Contents

Manufacturing Insight: 3D Printed Steel

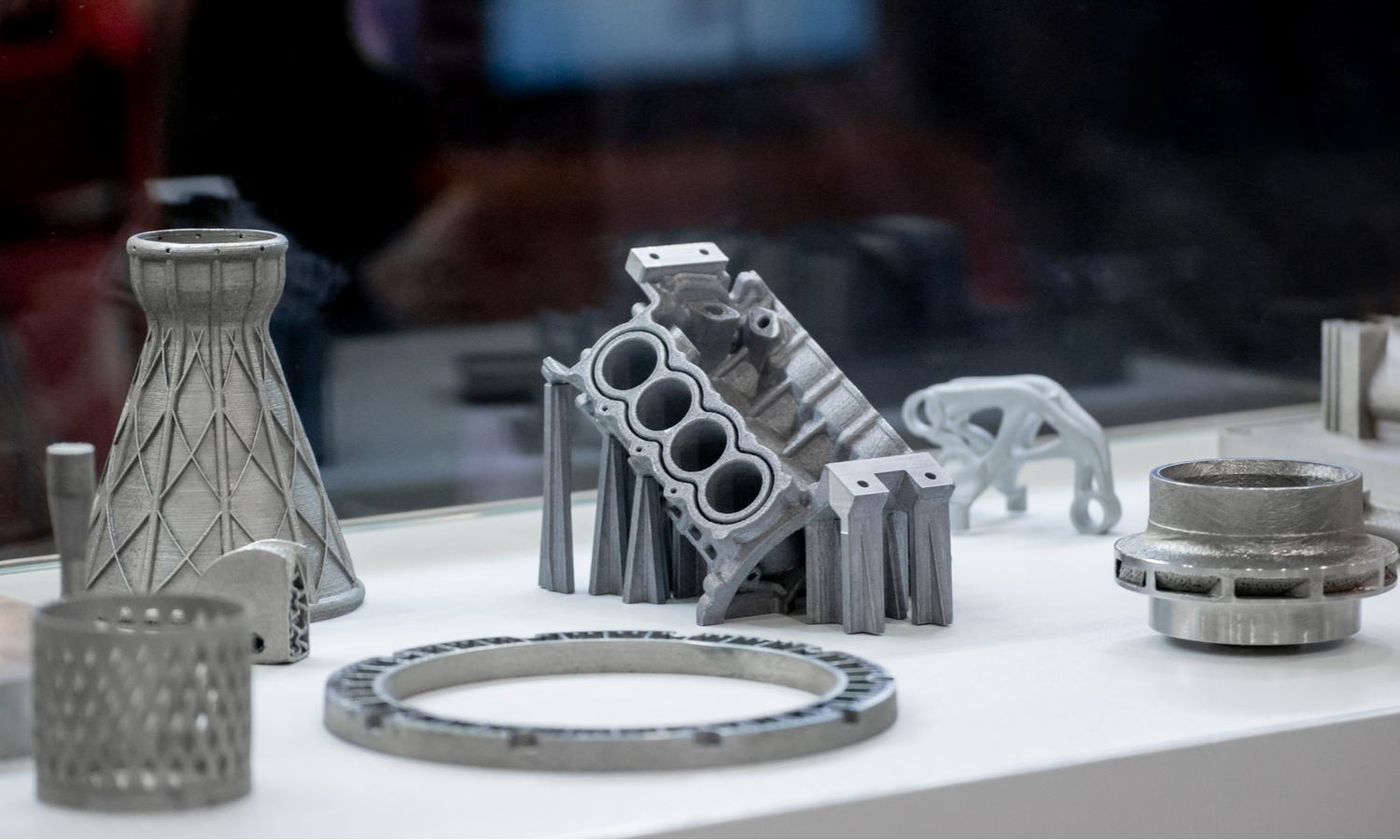

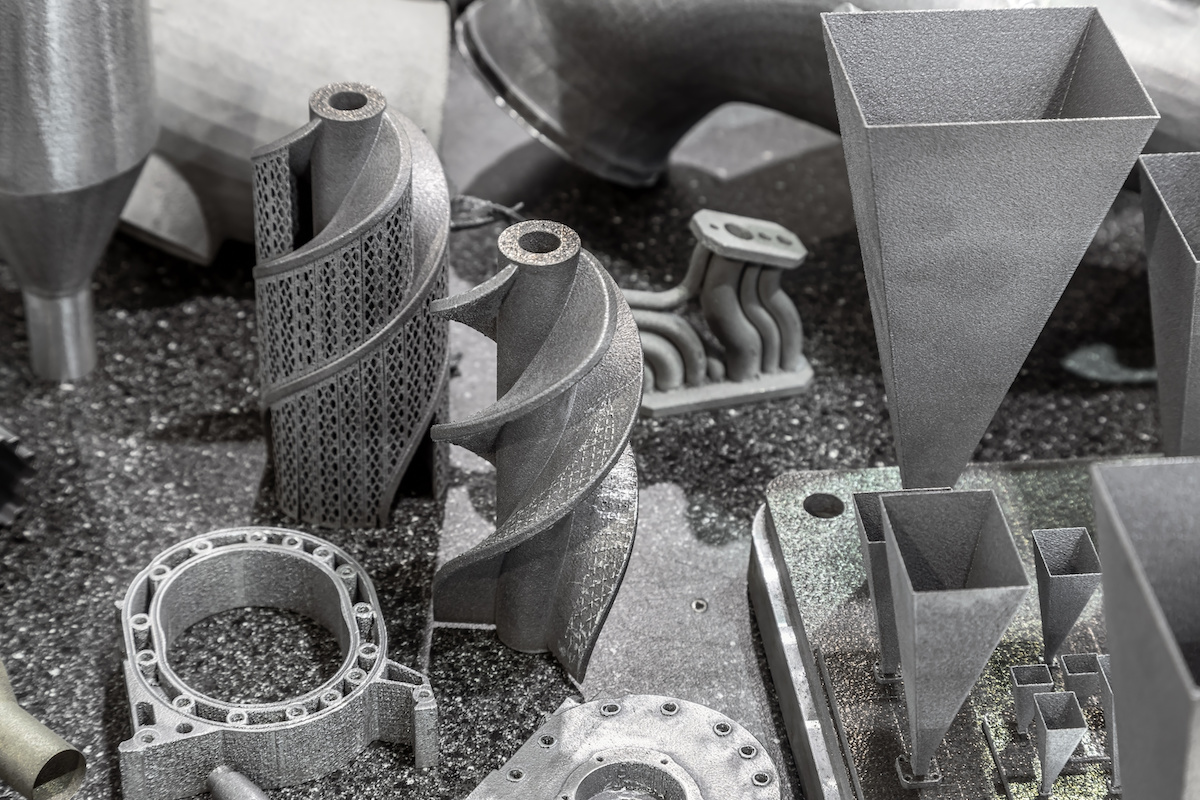

Precision Steel Components Through Industrial 3D Printing

Honyo Prototype delivers mission-critical steel components via advanced industrial 3D printing, transforming complex design concepts into high-performance, end-use parts. Our metal additive manufacturing processes, specifically optimized for engineering-grade stainless and tool steels, overcome traditional fabrication limitations by enabling intricate geometries, consolidated assemblies, and topology-optimized structures impossible with machining or casting. This capability directly addresses industry pain points in aerospace, medical device, and industrial machinery sectors where weight reduction, fluid dynamics, and part consolidation are paramount.

We operate certified industrial metal systems under stringent environmental controls, ensuring repeatable material properties, tight tolerances, and full traceability from powder to finished component. Our engineering team provides deep Design for Additive Manufacturing (DfAM) expertise, guiding clients from initial concept validation through post-processing and rigorous quality assurance to achieve parts engineered for real-world performance and regulatory compliance.

Accelerate your path from design to production with Honyo’s seamless workflow. Our Online Instant Quote platform provides transparent, real-time cost and lead time estimates for steel 3D printing projects within minutes, eliminating procurement delays. Simply upload your CAD file to immediately evaluate feasibility and budgetary requirements for industrial-scale metal additive manufacturing.

| Fabrication Challenge | Traditional Method Limitation | Honyo Steel 3D Printing Solution |

|---|---|---|

| Complex Internal Channels | Cost-prohibitive tooling, assembly required | Single-piece construction, optimized flow paths |

| Lightweight Structural Components | Material waste, strength-to-weight trade-offs | Generative design, topology optimization |

| Low-Volume Tooling | Long lead times, high unit costs | Rapid production, part consolidation |

Technical Capabilities

SLA, SLS, MJF, and DMLS are additive manufacturing technologies commonly used in prototyping and production, but not all support steel or metal materials. Below is a technical overview of each process with respect to material compatibility, particularly focusing on steel, aluminum, ABS, and nylon. Note that SLA does not support metal printing and is primarily used for photopolymers, so true “3D printed steel” is not achievable via SLA.

| Technology | Full Name | Compatible Materials | Steel Capability | Aluminum Capability | ABS Capability | Nylon Capability | Key Technical Notes |

|---|---|---|---|---|---|---|---|

| SLA | Stereolithography | Photopolymer resins (e.g., standard, tough, castable, high-temp) | No | No | No | No | Uses UV laser to cure liquid resin layer by layer. High resolution and surface finish. Not suitable for metals or engineering thermoplastics like ABS or nylon. |

| SLS | Selective Laser Sintering | Nylon-based powders (e.g., PA11, PA12, glass-filled nylon), TPU | No | No | No | Yes | Uses CO₂ laser to sinter polymer powder. Excellent for functional nylon parts with good mechanical properties. No metal support. |

| MJF | Multi Jet Fusion | Primarily PA11 and PA12 nylon powders, some composites | No | No | No | Yes | Inkjet array deposits fusing and detailing agents, then heated by thermal source. High throughput and consistent mechanical properties. Limited to polymers. |

| DMLS | Direct Metal Laser Sintering | Stainless steel (e.g., 316L, 17-4 PH), tool steel, aluminum (e.g., AlSi10Mg), titanium, Inconel | Yes | Yes | No | No | High-power laser sinters metal powder layer by layer. Suitable for fully dense metal parts with high strength. Used in aerospace, medical, and tooling. Requires post-processing (stress relief, HIP, machining). |

Key Clarifications:

DMLS is the appropriate technology for 3D printing steel and aluminum components. SLS and MJF are polymer-based and support nylon but not metals or ABS. SLA is resin-based and incompatible with all listed engineering materials except in specialty filled resins that mimic metal or nylon properties, but these are not true metal or thermoplastic materials. ABS is typically processed via FDM (Fused Deposition Modeling), not any of the listed technologies.

From CAD to Part: The Process

Honyo Prototype delivers precision 3D printed steel components through a tightly integrated digital workflow designed for engineering-grade metal parts. Our process begins when a client uploads a native CAD file (STEP, IGES, or Parasolid formats preferred) to our secure customer portal. This triggers our proprietary AI-driven quoting system which analyzes geometric complexity, material requirements, build orientation, support structure needs, and post-processing scope against real-time machine availability and material costs. The AI generates a preliminary quote with cost breakdown and estimated lead time within 90 minutes, though complex geometries may require 4 business hours for full assessment.

Following quote acceptance, the Design for Manufacturing (DFM) phase commences under direct supervision of our AM engineering team. This is not an automated step—we conduct manual review to optimize part orientation, support structures, and thermal management strategies specific to steel alloys like 17-4 PH stainless, 316L, or Inconel 718. Critical considerations include mitigating residual stress in thin walls, ensuring proper overhang angles below 45 degrees, and validating minimum feature sizes against our laser powder bed fusion capabilities. Clients receive a formal DFM report with actionable recommendations and tolerance validation within 72 business hours, with optional virtual engineering consultations available.

Production leverages our industrial-grade metal additive systems operating under strict NADCAP-accredited protocols. Key build parameters for steel components include:

| Parameter | Specification |

|---|---|

| Layer Thickness | 20-50 μm (alloy dependent) |

| Build Envelope | Up to 500 x 500 x 500 mm |

| Laser Power | 500-1000 W |

| Atmosphere | Argon with <100 ppm O₂ |

| Post-Processing | Stress relief, HIP, machining per drawing |

All steel builds undergo in-process monitoring with melt pool sensors and layer-wise thermal imaging. Post-build, parts proceed through our certified finishing sequence: base plate separation via wire EDM, support removal, hot isostatic pressing (HIP) for critical applications, precision machining of critical features, and final surface treatment per ASTM F3055 standards. Dimensional inspection uses 5-axis CMM with GD&T validation against the original CAD model.

Delivery includes comprehensive traceability documentation: material certs with full chemical analysis, build parameter logs, NDT reports (if specified), and first-article inspection data. Parts ship in anti-corrosion packaging with humidity indicators, typically within 10-15 business days from DFM approval for standard steel builds. Expedited options down to 5 days are available for qualifying geometries. Every shipment meets AS9100D requirements with full revision-controlled records accessible through our client portal for 7 years. For mission-critical steel components, we recommend initiating the process with a pre-production DFM consultation to optimize cost and performance. Contact our engineering team directly for alloy-specific capability details.

Start Your Project

Looking to leverage the strength and precision of 3D printed steel for your next project? Honyo Prototype delivers high-quality, industrial-grade 3D printed steel components with fast turnaround times, directly from our advanced manufacturing facility in Shenzhen.

For expert support and project inquiries, contact Susan Leo at [email protected]. Let us help you turn your designs into durable, production-ready parts.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.