Contents

Manufacturing Insight: 3D Metal Printing Price

Precision Metal Additive Manufacturing with Transparent Industrial Pricing

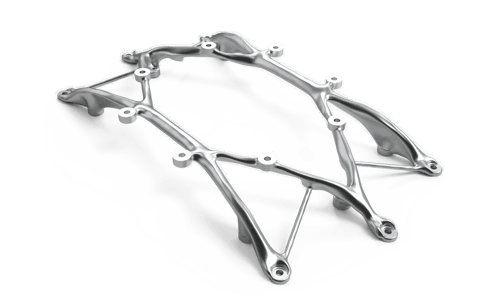

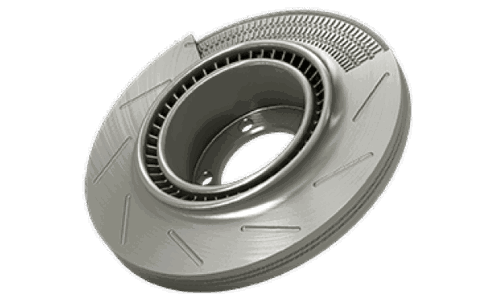

Honyo Prototype delivers end-to-end industrial 3D metal printing services engineered for demanding aerospace, medical, and energy applications. Our production-grade metal AM solutions utilize certified materials—including Ti-6Al-4V, Inconel 718, and 17-4 PH stainless steel—processed on EOS M 400-4 and SLM Solutions S500 systems with 500 x 500 x 500 mm build volumes. Unlike conventional quoting processes, we eliminate pricing ambiguity through rigorous DfAM analysis and standardized cost modeling based on geometric complexity, material density, and post-processing requirements.

Industrial metal AM pricing traditionally suffers from opaque calculations and extended lead times for quotations. Honyo addresses this critical workflow bottleneck with our proprietary Online Instant Quote platform, providing validated production-ready cost estimates in under 90 seconds. Upload your STEP or native CAD file to receive a granular breakdown of build time, material consumption, support structure requirements, and finishing options—no sales intermediary required. This transparency enables rapid design iteration and procurement decisions while maintaining ISO 13485 and AS9100 compliance standards.

Accelerate your path from digital model to certified metal component. Access Honyo’s industrial 3D metal printing capabilities and immediate pricing validation at honyoprototype.com/quote.

Technical Capabilities

The term “3D metal printing price” can be misleading as not all listed technologies support metal materials. Below is a technical and commercial comparison of Selective Laser Melting (DMLS), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Stereolithography (SLA), with clarification on material compatibility and associated pricing factors.

Note: SLA and SLS do not support metal printing—SLA is for photopolymers and SLS primarily for thermoplastics like Nylon. DMLS is the appropriate metal additive process among these. MJF is polymer-based but included for comparative context.

| Technology | Material Compatibility | Typical Materials | Build Volume (Typical) | Layer Thickness Range | Accuracy (Typical) | Lead Time (Standard) | Relative Cost (USD per part) | Notes |

|---|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymers only (non-metal) | ABS-like resins, Standard/Clear/Dental resins | 145 x 145 x 175 mm to 1500 x 750 x 500 mm (industrial) | 25–200 µm | ±0.1 mm (small parts) to ±0.3 mm | 2–5 days | $50–$300 | High surface finish; not suitable for functional metal parts |

| SLS (Selective Laser Sintering) | Thermoplastics only (non-metal) | Nylon (PA 11, PA 12), Glass-filled Nylon | 200 x 200 x 180 mm to 700 x 380 x 580 mm | 80–120 µm | ±0.3 mm | 3–6 days | $75–$500 | Good for functional prototypes; no support structures needed |

| MJF (Multi Jet Fusion) | Thermoplastics only (non-metal) | Nylon (PA 12), Glass-filled PA 12 | 380 x 280 x 380 mm | 80 µm | ±0.3 mm | 3–6 days | $80–$600 | Faster than SLS; excellent mechanical consistency |

| DMLS (Direct Metal Laser Sintering) | Metals only | Aluminum (AlSi10Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel | 250 x 250 x 325 mm to 500 x 400 x 400 mm | 20–50 µm | ±0.1 mm (small parts), ±0.2 mm (complex) | 7–15 days | $500–$5,000+ | High precision metal parts; post-processing increases cost |

Clarifications:

ABS: Not a native 3D printing material in SLS or MJF—however, ABS-like mechanical properties are achieved through engineering resins in SLA or specific nylons in SLS/MJF.

Aluminum and Steel: Only printable via DMLS (or similar metal processes like SLM). Common aluminum alloy is AlSi10Mg; steels include 316L (stainless) and 17-4 PH (precipitation-hardening).

Nylon: Used in SLS and MJF. PA 12 is standard; glass-filled variants enhance stiffness and thermal performance.

Pricing Factors: Include part volume, complexity, support structures, post-processing (e.g., heat treatment, HIP, CNC finishing), material cost, and build time. Metal printing (DMLS) is significantly more expensive due to machine cost, inert gas requirements, and slower build rates.

For metal part production, DMLS is the only viable option among the four. SLS, MJF, and SLA serve polymer-based applications and are not substitutes for metal performance requirements.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for 3D metal printing quotations and production, ensuring technical accuracy, manufacturability, and cost transparency for B2B clients. Our process begins when a client uploads a native CAD file (STEP or IGES format preferred) to our secure portal. This file undergoes immediate validation for geometric integrity and format compatibility, with automated checks flagging common issues like non-manifold edges or unit inconsistencies before proceeding.

The validated CAD model enters our AI-assisted quoting engine, which analyzes over 15 technical parameters including part volume, bounding box dimensions, surface area-to-volume ratio, anticipated support structure density, material type (e.g., Ti-6Al-4V, Inconel 718, AlSi10Mg), and orientation complexity. Crucially, this AI layer is not fully autonomous; it generates a preliminary cost estimate which is then reviewed and refined by our in-house metal additive manufacturing engineers. They adjust for real-world factors the algorithm cannot fully quantify, such as geometric intricacies requiring specialized build strategies or material certification requirements. Clients receive this engineered quote within 4 business hours, detailing base material cost, machine time, post-processing variables, and quality assurance inclusions.

Following quote acceptance, the Design for Additive Manufacturing (DFM) phase commences as a collaborative engineering review. Our team evaluates thermal distortion risks, optimal build orientation for minimal supports, critical feature resolution against machine capabilities (e.g., laser spot size limitations), and part nesting efficiency within the build envelope. We provide specific, actionable feedback—such as recommending minor design modifications to eliminate 45-degree overhangs or suggesting alternative support structures—rather than generic rejections. This step typically reduces post-build rework by 30-50% and is documented in a formal DFM report shared with the client for approval.

Production occurs on calibrated industrial metal systems (EOS M 400-4, RenAM 500Q) under controlled Class 10,000 cleanroom conditions. Each build includes real-time melt pool monitoring, inert gas atmosphere control (oxygen < 100 ppm), and layer-by-layer thermal imaging. Material traceability is maintained from certified powder lot to final part, with full build parameter logs archived. Post-processing follows AS9100-compliant procedures: support removal via wire EDM or CNC, stress relief annealing per material-specific profiles, precision machining of critical interfaces, and optional surface treatments like isotropic finish or HIP.

Final delivery encompasses comprehensive documentation alongside physical parts. Every shipment includes first-article inspection reports (FAIR) with CMM data for critical dimensions, material test certificates (tensile, chemical composition), non-destructive testing results (if specified), and a build summary log. Standard lead time from DFM approval to delivery is 10-15 business days for quantities under 25 parts, though this varies based on complexity and finishing requirements as indicated in the initial quote.

Key cost drivers in our transparent pricing model include:

| Parameter | Impact on Cost | Engineering Consideration |

|——————–|—————————————–|—————————————–|

| Support Density | Direct 15-35% material/time increase | Optimized via DFM to minimize waste |

| Critical Features | Adds precision machining steps | Requires ±0.05mm tolerance validation |

| Material Type | Inconel 718 costs 2.8x AlSi10Mg base | Certification (AMS 7000) adds 12-18% |

| Build Volume Use | Under 30% efficiency incurs surcharge | DFM nests multiple parts where feasible |

This integrated approach ensures clients receive technically viable parts at predictable costs, with engineering rigor applied at every transition point between quotation and delivery. We maintain open communication channels throughout, allowing design iterations during DFM without quote invalidation—a critical differentiator for complex metal AM projects.

Start Your Project

Get an instant quote for high-precision 3D metal printing services—ideal for prototypes and low-volume production.

Contact Susan Leo at [email protected] for competitive pricing and fast turnaround.

Our advanced manufacturing facility is located in Shenzhen, ensuring strict quality control and efficient global delivery.

Request your custom quote today and accelerate your product development with Honyo Prototype.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.