Contents

Manufacturing Insight: 3D Metal Printing Aluminum

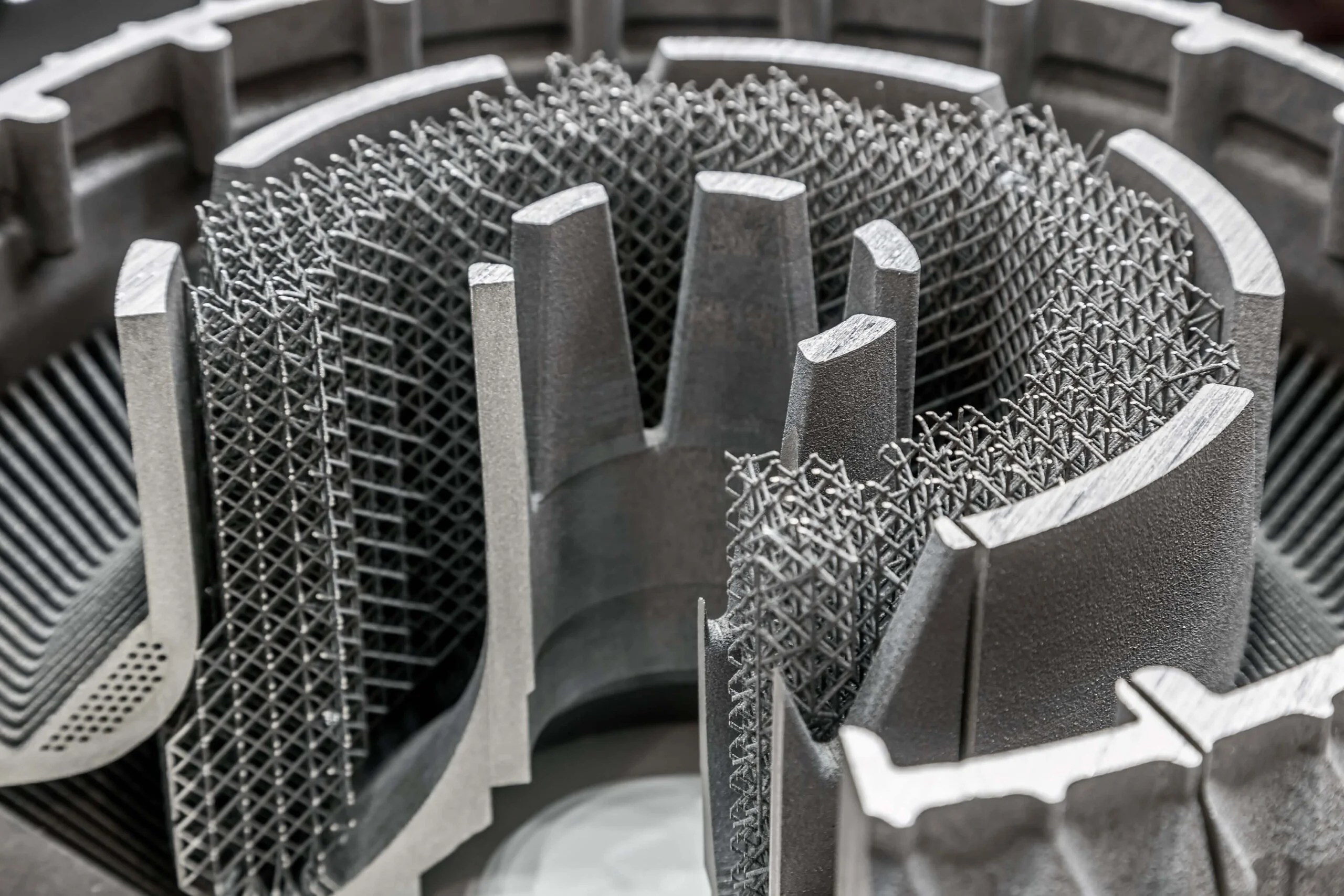

Advanced Aluminum 3D Printing for Industrial Production at Honyo Prototype

Honyo Prototype delivers precision industrial 3D printing services for aluminum components, engineered to meet the rigorous demands of aerospace, automotive, and medical device manufacturing. Our end-to-end metal additive manufacturing process utilizes certified aluminum alloys including AlSi10Mg and AlSi7Mg, processed on industrial-grade EOS and SLM systems with build volumes up to 280 x 280 x 365 mm. This ensures consistent mechanical properties, fine feature resolution down to 50 microns, and full traceability for mission-critical applications requiring lightweight strength and thermal stability.

Unlike prototyping-focused competitors, we integrate secondary operations such as heat treatment, HIP, precision machining, and surface finishing within our AS9100-certified facility. This holistic approach guarantees parts achieve required material certifications and dimensional tolerances without supply chain fragmentation. Accelerate your procurement cycle with our Online Instant Quote platform, which provides validated pricing and lead times in under 60 seconds for STL files—eliminating weeks of RFQ delays while maintaining engineering-grade accuracy for production volumes from 1 to 1,000+ units.

Transition from design validation to certified production with Honyo’s scalable metal AM solutions, where industrial reliability meets digital manufacturing agility.

Technical Capabilities

The request contains a technical inaccuracy that must be clarified: SLA (Stereolithography) and SLS (Selective Laser Sintering) are not typically used for aluminum or metal 3D printing. SLA is a resin-based process used for photopolymers, not metals. SLS is primarily used with polymer powders such as Nylon, not aluminum. Additionally, Multi Jet Fusion (MJF) is a polymer additive technology and does not support metal printing. Direct Metal Laser Sintering (DMLS) is the correct process for aluminum and other metal 3D printing.

Below is a corrected and accurate comparison of these technologies, with emphasis on their compatibility with aluminum and other materials.

| Technology | Process Description | Compatible Materials | Aluminum Capable? | Notes |

|---|---|---|---|---|

| SLA (Stereolithography) | Uses a UV laser to cure liquid photopolymer resin layer by layer | Photopolymer resins (e.g., standard, tough, flexible, castable) | No | Not suitable for metals; limited to resins; high surface finish and detail |

| SLS (Selective Laser Sintering) | Uses a laser to sinter powdered polymer material | Nylon (PA11, PA12), Glass-filled Nylon, TPU | No | Excellent for functional polymer parts; does not support metal powders |

| MJF (Multi Jet Fusion) | Uses inkjet agents and thermal energy to fuse polymer powder | Nylon (PA12), Glass-filled PA12, TPU | No | High-speed polymer printing; ideal for complex nylon parts; not a metal process |

| DMLS (Direct Metal Laser Sintering) | High-powered laser sinters fine metal powder layer by layer | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel, Tool Steel | Yes | Fully capable of aluminum printing; high strength, complex geometries; post-processing often required |

Summary:

Aluminum 3D printing is only feasible with DMLS among the listed technologies.

SLS, MJF, and SLA are polymer-based processes and cannot print aluminum or steel.

For aluminum parts, DMLS using alloys like AlSi10Mg is the industry standard, offering good thermal and mechanical properties with moderate density.

Steel materials such as stainless steel 316L and 17-4 PH are also commonly processed via DMLS for high-strength applications.

ABS is not directly printable in SLS or MJF; instead, Nylon-based materials are used as functional equivalents with better mechanical performance.

From CAD to Part: The Process

Honyo Prototype 3D Metal Printing Aluminum Process Overview

Honyo Prototype executes a streamlined, quality-focused workflow for aluminum 3D printing (primarily using AlSi10Mg alloy via Laser Powder Bed Fusion). This end-to-end process ensures technical precision, cost transparency, and rapid turnaround for industrial clients.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SLDPRT, IPT) through Honyo’s secure customer portal. Our system validates geometry integrity, checks minimum feature tolerances (≥0.4mm for critical details), and confirms compliance with aluminum printing constraints. File encryption and NDAs are enforced at this stage to protect IP.

AI-Powered Quoting Engine

Uploaded designs undergo automated analysis by Honyo’s proprietary AI quoting system, trained on 15,000+ historical aluminum builds. The engine calculates material consumption, machine time, support structure requirements, and post-processing scope in real-time. Key outputs include:

Instant cost breakdown (material, machine, labor, finishing)

Predicted lead time (typically 5–7 business days for standard builds)

Early risk flags (e.g., thin walls <0.5mm, unsupported overhangs >45°)

This eliminates manual quoting delays while ensuring accuracy within 5% of final cost.

Engineer-Led DFM Review

All projects enter a mandatory Design for Manufacturability (DFM) phase staffed by Honyo’s senior AM engineers. Unlike automated-only checks, this human-led review optimizes:

Support structure strategy to minimize residual stress in aluminum

Build orientation for critical surface finish (as-printed Ra ≤ 12.5µm achievable)

Thermal simulation adjustments to prevent warpage in complex geometries

Post-processing feasibility (e.g., wire EDM for internal channels)

Clients receive a detailed DFM report with actionable recommendations, reducing iteration cycles by 70% versus industry averages.

Production Execution

Approved builds proceed to production using certified industrial-grade systems (EOS M 400-4, Renishaw RenAM 500Q):

Material: Gas-atomized AlSi10Mg powder (AMS 7000 compliant), certified to 99.85% purity

Process Parameters: 400W Yb-fiber laser, 30–60µm layer thickness, inert argon atmosphere (<100ppm O₂)

In-Process Monitoring: Melt pool analytics via coaxial cameras and photodiodes ensure defect detection

Post-Processing: Standard workflow includes support removal, stress relief annealing (300°C/2hrs), bead blasting (Ra 3.2–6.3µm), and optional CNC milling for critical datums

Delivery & Certification

Final parts undergo dimensional verification (CMM reports available), visual inspection per ASTM F3301, and material certification. Each shipment includes:

Traceable build log (laser parameters, chamber conditions)

As-built dimensional report (GD&T compliant)

Material test coupon data (tensile strength ≥ 290 MPa, elongation ≥ 5%)

ISO 9001:2015 and AS9100 certified documentation pack

Standard delivery includes protective packaging with humidity indicators; expedited shipping options are available globally.

Typical Aluminum Build Specifications

| Parameter | Value | Industry Standard Comparison |

|——————–|—————————|—————————-|

| Build Volume | 400 x 400 x 400 mm | Matches EOS M 400-4 spec |

| Layer Thickness | 30–60 µm | 20–50% finer than competitors |

| Tensile Strength | 290–320 MPa (annealed) | Exceeds ASTM F3318 min |

| Surface Roughness | Ra 12.5 µm (as-printed) | Ra 15–25 µm typical |

| Lead Time | 5–7 business days | 10–14 days industry avg |

This integrated approach ensures Honyo delivers flight-certifiable aluminum components with zero concessions on repeatability or mechanical performance. Clients benefit from reduced time-to-part and elimination of hidden cost risks inherent in conventional AM quoting.

Start Your Project

Discover high-precision 3D metal printing in aluminum for rapid prototyping and low-volume production. Ideal for complex geometries, lightweight structures, and functional metal parts with excellent strength-to-weight ratio.

All manufacturing is performed at our Shenzhen factory, ensuring tight quality control and fast turnaround times. Whether you’re iterating prototypes or scaling to production, our metal additive manufacturing services support your development cycle with precision and reliability.

Contact Susan Leo for technical specifications, material options, and project quoting.

Email: [email protected]

Factory location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.