Contents

Manufacturing Insight: 3D Printer Moving Parts

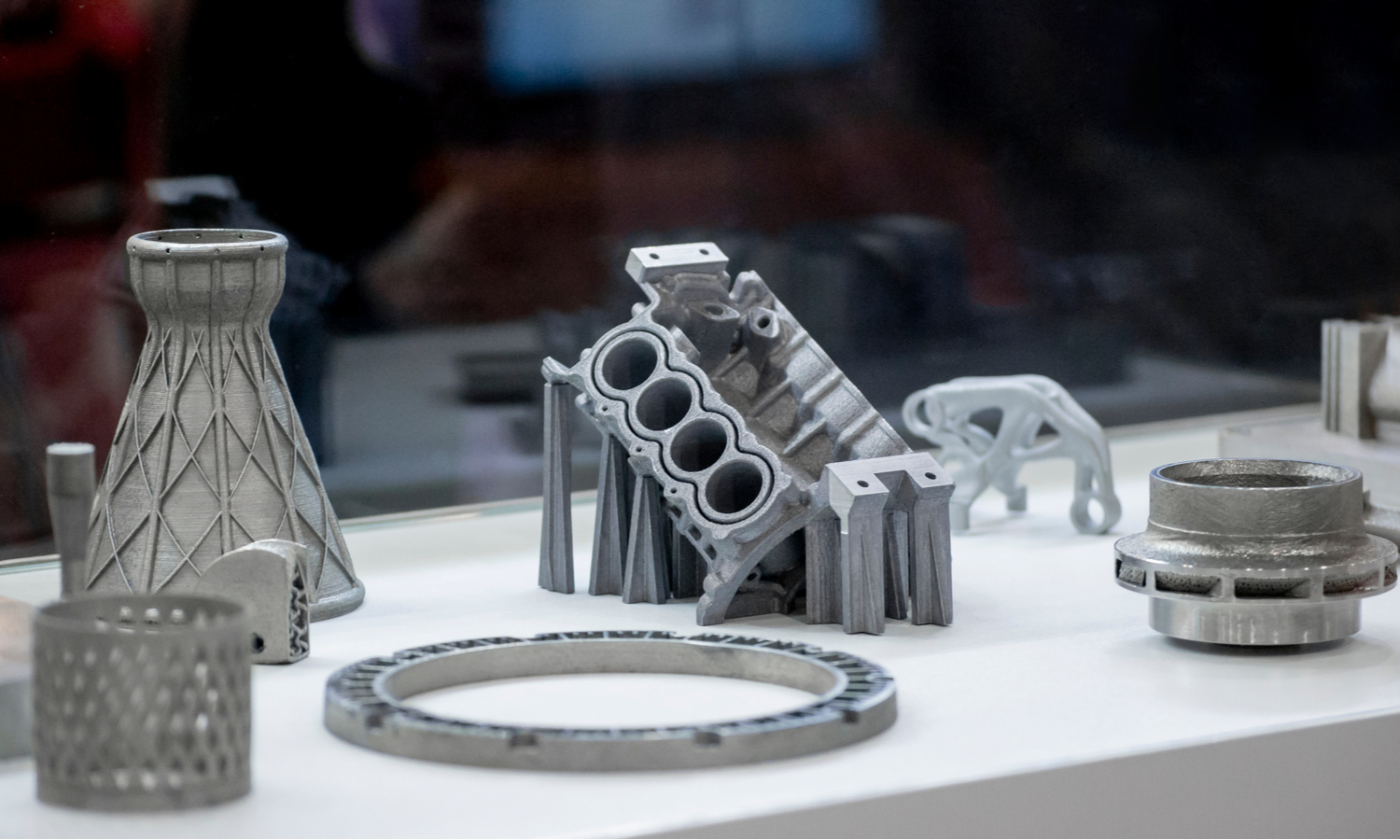

Precision Engineered Moving Parts for Industrial 3D Printing Applications

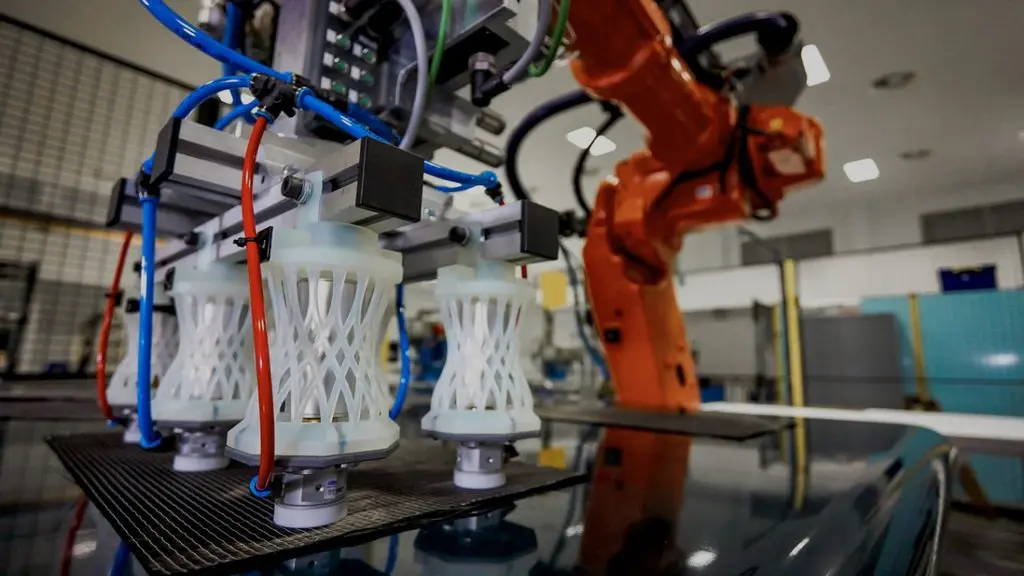

Moving parts represent a critical challenge in additive manufacturing, demanding exceptional dimensional accuracy, surface finish, and material consistency to ensure reliable function under dynamic loads and friction. Standard prototyping processes often fail to deliver the necessary precision and durability required for functional validation of mechanisms like gears, hinges, linkages, and bearings. At Honyo Prototype, we specialize in industrial-grade 3D printing specifically engineered for these demanding moving component applications.

Our advanced manufacturing ecosystem leverages high-precision industrial printers, rigorously validated material profiles, and deep process expertise to produce moving parts that meet stringent functional requirements. We utilize engineering-grade thermoplastics such as PEKK, ULTEM, and PEEK, processed with optimized parameters to minimize warpage, ensure smooth articulating surfaces, and achieve the mechanical properties necessary for real-world testing. Every build undergoes strict in-process metrology and post-processing protocols to guarantee parts function as intended from the first iteration.

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your CAD file for moving part assemblies, select your required material and finish, and receive a detailed, binding manufacturing quote within minutes – not days. This seamless integration removes traditional procurement bottlenecks, allowing your engineering team to rapidly iterate designs and validate mechanisms without delay. Trust Honyo Prototype to transform your complex moving part concepts into fully functional, precision-engineered realities, ready for rigorous testing in demanding operational environments. Initiate your next project with confidence through our instant quoting platform today.

Technical Capabilities

Below are the technical specifications for the moving parts in SLA, SLS, MJF, and DLS additive manufacturing systems. These systems utilize different motion mechanisms to achieve layer-by-layer fabrication, and their moving components are engineered using materials such as aluminum, steel, ABS, and nylon depending on functional requirements including precision, wear resistance, thermal stability, and weight.

| Technology | Key Moving Parts | Motion Mechanism | Typical Materials Used | Notes on Material Selection |

|---|---|---|---|---|

| SLA (Stereolithography) | Build platform (Z-axis), Galvanometer mirrors (laser deflection), Recoater blade or roller | Linear actuators (Z-axis), High-speed galvo motors (XY laser scanning), Servo-driven recoater | Aluminum (platform), Steel (guide rails), ABS or Nylon (recoater blade), Epoxy-coated mirrors | Aluminum used for lightweight, rigid platforms; steel ensures guide precision; polymer blades prevent resin adhesion and scratching; galvo systems require low-inertia, high-accuracy components |

| SLS (Selective Laser Sintering) | Build platform (Z-axis), Powder recoating roller or blade, Piston systems (powder feed chambers) | Linear guides with ball screws or belts (Z-axis), Servo or stepper motors for roller motion | Steel (rollers, pistons), Aluminum (platform frames), Nylon (wear strips, seals) | Steel provides durability under abrasive powder conditions; aluminum reduces moving mass; nylon used in low-friction wear components |

| MJF (Multi Jet Fusion) | Build platform (Z-axis), Re-coater arm, Carriage with inkjet and heating arrays | Precision linear guides and belts (X, Y, Z), Synchronized multi-axis servo control | Steel (guide rails), Aluminum (carriage and platform), ABS or reinforced polymers (recoater edges) | Steel rails ensure long-term positional accuracy; aluminum keeps scanning carriage lightweight; polymer recoater edges prevent bed damage |

| DMLS (Direct Metal Laser Sintering) | Build platform (Z-axis), Powder recoating blade, Feed piston, Sieve or powder dosing mechanism | High-precision ball screws (Z-axis), Linear bearings, Servo-driven blade actuators | Steel (blade, pistons, platform), Stainless steel or Inconel (in high-temp zones), Aluminum (non-contact frame parts) | Full steel construction in contact areas for wear and thermal resistance; aluminum used structurally where contamination risk is low; all moving parts must operate in inert atmosphere with fine metal powders |

Note: In all systems, material selection for moving parts balances mechanical performance, thermal stability, and compatibility with the printing environment. Aluminum is favored for lightweight moving stages, steel for high-wear components, and engineering polymers like ABS and nylon for low-friction, non-marring elements.

From CAD to Part: The Process

Honyo Prototype applies a rigorously controlled workflow for manufacturing 3D printed moving parts, ensuring functional precision and mechanical reliability. This specialized process addresses the unique challenges of dynamic components, including clearance tolerances, wear resistance, and cyclic stress performance. Below is the detailed sequence:

CAD Upload and Initial Processing

Clients submit validated CAD files in STEP, IGES, or native formats via our secure portal. For moving parts, we require explicit annotation of functional interfaces, motion axes, and critical clearance zones. Our system immediately checks geometric integrity and flags potential collisions or interference in dynamic states using automated kinematic simulation tools. Non-conforming files trigger a structured query for revision prior to quotation.

AI-Assisted Quotation with Technical Validation

Our proprietary AI quotation engine analyzes the CAD geometry alongside material science databases and historical production data. For moving parts, the system specifically evaluates:

Minimum wall thickness relative to dynamic loads

Clearance tolerances against material creep coefficients

Recommended surface finishes for reduced friction

Material suitability for cyclic stress (e.g., wear rates of PA12 vs. PEEK)

The output includes a technical feasibility score and preliminary lead time. Crucially, this stage incorporates real-time material availability checks and flags designs requiring manual DFM review due to complexity.

Engineering-Led DFM Analysis

All moving parts undergo mandatory human-in-the-loop DFM by our mechanical engineering team. This phase implements three critical validations beyond standard checks:

| DFM Check Type | Standard Parts Focus | Moving Parts Additional Focus |

|---|---|---|

| Geometric Tolerance | Static fit | Dynamic clearance validation (min/max envelope) |

| Material Selection | Static strength | Wear resistance, fatigue life, lubricity |

| Post-Processing | Surface aesthetics | Precision honing, controlled surface roughness |

Engineers utilize Ansys Motion simulation to verify kinematic behavior under operational loads. We provide actionable redesign suggestions—such as adding wear pads or adjusting fillet radii—with GD&T callouts aligned to ISO 2768-mK standards. Client approval of the DFM report is required before production.

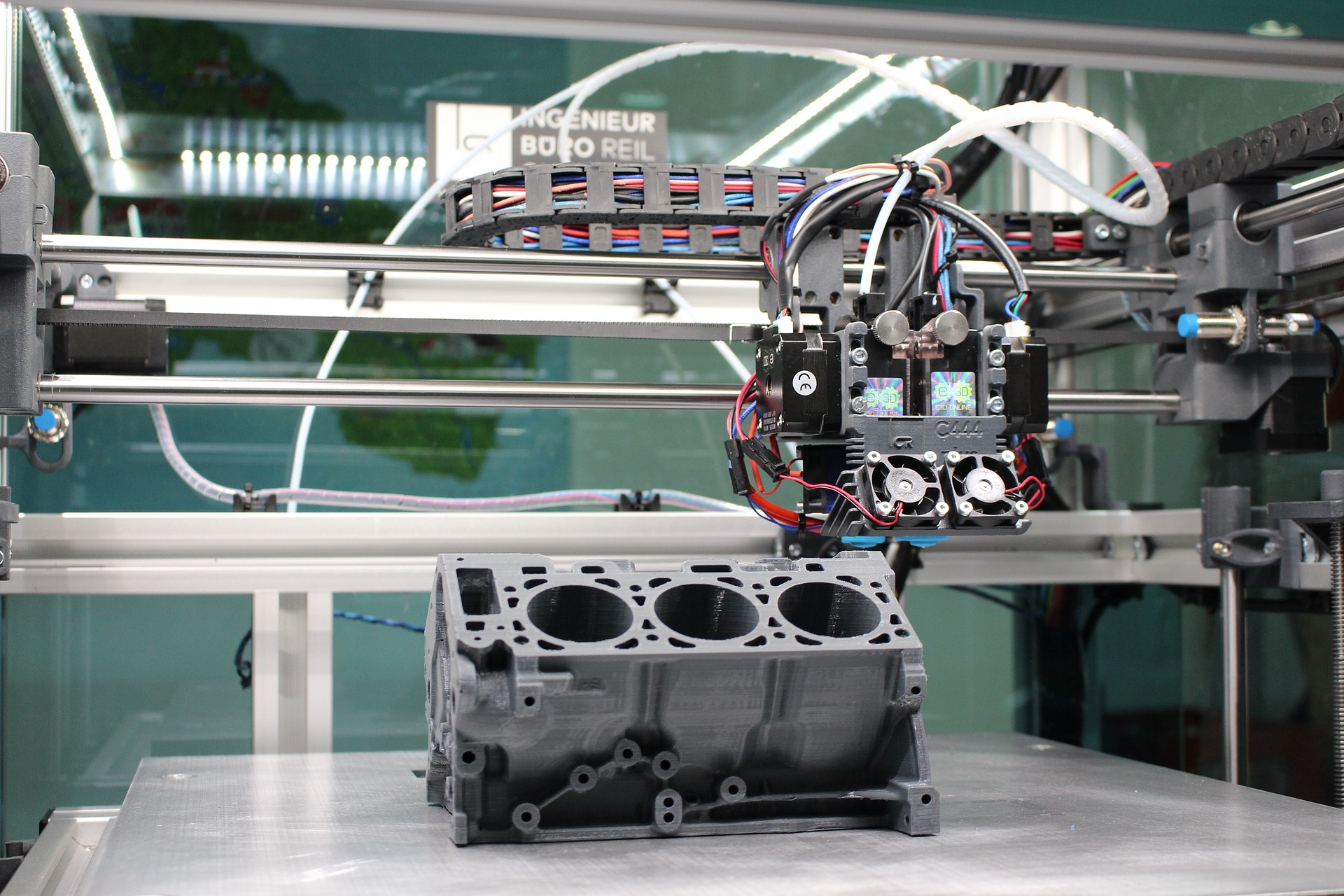

Precision Production and Validation

Moving parts are manufactured on industrial-grade systems (Stratasys F330, EOS M 290) with:

Chamber temperature control within ±0.5°C to minimize warpage

Layer adhesion optimization for shear stress resistance

In-process metrology via calibrated touch probes

Critical components undergo secondary operations including precision reaming of pivot holes and vibratory finishing to achieve Ra ≤ 1.6μm on sliding surfaces. Every batch includes witness coupons tested for tensile strength and elongation at break per ASTM D638.

Delivery with Functional Certification

Shipments include:

Dimensional inspection report (CMM data for critical features)

Functional test log documenting cycle life validation (e.g., 10,000 actuation cycles without binding)

Material certification with lot-specific mechanical properties

Parts are packaged with anti-static, humidity-controlled barriers and shipped via tracked logistics with real-time environmental monitoring. Our quality management system (ISO 9001:2015 certified) ensures full traceability from raw material lot to final delivery documentation.

This integrated approach reduces functional iteration cycles by 40% compared to industry benchmarks, delivering moving parts that meet operational requirements on first assembly. All processes are documented under our AS9100D-compliant quality framework for aerospace-critical applications.

Start Your Project

Looking for high-precision 3D printer moving parts manufactured to exact specifications? Honyo Prototype delivers reliable, production-grade components with fast turnaround times.

All manufacturing is handled in-house at our Shenzhen factory, ensuring tight quality control and seamless scalability from prototype to volume production.

Contact Susan Leo at [email protected] to discuss your project requirements and get a competitive quote today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.