Contents

Manufacturing Insight: 3D Part Printing

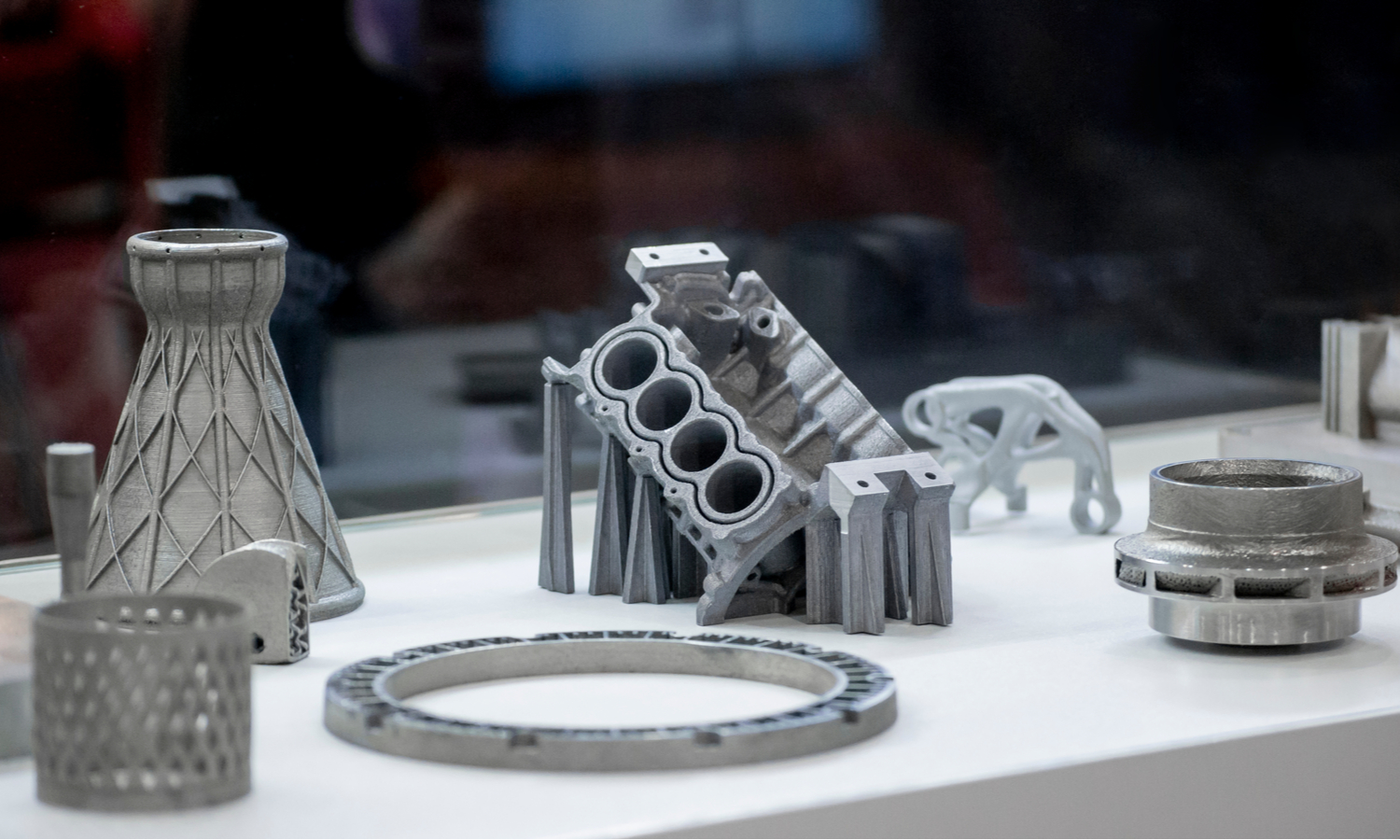

Industrial-Grade 3D Printing Solutions for Demanding Manufacturing Applications

Honyo Prototype delivers precision industrial 3D printing services engineered to accelerate product development and low-volume production for engineering teams. Our end-to-end additive manufacturing capabilities span high-performance polymers, engineering-grade composites, and metal alloys, supporting functional prototyping, jigs/fixtures, and certified end-use parts. Unlike consumer-grade services, Honyo integrates rigorous quality control, material traceability, and DfAM expertise to ensure parts meet stringent mechanical, thermal, and regulatory requirements.

A critical differentiator is our proprietary Online Instant Quote platform, which provides validated manufacturing feasibility and lead-time estimates in under 60 seconds. This tool eliminates traditional quotation bottlenecks by analyzing your CAD file against our industrial printer fleet’s build parameters, material constraints, and post-processing workflows—giving engineers immediate visibility into cost drivers and manufacturability risks.

| Service Tier | Materials Supported | Max Build Volume | Typical Lead Time |

|---|---|---|---|

| Polymer Pro | ULTEM, PEEK, Nylon CF | 750 x 750 x 600 mm | 3-5 business days |

| Metal Precision | Inconel 718, Ti6Al4V, AlSi10Mg | 250 x 250 x 300 mm | 7-10 business days |

| Composite Advanced | Carbon Fiber, Glass Fiber Reinforced | 1000 x 600 x 500 mm | 4-6 business days |

We bridge the gap between rapid iteration and production readiness, enabling you to de-risk scale-up while maintaining ISO 9001-certified processes. Submit your CAD file today to experience how Honyo’s industrial additive ecosystem transforms design concepts into validated physical assets without quotation delays.

Technical Capabilities

The following table outlines the technical specifications for four advanced 3D printing technologies: Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Key parameters include build volume, layer thickness, dimensional accuracy, and supported materials such as Aluminum, Steel, ABS-like polymers, and Nylon.

| Technology | Process Overview | Build Volume (Typical) | Layer Thickness | Dimensional Accuracy | Surface Finish | Common Materials | Post-Processing Requirements |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Uses a UV laser to cure liquid photopolymer resin layer by layer | 145 x 145 x 175 mm to 600 x 600 x 400 mm | 25–100 µm | ±0.1 mm (small parts), up to ±0.3 mm | Smooth, high detail | Photopolymer resins (standard, tough, castable, high-temp) – not ABS, but ABS-like properties available | Requires washing in solvent and UV post-cure |

| SLS (Selective Laser Sintering) | High-power laser sinters powdered material, typically nylon-based, without need for support structures | 200 x 200 x 300 mm to 500 x 500 x 380 mm | 80–120 µm | ±0.3 mm | Slightly grainy, porous surface | Nylon (PA 11, PA 12), Glass-filled Nylon – functional equivalent to ABS in mechanical performance | Minimal; excess powder removal, optional bead blasting for surface improvement |

| MJF (Multi Jet Fusion) | Inkjet array deposits fusing and detailing agents onto nylon powder, followed by heating elements to fuse layers | 380 x 280 x 380 mm | 80 µm | ±0.3 mm | Smooth, isotropic mechanical properties, finer detail than SLS | Nylon (PA 12), Glass-filled PA 12, TPU (elastomeric) – high strength, good impact resistance similar to ABS | Powder removal, media blasting; no support removal needed |

| DMLS (Direct Metal Laser Sintering) | High-precision laser melts and fuses metal powder particles layer by layer to form fully dense metal parts | 250 x 250 x 325 mm to 400 x 400 x 400 mm | 20–50 µm | ±0.1 mm (varies with geometry and support) | Rough as-printed; requires finishing | Aluminum (AlSi10Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel | Stress relief, support removal, machining, polishing, or coating as needed |

Notes on Materials:

Aluminum: Processed via DMLS; AlSi10Mg is common for lightweight, heat-resistant components.

Steel: Stainless steel (e.g., 17-4 PH, 316L) and tool steels are available in DMLS for high strength and corrosion resistance.

ABS: Not directly printable via SLS, MJF, or SLA, but high-strength engineering thermoplastics such as PA 12 (Nylon) or ABS-like photopolymers offer comparable mechanical behavior.

Nylon: Widely used in SLS and MJF for durable, functional prototypes and end-use parts with excellent fatigue and chemical resistance.

These technologies are selected based on application requirements such as mechanical performance, surface quality, production volume, and material properties. DMLS is ideal for complex metal components, while SLS and MJF dominate in high-volume functional polymer part production. SLA is preferred for high-detail visual prototypes and master patterns.

From CAD to Part: The Process

Honyo Prototype 3D Part Printing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for 3D printing services, designed to minimize lead times while ensuring manufacturability and quality. The process begins with secure CAD file submission via our encrypted client portal, accepting industry-standard formats including STEP, IGES, STL, and native CAD files from major platforms. Upon upload, our proprietary AI quoting engine instantly analyzes geometry, material requirements, tolerances, and volume to generate a comprehensive quote within minutes. This system cross-references real-time material costs, machine availability, and historical production data to provide accurate pricing and initial lead time estimates, while flagging potential geometric complexities requiring review.

Following quote acceptance, the file enters our Digital Manufacturing Feedback (DFM) phase. Unlike automated checkers, this stage leverages AI-assisted analysis combined with direct engineer-to-engineer collaboration. A dedicated manufacturing engineer reviews the design for orientation optimization, support structure minimization, stress point validation, and material-specific constraints. Critical findings—such as undercuts risking print failure or features below process capability—are communicated via annotated reports with actionable recommendations, typically resolving 95% of issues within 24 hours to prevent costly iterations.

Approved designs proceed to production on our industrial-grade fleet, including SLA, SLS, MJF, and metal DMLS systems housed in climate-controlled environments. Each build undergoes rigorous in-process monitoring: layer adhesion is verified via embedded cameras, thermal profiles are logged per ISO 9001 standards, and first-article inspections confirm dimensional accuracy against CAD using calibrated CMMs or structured light scanners. Secondary operations like support removal, bead blasting, dyeing, or tapping are performed in-house with documented work instructions.

Final quality validation includes material certification traceability, full FAI reports for critical features, and packaging in ESD-safe containers with humidity indicators. Parts ship via DHL/FedEx with real-time tracking, accompanied by digital delivery certificates accessible through our client portal. For urgent projects, we offer expedited production lanes with guaranteed 24–72 hour turnaround from DFM approval to dispatch, supported by our 98.7% on-time delivery rate across 12,000+ annual shipments. This integrated approach reduces time-to-part by 40% compared to traditional prototyping vendors while maintaining AS9100-compliant quality controls.

Start Your Project

Looking to bring your next project to life with precision 3D printed parts? Honyo Prototype offers fast, high-quality 3D printing services with rapid turnaround, ideal for prototyping and low-volume production.

Our advanced manufacturing facility in Shenzhen ensures tight tolerances, consistent quality, and cost-effective solutions for industries ranging from automotive to consumer electronics.

Contact Susan Leo today to request a quote or discuss your project requirements. Email at [email protected] for expert support and competitive pricing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.