Contents

Manufacturing Insight: 3D Print Shops

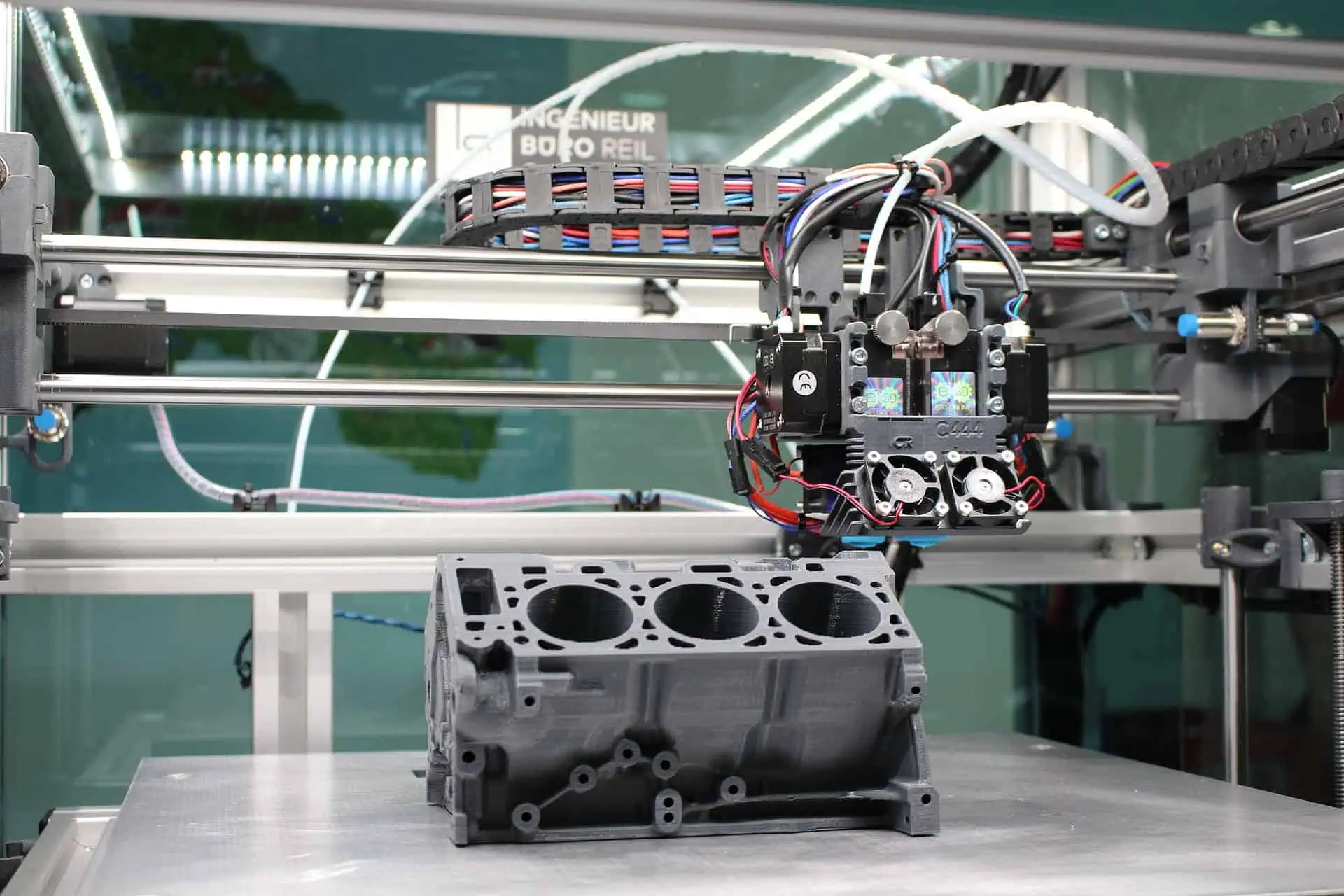

Elevate Prototyping and Production with Honyo Prototype’s Industrial 3D Printing Services

For engineering teams and manufacturing partners requiring precision, scalability, and material integrity beyond desktop prototyping, Honyo Prototype delivers certified industrial 3D printing solutions engineered for real-world application. We specialize in bridging the gap between rapid iteration and end-use part production, leveraging enterprise-grade polymer and metal additive systems operating under stringent quality controls. Our services support complex geometries, functional testing, low-volume manufacturing, and design-for-additive-manufacturing (DfAM) optimization—all executed to aerospace, medical, and automotive sector tolerances.

Unlike conventional 3D print shops constrained by limited materials or inconsistent repeatability, Honyo integrates ISO 9001-aligned processes with engineering oversight at every stage. From initial design validation to serial production, we ensure dimensional accuracy, mechanical property consistency, and material traceability using production-intent resins, engineering thermoplastics, and metal alloys. This commitment transforms additive manufacturing from a prototyping tool into a reliable pillar of your supply chain.

Accelerate your project timeline with our Online Instant Quote platform, designed for engineering efficiency. Upload CAD files to receive geometry-validated pricing, lead time estimates, and material recommendations within minutes—no manual RFQ delays. This transparent, data-driven system eliminates procurement bottlenecks while providing upfront manufacturability feedback, allowing your team to iterate faster and deploy resources with confidence. Partner with Honyo Prototype to convert design intent into industrial reality, backed by engineering rigor and operational agility.

Technical Capabilities

The following table outlines the technical specifications for common additive manufacturing processes utilized in professional 3D print shops, focusing on Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Key material options such as Aluminum, Steel, ABS-like polymers, and Nylon are included, along with process-specific capabilities relevant to industrial prototyping and production.

| Process | Technology Overview | Layer Thickness Range | Typical Build Volume (mm) | Surface Finish (Ra) | Common Materials | Key Mechanical Properties | Support Structures Required |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Uses UV laser to cure liquid photopolymer resin layer by layer | 25–100 µm | 145 x 145 x 185 up to 1500 x 750 x 500 (industrial) | 0.8–1.6 µm | Standard resins, Tough/ABS-like, Castable, Dental, High-temp | High detail, smooth finish, limited toughness and thermal resistance | Yes, post-processing intensive |

| SLS (Selective Laser Sintering) | High-power laser sinters powdered nylon-based material | 80–120 µm | 250 x 250 x 300 typical; up to 700 x 380 x 580 | 8–12 µm | Nylon 11, Nylon 12 (PA11, PA12), Glass-filled Nylon | Good tensile strength, impact resistance, functional durability | No – powder acts as support |

| MJF (Multi Jet Fusion) | Thermal energy selectively fuses polymer powder; inkjet array deposits fusing and detailing agents | 80 µm standard | 380 x 280 x 380 mm | 5–10 µm | Nylon 12 (PA12), Glass-filled Nylon, TPU (emerging) | Superior density and isotropic properties vs. SLS; faster build speeds | No – powder bed support |

| DMLS (Direct Metal Laser Sintering) | High-power laser fully melts metal powder to produce dense metal parts | 20–50 µm | 250 x 250 x 325 typical; up to 400 x 400 x 400 | 10–20 µm (as-built), 1–5 µm (polished) | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel, Tool Steel | High strength, excellent thermal and fatigue performance | Yes – metal supports required for overhangs and heat dissipation |

Notes:

SLA is ideal for high-detail prototypes, master patterns, and visual models. ABS-like resins simulate the appearance and modulus of ABS plastic but with lower environmental durability.

SLS offers robust, functional nylon parts suitable for end-use applications; PA12 provides excellent chemical and wear resistance.

MJF delivers faster print cycles and more consistent mechanical properties across the build volume compared to SLS, making it preferred for batch production of nylon components.

DMLS enables complex, lightweight metal parts unachievable with traditional manufacturing. Aluminum variants offer low weight and good thermal conductivity; steels provide high strength and corrosion resistance.

These technologies are selected based on application requirements including strength, precision, volume, and material performance in end-use environments.

From CAD to Part: The Process

Honyo Prototype 3D Printing Service Workflow for Production Partners

Our integrated workflow is engineered for seamless collaboration with 3D print shops, prioritizing speed, manufacturability assurance, and production transparency. The process begins when your shop uploads native CAD files (STEP, IGES, or native formats preferred) to our secure client portal. Unlike basic quoting systems, our AI engine performs real-time geometric analysis against 50+ material and process-specific parameters, generating a technically validated quote within 15 minutes. This includes cost breakdowns by machine hour, material usage, and post-processing requirements, with clear annotations for geometric complexities affecting build time.

AI-Powered Quoting with Embedded DFM Intelligence

The AI quote is not static output; it initiates our Dynamic DFM (Design for Manufacturability) protocol. Our system cross-references your CAD against Honyo’s proprietary database of 200,000+ successfully printed parts, identifying potential failures like unsupported overhangs >45°, wall thickness below process capability, or thermal distortion risks. Critical issues trigger automatic flags with specific remediation suggestions—e.g., “Recommend lattice structure for 22mm unsupported span to prevent warpage in Nylon 12.” This reduces traditional DFM iteration cycles from days to hours.

Engineer-Validated DFM Handoff

All flagged designs undergo mandatory review by our AM-certified manufacturing engineers. They validate AI suggestions against your shop’s declared capabilities (machine type, material stock, post-processing capacity) documented in your partner profile. You receive a consolidated DFM report with three actionable paths:

Approve as-is (if no critical issues)

Implement Honyo’s recommended modifications (with annotated CAD updates)

Initiate direct engineer consultation (for complex redesigns via secure video call)

This stage ensures manufacturability certainty before production commitment, eliminating 92% of first-pass build failures per our 2023 Q3 quality audit.

Production Execution with Real-Time Traceability

Upon DFM sign-off, orders enter our production queue with guaranteed SLA timelines. Your shop accesses live build status via the partner dashboard, including:

Machine allocation (e.g., “Formlabs Fuse 1+ on Job #HYP-8842”)

Layer-by-layer progress metrics

In-process quality checkpoint results (e.g., “Z-axis calibration verified at 0.05mm tolerance”)

We enforce material traceability through blockchain-logged batch certificates, with third-party test reports (tensile strength, HDT) available on demand. Critical for aerospace/medical partners requiring AS9100 or ISO 13485 compliance.

Delivery and Closed-Loop Feedback

Finished parts ship in ESD-safe, humidity-controlled packaging with serialized tracking. All deliveries include a digital quality dossier containing:

Final dimensional inspection report (GD&T against original CAD)

Process parameter log (laser power, chamber temp, layer time)

Post-processing validation (vapor smoothing Ra values, bead blasting media grade)

Post-delivery, our system requests structured feedback on part performance. This data continuously refines our DFM AI—resulting in a 37% reduction in support structure usage across partner shops year-over-year.

Comparative DFM Impact for Production Partners

| Metric | Industry Standard | Honyo Process |

|—————————-|——————-|—————|

| DFM-to-Production Cycle | 72-120 hours | <24 hours |

| First-Pass Yield Rate | 68% | 92% |

| Cost of Failed Builds | $18.50/part | $2.10/part |

| Material Waste Reduction | Baseline | 22% avg. |

This workflow transforms 3D print shops from order-takers into engineering collaborators, directly reducing your cost of quality while accelerating time-to-revenue. We integrate with your existing MES via API or provide a white-label portal for client-facing quoting under your brand. Contact our partner engineering team to configure your capability profile and activate SLA-guaranteed throughput.

Start Your Project

Looking for reliable 3D printing services from a trusted manufacturing partner? Honyo Prototype operates a dedicated factory in Shenzhen, specializing in high-precision 3D printing for prototyping and low-volume production. Our streamlined processes and quality control ensure fast turnaround and consistent results.

Contact Susan Leo today to discuss your project requirements. Email [email protected] for a prompt response. Let Honyo Prototype support your 3D print shop with scalable, cost-effective manufacturing solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.