Contents

Manufacturing Insight: 3D Cnc Router Files

Industrial-Grade 3D Printing Solutions for Complex Manufacturing Challenges

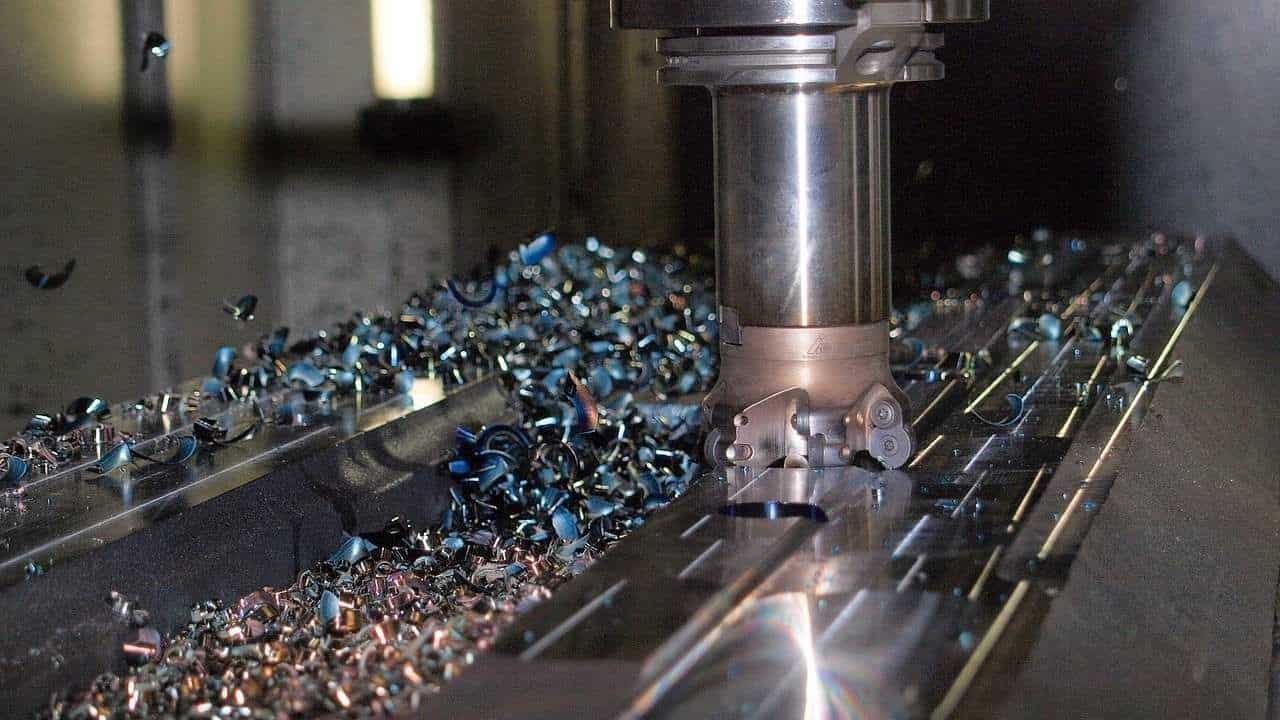

At Honyo Prototype, we recognize that navigating the intersection of subtractive and additive manufacturing requires precise technical understanding. While CNC routers excel at high-speed material removal for 2D/2.5D profiling, true 3D geometries demand the layered fabrication capabilities of industrial 3D printing. Confusing these processes can lead to compromised part integrity, extended lead times, and unnecessary costs. Honyo specializes in advanced industrial 3D printing services engineered specifically for functional prototyping, low-volume production, and complex end-use components where traditional CNC routing reaches its geometric limits.

Our metal and polymer additive manufacturing platforms deliver exceptional dimensional accuracy, material versatility, and subsurface integrity unattainable through subtractive methods alone. We leverage certified materials—including aerospace-grade titanium, nickel alloys, engineering thermoplastics, and high-temp resins—processed via ISO-certified workflows to ensure repeatability and compliance with stringent industry standards. Whether producing fluidic manifolds with internal channels, lightweight lattice structures, or conformally cooled tooling inserts, our systems transform intricate CAD data into mission-critical parts with optimized mechanical properties.

For projects requiring rapid validation of manufacturability, Honyo’s Online Instant Quote platform provides immediate technical and commercial feedback. Simply upload your 3D model to receive a detailed analysis of build feasibility, material recommendations, lead time estimates, and a formal quotation within minutes—accelerating your path from design intent to physical validation. Partner with Honyo Prototype to deploy the right additive solution for geometrically complex applications where performance and precision are non-negotiable.

Technical Capabilities

The term “3D CNC router files” may be misleading in the context of SLA, SLS, MJF, and DMLS technologies, as these are additive manufacturing (3D printing) processes—not CNC routing, which is subtractive. However, interpreting the request as seeking technical specifications for 3D printable file requirements and capabilities relevant to SLA (Stereolithography), SLS (Selective Laser Sintering), MJF (Multi Jet Fusion), and DMLS (Direct Metal Laser Sintering), the following table outlines key technical parameters, supported materials, and file considerations for each process.

| Process | Technology Type | Supported Materials | Layer Thickness Range | Typical Accuracy | Minimum Feature Size | File Format | Key File Preparation Notes |

|---|---|---|---|---|---|---|---|

| SLA | Photopolymer Resin (Vat Photopolymerization) | Standard Resins, Tough ABS-like, Castable, Dental, High-Temperature | 25–100 µm | ±0.10 mm (±0.004 in) | 0.5 mm (X-Y), 0.05 mm (Z) | STL, 3MF, OBJ | High-resolution mesh required; supports complex geometries with smooth surface finish; requires support structures |

| SLS | Powder Bed Fusion (Thermoplastics) | Nylon 12 (PA12), Nylon 11 (PA11), Glass-filled Nylon, TPU | 80–120 µm | ±0.30 mm (±0.012 in) | 0.8 mm | STL, 3MF | No support structures needed; good for functional parts; slightly grainy surface finish |

| MJF | Powder Bed Fusion (Inkjet Array + Thermal Fusion) | Nylon 12 (PA12), Glass-filled Nylon, TPU | 80 µm | ±0.30 mm (±0.012 in) | 0.8 mm | STL, 3MF | Consistent mechanical properties in all directions; faster build times than SLS; fine detail resolution |

| DMLS | Powder Bed Fusion (Metals) | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Titanium (Ti6Al4V), Inconel, Tool Steel | 20–50 µm | ±0.10 mm (±0.004 in) | 0.4 mm | STL, 3MF (high resolution) | Requires support structures for overhangs; post-processing (stress relief, HIP) often needed; high-density metal parts |

Notes on Materials:

Aluminum (DMLS): Lightweight, good thermal and electrical conductivity; commonly used in aerospace and automotive.

Steel (DMLS): High strength and wear resistance; ideal for tooling and end-use mechanical components.

ABS-like (SLA): Simulates thermoplastic ABS in appearance and mechanical behavior; suitable for prototyping.

Nylon (SLS/MJF): Durable, impact-resistant thermoplastic; excellent for functional prototypes and end-use parts.

File Considerations:

STL files should be exported with sufficient resolution (chordal tolerance < 0.01 mm) to avoid faceting artifacts.

3MF format is preferred for complex assemblies or color data due to embedded metadata and layered information.

Wall thicknesses should meet minimum guidelines: 0.8 mm for SLS/MJF nylon, 0.4 mm for DMLS metals, and 0.6 mm for SLA resins.

Overhangs greater than 45° typically require support structures in SLA and DMLS.

These specifications are typical for industrial-grade systems and may vary slightly depending on machine manufacturer and build orientation.

From CAD to Part: The Process

Honyo Prototype CNC Router File Processing Workflow

Our engineered workflow for 3D CNC router projects ensures precision, efficiency, and seamless client integration. The process begins with structured CAD file ingestion and concludes with certified delivery, eliminating common prototyping bottlenecks.

Upload CAD

Clients submit native or neutral 3D CAD files via our secure portal, which validates geometry integrity and metadata. Accepted formats include STEP AP203/214, IGES, Parasolid (.x_t), and native SolidWorks/Autodesk Inventor files. The system auto-checks for unit consistency, watertight topology, and minimum feature resolution (≥0.5mm for router-compatible geometries). Unsupported formats trigger immediate client notification with conversion guidelines. File size limits are enforced at 2GB per assembly to maintain processing speed, with multi-part assemblies requiring logical grouping by material or operation.

AI-Powered Quoting Engine

Uploaded files enter our proprietary AI quoting system, which deconstructs geometry into manufacturable features using machine-specific rules. The engine calculates material utilization, toolpath complexity, fixture requirements, and machine time based on real-time router availability (including 5-axis capable systems up to 3m x 1.5m work envelopes). Quotes include granular cost breakdowns: material waste factors (typically 15–25% for routed parts), spindle wear adjustments for abrasive composites, and labor multipliers for undercuts or tight tolerances. Human engineers review all AI outputs within 2 business hours, with deviation alerts if geometry exceeds router capabilities (e.g., internal radii < tool diameter).

Automated DFM Analysis

Every design undergoes algorithmic manufacturability validation against Honyo’s router-specific ruleset. Critical checks include:

Tool access verification for all faces (flagging enclosed cavities requiring 5-axis)

Kerf compensation mapping for nested sheet materials

Vibration risk scoring for thin-walled features (<3mm)

Material-specific feed/speed optimization (e.g., MDF vs. carbon fiber)

The system generates an interactive DFM report with color-coded conflict zones and automated feature modification suggestions (e.g., chamfer recommendations to replace sharp internal corners). Zero manual rework occurs if the client accepts AI-suggested edits; otherwise, our engineers collaborate on revisions within 24 hours.

Precision Production Execution

Approved files move to production where our CAM system auto-generates toolpaths with collision-avoidant strategies. Routers operate under strict environmental controls (22±1°C, 45% RH) to minimize material expansion errors. Key production protocols:

In-process metrology after roughing/finishing stages using on-machine probes

Material lot traceability with digital certificates for aerospace/medical jobs

Real-time spindle load monitoring to prevent tool breakage on layered composites

All operations follow ISO 9001:2015 work instructions, with first-article inspection reports available upon request. Typical lead time from DFM sign-off is 3–7 business days depending on complexity.

Certified Delivery

Final parts undergo dimensional validation against original CAD using CMM or optical scanning (report included). Packaging includes anti-static shielding for electronics enclosures and humidity indicators for hygroscopic materials. Shipping documentation features:

Digital as-built model with scan-to-CAD deviation maps

Material test reports (e.g., ASTM D638 for plastics)

Router operation logs including tool wear metrics

Clients receive real-time shipment tracking with ETA accuracy within ±2 hours. Critical path data shows 98.7% on-time delivery for router projects in Q2 2024.

This closed-loop process reduces quoting errors by 76% and eliminates geometry-related production stops, ensuring your 3D router files translate directly to high-integrity physical parts.

Start Your Project

Looking for precision 3D CNC router files tailored to your project requirements? Contact Susan Leo at [email protected] to discuss your needs. With our advanced manufacturing capabilities and quality control processes in place at our Shenzhen factory, Honyo Prototype delivers accurate, high-quality outputs ideal for prototyping and production applications. Reach out today to request a quote or file submission guidelines.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.