Introduction: Navigating the Global Market for 3d printing china

In today’s competitive landscape, international B2B buyers face the challenge of sourcing high-quality 3D printing solutions from China. With a myriad of options available, selecting the right supplier can be overwhelming, especially when considering factors like technology, material diversity, and production capabilities. This comprehensive guide aims to demystify the global market for 3D printing in China, providing insights into various types of printing technologies, practical applications across industries, and essential tips for effective supplier vetting.

Buyers will discover how to navigate complexities such as cost structures, lead times, and quality assurance processes. Whether you’re an entrepreneur in Brazil seeking rapid prototyping solutions or a purchasing manager in Nigeria looking for reliable production partners, this guide equips you with the knowledge to make informed decisions. By addressing key considerations and offering actionable strategies, we empower businesses from Africa, South America, the Middle East, and Europe to leverage China’s robust 3D printing capabilities, ultimately enhancing their product development cycles and market competitiveness.

As you explore this guide, expect to gain a clearer understanding of how to capitalize on the opportunities presented by the booming 3D printing industry in China, ensuring your sourcing decisions align with your business goals and quality standards.

Understanding 3d printing china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fused Deposition Modeling (FDM) | Utilizes thermoplastic filaments melted and extruded layer by layer. | Prototyping, tooling, and low-volume production. | Pros: Cost-effective, accessible materials. Cons: Limited detail and finish quality compared to other methods. |

| Stereolithography (SLA) | Employs UV light to cure liquid resin into hardened plastic. | High-detail prototypes and intricate designs. | Pros: Exceptional detail and smooth finishes. Cons: Slower production speed and higher material costs. |

| Selective Laser Sintering (SLS) | Uses a laser to fuse powdered materials into solid structures. | Functional prototypes, aerospace, and automotive parts. | Pros: Strong and durable parts; no support structures needed. Cons: Higher costs and limited material choices. |

| Direct Metal Laser Sintering (DMLS) | Melts metal powders with a laser to create complex geometries. | Aerospace components, medical devices, and tooling. | Pros: High strength and precision; suitable for complex designs. Cons: Expensive setup and material costs. |

| Multi Jet Fusion (MJF) | Utilizes inkjet technology to apply fusing agents to nylon powder. | Rapid prototyping and production of functional parts. | Pros: Fast production times and excellent mechanical properties. Cons: Limited to specific materials and higher initial costs. |

What are the Characteristics of Fused Deposition Modeling (FDM)?

Fused Deposition Modeling (FDM) is one of the most common 3D printing technologies, particularly favored for its affordability and ease of use. FDM printers utilize thermoplastic filaments that are heated and extruded layer by layer to create parts. This method is suitable for creating prototypes, tools, and low-volume production runs. When considering FDM, buyers should evaluate the desired material properties, as the technology is limited in terms of detail and finish quality compared to other methods.

How Does Stereolithography (SLA) Stand Out in 3D Printing?

Stereolithography (SLA) is renowned for its ability to produce high-detail prototypes with smooth surface finishes. It employs a UV laser to cure liquid resin into solid objects, making it ideal for intricate designs and applications that require precision. B2B buyers seeking high-quality visual models or functional prototypes should consider SLA, but they should also be mindful of its slower production speeds and higher material costs, which can affect timelines and budgets.

What are the Advantages of Selective Laser Sintering (SLS)?

Selective Laser Sintering (SLS) uses a laser to fuse powdered materials into solid parts, making it suitable for producing functional prototypes and parts in industries like aerospace and automotive. This technology is advantageous because it creates strong, durable parts without the need for support structures, which can simplify post-processing. However, buyers should be aware of the higher costs associated with SLS and the limited material choices available compared to other technologies.

Why Choose Direct Metal Laser Sintering (DMLS) for Metal Parts?

Direct Metal Laser Sintering (DMLS) is a cutting-edge technology that melts metal powders to create complex geometries, making it ideal for industries that require high precision and strength, such as aerospace and medical devices. The ability to produce intricate designs without traditional tooling is a significant advantage. However, DMLS comes with higher setup and material costs, which can be a barrier for some buyers, particularly in low-volume applications.

How Does Multi Jet Fusion (MJF) Enhance Production Efficiency?

Multi Jet Fusion (MJF) leverages inkjet technology to apply fusing agents to nylon powder, resulting in rapid prototyping and production of functional parts. This method is characterized by its fast production times and excellent mechanical properties, making it a strong contender for businesses needing quick turnaround times. While MJF offers numerous benefits, buyers should consider its higher initial costs and the fact that it is currently limited to specific materials.

Key Industrial Applications of 3d printing china

| Industry/Sector | Specific Application of 3D Printing China | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight component manufacturing | Reduced weight leads to fuel efficiency and cost savings | Compliance with aerospace standards and regulations |

| Automotive | Rapid prototyping of parts and tools | Accelerated product development and reduced time-to-market | Material quality and precision in manufacturing processes |

| Healthcare | Custom medical devices and prosthetics | Enhanced patient care through personalized solutions | Regulatory compliance and biocompatibility of materials |

| Consumer Electronics | Production of intricate components for devices | Improved product design flexibility and faster iterations | Supply chain reliability and cost-effectiveness |

| Industrial Equipment | Spare parts production and on-demand tooling | Minimizes downtime and inventory costs | Lead time and quality assurance in production |

How is 3D Printing Used in the Aerospace Industry?

In the aerospace sector, 3D printing is utilized for manufacturing lightweight components that contribute to overall aircraft efficiency. By using advanced materials and additive manufacturing techniques, companies can create parts that are not only lighter but also more complex than traditional manufacturing methods allow. This results in significant cost savings through improved fuel efficiency. For international buyers, it’s crucial to ensure that suppliers comply with stringent aerospace regulations and quality standards to maintain safety and reliability.

What Role Does 3D Printing Play in Automotive Prototyping?

The automotive industry leverages 3D printing for rapid prototyping of parts and tools, significantly speeding up the product development process. This technology enables manufacturers to create functional prototypes quickly, facilitating design iterations and testing before mass production. For B2B buyers, sourcing from China can provide cost advantages, but it’s essential to verify the material quality and the precision of the manufacturing processes to meet automotive industry standards.

How Does 3D Printing Enhance Healthcare Solutions?

In healthcare, 3D printing is revolutionizing the production of custom medical devices and prosthetics tailored to individual patients. This technology allows for the creation of complex shapes and personalized solutions that improve patient care and outcomes. For international buyers, especially from regions with varying regulations, understanding the biocompatibility of materials and ensuring compliance with local medical device regulations is critical when sourcing from China.

What Advantages Does 3D Printing Offer in Consumer Electronics?

In the consumer electronics sector, 3D printing is employed to produce intricate components that enhance product design and functionality. This technology allows for rapid iterations and customization, enabling companies to respond quickly to market demands. For B2B buyers, ensuring a reliable supply chain and cost-effectiveness while maintaining high-quality standards is paramount when engaging with manufacturers in China.

How is 3D Printing Transforming Industrial Equipment Manufacturing?

3D printing plays a vital role in the manufacturing of spare parts and on-demand tooling for industrial equipment. By enabling businesses to produce parts as needed, companies can significantly reduce inventory costs and minimize equipment downtime. For international buyers, it is essential to consider lead times and quality assurance processes in place at the manufacturing facilities to ensure timely and reliable delivery of high-quality components.

3 Common User Pain Points for ‘3d printing china’ & Their Solutions

Scenario 1: Navigating Quality Assurance in 3D Printing from China

The Problem: B2B buyers often face uncertainties regarding the quality of 3D printed parts when sourced from China. With a plethora of manufacturers, it can be challenging to ascertain whether the parts will meet the required specifications and standards. Many buyers report receiving products that do not align with their expectations, leading to costly reworks and delays in production timelines. This issue is particularly acute for businesses in sectors such as aerospace and medical, where precision is non-negotiable.

The Solution: To mitigate quality risks, buyers should prioritize working with manufacturers that offer comprehensive quality assurance processes. Engage suppliers that are ISO-certified, as this indicates adherence to international quality standards. Request detailed documentation of their quality control measures, such as Design for Manufacturability (DFM) analyses, which help identify potential issues before production begins. Additionally, consider ordering sample parts to evaluate quality firsthand before committing to larger orders. Establishing a clear communication channel with the manufacturer can also facilitate real-time updates and adjustments during the production process, ensuring the final products meet your specifications.

Scenario 2: Overcoming Communication Barriers in 3D Printing Projects

The Problem: International B2B buyers often encounter communication challenges when collaborating with 3D printing companies in China. Language barriers and cultural differences can lead to misunderstandings regarding project requirements, timelines, and specifications. This miscommunication frequently results in delays, increased costs, and products that do not meet the buyer’s needs, causing frustration and potential damage to business relationships.

The Solution: To improve communication, B2B buyers should choose manufacturers that provide dedicated project managers who are fluent in the buyer’s language. This ensures that all instructions and feedback are clearly understood. It’s also beneficial to use visual aids, such as diagrams and annotated drawings, to convey complex design ideas more effectively. Implementing project management tools that allow for collaborative feedback can help streamline the communication process. Regular check-ins and updates can further ensure alignment throughout the project lifecycle, reducing the likelihood of miscommunication.

Scenario 3: Managing Lead Times and Delivery Expectations with 3D Printing

The Problem: B2B buyers often struggle with lead times and delivery schedules when sourcing 3D printed parts from China. Many businesses report that estimated delivery times provided by manufacturers are often inaccurate, leading to unexpected delays that can derail production schedules and affect market competitiveness. This is especially critical for industries requiring rapid prototyping and quick turnaround times, such as electronics and automotive.

The Solution: To better manage lead times, buyers should conduct thorough research on potential manufacturers to understand their production capabilities and historical performance on delivery timelines. It is advisable to request detailed information about their production process, including average turnaround times for various materials and technologies. Establishing clear deadlines and milestones in contracts can also help hold manufacturers accountable. Additionally, consider diversifying your supplier base to include multiple manufacturers who can fulfill orders concurrently, providing flexibility and reducing reliance on a single source. Utilizing local suppliers for urgent needs can further enhance responsiveness and maintain production continuity.

Strategic Material Selection Guide for 3d printing china

What Are the Key Properties of Common 3D Printing Materials in China?

When selecting materials for 3D printing in China, international B2B buyers must consider various factors, including material properties, cost-effectiveness, and suitability for specific applications. Below, we analyze four common materials used in 3D printing, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does PLA (Polylactic Acid) Perform in 3D Printing?

PLA is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It is known for its ease of use and excellent printability.

- Key Properties: PLA has a melting temperature of around 180-220°C, making it suitable for low to moderate temperature applications. It exhibits good rigidity and is not prone to warping.

- Pros & Cons: PLA is affordable and widely available, making it a popular choice for prototyping. However, it has lower durability and heat resistance compared to other materials, which limits its use in high-stress environments.

- Impact on Application: PLA is ideal for applications like educational models and decorative items but may not be suitable for functional parts exposed to high temperatures or mechanical stress.

- Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations, especially in regions prioritizing sustainable materials. Standards such as ASTM D6400 for compostability may be relevant.

What Are the Benefits of ABS (Acrylonitrile Butadiene Styrene)?

ABS is a widely used thermoplastic known for its strength and impact resistance.

- Key Properties: ABS has a melting point of approximately 220-260°C and offers good toughness and thermal stability. It is also resistant to many chemicals.

- Pros & Cons: ABS is durable and suitable for functional prototypes and end-use parts. However, it can be challenging to print due to warping and requires a heated bed to minimize this issue.

- Impact on Application: ABS is commonly used in automotive components, consumer products, and electronic housings. Its robustness makes it suitable for applications requiring durability.

- Considerations for International Buyers: Compliance with safety standards like ISO 9001 is crucial, especially in the automotive sector. Buyers should also consider the availability of ABS in specific colors or formulations that meet local market demands.

How Does Nylon (Polyamide) Compare in 3D Printing?

Nylon is a versatile material known for its excellent mechanical properties and flexibility.

- Key Properties: Nylon has a melting temperature of around 220-260°C and offers high strength, flexibility, and abrasion resistance. It is also resistant to chemicals and moisture.

- Pros & Cons: Nylon is ideal for producing strong, functional parts, but it can be more expensive than other materials. The hygroscopic nature of nylon means it absorbs moisture, which can affect print quality.

- Impact on Application: Nylon is commonly used in applications such as gears, functional prototypes, and parts requiring flexibility and strength. Its durability makes it suitable for both industrial and consumer applications.

- Considerations for International Buyers: Buyers should be aware of the specific nylon grades available and their compliance with relevant industry standards, such as ASTM D638 for tensile properties.

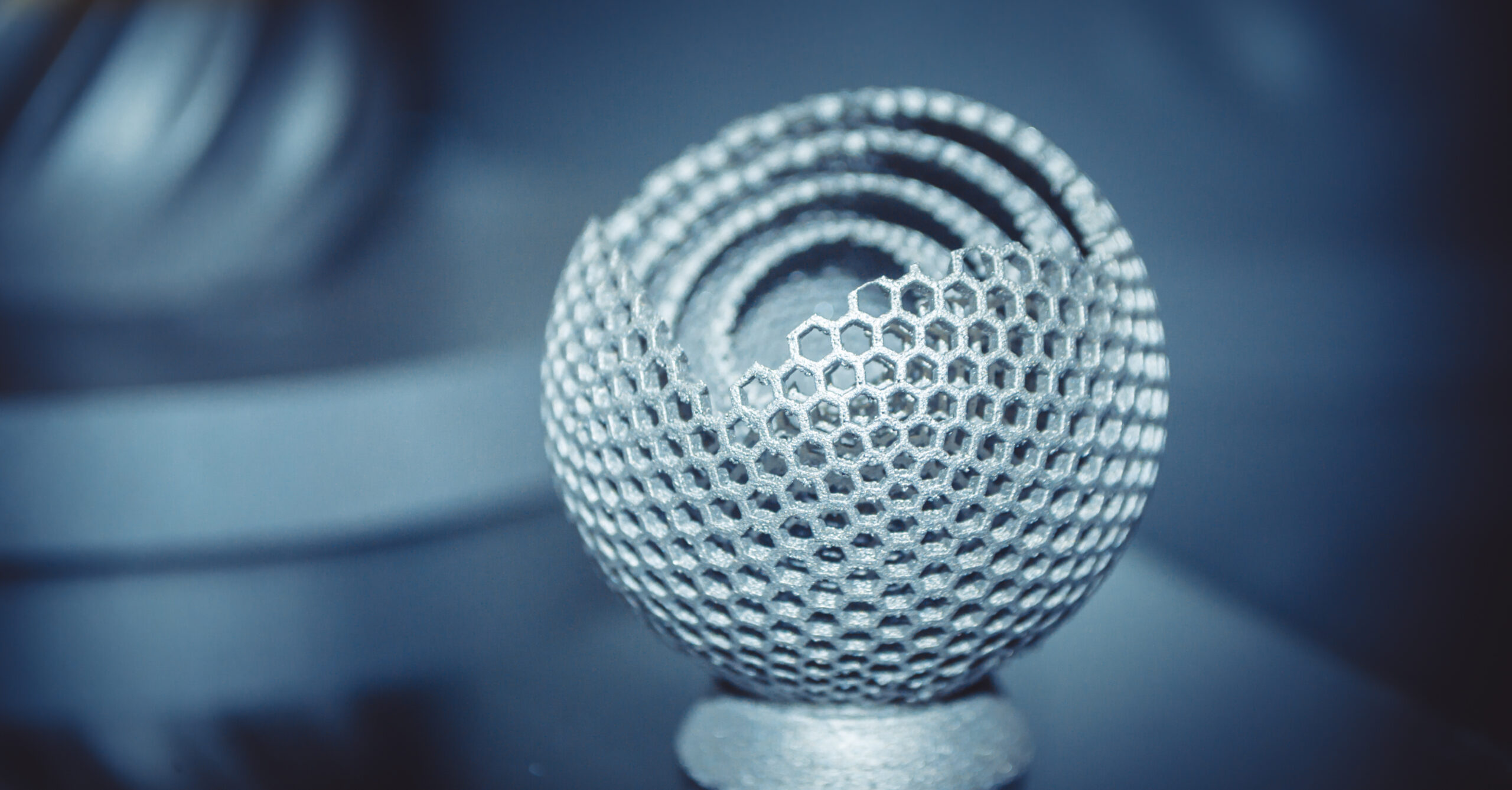

What Advantages Does Metal (Stainless Steel) Offer in 3D Printing?

Metal 3D printing, particularly with stainless steel, is gaining traction for its strength and durability.

- Key Properties: Stainless steel has high melting points (around 1400-1450°C) and excellent corrosion resistance. It offers superior mechanical properties compared to polymers.

- Pros & Cons: Metal parts are incredibly durable and can withstand high stress and temperature. However, metal 3D printing is typically more expensive and requires specialized equipment.

- Impact on Application: Stainless steel is ideal for aerospace, automotive, and medical applications where strength and durability are paramount.

- Considerations for International Buyers: Compliance with international standards such as ASTM A276 for stainless steel is critical. Buyers should also consider the cost implications of shipping heavy metal parts across regions.

Summary Table of Material Selection for 3D Printing in China

| Material | Typical Use Case for 3D Printing China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, decorative items | Biodegradable, easy to print | Low heat resistance, less durable | Low |

| ABS | Automotive parts, consumer products | Strong and impact-resistant | Prone to warping, requires heated bed | Medium |

| Nylon | Functional prototypes, gears | High strength and flexibility | Absorbs moisture, higher cost | High |

| Stainless Steel | Aerospace, medical applications | Exceptional durability and strength | Expensive, requires specialized equipment | High |

This strategic material selection guide equips international B2B buyers with the insights needed to make informed decisions when sourcing 3D printing materials from China, ensuring they meet their specific application requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printing china

What Are the Main Stages of the Manufacturing Process for 3D Printing in China?

The manufacturing process for 3D printing in China typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring that the final product meets the required specifications and quality standards.

Material Preparation

The first step in the manufacturing process is the preparation of materials, which may include plastics, resins, metals, and composites. Suppliers often offer a variety of materials, such as ABS, nylon, and high-performance polymers like PEEK. It’s essential for B2B buyers to ensure that the materials are sourced from reputable suppliers and meet specific industry requirements. This stage may also involve pre-processing treatments to enhance material properties, such as drying or mixing.

Forming

The forming stage involves converting the prepared materials into the desired shapes using various 3D printing technologies. Common techniques include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). Each method has its unique advantages; for instance, SLA is known for its high detail and smooth finishes, while SLS is favored for producing robust parts from powdered materials. Understanding which technology best suits your project is crucial for optimizing quality and performance.

Assembly

Once the individual parts are formed, they may require assembly. This could involve joining multiple components, adding threaded inserts, or integrating electronic elements. Some manufacturers provide additional assembly services, which can save time and reduce the complexity for B2B buyers. Ensure that the supplier has capabilities to handle intricate assembly tasks, especially for complex products.

Finishing

The finishing stage encompasses post-processing techniques that improve the aesthetic and functional properties of the printed parts. This may include sanding, polishing, painting, or applying surface treatments like anodizing for metals. Finishing processes can significantly enhance the final product’s performance, particularly in terms of durability and appearance.

How Is Quality Assurance Managed in 3D Printing Manufacturing in China?

Quality assurance (QA) is a crucial component of the manufacturing process in 3D printing, particularly for international B2B buyers. Suppliers often adhere to established international standards to ensure quality and reliability.

What International Standards Are Relevant for 3D Printing Quality Assurance?

Many manufacturers in China are ISO 9001 certified, indicating they follow a quality management system that meets international standards. Additionally, depending on the industry, products may require compliance with specific certifications, such as CE marking for the European market or API standards for the oil and gas sector. Understanding these certifications can help buyers assess the reliability of suppliers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control typically consists of several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, ongoing inspections and tests are conducted to monitor quality and detect any issues early.

- Final Quality Control (FQC): Once production is complete, a thorough examination of the final product is performed to ensure it meets all specifications before shipping.

These checkpoints help maintain high standards throughout the manufacturing process.

What Common Testing Methods Are Used in Quality Assurance for 3D Printed Parts?

Various testing methods are employed to verify the quality of 3D printed parts. Common techniques include:

- Dimensional Inspection: Using tools like calipers and coordinate measuring machines (CMM) to verify that parts meet dimensional specifications.

- Mechanical Testing: Assessing the mechanical properties of materials through tensile, compression, or impact tests.

- Surface Finish Evaluation: Techniques such as visual inspections and surface roughness measurements ensure that parts meet the required aesthetic and functional surface standards.

- Non-Destructive Testing (NDT): Methods like ultrasonic or X-ray testing can be used to detect internal defects without damaging the part.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure that their suppliers maintain rigorous quality control standards. Here are several strategies:

- Conduct Audits: Regular audits of the supplier’s facilities can provide insights into their manufacturing processes and quality assurance practices.

- Request Quality Reports: Suppliers should be able to provide documentation of quality control processes, including inspection reports and compliance certificates.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing 3D printed parts from China, international buyers must be aware of specific nuances related to quality control. These include:

- Cultural Differences: Understanding local manufacturing practices and communication styles can help facilitate better collaboration and quality assurance.

- Regulatory Compliance: Different regions may have varying regulations and standards that must be adhered to, so being informed about these can prevent compliance issues.

- Supply Chain Management: Establishing a robust supply chain with clear communication can ensure that quality standards are met consistently.

By actively engaging in the manufacturing and quality assurance processes, international B2B buyers can better secure high-quality 3D printed parts that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3d printing china’

In today’s global marketplace, leveraging 3D printing capabilities in China can significantly enhance your product development process, offering rapid prototyping and customized production at competitive prices. This guide serves as a practical checklist for international B2B buyers looking to procure 3D printing services from Chinese manufacturers.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in the sourcing process. Consider factors such as material type, dimensional tolerances, and surface finishes that align with your project needs. This clarity will help potential suppliers understand your expectations and provide accurate quotes.

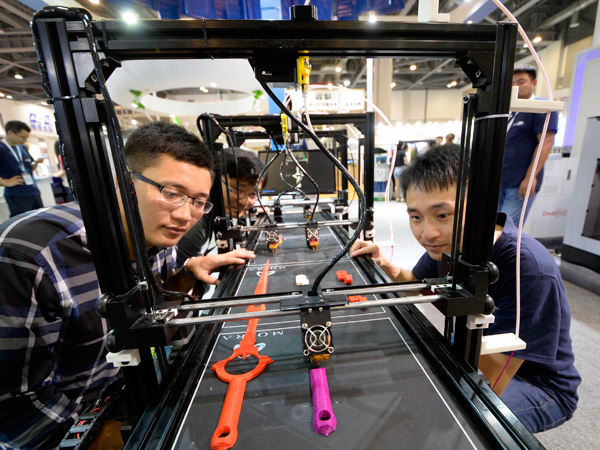

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable 3D printing companies in China. Utilize industry platforms, trade shows, and supplier directories to compile a list of candidates. Pay attention to their specialization in various printing technologies (e.g., SLA, SLS, FDM) and their experience with materials relevant to your project.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet your shortlisted suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Look for customer reviews and ratings to gauge their reliability and quality of service.

- Ask for samples of previous work to assess print quality.

- Verify their production capabilities, including machine types and capacity.

Step 4: Verify Supplier Certifications

Ensure that the suppliers you are considering have the necessary certifications, such as ISO 9001, which indicates a commitment to quality management. This step is essential as it reflects their adherence to industry standards and practices. Additionally, inquire about their compliance with international shipping and export regulations, especially if you are sourcing from regions like Africa or South America.

Step 5: Request Quotes and Compare Pricing

Once you have a shortlist of suppliers, request detailed quotes that include pricing, lead times, and any additional costs such as shipping and customs duties. Comparing these quotes will help you identify the best value for your project, but remember that the lowest price may not always equate to the best quality or service.

- Consider the total cost of ownership, including potential rework or quality issues.

- Look for transparency in pricing structures.

Step 6: Communicate and Collaborate on Design

Engage in open communication with your selected supplier regarding your design files. Upload your 3D files for a Design for Manufacturability (DFM) analysis, which can provide insights into any potential manufacturing challenges. This collaboration is crucial for ensuring that your design can be effectively produced without costly modifications.

Step 7: Establish Clear Payment Terms and Logistics

Finally, clarify payment terms and logistics before placing an order. Discuss acceptable payment methods, such as letters of credit or secure online payments, to safeguard your transactions. Additionally, confirm shipping arrangements, including lead times and tracking options, to ensure timely delivery.

By following these steps, you can effectively navigate the sourcing process for 3D printing services in China, ultimately enhancing your product development capabilities while minimizing risks.

Comprehensive Cost and Pricing Analysis for 3d printing china Sourcing

What Are the Key Cost Components in 3D Printing Sourcing from China?

When considering 3D printing sourcing from China, international B2B buyers need to understand the various cost components that influence the overall pricing. The primary elements include:

-

Materials: The type of material significantly affects the cost. Common materials like PLA or ABS are generally less expensive than specialized options such as Nylon or metal alloys. Prices can vary based on market demand, availability, and quality certifications.

-

Labor: Labor costs in China are relatively low compared to Western countries. However, the complexity of the print and the expertise required for specific processes (like DMLS or SLA) can lead to variations in labor expenses.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and equipment depreciation. High-quality manufacturers with advanced technology often have higher overhead costs, which can influence the final price.

-

Tooling: For custom parts, tooling can be a significant expense. While 3D printing typically reduces the need for extensive tooling, specific applications may still require it, impacting overall costs.

-

Quality Control (QC): Ensuring product quality is crucial, especially for industries such as aerospace or medical. QC processes add to the cost but are essential for maintaining standards and certifications.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and urgency. Buyers should consider Incoterms that define responsibilities for shipping, insurance, and tariffs, as these can influence total costs.

-

Margin: Suppliers will add a margin to cover their operational costs and profit. Understanding the competitive landscape and average margins in the industry can aid in negotiations.

How Do Pricing Influencers Impact 3D Printing Costs?

Pricing in 3D printing is not static and is influenced by several factors:

-

Volume/MOQ: Bulk orders typically benefit from lower per-unit costs. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications and Customization: Highly customized parts or those requiring intricate designs usually incur higher costs. Buyers should balance their need for customization with budget constraints.

-

Material Selection: As noted, the choice of material has a direct impact on pricing. High-performance materials will naturally cost more but may be necessary for specific applications.

-

Quality and Certifications: Compliance with international standards can lead to higher costs but ensures reliability and safety, particularly for critical applications.

-

Supplier Factors: The reputation and capabilities of the supplier can influence pricing. Established manufacturers may charge more due to their expertise and track record.

What Are Some Buyer Tips for Cost-Efficiency in 3D Printing Sourcing?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, here are actionable tips to enhance cost-efficiency:

-

Negotiate Effectively: Engage in discussions with suppliers about pricing structures. Understanding their cost breakdown can provide leverage for better deals.

-

Consider Total Cost of Ownership: Evaluate not only the initial pricing but also the long-term costs associated with product performance, durability, and potential rework.

-

Be Aware of Pricing Nuances: International buyers should consider exchange rates, tariffs, and shipping costs that can affect the overall budget. Getting quotes in local currencies can help in assessing true costs.

-

Research Multiple Suppliers: Comparing various suppliers can unveil significant differences in pricing and service quality. Utilize platforms that offer instant quotes to streamline this process.

-

Utilize Local Expertise: Engaging local consultants or sourcing agents familiar with the Chinese market can aid in navigating complexities and securing favorable terms.

Disclaimer on Pricing

Prices in the 3D printing sector can fluctuate based on market conditions, material availability, and changes in supplier pricing strategies. The figures mentioned should be viewed as indicative and may not reflect real-time costs. Always request updated quotes from suppliers to ensure accuracy.

Alternatives Analysis: Comparing 3d printing china With Other Solutions

Introduction: Understanding Alternatives in 3D Printing Solutions

As businesses explore manufacturing solutions, the availability of various technologies offers significant flexibility. 3D printing in China has emerged as a popular choice due to its advanced capabilities and competitive pricing. However, it’s crucial for B2B buyers to consider alternative methods that might better suit specific needs. This section compares 3D printing in China against two viable alternatives: CNC machining and traditional injection molding. Each method offers unique benefits and challenges that can influence purchasing decisions.

Comparison Table

| Comparison Aspect | 3D Printing China | CNC Machining | Injection Molding |

|---|---|---|---|

| Performance | High precision; complex geometries | Extremely precise; suitable for metals | High volume; excellent repeatability |

| Cost | Lower for small batches; higher for large | Higher setup costs; cost-effective for large runs | High initial cost; economical for large volumes |

| Ease of Implementation | Quick setup; easy design iterations | Requires skilled operators; longer lead times | Complex setup; requires molds |

| Maintenance | Low maintenance; minimal downtime | Regular maintenance required; machine-intensive | Low maintenance once molds are established |

| Best Use Case | Prototyping, low-volume production | High-precision parts, complex designs | High-volume production runs |

Detailed Breakdown of Alternatives

CNC Machining: What Are Its Advantages and Limitations?

CNC machining is a subtractive manufacturing process that offers exceptional precision and the ability to work with a variety of materials, including metals and plastics. It is particularly advantageous for producing high-tolerance components essential in industries such as aerospace and automotive. While it generally involves higher setup costs and a more extended lead time compared to 3D printing, CNC machining becomes cost-effective for larger production runs. The complexity of CNC operations requires skilled technicians, which can pose a challenge for companies lacking in-house expertise.

Injection Molding: When Is It the Right Choice?

Injection molding is a traditional manufacturing method that excels in producing large volumes of identical parts quickly and efficiently. The initial costs associated with creating molds can be substantial, making it less ideal for short runs or prototypes. However, once the mold is produced, the cost per unit decreases significantly, making it highly economical for large-scale production. Injection molding is suitable for high-volume consumer products, but its inflexibility in design changes and the lengthy setup time can be drawbacks for businesses seeking agility in their manufacturing processes.

Conclusion: How to Choose the Right Solution for Your Needs

Choosing the right manufacturing solution hinges on understanding your specific requirements, including production volume, material types, and budget constraints. 3D printing in China offers rapid prototyping and flexibility for small to medium runs, making it a strong contender for innovative projects. Conversely, CNC machining provides unmatched precision for high-quality parts, while injection molding is ideal for businesses focused on mass production. By evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for 3d printing china

What Are the Essential Technical Properties for 3D Printing in China?

When navigating the 3D printing landscape in China, understanding key technical specifications is crucial for making informed purchasing decisions. Here are some of the most critical properties that B2B buyers should consider:

What is Material Grade and Why is It Important?

Material grade refers to the specific classification of materials used in 3D printing, including plastics, metals, and composites. Common materials include ABS, PLA, nylon, and various metal alloys like stainless steel and titanium. The choice of material affects the durability, flexibility, and overall performance of the final product. For instance, nylon is often preferred for its strength and flexibility, while ABS is valued for its ease of printing and post-processing. Selecting the right material grade is essential for meeting the specific requirements of your application, whether for prototypes or end-use parts.

How Does Tolerance Impact 3D Printed Parts?

Tolerance in 3D printing refers to the allowable variation in dimensions of the printed parts. This is typically expressed in millimeters (mm) and can range from ±0.05mm for CNC machined parts to ±0.2mm for 3D printed components. Understanding tolerance is vital for ensuring that parts fit together correctly, especially in assemblies. Inaccurate tolerances can lead to increased production costs and project delays, making it a critical factor in the procurement process.

Why is Lead Time a Key Consideration?

Lead time is the total time required to produce and deliver a 3D printed part. In China, lead times can vary significantly based on the technology used (e.g., SLA, SLS, FDM) and the complexity of the design. For example, while some services offer rapid prototyping with lead times as short as one day, others may take several days for complex geometries. Understanding lead time is crucial for aligning production schedules and meeting market demands, particularly in industries where time-to-market is a competitive advantage.

What Are Common Trade Terms Used in 3D Printing?

In addition to technical specifications, familiarity with industry terminology can enhance communication and negotiation with suppliers. Here are some essential terms:

What Does OEM Mean in the 3D Printing Context?

OEM stands for Original Equipment Manufacturer. In the context of 3D printing, an OEM produces parts based on the specifications provided by a client, which can range from prototypes to finished components. Understanding OEM relationships can help buyers secure tailored solutions that meet specific project requirements.

Why is MOQ Important for B2B Buyers?

MOQ, or Minimum Order Quantity, refers to the smallest quantity of a product that a supplier is willing to sell. In 3D printing, MOQs can vary widely between manufacturers and can affect production costs. Buyers should be aware of MOQs when planning their budgets and inventory, as high MOQs may lead to excess stock or increased costs.

How Does RFQ Influence Supplier Selection?

RFQ stands for Request for Quotation. This is a formal process where buyers request pricing and availability from suppliers for specific quantities and specifications. An RFQ is essential for comparing different suppliers, ensuring that all parties have a clear understanding of requirements and pricing structures.

What Are Incoterms and Their Relevance?

Incoterms, short for International Commercial Terms, are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to avoid misunderstandings and ensure compliance with international shipping regulations.

By grasping these essential technical properties and trade terminologies, B2B buyers can navigate the complexities of 3D printing in China more effectively, making informed decisions that align with their project needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the 3d printing china Sector

What Are the Key Drivers and Trends in the Global 3D Printing Market?

The global 3D printing market, particularly in China, is driven by technological advancements, increasing demand for customization, and the need for rapid prototyping. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are keenly observing these trends. The capability to produce complex geometries at a lower cost and with shorter lead times is reshaping manufacturing processes across various industries, including automotive, aerospace, and consumer goods.

Emerging technologies such as Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) are gaining traction, allowing for the production of high-quality parts with enhanced material properties. Additionally, the rise of on-demand manufacturing is enabling companies to reduce inventory costs and streamline their supply chains. This trend is particularly beneficial for international buyers who seek flexibility and responsiveness in their sourcing strategies. The ability to receive instant quotes and fast turnaround times—from as little as 24 hours—further enhances the attractiveness of sourcing from Chinese manufacturers.

Moreover, the increasing emphasis on digital manufacturing technologies is enabling businesses to integrate 3D printing into their existing production lines, fostering innovation and efficiency. This integration is essential for companies looking to maintain competitiveness in a rapidly evolving market.

How Is Sustainability and Ethical Sourcing Addressed in the 3D Printing Sector?

Sustainability and ethical sourcing are becoming increasingly critical considerations for B2B buyers in the 3D printing sector. The environmental impact of traditional manufacturing processes has prompted a shift towards additive manufacturing, which typically generates less waste and utilizes materials more efficiently. International buyers are now prioritizing manufacturers that adopt sustainable practices, such as using biodegradable materials and implementing energy-efficient production methods.

The importance of ethical supply chains cannot be overstated. Companies are increasingly scrutinizing their suppliers to ensure they adhere to labor laws and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and the use of green materials are becoming prerequisites for suppliers to attract international business. This focus not only enhances corporate social responsibility but also aligns with the values of consumers who prefer brands that demonstrate a commitment to sustainability.

Moreover, the development and use of ‘green’ materials—such as bio-based plastics and recycled composites—are gaining momentum in the 3D printing landscape. This trend not only reduces the carbon footprint of production but also allows companies to market their products as environmentally friendly, appealing to a growing segment of eco-conscious consumers.

What Is the Evolution of the 3D Printing Industry and Its Relevance for B2B Buyers?

The evolution of the 3D printing industry has been marked by significant technological advancements since its inception in the 1980s. Initially limited to prototyping, 3D printing has expanded to encompass a wide range of applications, including end-use parts production, tooling, and even complex assemblies. This shift has been largely driven by improvements in printing technologies, materials, and software capabilities.

For B2B buyers, understanding this evolution is crucial. The transition from prototyping to full-scale production means that companies can now leverage 3D printing for more than just initial design validation; they can utilize it for creating market-ready products. This capability opens new avenues for innovation and reduces time-to-market—a vital factor in today’s competitive landscape. As the technology continues to advance, buyers must stay informed about emerging trends and capabilities to make strategic sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printing china

-

How do I choose the right 3D printing technology for my project?

Selecting the appropriate 3D printing technology depends on your project requirements, including material type, part complexity, and intended use. Common technologies include Fused Deposition Modeling (FDM) for low-cost prototypes, Stereolithography (SLA) for high-detail parts, and Selective Laser Sintering (SLS) for durable, functional prototypes. Evaluate factors like lead time, surface finish, and tolerance levels to determine the best fit. Consulting with suppliers can also provide insights based on their capabilities and past projects. -

What are the advantages of sourcing 3D printing services from China?

China offers competitive pricing, a wide range of materials, and advanced manufacturing technologies, making it an attractive option for B2B buyers. The country has a robust supply chain infrastructure, enabling quick turnaround times and efficient logistics. Additionally, many Chinese manufacturers are ISO-certified, ensuring consistent quality standards. Collaborating with experienced suppliers can also provide access to innovative solutions and customized services tailored to specific industry needs. -

What minimum order quantities (MOQs) should I expect when sourcing 3D printing services?

MOQs for 3D printing services can vary significantly among suppliers, depending on the material and technology used. Some manufacturers may accept low MOQs for prototypes, while others might require larger quantities for production runs to optimize costs. Always clarify the MOQ with potential suppliers during the initial inquiry, as this can influence your production planning and budgeting. -

How can I ensure quality assurance (QA) when sourcing 3D printed parts?

To ensure quality assurance, choose suppliers who adhere to international quality standards, such as ISO 9001. Request samples before placing large orders to evaluate material properties and manufacturing accuracy. Additionally, inquire about their QA processes, including design for manufacturability (DFM) checks, in-process inspections, and post-production testing. Establishing clear specifications and communication channels with the supplier can also help maintain quality throughout the production process. -

What payment terms should I consider when working with a 3D printing supplier in China?

Payment terms can vary widely, but common options include upfront payments, partial payments (e.g., 30% upfront and 70% upon delivery), or payment upon receipt of goods. It’s essential to negotiate terms that suit your cash flow while ensuring the supplier’s confidence in fulfilling your order. Using secure payment methods, such as PayPal or escrow services, can also provide additional protection for your transaction. -

How do I vet potential 3D printing suppliers in China?

To vet potential suppliers, begin by researching their company background, certifications, and customer reviews. Request references from previous clients and check their portfolio to assess their experience in your industry. Additionally, consider visiting the facility if possible or conducting virtual tours to evaluate their capabilities and equipment. Establishing clear communication and responsiveness during initial discussions can also indicate their reliability and professionalism. -

What logistics considerations should I be aware of when importing 3D printed parts from China?

Logistics play a crucial role in international trade. Consider shipping methods, lead times, and customs clearance procedures. Collaborate with suppliers who offer comprehensive logistics support, including shipping arrangements and tracking services. Additionally, familiarize yourself with import regulations and tariffs in your country to avoid unexpected costs. Utilizing reliable courier services like DHL or FedEx can enhance delivery efficiency and ensure timely arrival of your products. -

Can I customize my 3D printed parts, and what is the process?

Yes, customization is one of the key benefits of 3D printing. You can modify designs based on specific requirements, such as size, material, and functional features. The process typically begins with submitting your CAD files to the supplier, who will conduct a design for manufacturability (DFM) analysis. They will provide feedback on any modifications needed for optimal printing. Collaborating closely with the supplier throughout this process ensures that your custom specifications are met effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 3D Printing China Manufacturers & Suppliers List

1. Unionfab – 3D Printing & CNC Machining Services

Domain: unionfab.com

Registered: 2019 (6 years)

Introduction: Unionfab offers a wide range of 3D printing and CNC machining services, including:

**3D Printing Technologies:**

– Stereolithography Apparatus (SLA)

– Digital Light Processing (DLP)

– Fused Deposition Modeling (FDM)

– Selective Laser Melting (SLM)

– Multi Jet Fusion (MJF)

– PolyJet

– Selective Laser Sintering (SLS)

– Large Scale Printing

– Metal 3D Printing

**CNC Machining Services:**

– CNC Turn…

2. In3Dtec – High Quality 3D Printing Services

Domain: in3dtec.com

Registered: 2017 (8 years)

Introduction: Commercial High Quality 3D Printing Service

**Capabilities:**

– Stereolithography (SLA):

– Speed: As fast as 1 day

– Materials: 10+ materials

– Colors: 26+

– Surface finishes: 10+

– Max Build: 1.7m x 0.8m x 0.8m

– Fused Deposition Modeling (FDM):

– Speed: As fast as 1 day

– Materials: 30+ materials

– Colors: 26+

– Surface finishes: 10+

– Max Build: 1m x 1m x 1m

– Direct Meta…

3. 3D Printing Companies – China Manufacturers

Domain: 3d.directory

Registered: 2020 (5 years)

Introduction: 3D Printing Companies in China include various manufacturers such as 3ERP, BLT, Facfox, Falcontech, HLH Prototypes Co LTD, Lava, Rapid Direct, Rapiddirect, RP World, Shanghai Digital Manufacturing (SHDM), Star Rapid, Start Prototyping, Voxelijet, Winsun, and ZRapid. The directory allows users to filter companies based on capabilities including order type (Prototype or Production), materials (Plast…

4. BigRep – High-Performance 3D Printers

Domain: bigrep.com

Registered: 2004 (21 years)

Introduction: BigRep Industrial 3D Printers: ALTRA 280 (High-Performance Machine), IPSO 105 (Maximum Performance, Unbeatable Price), PRO (Industrial Quality Meets Cost Efficiency), VIIO 250 (Next Level of Automated Production), ONE (Legacy of Innovation, Original Large Format), STUDIO (Graduate From Desktop to Industrial). Filament Dry Cabinet: DRYCON. Materials: HI-TEMP PETG, PLA, PLX PRO HT, Fiber-Reinforced …

5. China 3D Printing – Metal 3D Printing Solutions

Domain: china-3dprinting.com

Registered: 2021 (4 years)

Introduction: {“Metal_3D_Printing”:{“Lead_Time”:”5 Days”,”Materials”:[“AISi10Mg”,”316L”,”Ti6Al4V”,”IN718″,”IN625″,”Copper”,”1.2709″,”CX”],”Description”:”For High Performance Functional Metal 3D Printed Products”,”Technology”:”Direct Metal Laser Sintering / Selective Laser Melting 3D Printing”},”MJF_3D_Printing”:{“Lead_Time”:”3 Days”,”Materials”:[“PA11″,”PA12″,”PA12 GB”],”Description”:”For Functional Nylon 3D Pr…

6. JSADD 3D – Comprehensive 3D Printing Services

Domain: jsadditive.com

Registered: 2022 (3 years)

Introduction: JSADD 3D offers a range of 3D printing services including SLA (Stereolithography), SLS (Selective Laser Sintering), SLM (Selective Laser Melting), MJF (Multi Jet Fusion), CNC Machining, and Vacuum Casting. The company has over 15 years of experience in 3D printing services and operates from a factory with more than 80,000 square meters of floor space. They utilize over 150 large industrial 3D prin…

Strategic Sourcing Conclusion and Outlook for 3d printing china

In today’s competitive landscape, strategic sourcing in the realm of 3D printing in China offers international B2B buyers an unparalleled opportunity to optimize their manufacturing processes. With numerous manufacturers providing a diverse range of materials and advanced technologies, businesses can leverage China’s capabilities for rapid prototyping and on-demand production. Key players like Unionfab and JLC3DP demonstrate the potential for cost savings, high-quality outputs, and swift turnaround times, making them ideal partners for companies seeking to innovate while managing costs effectively.

For buyers from Africa, South America, the Middle East, and Europe, the value of sourcing from China cannot be overstated. With the ability to access cutting-edge technologies and competitive pricing, companies can enhance their product offerings and stay ahead in their respective markets.

Looking ahead, the future of 3D printing in China is bright, with continuous advancements in materials and processes. Now is the time for international B2B buyers to explore these opportunities, establish partnerships, and integrate 3D printing solutions into their operations. Embrace the transformative power of strategic sourcing and unlock the potential for growth and innovation in your business.