Guide Contents

Project Insight: 3D Printer Print Metal

Manufacturing Insight: Metal 3D Printing for Rapid Product Development

Why Speed & Precision Are Critical for Modern Hardware Innovation

Traditional manufacturing delays iterations with weeks-long tooling cycles and high setup costs

Complex geometries often require multi-step assembly, increasing failure risk and time-to-market

Market leaders prioritize speed to validate concepts before competitors—every day counts in product development

Honyo Prototype: Your Digital Manufacturing Partner for Metal 3D Printing

Online Instant Quote: AI-powered platform delivers real-time pricing in seconds—no manual quotes, no delays

5-7 Day Turnaround: Functional metal parts delivered faster than traditional methods, accelerating your development cycle

Precision DMLS Technology: Achieve ±0.05mm tolerances and intricate internal features for aerospace, medical, and automotive applications

Zero Capital Investment: Access industrial-grade metal printing without purchasing $50K–$1M+ equipment or facility upgrades

At Honyo Prototype, we transform your CAD files into functional metal prototypes in record time—so you can iterate faster, reduce risk, and bring innovation to market before anyone else.

Honyo Capabilities & Technology

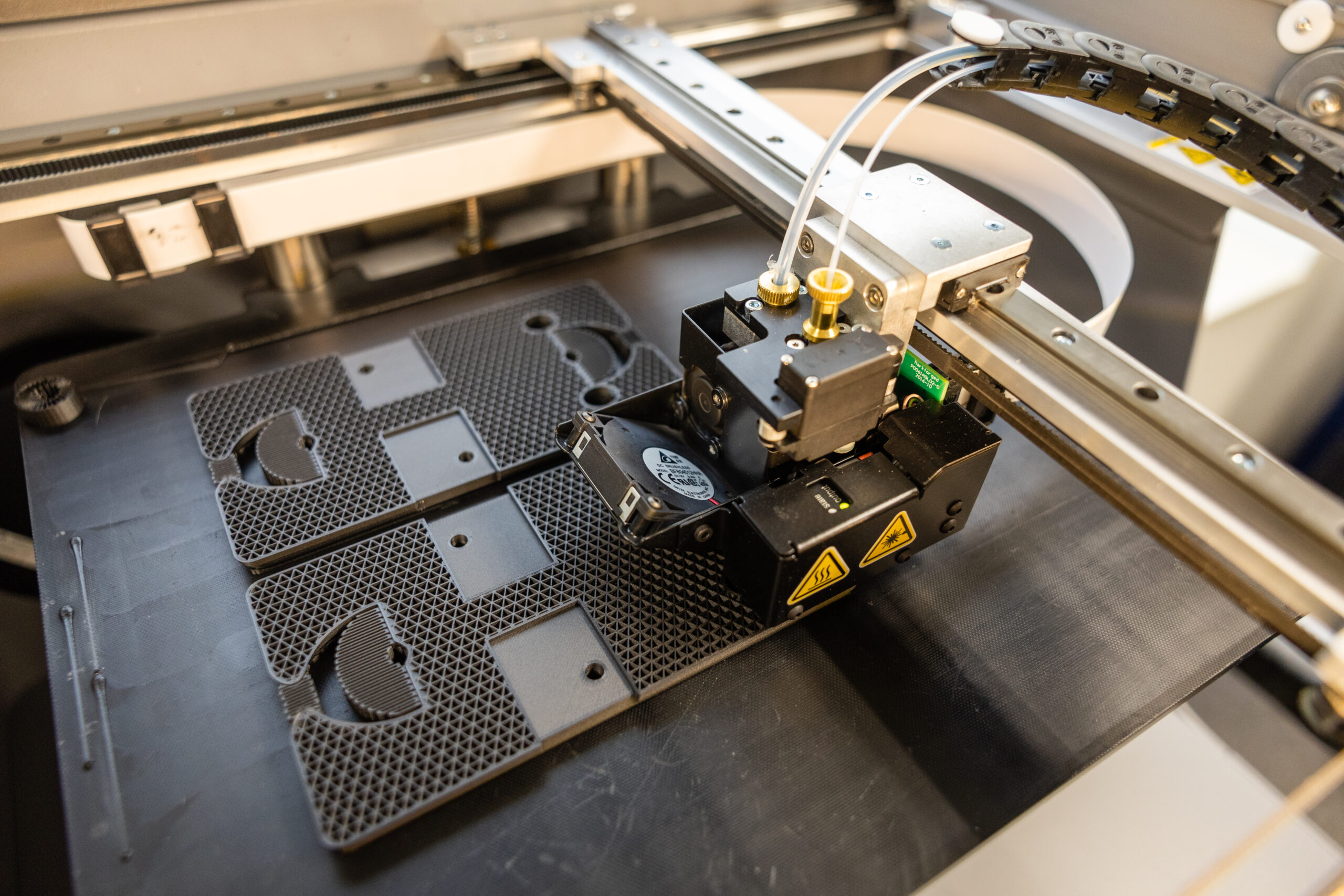

Precision Metal 3D Printing with DMLS Technology

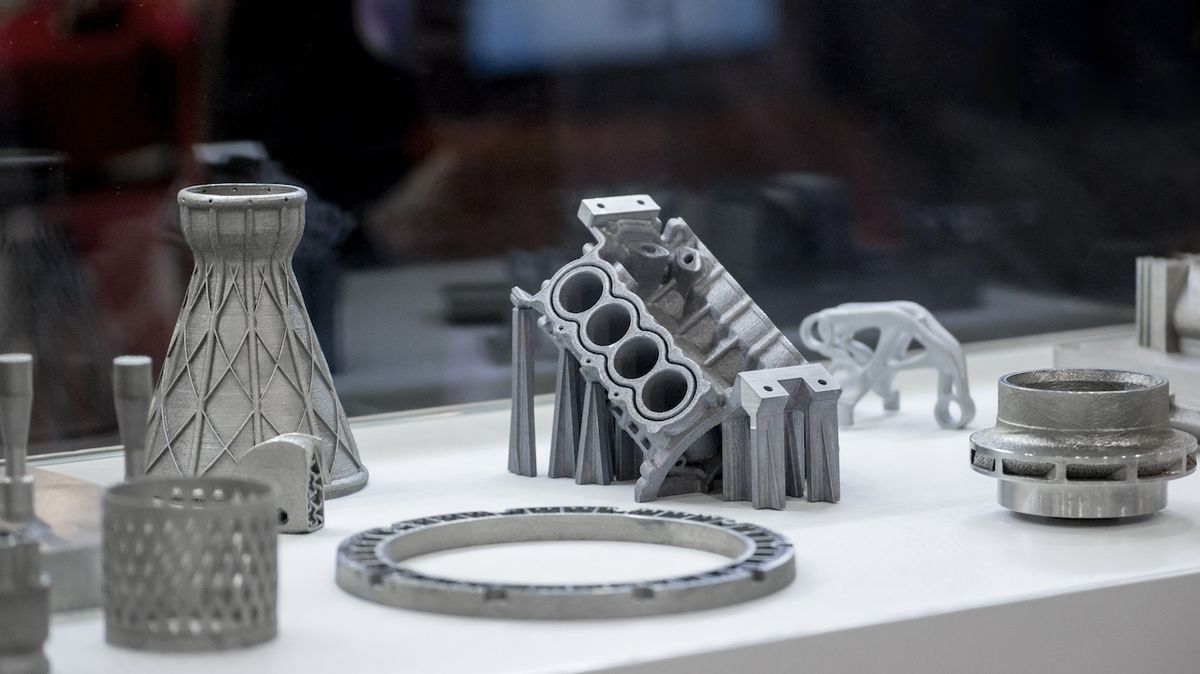

Unmatched Design Freedom for Complex Parts

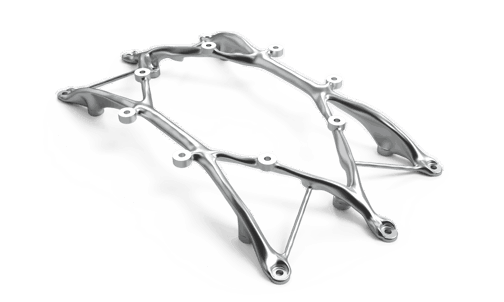

Create intricate geometries impossible with traditional machining (internal channels, lattice structures, organic shapes)

Eliminate tooling costs and lead times – iterate designs in days, not weeks

Lightweight components with optimized topology for performance

AI-Powered Instant Quote & Rapid Turnaround

Upload CAD files for real-time pricing in seconds – no manual quotes

AI-driven DFM analysis optimizes part orientation, support structures, and cost

Prototypes delivered in 5 business days; production runs scaled seamlessly

Dedicated project manager for seamless execution

Scalable Production from 1 to 10,000+ Parts

Cost-effective for low-volume runs with no minimum order quantities

Seamless transition from prototype to high-volume production

No tooling investments – pay only for the parts you need

ISO 9001 Certified Quality Assurance

Certified materials (Ti64, 316L Stainless, AlSi10Mg, Inconel 718)

Rigorous in-process and final inspection protocols

Post-processing options (polishing, heat treatment, coating) for final quality

Materials & Surface Finishes

Material Options & Finishes for Industrial Metal 3D Printing

Material Options

Plastic & Resin Materials

ABS-like: Durable, cost-effective for functional prototypes requiring impact resistance and moderate heat tolerance.

Nylon PA12: High strength, flexibility, and chemical resistance—ideal for living hinges, gears, and complex geometries.

Metal Materials (DMLS Technology)

Stainless Steel 316L: Exceptional corrosion resistance for medical implants, marine components, and chemical processing equipment.

Titanium Grade 5 (Ti6Al4V): High strength-to-weight ratio and biocompatibility—perfect for aerospace components and surgical tools.

Aluminum 6061: Lightweight with excellent thermal conductivity—ideal for heat exchangers, automotive brackets, and electronics housings.

Inconel 718: Superior high-temperature strength and oxidation resistance—used in jet engines, gas turbines, and nuclear applications.

Surface Finishing Options

For Plastic Parts

Painting: Custom color matching for aesthetic prototypes.

Polishing: Smooth, glossy finish for visual models or consumer-facing parts.

Vapor Smoothing: Seamless surface finish for improved fluid dynamics in resin-based parts.

For Metal Parts

Electropolishing: Removes surface imperfections and enhances corrosion resistance (Ra < 0.4µm) for medical-grade stainless steel or titanium.

Sandblasting: Uniform matte finish; ideal for removing support structures and preparing surfaces for coatings.

Anodizing (Aluminum only): Adds wear resistance and vibrant color options for outdoor or decorative components.

Powder Coating: Durable, UV-resistant finish for metal parts exposed to harsh environments.

CNC Machining: Precision post-processing for tight tolerances (±0.025mm) on critical features.

How to Choose the Right Material for Metal 3D Printing

Match Performance to Application:

Need extreme heat resistance? Inconel 718 outperforms stainless steel in jet engine components.

Prioritizing weight savings? Titanium Grade 5 delivers 40% lighter parts than steel without sacrificing strength.

Consider Environmental Factors:

Marine or chemical exposure? Stainless Steel 316L resists saltwater corrosion better than standard alloys.

Biocompatibility required? Titanium Grade 5 meets ISO 13485 standards for medical implants.

Balance Cost and Functionality:

Aluminum 6061 offers 50% lower material costs than titanium for non-critical aerospace brackets.

Stainless Steel 316L provides robustness at 30% lower cost than titanium for non-implant medical devices.

Optimize Post-Processing:

Electropolishing is essential for surgical tools to eliminate microscopic burrs.

Powder coating extends the lifespan of outdoor metal components exposed to UV and moisture.

Why Honyo Prototype Accelerates Your Metal Prototyping

Online Instant Quote:

Get accurate pricing and feasibility feedback in seconds—no manual calculations. Our platform instantly analyzes geometry complexity, material requirements, and lead times.

AI-Powered Optimization:

Our smart system recommends the optimal material, orientation, and support structure to minimize costs while maximizing performance—no engineering guesswork.

Fast Turnaround:

Shenzhen-based production with 3–5 day lead times on metal parts—prototype faster and iterate smarter without sacrificing quality.

“Complex geometries? We’ve got you covered. From aerospace brackets to medical implants, Honyo’s DMLS technology turns your toughest designs into reality—faster and smarter than traditional manufacturing.”

— Susan Leo, Founder of Honyo Prototype

From Quote to Part: Our Process

Seamless CAD-to-Part Workflow: Precision, Speed, Transparency

At Honyo Prototype, we’ve redefined metal 3D printing with an end-to-end digital workflow designed for speed, transparency, and innovation. Our AI-powered platform eliminates traditional bottlenecks, delivering high-quality metal parts with unprecedented efficiency.

1. Upload Your CAD File in Seconds

Zero friction: Submit STEP, STL, OBJ, or IGES files via our secure cloud portal—no software required.

IP protection: Military-grade encryption ensures your designs stay confidential.

Instant validation: AI checks file integrity and compatibility before processing.

2. Instant AI-Powered Quote in Under 60 Seconds

Real-time pricing: Get accurate quotes for DMLS metal printing with transparent breakdowns (material like 316L stainless steel, Ti64 titanium, or Inconel 718; build time; supports; post-processing; shipping).

No manual quotes: Our AI analyzes geometry complexity, material requirements, and production constraints instantly.

Cost optimization tips: See how design tweaks can reduce costs before production begins.

3. Engineer-Verified DFM Analysis

Metal-specific checks: Automated validation for thermal stress, support structure efficiency, powder removal channels, and minimum wall thickness.

Expert recommendations: Our engineers provide actionable insights to enhance part strength, reduce material waste, and accelerate turnaround.

Collaborative platform: Revise designs in real-time with our team—no back-and-forth delays.

4. Rapid Production & Delivery

Industry-leading speed: DMLS metal prototypes delivered in 3–5 business days; production batches in 7–10 days (with expedited options available).

Precision quality control: ISO 9001-certified inspections for dimensional accuracy, surface finish, and mechanical properties.

Global tracking: Real-time shipment updates from our Shenzhen facility to your location worldwide—no surprises, no delays.

💡 Why Honyo?

While competitors charge $50K–$1M+ for metal printers, we leverage industrial-grade DMLS systems with zero upfront investment for you. Our AI-driven platform cuts lead times by 40% vs. traditional manufacturers—so you iterate faster, fail fast, and launch smarter.

Ready to transform your metal part design?

Get your instant quote in 60 seconds → Upload Now

Start Your Project with Honyo

Start Your Project with Honyo

Precision Metal Printing, Engineered for Innovation

Online Instant Quote: Get real-time pricing for metal parts via our AI-driven platform—accurate, transparent, and ready in seconds. No manual quotes, no delays.

AI-Powered Design Optimization: Refine your geometry for DMLS manufacturing to minimize material waste, enhance structural integrity, and slash production timelines.

Fast Turnaround: Deliver metal prototypes in as little as 3 days from our Shenzhen/Dongguan facilities—perfect for agile hardware development cycles.

Let’s Build the Future Together

Founder Susan Leo and our expert engineering team are ready to transform your vision into high-performance metal parts. Contact us today:

Email: [email protected]

Phone: +86 139 2843 8620

Visit: Shenzhen and Dongguan facilities for collaborative innovation and hands-on support

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.