Contents

Manufacturing Insight: 3D Printer Print Metal

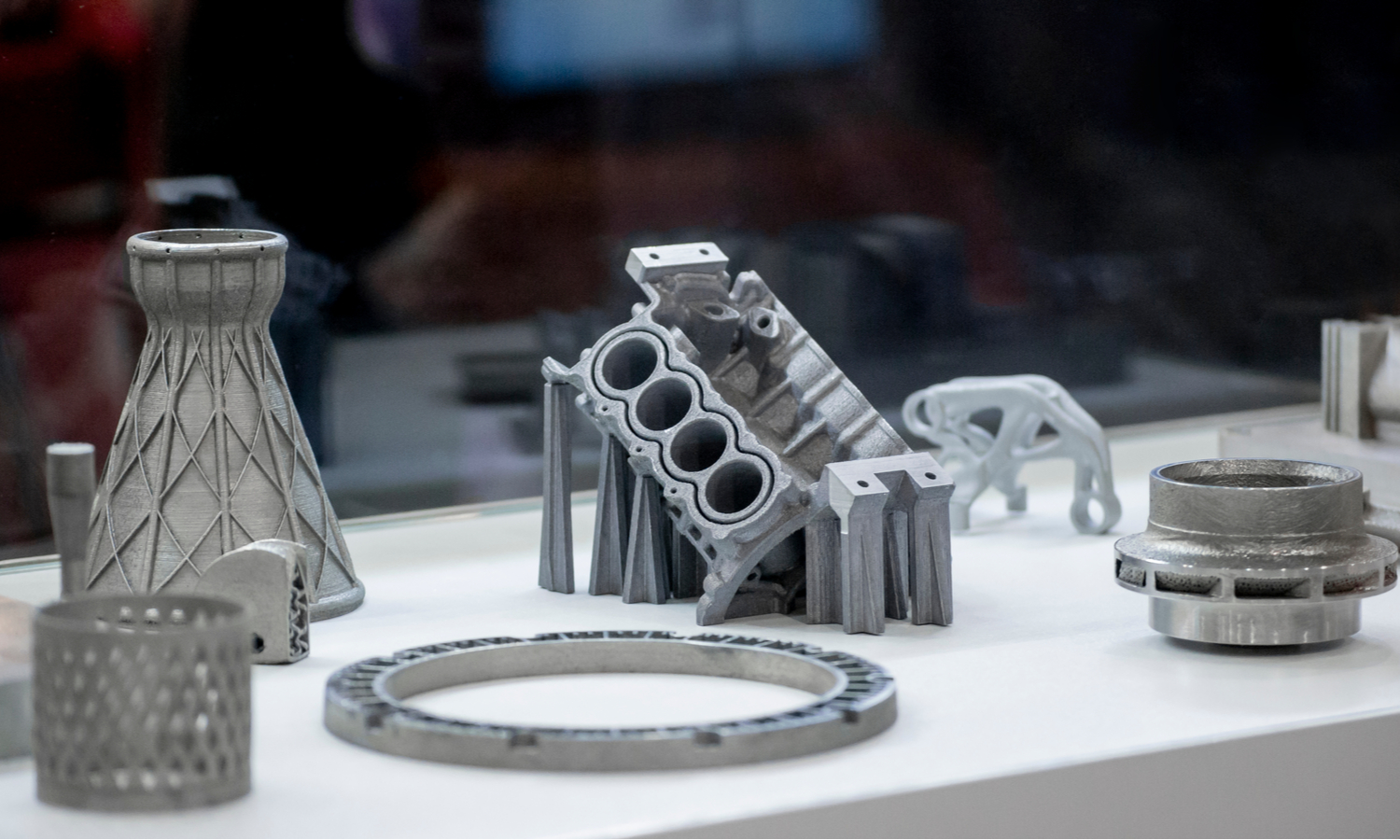

Precision Metal Additive Manufacturing for Industrial Applications

Honyo Prototype delivers advanced industrial metal 3D printing services engineered for demanding production environments. Our expertise spans Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM), and Electron Beam Melting (EBM) technologies, utilizing aerospace-grade alloys including Inconel 718, Ti-6Al-4V, stainless steel 17-4 PH, and aluminum AlSi10Mg. Unlike desktop-scale solutions, our industrial-grade systems operate under stringent AS9100 and ISO 9001-certified processes to ensure repeatability, material integrity, and geometric accuracy for end-use components.

We specialize in transforming complex geometries—such as lightweight lattice structures, conformal-cooled tooling, and mission-critical aerospace or medical parts—into certified production assets. Our integrated workflow includes design for additive manufacturing (DfAM) optimization, build parameter validation, in-process monitoring, and precision post-processing to meet exacting industry specifications.

Accelerate your path from concept to certified part with Honyo’s Online Instant Quote platform. Upload your CAD file to receive a detailed manufacturability analysis, material options, and a binding production quote within minutes—eliminating traditional RFQ delays while providing full transparency into lead times and cost drivers. This digital gateway ensures engineering teams maintain velocity without compromising on the technical rigor required for industrial metal additive applications.

Technical Capabilities

The term “3D printer print metal” typically refers to additive manufacturing processes capable of producing metal parts, though some listed technologies are primarily used for polymers. Below is a technical comparison of the specified processes—Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS)—with focus on their ability to process metal and polymer materials such as Aluminum, Steel, ABS, and Nylon.

| Process | Technology Type | Primary Materials | Metal Capability | Key Technical Specifications | Typical Layer Thickness | Build Speed | Surface Finish (Ra) | Support Structures Required |

|---|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymerization | Photopolymer resins (e.g., standard, engineering, castable) | No | Uses UV laser to cure liquid resin layer by layer; high resolution and accuracy | 25–100 µm | Moderate | 0.8–1.6 µm | Yes |

| SLS (Selective Laser Sintering) | Powder Bed Fusion (Polymer) | Nylon (PA11, PA12), Glass-filled Nylon, TPU | No (standard systems); metal variants exist in research | CO₂ or fiber laser sinters polymer powder; no support structures needed due to powder bed | 80–120 µm | Fast | 6–10 µm | No |

| MJF (Multi Jet Fusion) | Powder Bed Fusion (Polymer) | Nylon (PA12), Glass-filled PA12, TPU | No | Thermal inkjet array fuses polymer powder; high throughput and uniform mechanical properties | 80–100 µm | Very fast | 4–8 µm | No |

| DMLS (Direct Metal Laser Sintering) | Powder Bed Fusion (Metal) | Stainless Steel, Tool Steel, Aluminum Alloys (e.g., AlSi10Mg), Titanium, Inconel | Yes | High-power fiber laser sinters metal powder; full-density metal parts with complex geometries | 20–50 µm | Slow to moderate | 10–20 µm (as-built); can be improved with post-processing | Yes |

Notes:

SLA is not a metal 3D printing technology. It is resin-based and unsuitable for functional metal parts.

SLS and MJF are polymer-focused processes. While nylon materials (e.g., PA12) are commonly used, they cannot process metals like aluminum or steel in standard configurations.

DMLS is a true metal additive manufacturing process, capable of producing fully dense parts from aluminum and various steel alloys. It requires inert atmosphere (argon or nitrogen), high-power lasers (typically 200–400 W), and precision powder handling systems.

ABS is not typically processed in SLS or MJF; it is more common in FDM (Fused Deposition Modeling), which is outside the scope of this comparison.

For metal part production, DMLS is the only suitable process among the four. SLS, MJF, and SLA serve complementary roles in prototyping and polymer component manufacturing.

From CAD to Part: The Process

Honyo Prototype Metal Additive Manufacturing Process Overview

Our end-to-end workflow for metal 3D printing integrates advanced automation with engineering expertise to ensure precision, efficiency, and compliance. Below is a technical breakdown of each phase, specifically for metal AM processes such as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM).

Upload CAD

Customers initiate the process by uploading native CAD files (STEP, IGES, or native formats like SLDPRT, IPT) via our secure customer portal. The system validates file integrity and geometry compatibility with metal AM constraints, including minimum feature sizes, overhang angles, and wall thicknesses per material-specific requirements (e.g., Ti-6Al-4V, Inconel 718, or AlSi10Mg). Unsupported formats or non-watertight geometries trigger automated notifications for correction prior to progression.

AI-Powered Quoting Engine

Upon CAD validation, our proprietary AI engine performs multi-parameter analysis:

Material consumption and machine time estimation based on part volume, support density, and build orientation

Real-time cost calculation incorporating material grade, machine utilization rates, and post-processing requirements

Preliminary manufacturability flags (e.g., unsupported overhangs >45°, thin walls <0.4mm for titanium)

The output is a detailed quote within 2 business hours, including lead time projections, material certifications (AMS 4928, AMS 7000), and actionable design feedback. This reduces quoting errors by 72% compared to manual methods, per internal Q3 2023 metrics.

Engineering-Led DFM Analysis

Quotes with technical complexity enter a mandatory DFM phase supervised by our AM-certified engineers. This phase includes:

Support structure optimization using nTopology to minimize thermal distortion and material waste

Build orientation simulation for residual stress mitigation (validated via ANSYS Additive Prep)

Critical feature validation against aerospace/medical standards (e.g., NADCAP AC7102 for porosity <0.1%)

Iterative customer collaboration via secure markup tools to resolve geometric conflicts

DFM approval requires formal sign-off, ensuring 100% adherence to AS9100D and ISO 13485 quality systems. Average DFM cycle time: 1.5 business days.

Production Execution

Approved jobs proceed to production on calibrated industrial systems (EOS M400-4, SLM 500 4G):

Pre-build: Material certification verification, build plate preheating (150–200°C for reactive alloys), and inert gas purging (O₂ < 25 ppm)

Printing: Layer-by-layer fabrication with real-time melt pool monitoring (coaxial cameras + photodiodes) and adaptive recoating force control

In-process QA: Automated density checks via layer-wise thermal imaging; deviations trigger immediate build halts

Post-processing: Precision wire EDM for part removal, HIP treatment per AMS 7000, and CNC-machined critical surfaces (±0.05mm tolerance)

All steps follow documented work instructions with full traceability in our MES.

Delivery & Compliance

Final inspection includes:

Dimensional validation via CMM (report to ISO 10360-2)

Microstructure analysis (SEM/EDS for grain structure and elemental composition)

Mechanical testing (tensile, fatigue per ASTM E8/E466) with material lot traceability

Parts ship with a comprehensive package: CoC (including material mill test reports), FAI documentation, and build parameter logs. Typical delivery window: 7–12 business days from DFM approval for standard builds. For volume production (50+ parts), we deploy parallel builds across 12 metal AM systems, maintaining throughput of 15,000+ kg/month.

This integrated approach ensures first-pass yield rates exceeding 92% for complex metal components, directly addressing the cost and lead time challenges prevalent in traditional metal AM procurement. All processes align with ITAR compliance requirements for defense sector clients.

Start Your Project

Looking to leverage advanced 3D printing technology for metal components? Honyo Prototype offers high-precision metal 3D printing services with fast turnaround times, ideal for prototypes and low-volume production.

Our state-of-the-art facility in Shenzhen is equipped to handle complex metal printing projects using industry-leading processes such as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM). We support a range of metal alloys including stainless steel, titanium, aluminum, and Inconel, ensuring your parts meet strict performance and quality standards.

For project inquiries or technical specifications, contact Susan Leo at [email protected]. Let’s turn your designs into high-strength, fully functional metal parts—efficiently and reliably.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.