylonitrile Butadiene Styrene (ABS) is another popular thermoplastic known for its strength and impact resistance. It can withstand higher temperatures than PLA, making it suitable for functional prototypes and end-use parts.

Pros: ABS is durable and can be easily machined or post-processed. It is widely used in automotive and consumer goods applications.

Cons: The material can emit fumes during printing, necessitating proper ventilation. ABS is also more prone to warping than PLA, which can complicate the printing process.

Impact on Application: ABS is ideal for parts requiring toughness and heat resistance, such as housings for electronics.

Considerations for International Buyers: Buyers from South America and Africa should ensure compliance with local safety standards, as ABS may have specific regulations regarding emissions during processing.

Why Is Nylon a Preferred Choice for Functional Parts?

Nylon, particularly Nylon 12, is favored for its excellent mechanical properties, including high tensile strength and flexibility. It is resistant to abrasion and chemicals, making it suitable for demanding applications.

Pros: Nylon offers superior durability and is ideal for functional parts in automotive, aerospace, and consumer applications.

Cons: It can be more expensive than PLA and ABS, and requires more complex printing conditions, including a heated chamber to minimize warping.

Impact on Application: Nylon’s chemical resistance makes it suitable for parts exposed to oils and solvents, enhancing its versatility in various industries.

Considerations for International Buyers: Compliance with DIN and JIS standards is crucial for buyers in Europe and Asia, as these standards govern material specifications and performance.

What Are the Benefits of Metal 3D Printing, Specifically Stainless Steel?

Metal 3D printing, particularly using stainless steel, is gaining traction for its strength and durability. Stainless steel parts can withstand high temperatures and corrosive environments, making them ideal for industrial applications.

Pros: Metal parts offer superior strength and can be used in high-stress applications, including aerospace and medical devices.

Cons: The cost of metal printing is significantly higher, and the process is more complex, requiring specialized equipment and expertise.

Impact on Application: Stainless steel is suitable for components that must endure harsh conditions, such as engine parts or surgical instruments.

Considerations for International Buyers: Compliance with international quality standards is essential, especially for buyers in the Middle East and Europe, where stringent regulations govern metal parts in critical applications.

Summary Table of Material Selection for 3D Printing Services in China

| Material | Typical Use Case for 3D Printing Service China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, consumer goods | Environmentally friendly, easy to print | Low heat resistance, less durable | Low |

| ABS | Functional prototypes, automotive parts | Durable, impact-resistant | Emits fumes, prone to warping | Medium |

| Nylon | Functional parts, industrial applications | High durability, chemical resistance | Higher cost, complex printing | High |

| Stainless Steel | Aerospace, medical devices | Superior strength, high-temperature tolerance | High cost, complex process | High |

This guide provides a comprehensive overview of material selection for 3D printing services in China, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printing service china

What Are the Key Manufacturing Processes in 3D Printing Services in China?

Manufacturing processes for 3D printing services in China involve several critical stages, each designed to ensure the efficient and high-quality production of parts. Understanding these stages can help B2B buyers make informed decisions when selecting a supplier.

What Are the Main Stages of the 3D Printing Manufacturing Process?

-

Material Preparation

The first step in the manufacturing process involves selecting and preparing the raw materials. Common materials used in 3D printing include plastics (like ABS and PLA), metals (such as aluminum and stainless steel), and resins. Suppliers often conduct a Material Safety Data Sheet (MSDS) review to ensure compliance with safety regulations and to understand the material properties, which can affect the final product’s performance. -

Forming

The forming stage is where the actual 3D printing occurs. Depending on the chosen technology—such as Stereolithography (SLA), Selective Laser Sintering (SLS), or Fused Deposition Modeling (FDM)—the manufacturing process will vary. Each method has its unique advantages:

– SLA uses a laser to cure liquid resin into solid parts, ideal for high-detail prototypes.

– SLS employs a laser to fuse powdered material, suitable for functional end-use parts.

– FDM extrudes thermoplastic filaments, often used for rapid prototyping. -

Assembly

In some cases, especially for complex designs, multiple components may need to be assembled after printing. This stage includes post-processing techniques such as machining, threading, or adding electronic components. B2B buyers should inquire about the supplier’s capabilities in assembly to ensure that they can meet specific project requirements. -

Finishing

The finishing stage is crucial for enhancing the aesthetic and functional properties of the printed parts. Common finishing techniques include sanding, painting, coating, and polishing. This stage not only improves the appearance but can also affect durability and performance. For B2B buyers, understanding the finishing options available can significantly impact the product’s marketability.

How Is Quality Assurance Integrated into 3D Printing Services?

Quality assurance (QA) is a vital aspect of the 3D printing process, ensuring that the final products meet international standards and customer specifications.

What International Standards Should B2B Buyers Consider?

-

ISO 9001 Certification

Many reputable 3D printing companies in China are ISO 9001 certified, indicating that they adhere to international quality management standards. This certification assures buyers that the supplier has established a quality management system that focuses on continuous improvement and customer satisfaction. -

Industry-Specific Certifications

Depending on the industry, additional certifications may be relevant. For example, the CE marking is essential for products sold in the European Economic Area, while API certification is crucial for companies working in the oil and gas sector. B2B buyers should verify that their suppliers possess the necessary certifications for their specific industry.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials before they enter the production process. Suppliers typically conduct material tests and verification checks to ensure compliance with specifications. -

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC ensures that each stage meets predefined standards. This may involve real-time monitoring of production parameters and regular inspections to identify defects early. -

Final Quality Control (FQC)

Upon completion of the manufacturing process, FQC involves thorough testing of the final products against quality standards. Common testing methods include dimensional checks, mechanical property tests, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

-

Supplier Audits

Conducting audits is an effective way for buyers to assess a supplier’s quality management practices. During an audit, buyers can evaluate the supplier’s facilities, equipment, and processes, ensuring they align with industry standards. -

Quality Reports and Documentation

Requesting detailed quality reports can provide insights into a supplier’s quality control practices. These reports should include information on testing methods, results, and any corrective actions taken to address issues. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. This is particularly useful for international buyers who may not have the capacity to conduct on-site inspections.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances when dealing with suppliers in China.

-

Cultural Considerations

Understanding cultural differences can significantly impact communication and expectations regarding quality. Building a strong relationship with suppliers can enhance collaboration and lead to better quality outcomes. -

Compliance with Export Regulations

Buyers should ensure that products meet the regulatory requirements of their home countries. This may involve additional certifications or testing, which suppliers should be prepared to facilitate. -

Understanding Lead Times and Logistics

Lead times can vary significantly depending on the complexity of the parts and the supplier’s capacity. Buyers should maintain clear communication regarding timelines and logistics to avoid delays.

Conclusion

The manufacturing processes and quality assurance practices in China’s 3D printing services are designed to meet the diverse needs of B2B buyers across various industries. By understanding these processes and actively engaging in quality verification, international buyers can ensure that they receive high-quality products that meet their specifications and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printing service china’

Introduction

Navigating the complexities of sourcing 3D printing services from China can be daunting, especially for international B2B buyers. This guide provides a practical checklist to streamline your procurement process, ensuring you find a reliable supplier that meets your technical and financial requirements. By following these steps, you can enhance your product development efficiency while minimizing risks.

Step 1: Define Your Technical Specifications

Clearly outlining your project requirements is the first step to successful sourcing. Detail your desired materials, dimensions, tolerances, and production timelines. This information will help suppliers provide accurate quotes and assess their capability to meet your needs.

- Material Selection: Consider the type of materials required (e.g., plastics, metals, resins) and ensure the supplier has experience with them.

- Tolerance Levels: Specify the precision needed for your parts, as different 3D printing methods offer varying levels of accuracy.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies with a proven track record in your industry, and prioritize those that specialize in the types of materials and technologies you need.

- Review Portfolios: Examine case studies or sample works to gauge the quality of their previous projects.

- Check Reviews and Ratings: Utilize platforms like Trustpilot or industry-specific forums to read customer feedback.

Step 3: Verify Supplier Certifications

Ensure your potential suppliers adhere to recognized quality standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management.

- Quality Assurance Practices: Ask about their quality control processes and how they ensure the consistency of their output.

- Compliance with Regulations: Ensure they comply with any relevant industry regulations, especially if your products require specific certifications.

Step 4: Request Detailed Quotes

After narrowing down your list, request detailed quotes from each supplier. A comprehensive quote should include pricing, lead times, and any additional costs such as shipping or tooling.

- Transparent Pricing: Ensure the quote breaks down costs by material, labor, and any other charges to avoid hidden fees later.

- Lead Time Expectations: Discuss production timelines and confirm if they can meet your deadlines.

Step 5: Evaluate Communication and Support

Effective communication is crucial for successful collaboration. Assess how responsive and helpful the supplier is during the inquiry phase.

- Technical Support Availability: Determine if they offer ongoing support for design optimization or troubleshooting.

- Language Proficiency: Ensure there are no language barriers that could lead to misunderstandings.

Step 6: Conduct a Trial Order

Before committing to larger production runs, place a small trial order to evaluate the supplier’s capabilities and service quality.

- Quality Assessment: Inspect the delivered parts for accuracy, quality, and adherence to specifications.

- Delivery Timeliness: Note whether the supplier meets the promised delivery schedule.

Step 7: Establish a Long-term Partnership

Once you find a reliable supplier, consider building a long-term relationship. This can lead to better pricing, priority service, and a deeper understanding of your needs.

- Regular Feedback: Maintain open lines of communication for continuous improvement.

- Volume Discounts: Discuss potential discounts for larger orders or repeat business.

By following this checklist, you can enhance your sourcing strategy for 3D printing services in China, ensuring that you find a partner that meets your business needs effectively.

Comprehensive Cost and Pricing Analysis for 3d printing service china Sourcing

What are the Key Cost Components in 3D Printing Service Sourcing from China?

When considering 3D printing services in China, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly influences the cost. Common options like plastics, metals, and resins vary in price based on quality and availability. For example, high-performance materials such as Nylon PA12 or metal powders for SLM (Selective Laser Melting) can be more expensive than standard PLA or ABS plastics.

-

Labor: Skilled labor is essential for operating advanced 3D printing equipment and conducting post-processing. While labor costs in China are generally lower than in Europe or North America, the expertise required for complex projects can drive prices up.

-

Manufacturing Overhead: This includes costs related to equipment maintenance, utilities, and facility management. Manufacturers with advanced capabilities and certifications (like ISO 9001) may have higher overhead costs, but they often offer better quality assurance.

-

Tooling: Initial setup costs for custom projects may involve tooling expenses, especially if molds or specific fixtures are required. This is particularly relevant for low-volume production runs.

-

Quality Control (QC): Ensuring product quality through stringent QC processes is a non-negotiable aspect of 3D printing. This adds to the overall cost but is vital for meeting international quality standards.

-

Logistics: Shipping costs vary based on destination, weight, and volume of the products. Buyers should consider the total landed cost, which includes shipping, customs duties, and taxes.

-

Margin: Manufacturers in China typically have flexible pricing strategies, allowing for varying margins depending on order size and client relationships.

What Influences Pricing for 3D Printing Services in China?

Several factors affect the pricing of 3D printing services, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Higher order quantities often lead to lower per-unit costs. Suppliers may provide discounts for bulk orders, making it essential to assess your needs carefully.

-

Specifications and Customization: Customized designs or complex geometries may incur additional costs. Detailed specifications can also lead to higher pricing due to the additional design and engineering work involved.

-

Materials: The choice of material not only impacts the cost but also the final product’s performance. Buyers should evaluate material properties against project requirements to achieve a balance between cost and functionality.

-

Quality and Certifications: Products that meet international standards or require specific certifications will typically cost more. This is particularly important for industries like aerospace and healthcare, where compliance is critical.

-

Supplier Factors: The reputation, experience, and technological capabilities of the supplier can influence pricing. Established manufacturers may charge a premium but often guarantee better quality and reliability.

-

Incoterms: Understanding the terms of shipping and delivery is vital. Different Incoterms (e.g., FOB, CIF) will affect the total cost of ownership and risk management during transport.

How Can International Buyers Optimize Costs When Sourcing 3D Printing Services from China?

-

Negotiation Strategies: Engage in thorough negotiations with suppliers. Discuss pricing, payment terms, and potential discounts for bulk orders. Building a relationship can lead to better pricing in the long run.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial quotes. Consider long-term costs, including maintenance, logistics, and potential rework or adjustments.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structures of various suppliers. Some may have hidden costs or additional charges for services that others include in their base price.

-

Leverage Technology: Use online platforms to obtain instant quotes and compare prices across multiple suppliers. This can help identify competitive pricing and service offerings.

-

Request Prototypes: Before committing to large orders, request prototypes to assess quality. This can save costs on subpar products and ensure that the final outputs meet your specifications.

By understanding these components and factors, international B2B buyers can make informed decisions when sourcing 3D printing services from China, leading to cost-effective and high-quality solutions tailored to their needs.

Alternatives Analysis: Comparing 3d printing service china With Other Solutions

Understanding Alternatives in 3D Printing Solutions

When considering 3D printing services, particularly from China, it’s essential for B2B buyers to evaluate various alternatives that can meet their production needs. Different technologies and methods can offer unique advantages and may suit specific applications better than others. Below, we compare 3D printing services in China against traditional manufacturing methods such as CNC machining and injection molding, providing insights into their performance, cost, implementation, maintenance, and best use cases.

| Comparison Aspect | 3D Printing Service China | CNC Machining | Injection Molding |

|---|---|---|---|

| Performance | High precision, complex geometries possible | Excellent precision, but limited to simpler designs | High volume production with consistent quality |

| Cost | Affordable for low-volume and prototypes | Higher setup costs, cost-effective for large runs | High initial costs, economical for mass production |

| Ease of Implementation | Easy to upload files and get instant quotes | Requires skilled operators and setup | Complex tooling and setup required |

| Maintenance | Low maintenance; reliant on service provider | Moderate maintenance for machinery | High maintenance for molds and machines |

| Best Use Case | Prototyping, custom parts, low-volume runs | One-off parts, detailed designs | Mass production of identical parts |

Pros and Cons of CNC Machining as an Alternative

CNC (Computer Numerical Control) machining is a subtractive manufacturing method that excels in producing high-precision components. Its primary advantage lies in its ability to create parts from a wide variety of materials, including metals and plastics, with tolerances as tight as 0.05mm. This makes CNC machining an excellent choice for industries requiring exact specifications, such as aerospace and automotive.

However, CNC machining can be cost-prohibitive for small production runs due to high setup costs associated with tooling and programming. Additionally, the process can be time-consuming, especially for more complex designs that require multiple setups. As such, while CNC is ideal for precision work, it may not be the best option for rapid prototyping or low-volume production.

Evaluating Injection Molding for Mass Production Needs

Injection molding is a manufacturing process that involves injecting molten material into a mold to produce parts in high volumes. This method is exceptionally efficient for large-scale production, offering low per-unit costs once the initial mold is created. It is particularly well-suited for producing identical parts, making it a go-to for consumer goods and automotive components.

The main drawback of injection molding is its high upfront costs and longer lead times due to the mold creation process. This can be a barrier for startups or companies looking to test new products in the market. Furthermore, design changes can be costly and time-consuming, as they often require new molds. Therefore, while injection molding is advantageous for mass production, it lacks flexibility compared to 3D printing services.

Conclusion: How to Choose the Right Manufacturing Solution

Choosing the right manufacturing solution involves understanding your specific needs and constraints. If your project requires rapid prototyping or customization, 3D printing services from China can provide an efficient and cost-effective solution. Conversely, if you are looking at large-scale production with high precision, CNC machining or injection molding may be more suitable, albeit with higher initial costs and longer lead times. By carefully assessing your production requirements, budget, and timeline, you can select the most appropriate manufacturing method that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for 3d printing service china

What Are the Key Technical Properties of 3D Printing Services in China?

Understanding the essential technical specifications of 3D printing services is crucial for international B2B buyers to make informed decisions. Here are some critical properties that you should consider:

1. Material Grade

The material used in 3D printing significantly affects the quality, durability, and functionality of the final product. Common materials include plastics (e.g., ABS, PLA, Nylon), metals (e.g., Aluminum, Stainless Steel), and specialized resins. Different materials have unique properties such as tensile strength, flexibility, and thermal resistance. Selecting the right material for your application is vital to ensure the product meets industry standards and customer expectations.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In 3D printing, tolerances can range from ±0.1mm to ±0.5mm depending on the technology used (e.g., SLA, SLS, FDM). High-precision tolerances are crucial for parts that fit into assemblies or require precise measurements, such as in the automotive or aerospace industries. Understanding the tolerance capabilities of your 3D printing service provider will help ensure the parts function as intended.

3. Build Volume

Build volume is the maximum size of the object that can be printed in a single run. This is especially important for large-scale projects, as exceeding the build volume may require multiple prints or assembly. Knowing the build volume capabilities of the service provider enables you to plan your projects effectively and avoid unexpected costs.

4. Lead Time

Lead time is the duration from when an order is placed to when the final product is delivered. In the fast-paced B2B environment, quick turnaround times can be a competitive advantage. Different printing technologies and service providers offer varying lead times, typically ranging from a few days to a few weeks. Understanding lead times helps in project planning and meeting deadlines.

5. Surface Finish

Surface finish refers to the texture and smoothness of the printed part’s surface. Different printing methods yield different finishes, which can range from rough to very smooth. Surface finish can affect both the aesthetics and functionality of a product, especially in consumer-facing applications. Knowing the available finishing options allows businesses to select a provider that can meet their specific quality requirements.

What Are Common Trade Terms Used in the 3D Printing Industry?

Familiarizing yourself with industry terminology is essential for effective communication and negotiation with 3D printing service providers. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of 3D printing, businesses may partner with OEMs for custom parts that fit into their larger product lines. Understanding OEM relationships can streamline sourcing and production processes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is critical for budgeting and inventory management. Knowing the MOQ helps businesses plan their orders and avoid unnecessary costs associated with smaller, less economical orders.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. It is an essential tool for buyers to compare offerings from different manufacturers and negotiate better deals. A well-structured RFQ can lead to more favorable pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for managing international logistics and ensuring compliance.

5. DFM (Design for Manufacturability)

DFM is a design approach that focuses on the ease of manufacturing a product. By considering manufacturing processes during the design phase, businesses can reduce costs and improve product quality. Engaging in DFM discussions with your 3D printing provider can lead to better outcomes and fewer production issues.

By familiarizing yourself with these technical properties and industry terms, you can navigate the complexities of 3D printing services in China more effectively, ensuring that your business makes informed decisions that lead to successful outcomes.

Navigating Market Dynamics and Sourcing Trends in the 3d printing service china Sector

What are the Key Market Trends Influencing the 3D Printing Service Sector in China?

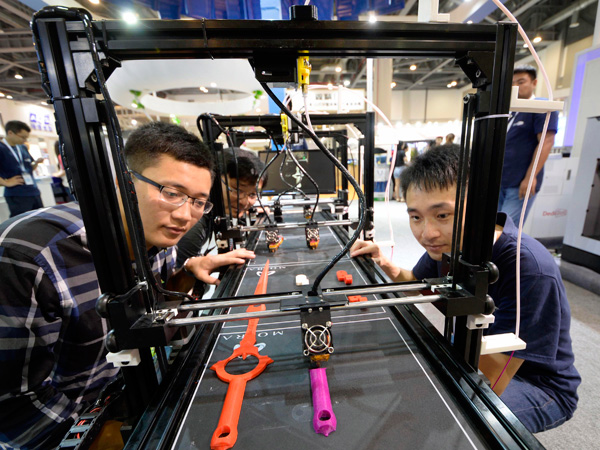

The 3D printing service sector in China is experiencing a significant transformation driven by global demand for rapid prototyping and customized manufacturing solutions. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, seek innovative ways to streamline production, they are increasingly turning to Chinese service providers. The key trends shaping this market include the rise of on-demand manufacturing, advancements in materials technology, and the integration of AI and machine learning to enhance design and production efficiency.

Additionally, the push for shorter lead times and cost-effective solutions is compelling companies to adopt 3D printing technologies that can produce high-quality parts quickly and at scale. For example, firms like Unionfab and JLC3DP are leveraging their extensive capabilities in various printing technologies (such as SLA, SLS, and MJF) to cater to diverse industry needs, from automotive to consumer electronics. This diversification allows international buyers to source tailored solutions that meet their specific requirements while reducing the time-to-market for new products.

Moreover, the increasing emphasis on digital manufacturing solutions is encouraging companies to adopt cloud-based platforms that facilitate real-time collaboration and immediate feedback on design iterations. This trend not only enhances the efficiency of the supply chain but also empowers international buyers to engage more actively in the product development process.

How is Sustainability Shaping Ethical Sourcing in the 3D Printing Industry?

As global awareness of environmental issues rises, sustainability has become a pivotal consideration for B2B buyers in the 3D printing sector. The environmental impact of manufacturing processes is under scrutiny, and companies are seeking partners who prioritize ethical sourcing and sustainable practices. This shift is particularly relevant for international buyers from regions like Europe, where regulatory frameworks around sustainability are becoming increasingly stringent.

Chinese 3D printing service providers are responding to this demand by adopting eco-friendly materials and processes. Many are now offering “green” certifications and utilizing biodegradable or recyclable materials in their production, which can significantly reduce the carbon footprint associated with manufacturing. For instance, some companies are investing in technologies that minimize waste during the printing process, thereby promoting a circular economy.

Furthermore, buyers are encouraged to engage suppliers that can provide transparency in their supply chains. This includes understanding the sourcing of raw materials, energy consumption, and waste management practices. By prioritizing suppliers with strong sustainability credentials, international buyers can not only meet their own corporate social responsibility goals but also enhance their brand reputation in increasingly eco-conscious markets.

How Has the 3D Printing Service Sector in China Evolved?

The evolution of the 3D printing service sector in China is marked by rapid technological advancements and a growing recognition of the technology’s potential across various industries. Initially, 3D printing was primarily utilized for prototyping, but it has now expanded into full-scale production, allowing companies to manufacture complex parts with remarkable precision.

Over the years, the Chinese government has supported the development of advanced manufacturing technologies, positioning the country as a global leader in 3D printing. This shift has been accompanied by a significant increase in the number of service providers, each offering specialized capabilities tailored to the needs of international buyers. Today, the sector is characterized by a diverse range of materials, from plastics to metals, and sophisticated printing technologies, enabling businesses to achieve faster turnaround times and cost savings.

The ongoing integration of digital technologies into the manufacturing process further exemplifies this evolution, as companies leverage data analytics and automation to optimize production efficiency and enhance customer engagement. As the landscape continues to change, international B2B buyers can expect an increasingly dynamic and responsive market, ripe with opportunities for innovation and collaboration.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printing service china

-

How do I evaluate the quality of a 3D printing service in China?

To assess the quality of a 3D printing service, start by reviewing their certifications, such as ISO 9001, which indicates adherence to quality management standards. Request samples of previous work to evaluate craftsmanship and material quality. Additionally, check customer reviews and case studies to gauge reliability and performance. Engaging in direct communication with their technical team can also provide insights into their expertise and ability to meet your specific requirements. -

What materials are commonly used in 3D printing services in China?

Chinese 3D printing services typically offer a diverse range of materials, including plastics like ABS and Nylon, metals such as Aluminum and Stainless Steel, and advanced materials like resin and composite filaments. The choice of material should align with your project’s specific needs, such as strength, flexibility, or heat resistance. Always consult the service provider about the suitability of different materials for your intended application, as well as their availability and pricing. -

What is the typical lead time for 3D printing services in China?

Lead times can vary based on the complexity of your project and the service provider’s capabilities. Generally, rapid prototyping services can deliver parts within 2 to 5 business days. However, for larger production runs or more complex designs, lead times may extend to several weeks. Always confirm the estimated delivery time before placing your order to ensure it aligns with your project timeline. -

What are the minimum order quantities (MOQs) for 3D printing services?

MOQs can vary significantly between different providers and depend on the type of service and material used. Many 3D printing services in China cater to both low-volume and high-volume orders, with some offering no minimums for prototyping services. However, for production runs, it’s common to see MOQs ranging from a few pieces to hundreds. Always clarify MOQs during the inquiry process to avoid unexpected costs. -

How can I ensure my design is manufacturable?

To ensure your design is manufacturable, consider requesting a Design for Manufacturability (DFM) analysis from your 3D printing service. This process evaluates your design against production capabilities and highlights any potential issues. Additionally, providing clear specifications, dimensions, and tolerances in your CAD files can help the service provider understand your requirements better. Engaging in early communication can lead to valuable feedback and adjustments to enhance manufacturability. -

What payment terms should I expect when ordering 3D printing services from China?

Payment terms can vary among 3D printing providers, but many require a deposit (often 30-50%) upfront with the balance due upon completion or prior to shipping. Some may offer flexible payment options, including credit cards, PayPal, or bank transfers. It’s essential to clarify the terms before finalizing your order, including any potential additional fees for international transactions or currency conversion. -

What logistics options are available for shipping 3D printed parts internationally?

Most 3D printing services in China offer a variety of shipping options, including express services like DHL, FedEx, and UPS, as well as standard shipping methods. The choice of logistics will depend on your urgency and budget. Be sure to discuss shipping costs, estimated delivery times, and tracking options with the service provider. Additionally, consider customs duties and import regulations for your country to avoid unexpected delays. -

How do I handle quality assurance (QA) for my 3D printed parts?

Establishing a robust QA process is crucial when sourcing 3D printed parts. Start by discussing quality standards with your supplier, ensuring they adhere to industry benchmarks. Request detailed reports on material properties and production processes. Conduct random inspections of the parts upon delivery and consider implementing a post-production testing phase if the parts are critical to your application. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 3D Printing Service China Manufacturers & Suppliers List

1. Unionfab – 3D Printing & CNC Machining Services

Domain: unionfab.com

Registered: 2019 (6 years)

Introduction: Unionfab offers a wide range of 3D printing and CNC machining services, including: 3D Printing Technologies: Stereo Lithography Apparatus (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), Selective Laser Melting (SLM), Multi Jet Fusion (MJF), PolyJet, Selective Laser Sintering (SLS), Large Scale Printing, and Metal 3D Printing. CNC Machining Services: CNC Turning, CNC Milling…

2. JLC 3DP – Custom 3D Printing Services

Domain: jlc3dp.com

Registered: 2021 (4 years)

Introduction: Online 3D Printing Service offering custom 3D printed parts using various technologies including Stereolithography (SLA), Multi Jet Fusion (MJF), Selective Laser Melting (SLM), Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and White Jet Process (WJP). Materials available include Resin, Nylon (MJF), Metal (SLM), Plastic, and Nylon (SLS). Tolerances down to 0.2mm for 3D printing …

3. in3Dtec – 3D Printing Solutions

Domain: in3dtec.com

Registered: 2017 (8 years)

Introduction: 3D Printing Service Overview:

– Types of 3D Printing Technologies: Stereolithography (SLA), Fused Deposition Modeling (FDM), Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF).

– Speed: SLA and FDM as fast as 1 day; DMLS, SLS, and MJF as fast as 3 days.

– Material Options: 10+ materials for SLA and FDM; 5+ materials for DMLS, SLS, and MJF.

– Color Options…

4. 3D.Directory – Leading 3D Printing Companies in China

Domain: 3d.directory

Registered: 2020 (5 years)

Introduction: This company, 3D.Directory – Leading 3D Printing Companies in China, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. China 3D Printing – Metal & MJF Solutions

Domain: china-3dprinting.com

Registered: 2021 (4 years)

Introduction: {“Metal 3D Printing”:{“Lead Time”:”5 Days”,”Materials”:[“AISi10Mg”,”316L”,”Ti6Al4V”,”IN718″,”IN625″,”Copper”,”1.2709″,”CX”],”Technology”:”Direct Metal Laser Sintering / Selective Laser Melting”},”MJF 3D Printing”:{“Lead Time”:”3 Days”,”Materials”:[“PA11″,”PA12″,”PA12 GB”],”Technology”:”HP Multi Jet Fusion”},”SLS 3D Printing”:{“Lead Time”:”3 Days”,”Materials”:[“PA2200″,”PA3200″,”PA11″,”PA12+GF”,”TP…

6. Beamler – Custom 3D Printing Services

Domain: beamler.com

Registered: 2016 (9 years)

Introduction: Professional 3D printing service in China offering custom parts from prototypes to end-parts. Features over 400 materials and a global manufacturing network. Key materials include:

– Stainless Steel: Tensile Strength: 50 MPa, Hardness: 230±20 HV1, Elasticity Modulus: 1250 MPa.

– Nylon: Hardness: Shore A80, Tensile Strength: 48 MPa, Elasticity Modulus: 1800 MPa.

– Silicone: Elongation at Break: 45…

7. ProtoFab – SLA 3D Printers

Domain: 3dprotofab.com

Registered: 2017 (8 years)

Introduction: ProtoFab offers a range of industrial 3D printers including SLA, SLM, and SLS technologies. Key products include:

– SLA 3D Printers: ProtoFab SLA100 DLC, SLA200 DLC, SLA300 DLC, SLA350S DLC, SLA450 DLC, SLA600A DLC, SLA800 DLC, SLA1100 DLC, SLA600B DLC, SLA600D DLC, SLA600E DLC, SLA1600 DLC, SLA2000 DLC, SLA2400 DLC, SLA600EX DLC, SLA800EX DLC, SLA600F DLC, SLA800F DLC.

– SLM 3D Printers: ProtoFa…

Strategic Sourcing Conclusion and Outlook for 3d printing service china

How Can International Buyers Leverage China’s 3D Printing Services for Competitive Advantage?

In conclusion, strategic sourcing from China’s 3D printing services offers international B2B buyers an unparalleled opportunity to enhance their product development processes. The diverse capabilities available—from SLA and SLS to metal 3D printing—enable companies to obtain high-quality prototypes and production parts with rapid turnaround times. With lead times as short as two business days and pricing structures that often undercut Western competitors, businesses can achieve cost efficiencies while maintaining product integrity.

Furthermore, the robust support and expertise offered by manufacturers, as evidenced by customer testimonials, highlight the reliability and innovation present in this sector. By harnessing these services, companies from Africa, South America, the Middle East, and Europe can streamline their supply chains and accelerate their go-to-market strategies.

As the demand for customized and complex parts continues to rise, now is the time to explore partnerships with leading Chinese 3D printing firms. Engaging with these providers will not only enhance your manufacturing capabilities but also position your business at the forefront of technological advancements in the industry. Take the next step—evaluate your needs and reach out to potential partners today to unlock the full potential of 3D printing for your organization.