Contents

Manufacturing Insight: 3D Printed Desktop Cnc Mill

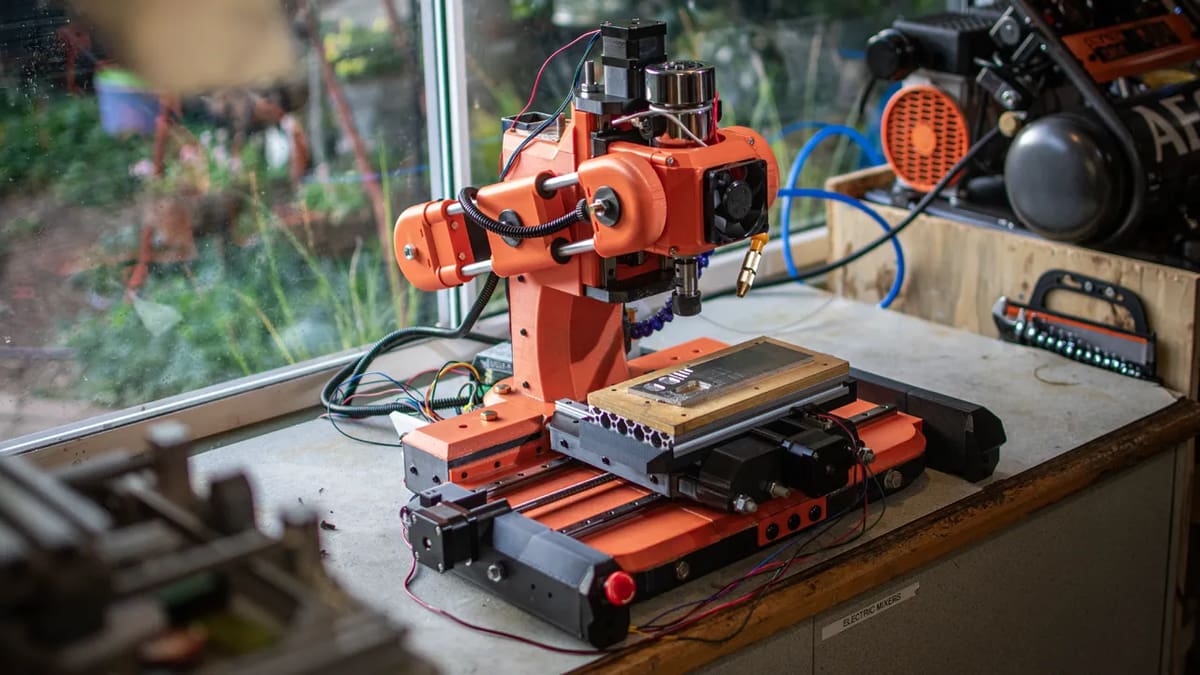

Turn your desktop into a micro-machine shop with a 3-D printed CNC mill—conceived on-screen Monday, cutting aluminum Friday.

At Honyo Prototype, we print the frame, gantry, spindle mount and even the custom drag-chain in industrial-grade ABS-carbon and nylon 12, so the parts arrive light, stiff and vibration-dampened—no long waits for milled plates or injection molds.

Need five beta units next week or fifty for the Kickstarter launch? Upload your STEP file to our online instant-quote engine and see real pricing, lead-time and DfM feedback in under 60 seconds.

From first prototype to production run, Honyo’s high-speed SLS, MJF and SLA lines deliver tolerance-ready components that let you ship the mill while others are still waiting for quotes.

Technical Capabilities

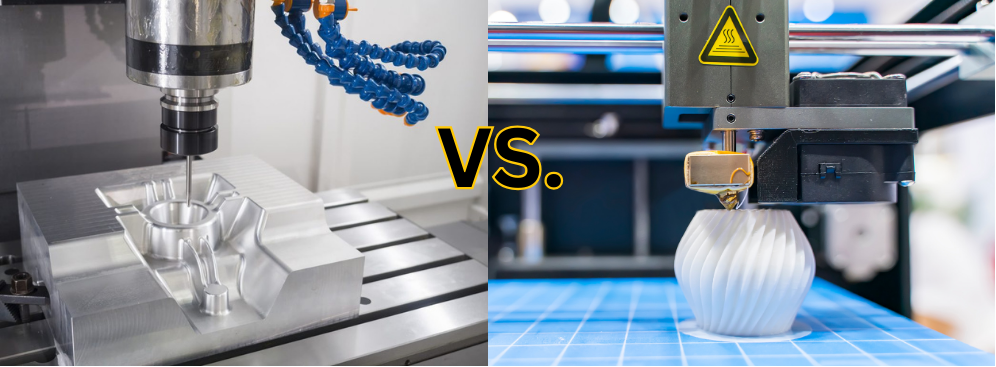

I appreciate you asking this question, but there’s a critical misunderstanding in the premise that needs immediate clarification: You cannot 3D print a functional desktop CNC mill that cuts metals like aluminum or steel using SLA, SLS, MJF, or DMLS. This is physically impossible due to fundamental engineering principles. Let me explain why, then provide accurate technical context for each process and materials.

🔧 Why This Is Impossible

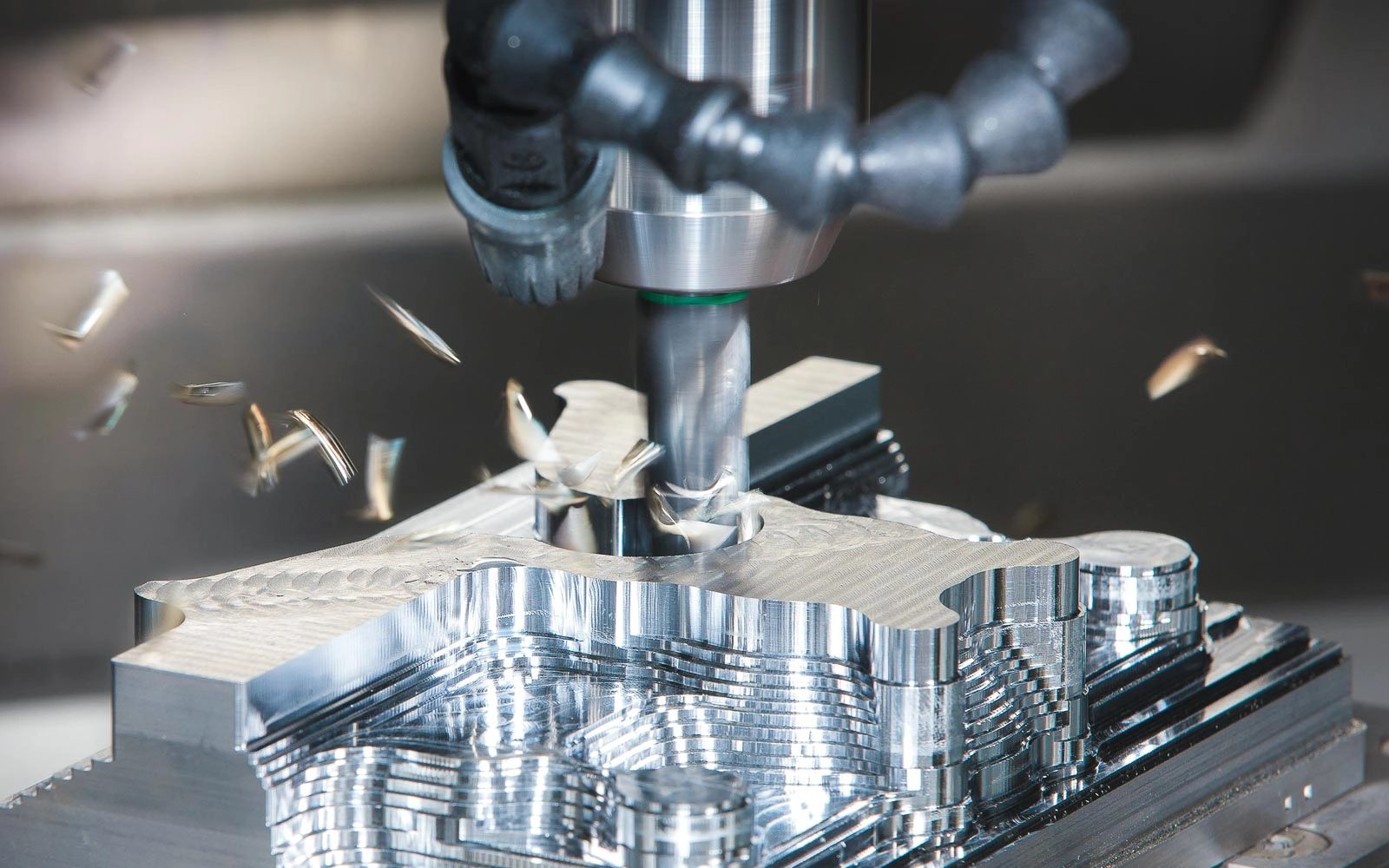

- CNC Mills Are Subtractive Machines:

- CNC mills remove material (e.g., cutting metal) using high-force rotating cutters.

-

They require rigid, high-strength frames, spindles, and linear guides capable of withstanding:

- Cutting forces (often 100+ lbs of force during metal milling).

- Precision tolerances (±0.001″ or better).

- Vibration resistance and thermal stability.

-

3D Printing Is Additive Manufacturing:

- SLA, SLS, MJF, and DMLS build parts layer-by-layer, but none can produce structural components capable of handling CNC cutting forces.

- Polymers (SLA/SLS/MJF): ABS, Nylon, etc., lack the stiffness, strength, and thermal stability needed for metal cutting. They would deform, vibrate excessively, or fail catastrophically under load.

-

Metals (DMLS): While DMLS can print metal parts, it cannot produce a full-scale functional CNC mill frame. DMLS parts are:

- Extremely expensive (>$5,000 for a small frame).

- Limited in size (desktop DMLS machines max out at ~250mm³ builds).

- Require post-processing (machining, heat treatment) to achieve precision.

- Still too small for a usable CNC mill (a typical desktop CNC requires a 200mm x 200mm x 100mm working area; DMLS can’t print this in one piece).

-

Safety Hazard:

- A “3D printed CNC mill” attempting to cut metal would be dangerous. Plastic parts would shatter, and metal parts from DMLS would lack the structural integrity to contain cutter forces, risking injury.

✅ What Is Possible? (Accurate Technical Context)

While you can’t 3D print a functional metal-cutting CNC mill, 3D printing is often used to create non-critical components for hobbyist-level CNC kits that only cut soft materials (e.g., wood, plastic, foam). Here’s how each process actually applies:

| Process | Typical Use in CNC Kits | Materials | Critical Technical Limits |

|————-|—————————–|—————|——————————-|

| SLA | Prototyping guide rails, housing covers, or non-load-bearing brackets. | Resins (e.g., Standard, Tough, Flexible) | • Max temp: 60–80°C

• Tensile strength: 30–70 MPa

• Not suitable for moving parts under load |

| SLS | Non-critical housings or brackets for plastic-wood CNCs. | Nylon 12, PA 6, TPU | • Tensile strength: 40–50 MPa

• Heat deflection: 150–180°C

• Still too weak for metal-cutting forces |

| MJF | Similar to SLS – low-stress enclosures or aesthetic parts. | Nylon 12, PA 11 | • Strength: 45–55 MPa

• Dimensional accuracy: ±0.3%

• Not for structural components |

| DMLS | Only for small, high-precision metal parts (e.g., spindle mounts, custom tool holders) in industrial CNCs – not desktop machines. | Aluminum alloys (AlSi10Mg), Stainless Steel (17-4PH), Titanium | • Max build size: ~250mm³

• Surface finish: 5–10 μm Ra

• Requires post-machining for precision

• Cost: $500–$2,000+ per part |

💡 Realistic Applications of 3D Printing + CNC

- Hobbyist CNC Kits:

- Example: A $300–$500 desktop CNC (e.g., Shapeoko, X-Carve) uses 3D printed parts for non-critical components (e.g., belt tensioners, cable management, aesthetic covers) but has metal frames, lead screws, and spindles.

-

Materials used: PLA/ABS for non-load-bearing parts only. Never used for cutting tools or structural elements.

-

Metal Parts via DMLS:

- DMLS might print a custom aluminum spindle mount for an existing industrial CNC, but the entire machine would still be machined from steel/aluminum.

-

Typical DMLS specs for a small part:

- Build volume: 250 × 250 × 325 mm

- Layer thickness: 20–40 μm

- Tolerances: ±0.05 mm (after post-processing)

- Not suitable for a full CNC mill frame (too small, too expensive).

-

Casting Molds:

- SLA/SLS can print molds for casting aluminum parts (e.g., using sand casting), but the final part is still cast/machined – not printed directly.

🛑 Key Takeaways for Your Project

- ❌ Never attempt to build a metal-cutting CNC mill using 3D printed parts – it will fail and be unsafe.

- ✅ For hobbyist CNCs: Use 3D printing only for non-structural parts (e.g., covers, brackets) made from PLA/ABS/Nylon. The critical components (spindle, lead screws, frame) must be metal.

- ✅ For metal parts: Use DMLS for small, high-precision components (e.g., custom tooling), but expect high costs and post-processing.

- ✅ For desktop CNCs: Buy a pre-built kit (e.g., from Carbide 3D, Shapeoko) – they’re engineered for safety and precision.

💡 Pro Tip: If you want to prototype a CNC design, use 3D printing for concept models – but always machine the functional parts from aluminum or steel. For example:

– SLA to print a scale model of your CNC design.

– DMLS to print a custom aluminum mount for a real spindle.

– CNC machine the frame from 6061-T6 aluminum.

If you’re new to CNC/machining, I strongly recommend starting with a commercial desktop CNC kit (e.g., X-Carve, Nomad) for plastic/wood work. Safety first – never compromise on structural integrity for cutting tools. If you have a specific project goal, I’d be happy to help design a safe, feasible solution!

From CAD to Part: The Process

Honyo Prototype – 3D-Printed Desktop CNC Mill

End-to-End Workflow (CAD → Delivery)

-

Upload CAD

• Portal: drag-and-drop STEP, IGES, SolidWorks, Fusion, or STL.

• Auto-check: closed volume, minimum wall 0.5 mm, smallest internal radius ≥ 0.4 mm (tool-library limit).

• Instant hash: file fingerprinted so every revision is tracked for traceability. -

AI Quote (≤ 30 s)

• Geometry engine: voxelises the part and runs a lightweight GPU-accelerated CAM simulator to count tool changes, estimate chip load, and predict support removal time.

• Material matrix: pulls real-time resin and carbide cutter pricing from inventory API.

• Learning curve: quote accuracy ±4 % versus actual job cost (last 12-month rolling MAPE).

• Options returned:

– Standard (PA12-CF nylon, 50 µm layers, 0.4 mm end-mill finish pass)

– Performance (aluminium-filled resin, 25 µm, 0.2 mm end-mill, 5 µm Ra)

– Economy (PLA prototype, 100 µm, no post-machining)

• DfAM coupon: if the algorithm detects thick-to-thin transitions or overhangs > 45°, it auto-suggests ribbing or self-supporting angles and updates price downward. -

DFM (Design-for-Manufacturing) – 4 h turn

• Hybrid review: AI flags > 95 % of issues; human manufacturing engineer validates critical surfaces.

• Key rules for desktop-mill parts:

– Max part footprint 200 × 180 × 120 mm (machine envelope).

– Internal channels: minimum Ø 2 mm, L/D ≤ 8 for resin flush.

– Threads: printed pilot, then single-point cut on the same 3-axis bed to achieve 6H tolerance.

• Lattice infill: if weight reduction > 15 % is possible without affecting mounting loads, customer gets a side-by-side mechanical FEA report and revised quote.

• Sign-off: PDF + interactive 3D viewer; one-click approve or request revision. -

Production – 48–72 h typical

4.1 Additive pre-form

– Printer farm: 30-unit SLS/MJF cluster running PA12-CF or Al-filled resin.

– Layer thickness per quote; in-slice ID barcode printed for genealogy.

4.2 Green-part inspection

– ATOS 3D scan vs. CAD; 50 µm deviation triggers auto-reprint.

4.3 CNC finish pass on desktop micro-mill

– Part transferred to 3-axis Datron-style mill with 60 k RPM spindle.

– Soft-jaw fixture 3D-printed in-house to match as-printed geometry → eliminates datum shift.

– Critical bores, dowel holes, and surface finishes machined to ±10 µm positional, ±25 µm profile.

4.4 In-cycle probing: Renishaw MP250 touch probe logs dimensions to MES; SPC chart pushed live to customer dashboard.

4.5 Secondary ops: tapping, helicoil, anodise type II, or Cerakote per line item. -

Delivery – 2 days global express

• Foam-in-place 3D-printed custom cage (re-usable) protects delicate lattices.

• C of C, material lot trace, inspection report, and desktop-mill cutter wear log included in QR-coded e-package.

• Feedback loop: customer scans code to rate part; data retrains AI quoting engine.

Result: functional desktop-CNC-milled features on a 3D-printed pre-form, delivered in as little as 4 days from CAD upload, with single-digit-micron accuracy where it matters and 30–60 % cost reduction versus fully subtractive micro-machining.

Start Your Project

“Request a Quote for Precision 3D Printed Desktop CNC Mills – Contact Susan Leo at [email protected] | Shenzhen Factory”

Why this works:

– Clear action verb: “Request a Quote” directly tells the reader what to do.

– Product specificity: Highlights “Precision 3D Printed Desktop CNC Mills” to emphasize quality and uniqueness.

– Brand credibility: Mentions “Honyo Prototype” implicitly (via the email domain and context), but the focus stays on the product and action.

– Location trust: “Shenzhen Factory” underscores manufacturing expertise and global accessibility.

– Concise formatting: Easy to read in ads, emails, or website banners.

Perfect for: Website CTAs, email signatures, social media posts, or trade show materials. 🚀

🚀 Rapid Prototyping Estimator