Introduction: Navigating the Global Market for 36 gauge copper sheet

Navigating the complexities of sourcing 36 gauge copper sheet for diverse industrial applications can be a daunting task for international buyers. With variations in quality, availability, and pricing across different regions, making informed decisions is crucial to ensuring both project success and cost-effectiveness. This guide provides a comprehensive overview of the critical factors that influence the procurement of 36 gauge copper sheets, including types, applications, supplier vetting processes, and cost considerations.

Understanding the various uses of copper sheets—from electrical applications and arts and crafts to construction and manufacturing—is vital for B2B buyers seeking to maximize their investments. This resource will delve into the specifications and advantages of 36 gauge copper, exploring its malleability, thermal conductivity, and suitability for various projects, including RF shielding and decorative finishes.

Moreover, the guide emphasizes best practices for supplier evaluation, helping buyers from Africa, South America, the Middle East, and Europe (including Germany and Vietnam) identify reliable partners. By providing actionable insights and expert recommendations, this guide empowers B2B buyers to make confident purchasing decisions, ultimately facilitating smoother transactions and fostering long-term supplier relationships in the global market.

Understanding 36 gauge copper sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pure Copper Sheet | 99.9% purity, smooth commercial finish | Electrical applications, arts and crafts | Pros: Excellent conductivity and malleability. Cons: Prone to oxidation if unsealed. |

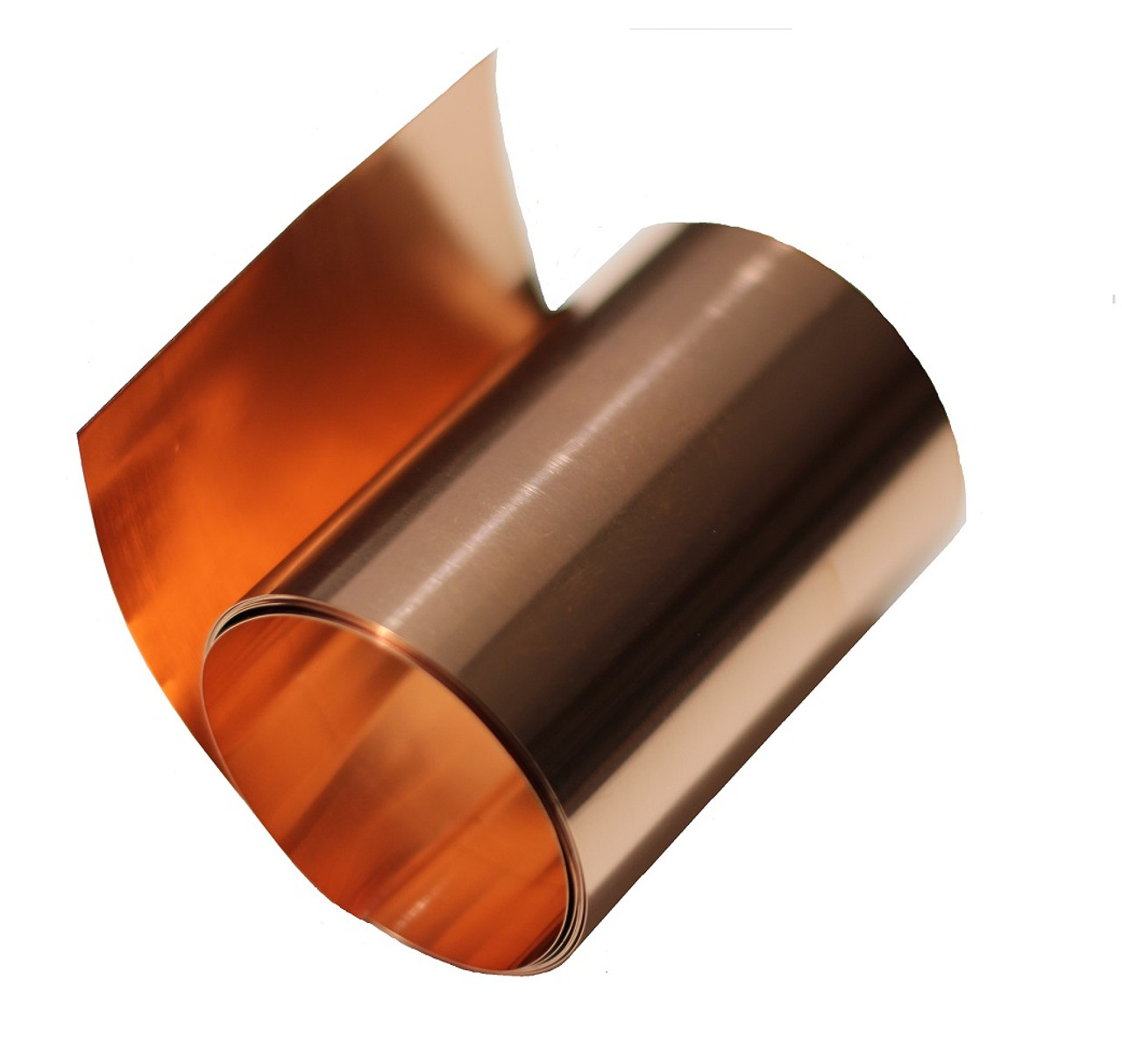

| Copper Foil | Extremely thin (.005 inches), highly pliable | Embossing, decorative crafts, DIY projects | Pros: Easy to cut and manipulate. Cons: Limited structural integrity for heavy-duty use. |

| Annealed Copper Sheet | Soft and malleable, ideal for shaping | Manufacturing, custom metalwork | Pros: Can be easily formed into complex shapes. Cons: Less durable than thicker options. |

| Patina Copper Sheet | Developed patina for aesthetic appeal | Architectural applications, art installations | Pros: Unique appearance and character. Cons: Maintenance required to preserve patina. |

| Copper Alloy Variants | Blends with other metals for enhanced properties | Specialized industrial applications | Pros: Improved strength and corrosion resistance. Cons: Potentially higher cost and complexity in sourcing. |

What Are the Characteristics of Pure Copper Sheets?

Pure copper sheets are known for their high purity level of 99.9%, providing excellent electrical and thermal conductivity. This type is often used in electrical applications, arts and crafts, and decorative elements. When sourcing pure copper, B2B buyers should consider the potential for oxidation, especially if the sheets will be exposed to outdoor conditions. Proper sealing can mitigate this issue, ensuring the longevity and appearance of the copper.

How Does Copper Foil Differ from Other Types?

Copper foil is extremely thin and pliable, making it an ideal choice for applications requiring intricate detailing, such as embossing and decorative crafts. Its lightweight nature allows for easy cutting and manipulation, making it suitable for DIY projects. However, its thinness limits its structural integrity, so buyers should evaluate whether it meets the demands of their specific applications before purchasing.

Why Choose Annealed Copper Sheets for Manufacturing?

Annealed copper sheets are characterized by their softness and malleability, which allow for easy shaping and forming into complex designs. This type is particularly beneficial in manufacturing and custom metalwork, where precision is key. When considering annealed copper, businesses should assess the trade-off between ease of use and potential durability issues, as these sheets may not withstand heavy loads as well as thicker variants.

What Are the Benefits of Patina Copper Sheets?

Patina copper sheets develop a unique color over time, resulting from oxidation, which can enhance the aesthetic appeal of architectural features and art installations. While this natural aging process provides character, it requires regular maintenance to preserve the patina’s appearance. Buyers should weigh the artistic benefits against the need for upkeep, particularly in environments where visual appeal is paramount.

What Should Buyers Know About Copper Alloy Variants?

Copper alloy variants combine copper with other metals to enhance specific properties, such as strength and corrosion resistance. These alloys are often used in specialized industrial applications where performance is critical. B2B buyers should be aware that sourcing copper alloys may involve higher costs and more complex procurement processes compared to pure copper options. Understanding the specific requirements of their applications will help in selecting the right alloy for their needs.

Key Industrial Applications of 36 gauge copper sheet

| Industry/Sector | Specific Application of 36 gauge copper sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical Manufacturing | RF Shielding in Electronic Devices | Enhanced signal integrity and reduced interference | Ensure compliance with industry standards (ASTM-B152) |

| Construction | Decorative and Functional Elements in Interiors | Aesthetic appeal and durability for high-end finishes | Evaluate thickness and substrate compatibility |

| Arts and Crafts | Embossing and Sculptural Projects | Versatility for creative applications and easy handling | Confirm availability of various sizes and finishes |

| HVAC Systems | Ductwork and Insulation Components | Excellent thermal conductivity and corrosion resistance | Verify material purity and gauge specifications |

| Automotive | Electrical Wiring and Connectors | Reliable performance in high-temperature environments | Consider sourcing from certified suppliers for quality |

How is 36 Gauge Copper Sheet Utilized in Electrical Manufacturing?

In the electrical manufacturing sector, 36 gauge copper sheets are extensively used for RF shielding in electronic devices. This application is crucial for maintaining signal integrity and minimizing electromagnetic interference (EMI). Businesses sourcing copper sheets for this purpose must ensure compliance with industry standards, such as ASTM-B152, and verify the purity of the copper to guarantee optimal performance. International buyers should also consider logistics and customs regulations when importing materials to their respective countries.

What Role Does 36 Gauge Copper Sheet Play in Construction?

In construction, 36 gauge copper sheets serve both decorative and functional purposes, often employed in high-end interior designs. They are used for creating tabletops, backsplashes, and other architectural elements that require both aesthetic appeal and durability. For buyers, evaluating the compatibility of the copper sheet with substrates is vital to ensure long-term performance, especially in varying climates found in regions like Africa and the Middle East. The malleability of this gauge allows for easy installation and customization, making it a favored choice among architects and designers.

How is 36 Gauge Copper Sheet Used in Arts and Crafts?

The arts and crafts industry leverages 36 gauge copper sheets for various applications, including embossing and sculptural projects. The material’s pliability makes it easy to manipulate, allowing artists to create intricate designs and textures. Suppliers should confirm the availability of different sizes and finishes to meet the diverse needs of artists. For international buyers, understanding the local market demand for specific artistic applications can guide purchasing decisions and inventory management.

What Benefits Does 36 Gauge Copper Sheet Provide in HVAC Systems?

In HVAC systems, 36 gauge copper sheets are utilized for ductwork and insulation components due to their excellent thermal conductivity and corrosion resistance. These properties ensure efficient temperature control and longevity of the system. Buyers should verify the purity and gauge specifications of the copper sheets to ensure they meet the rigorous demands of HVAC applications. Additionally, sourcing from certified suppliers can enhance the reliability of the materials used in these critical systems.

How is 36 Gauge Copper Sheet Relevant to the Automotive Industry?

In the automotive sector, 36 gauge copper sheets are crucial for electrical wiring and connectors, providing reliable performance in high-temperature environments. The high conductivity of copper ensures efficient power distribution, which is essential for vehicle performance. When sourcing, businesses should consider the certification of suppliers to ensure the quality of the copper used in automotive applications. Understanding regional automotive standards and regulations is also important for international buyers to maintain compliance in their local markets.

3 Common User Pain Points for ’36 gauge copper sheet’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality 36 Gauge Copper Sheet

The Problem: B2B buyers often face challenges in sourcing high-quality 36 gauge copper sheets. With numerous suppliers in the market, distinguishing between those offering genuine, pure copper and those providing inferior materials can be overwhelming. Buyers from industries such as manufacturing and construction need assurance that the copper they procure meets industry standards and specifications, as subpar materials can lead to project delays and additional costs.

The Solution: To ensure quality, buyers should prioritize suppliers who provide certifications, such as ASTM-B152, which guarantees that the copper sheet adheres to recognized industry standards. Additionally, engaging suppliers who offer transparency in their sourcing and manufacturing processes can give buyers greater confidence. It’s advisable to request material test reports or samples before making large orders. Establishing a long-term relationship with a reputable supplier who understands the specific needs of your industry can also streamline future sourcing and ensure consistent quality.

Scenario 2: Misunderstanding the Applications of 36 Gauge Copper Sheet

The Problem: Many B2B buyers are unsure about the suitable applications for 36 gauge copper sheets, leading to potential misuse. For instance, buyers may consider using this gauge for structural applications without realizing that it is more suited for decorative purposes, such as arts and crafts, or as a substrate in electrical applications. This misunderstanding can result in wasted resources and project failures.

The Solution: To overcome this challenge, buyers should invest time in understanding the properties of 36 gauge copper sheets, including their malleability, conductivity, and corrosion resistance. Providing educational resources or workshops can help inform buyers about the best applications. Additionally, suppliers should offer detailed product descriptions and project guidance on their websites. For those looking to use copper sheets in more structural applications, seeking advice from the supplier on combining the copper with a more robust substrate or exploring thicker gauges may be necessary. This proactive approach will help buyers make informed decisions that align with their project requirements.

Scenario 3: Challenges with Copper Sheet Handling and Fabrication

The Problem: Handling and fabricating 36 gauge copper sheets can be tricky, especially for businesses that may not have specialized equipment or experienced personnel. Issues such as tearing, improper cutting, or difficulty in achieving desired shapes can lead to frustration and increased costs. Buyers in sectors like manufacturing or DIY projects may find themselves struggling to process the material effectively.

The Solution: Providing comprehensive guidelines and resources on proper handling and fabrication techniques is crucial. Buyers should look for suppliers that offer tutorials, videos, and tips on how to cut and shape copper sheets safely and effectively. For example, using scissors for cutting, and emphasizing the importance of supporting the sheet during cutting to prevent tearing can be beneficial. Additionally, investing in basic tools like a metal shear or a rotary cutter can significantly improve the handling experience. Suppliers might also consider offering fabrication services or recommending local workshops that specialize in metalworking to assist buyers who lack the necessary equipment or expertise. By equipping buyers with the right tools and knowledge, suppliers can enhance customer satisfaction and foster loyalty.

Strategic Material Selection Guide for 36 gauge copper sheet

What are the Key Properties of 36 Gauge Copper Sheets?

36 gauge copper sheets are primarily made from Copper Alloy C110, which is 99.9% pure copper. This high purity level ensures excellent electrical and thermal conductivity, making it suitable for a wide range of applications, including electrical components, RF shielding, and decorative arts. The annealed temper of this copper sheet enhances its malleability, allowing it to be easily shaped and formed without cracking. Additionally, copper exhibits good corrosion resistance, particularly in non-acidic environments, which is crucial for longevity in various applications.

What are the Pros and Cons of Using 36 Gauge Copper Sheets?

When considering the use of 36 gauge copper sheets, there are several advantages. Their high conductivity makes them ideal for electrical applications, while their malleability allows for intricate designs in arts and crafts. However, there are also drawbacks. The relatively thin nature of 36 gauge sheets can make them susceptible to bending and denting under stress, which may not be suitable for heavy-duty applications. Moreover, the cost of pure copper can be higher compared to other metals, which may impact budget-sensitive projects.

How Does Material Selection Impact Application Compatibility?

The specific properties of 36 gauge copper sheets make them compatible with various media. For instance, they are often used in electrical applications where high conductivity is required, such as in wiring and connectors. Their corrosion resistance allows for use in humid environments, but they may not perform well in highly acidic or alkaline conditions. International buyers should consider the specific environmental conditions of their applications to ensure that copper sheets will perform adequately.

What Should International Buyers Consider When Sourcing 36 Gauge Copper Sheets?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, compliance with local standards is vital. In Europe, for example, DIN standards may apply, while ASTM standards are common in the U.S. and other regions. Buyers should ensure that their suppliers can provide certification that meets these standards. Additionally, understanding local market preferences and pricing structures can aid in making informed purchasing decisions. Factors such as shipping costs and lead times should also be considered, as these can vary significantly across different regions.

Summary Table of Material Analysis

| Material | Typical Use Case for 36 gauge copper sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper Alloy C110 | Electrical applications, arts and crafts | Excellent electrical and thermal conductivity | Susceptible to bending and denting | High |

| Copper Foil | Decorative arts, embossing | Highly malleable and easy to work with | Limited structural strength | Medium |

| Copper Flashing | Roofing, weatherproofing | Good corrosion resistance | Can be expensive for large projects | High |

| Copper Sheet | Manufacturing, RF shielding | Versatile for various applications | Requires careful handling during installation | Medium |

This analysis provides a comprehensive understanding of 36 gauge copper sheets, aiding international B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 36 gauge copper sheet

What Are the Main Stages in the Manufacturing Process of 36 Gauge Copper Sheet?

The manufacturing of 36 gauge copper sheets, typically measuring 0.005 inches in thickness, involves several critical stages to ensure high-quality output suitable for various applications.

-

Material Preparation: The process begins with the selection of high-purity copper, often alloy C110, which contains 99.9% copper. This material is sourced from reputable suppliers to maintain quality standards. The raw copper is then cut into manageable sizes for further processing. During this stage, suppliers may also conduct initial inspections to ensure that the material meets specified standards.

-

Forming: The next stage involves the rolling process. Copper sheets are passed through a series of rollers that gradually reduce their thickness to the desired gauge. The annealing process is crucial here, as it softens the copper, enhancing its malleability and ductility. This step is vital for applications that require detailed shaping or embossing, such as in artistic projects or electrical applications.

-

Assembly: While assembly is less common for sheets compared to other products, it can involve combining different thicknesses or types of copper for specific customer requirements. This may also include laminating the copper sheets to substrates for enhanced durability in applications like countertops or bar tops.

-

Finishing: Finally, the sheets undergo finishing processes, which may include surface treatments to enhance corrosion resistance or aesthetic appeal. The sheets may be polished to achieve a smooth commercial finish, and various patinas can be applied, depending on customer specifications.

How Is Quality Assurance Implemented in the Production of Copper Sheets?

Quality assurance (QA) is an integral part of the manufacturing process for 36 gauge copper sheets. Companies often adhere to international standards such as ISO 9001, which outlines the requirements for a quality management system. Here are the key components of a robust QA program:

-

Incoming Quality Control (IQC): Before production begins, raw materials are subjected to IQC, where samples are tested for purity, thickness, and mechanical properties. This ensures that only materials meeting stringent quality criteria are used.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to monitor parameters like temperature, pressure, and material thickness. This stage is crucial for detecting deviations early, allowing for corrective actions to be taken before defects occur.

-

Final Quality Control (FQC): Once the sheets are produced, they undergo FQC, which involves comprehensive testing to confirm that they meet the required specifications. Common tests include dimensional checks, tensile strength tests, and corrosion resistance evaluations.

What International Standards Should B2B Buyers Be Aware Of?

For international B2B transactions, understanding the relevant quality certifications is crucial. Apart from ISO 9001, other certifications like CE marking (for compliance with European health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for specific industrial applications may also be relevant. These certifications indicate that the products have undergone rigorous testing and meet international quality benchmarks.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can adopt several verification methods:

-

Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insights into their quality control processes. Buyers can assess compliance with international standards and identify areas for improvement.

-

Quality Control Reports: Requesting detailed quality control reports from suppliers can help buyers evaluate the consistency of product quality. These reports should include information on testing methods, results, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can add another layer of assurance. These inspectors can verify that the manufacturing processes align with the agreed-upon specifications and standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing 36 gauge copper sheets from international suppliers, buyers should be aware of the following nuances:

-

Cultural and Regulatory Differences: Different regions may have varied interpretations of quality standards. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local regulations and industry practices to ensure compliance and avoid potential issues.

-

Language Barriers: Miscommunication can lead to misunderstandings about quality specifications. It is advisable for buyers to engage with suppliers who have multilingual capabilities or to utilize professional translation services.

-

Logistical Considerations: Quality assurance does not end at the manufacturing facility. Buyers should consider the logistics of shipping and handling, as improper transport can lead to damage and quality degradation. Ensuring that suppliers have robust logistics practices in place is essential for maintaining product integrity.

Conclusion

The manufacturing processes and quality assurance practices for 36 gauge copper sheets are vital for ensuring that these products meet the high standards required by various industries. By understanding the key stages of production, relevant quality standards, and methods for verifying supplier compliance, B2B buyers can make informed decisions, ultimately leading to successful procurement and project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ’36 gauge copper sheet’

To assist international B2B buyers in effectively procuring 36 gauge copper sheets, this practical sourcing guide offers a step-by-step checklist. Each step is designed to ensure a thorough and efficient purchasing process, focusing on critical considerations for quality, supplier reliability, and compliance.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the specifications for the 36 gauge copper sheet you need. This includes dimensions, thickness, alloy type (preferably C110 for high purity), and surface finish. Having precise specifications helps eliminate ambiguity during the procurement process and ensures that the product meets your project requirements.

- Key Considerations:

- Confirm the thickness as 5 mil (0.005 inches) and ensure it complies with ASTM-B152 standards.

- Decide on the desired size; copper sheets are available in various widths ranging from 3 inches to 36 inches.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies that specialize in copper products and have a solid track record in the industry. Supplier credibility is essential to avoid issues with product quality and delivery.

- Key Actions:

- Check for online reviews and testimonials.

- Explore their product range to ensure they can meet your specific needs.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold necessary certifications. Compliance with international quality standards is crucial, especially when sourcing from different regions, such as Africa, South America, or Europe.

- Important Certifications to Look For:

- ISO certifications for quality management.

- Industry-specific standards that guarantee product reliability and safety.

Step 4: Request Samples

Always request samples of the 36 gauge copper sheets before finalizing your order. This allows you to assess the material quality, finish, and suitability for your intended application.

- Sampling Benefits:

- Evaluate physical characteristics like malleability and conductivity.

- Ensure the copper sheet meets your aesthetic and functional requirements.

Step 5: Review Pricing and Terms

Compare pricing across different suppliers while considering the total cost of ownership. Look beyond the unit price to assess shipping costs, payment terms, and potential discounts for bulk orders.

- Cost Considerations:

- Inquire about minimum order quantities.

- Understand their return and warranty policies for defective products.

Step 6: Confirm Lead Times and Delivery Options

Discuss lead times with your chosen suppliers to ensure they align with your project schedules. Timely delivery is critical in maintaining project timelines and avoiding costly delays.

- Logistics Factors:

- Clarify shipping methods and costs.

- Determine whether suppliers can accommodate urgent orders or expedited shipping.

Step 7: Finalize the Purchase Agreement

Once all details are confirmed, finalize the purchase agreement. Ensure that all terms discussed are documented, including specifications, pricing, delivery schedules, and payment conditions.

- Key Components of the Agreement:

- Include clear terms for liability and dispute resolution.

- Establish a communication protocol for updates during the order process.

By following these steps, B2B buyers can ensure a streamlined and effective procurement process for 36 gauge copper sheets, minimizing risks and enhancing project success.

Comprehensive Cost and Pricing Analysis for 36 gauge copper sheet Sourcing

What Are the Key Cost Components for Sourcing 36 Gauge Copper Sheet?

When sourcing 36 gauge copper sheets, understanding the cost structure is essential for effective budget planning. The primary cost components include:

-

Materials: The price of raw copper is a significant factor, often fluctuating based on global demand and supply dynamics. High-purity copper (99.9% pure, commonly referred to as C110) is generally more expensive but offers superior electrical and thermal conductivity, making it a preferred choice for various applications.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs, such as parts of South America and Africa, may offer competitive pricing. However, skilled labor is often necessary for quality assurance and finishing processes.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, equipment maintenance, and administrative expenses. Efficient operations can lead to lower overhead, impacting the final price.

-

Tooling: The initial setup costs for manufacturing equipment can be significant, especially for customized orders. Buyers should consider whether the supplier has the necessary tooling capabilities to meet their specific requirements.

-

Quality Control (QC): Ensuring that the copper sheets meet industry standards often involves additional QC costs. Certifications like ASTM-B152 can add to the cost but are essential for ensuring product reliability.

-

Logistics: Shipping costs are influenced by distance, mode of transport, and Incoterms. International shipping can be particularly expensive, and buyers should factor in customs duties and taxes.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This can vary based on supplier reputation, market competition, and demand.

How Do Price Influencers Affect the Cost of 36 Gauge Copper Sheet?

Several factors influence the pricing of 36 gauge copper sheets, including:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to maximize cost-efficiency.

-

Specifications/Customization: Custom sizes, finishes, or alloy compositions can increase costs. Buyers should evaluate whether standard products suffice for their applications to avoid unnecessary expenses.

-

Materials Quality/Certifications: Higher quality materials and certifications enhance reliability but can also raise prices. Buyers should assess the necessity of certifications based on application requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can impact pricing. Established suppliers may command higher prices due to perceived quality and service.

-

Incoterms: Understanding shipping terms is crucial. For instance, DDP (Delivered Duty Paid) may include all costs, while FOB (Free on Board) requires buyers to manage shipping and customs, potentially increasing total costs.

What Are the Best Practices for International Buyers in Sourcing 36 Gauge Copper Sheet?

International buyers, particularly from regions like Africa, South America, and the Middle East, can optimize their sourcing strategies by following these tips:

-

Negotiate Wisely: Develop strong relationships with suppliers and leverage volume purchases to negotiate better prices. Understanding the supplier’s cost structure can help in negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs, including logistics, maintenance, and potential scrap rates. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Be Aware of Pricing Nuances: Prices can vary significantly based on region, supplier capabilities, and market conditions. Conduct thorough market research to benchmark prices and understand the local economic context.

-

Request Samples: Before making large purchases, request samples to assess quality. This can prevent costly mistakes and ensure the product meets specific needs.

-

Stay Informed on Market Trends: Keep abreast of copper market trends, as fluctuations can impact pricing. Being informed allows buyers to make timely purchasing decisions that capitalize on favorable pricing.

In conclusion, a comprehensive understanding of cost components, price influencers, and best practices can significantly enhance the sourcing strategy for 36 gauge copper sheets, ensuring that buyers secure the best value for their investments.

Alternatives Analysis: Comparing 36 gauge copper sheet With Other Solutions

Exploring Alternatives to 36 Gauge Copper Sheet

In the realm of industrial materials, the selection of a suitable solution often hinges on performance, cost, and application specifics. While the 36 gauge copper sheet is a popular choice for its malleability and conductivity, various alternatives exist that may better suit specific project requirements. This analysis compares the 36 gauge copper sheet against two viable alternatives: aluminum sheets and stainless steel sheets.

| Comparison Aspect | 36 Gauge Copper Sheet | Aluminum Sheets | Stainless Steel Sheets |

|---|---|---|---|

| Performance | Excellent electrical and thermal conductivity; highly malleable | Good thermal conductivity; lightweight | Strong structural integrity; corrosion-resistant |

| Cost | Moderate to high cost, varies by supplier and purity | Generally lower cost, especially for thicker gauges | Higher cost due to alloying elements and manufacturing processes |

| Ease of Implementation | Easy to cut and shape; requires care to avoid tarnishing | Easy to work with; lightweight allows for simpler handling | Requires specialized tools for cutting and shaping; heavier |

| Maintenance | Requires regular cleaning to maintain appearance; prone to oxidation | Low maintenance; resistant to corrosion | Low maintenance; highly resistant to rust and corrosion |

| Best Use Case | Ideal for electrical applications, decorative arts, and crafts | Suitable for lightweight structures, packaging, and outdoor applications | Best for heavy-duty applications, food processing, and environments prone to corrosion |

Detailed Breakdown of Alternatives

Aluminum Sheets

Aluminum sheets offer a cost-effective alternative to copper, particularly when weight is a concern. They are lightweight, making them easier to handle and install. Aluminum also has a good level of thermal conductivity, albeit lower than copper. However, it does not match copper’s electrical conductivity, which limits its use in certain electrical applications. While aluminum is resistant to corrosion, it may require anodization or painting for aesthetic projects. Overall, aluminum sheets are best for applications where weight and cost are more critical than conductivity.

Stainless Steel Sheets

Stainless steel sheets are renowned for their strength and corrosion resistance, making them ideal for heavy-duty applications. While they excel in structural integrity, their thermal and electrical conductivity is inferior to copper. The processing of stainless steel requires specialized tools, and its weight can complicate installation. Maintenance is minimal, which is a significant advantage in environments where exposure to moisture is frequent. Stainless steel is particularly suited for food processing and industrial applications where hygiene and durability are paramount.

Conclusion: How to Choose the Right Solution

When considering alternatives to 36 gauge copper sheets, B2B buyers should weigh the specific requirements of their projects. If electrical conductivity and aesthetic qualities are paramount, copper remains unmatched. However, for projects prioritizing cost and weight, aluminum is a strong contender. On the other hand, stainless steel provides durability and corrosion resistance for heavy-duty applications. Ultimately, the decision should align with the project’s performance needs, budget constraints, and long-term maintenance considerations. By evaluating these factors, buyers can make informed choices that enhance their project outcomes.

Essential Technical Properties and Trade Terminology for 36 gauge copper sheet

What Are the Key Technical Properties of 36 Gauge Copper Sheet?

When considering 36 gauge copper sheets for industrial applications, understanding their technical specifications is crucial. Here are some critical properties that B2B buyers should be familiar with:

-

Material Grade (Copper Alloy 110)

Copper sheet of 36 gauge is typically made from Alloy 110, which is 99.9% pure copper. This high purity ensures excellent electrical and thermal conductivity, making it ideal for electrical and electronic applications. Understanding material grades helps in determining the suitability of copper for specific projects, especially in sectors like electronics, construction, and arts. -

Thickness (5 Mil / 0.005 inches)

The thickness of 36 gauge copper sheet is 5 mil, equivalent to 0.005 inches. This measurement is crucial for applications requiring specific weight and durability. Thicker sheets may be more suitable for structural applications, while thinner sheets can be ideal for decorative or crafting projects. Knowing the thickness helps buyers assess the product’s application and performance capabilities. -

Tolerance

Tolerance refers to the permissible limit of variation in physical dimensions. For copper sheets, a common tolerance might be +/- 0.125 inches. Understanding tolerance is essential for ensuring that the copper sheet fits correctly in its intended application, whether it be in manufacturing, construction, or arts. -

Finish Type (Annealed)

Most 36 gauge copper sheets come with an annealed finish, which makes the metal soft and malleable. This property allows for easier shaping and forming, which is particularly beneficial for artistic projects or custom fabrication. Buyers should consider the finish type based on how they plan to use the copper sheet. -

Weight (Approximately 3.74 ounces per square foot)

The weight of the copper sheet is an important factor for shipping and handling, as well as for the structural load it may need to support. Understanding the weight helps in logistics planning and ensures that the sheet can be managed safely during installation.

What Trade Terminology Should B2B Buyers Know When Purchasing Copper Sheets?

Navigating the B2B landscape involves familiarity with specific trade jargon. Here are some common terms related to purchasing 36 gauge copper sheets:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of copper sheets, an OEM might require specific grades or dimensions tailored for their products. Understanding OEM specifications ensures that buyers procure materials that meet their production needs. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management. Buyers should be aware of MOQs to avoid excess costs or inventory issues. -

RFQ (Request for Quote)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific quantities of materials. Utilizing RFQs can help buyers compare prices and terms effectively. This process is vital for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international shipping. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for managing the logistics of international trade effectively. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. This is critical for project planning, as delays can affect timelines and overall project costs. Buyers should factor in lead times when scheduling their operations.

By understanding these properties and terms, B2B buyers can make more informed purchasing decisions regarding 36 gauge copper sheets, ensuring they meet their specific application needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the 36 gauge copper sheet Sector

What Are the Key Market Dynamics Affecting the 36 Gauge Copper Sheet Sector?

The 36 gauge copper sheet market is currently shaped by several global drivers. Increased demand for renewable energy solutions, such as solar panels and electrical vehicles, is propelling the need for high-quality copper sheets due to their excellent conductivity. Additionally, industries such as construction and manufacturing are recognizing the versatility of copper, leading to broader applications ranging from decorative arts to structural components. The growth of e-commerce platforms has also simplified sourcing processes, allowing international buyers from regions like Africa, South America, the Middle East, and Europe (including Germany and Vietnam) to access a variety of suppliers with ease.

Emerging B2B technologies, including advanced supply chain management tools and digital marketplaces, are enhancing transparency and efficiency in sourcing. These technologies enable buyers to compare prices, assess quality, and evaluate supplier reliability more effectively. Furthermore, the rise of automated inventory management systems allows companies to optimize their stock levels, reducing lead times and costs. As international trade dynamics evolve, buyers must stay informed about tariffs, trade agreements, and geopolitical factors that can affect copper availability and pricing.

How Is Sustainability Shaping the Sourcing of 36 Gauge Copper Sheets?

Sustainability is becoming a critical focus in the sourcing of 36 gauge copper sheets. The environmental impact of copper mining and processing has led to an increasing demand for ethically sourced materials. B2B buyers are now more inclined to partner with suppliers who prioritize eco-friendly practices, such as using recycled copper or implementing responsible mining techniques. The adoption of “green” certifications, like the Responsible Minerals Initiative (RMI) and ISO 14001, is on the rise, providing buyers with assurances about the ethical sourcing of materials.

In addition, the trend towards circular economy practices is gaining traction. Companies are looking for suppliers who not only provide high-quality products but also engage in recycling programs or offer take-back schemes for end-of-life products. By prioritizing sustainable sourcing, businesses can reduce their carbon footprint, enhance their brand reputation, and meet the growing consumer demand for environmentally responsible products.

How Has the 36 Gauge Copper Sheet Market Evolved Over Time?

The 36 gauge copper sheet has a storied history, rooted in its versatile applications and inherent properties. Historically, copper has been favored for its excellent electrical and thermal conductivity, dating back to ancient civilizations that utilized the metal for tools and decorative artifacts. As industrialization progressed, the demand for copper expanded significantly, leading to innovations in processing techniques and the development of various alloys.

In recent years, the market has evolved further with the rise of digital technologies and e-commerce, transforming how B2B buyers source copper sheets. The availability of online platforms has democratized access to suppliers and facilitated global trade, making it easier for businesses in regions like Africa, South America, and Europe to procure high-quality copper products. This evolution reflects a broader trend towards increased connectivity and efficiency in the global marketplace, allowing companies to adapt swiftly to changing demands and market dynamics.

By understanding these trends and dynamics, international B2B buyers can make informed decisions in sourcing 36 gauge copper sheets that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of 36 gauge copper sheet

-

How do I determine the right thickness of copper sheet for my project?

Choosing the appropriate thickness for your copper sheet largely depends on the specific application. For most decorative and craft projects, 36 gauge (5 mil) copper is ideal due to its malleability and ease of use. However, for structural or heavy-duty applications, you might consider thicker gauges. It’s advisable to consult with your supplier about your project requirements to ensure you select the best thickness for durability and functionality. -

What are the primary applications for 36 gauge copper sheets?

36 gauge copper sheets are widely used in various industries, including electronics, construction, arts and crafts, and manufacturing. They are particularly suitable for applications like RF shielding, decorative items, and custom tabletops. Additionally, their pliability makes them a popular choice for embossing and repousse techniques in artistic endeavors. Understanding your specific use case will help you utilize this versatile material effectively. -

What should I consider when vetting international suppliers for copper sheets?

When sourcing copper sheets from international suppliers, evaluate their credibility by checking certifications, customer reviews, and industry reputation. Confirm that they comply with relevant standards, such as ASTM-B152 for copper sheets. Additionally, inquire about their production capabilities, quality assurance processes, and delivery timelines. A reliable supplier should also be open to providing samples and clear communication regarding order fulfillment. -

What are the minimum order quantities (MOQ) for 36 gauge copper sheets?

Minimum order quantities can vary significantly among suppliers. Some may offer flexible MOQs, while others might require bulk purchases for competitive pricing. Generally, it’s beneficial to discuss your specific needs with potential suppliers to negotiate favorable terms. If you are working on smaller projects, consider suppliers who allow for sample orders or smaller quantities to mitigate excess costs. -

What payment terms should I expect when purchasing copper sheets internationally?

Payment terms can differ based on the supplier and the nature of your business relationship. Common options include payment upfront, a deposit followed by the balance upon delivery, or letter of credit arrangements for larger transactions. Always clarify payment methods accepted by the supplier, including wire transfers, credit cards, or escrow services. Establishing clear terms early can help avoid misunderstandings later in the transaction. -

How can I ensure the quality of the copper sheets I receive?

To guarantee the quality of your copper sheets, request documentation such as Material Test Reports (MTRs) that certify the material’s purity and compliance with industry standards. Additionally, consider implementing quality assurance measures, such as on-site inspections or third-party testing. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations. -

What logistics considerations should I keep in mind when importing copper sheets?

When importing copper sheets, consider factors such as shipping costs, customs duties, and potential delays. Choose a reliable freight forwarder with experience in handling metal shipments, as they can provide valuable insights into logistics and regulatory requirements. Additionally, ensure that your supplier is aware of the necessary documentation for customs clearance to prevent any disruptions upon arrival. -

Can I customize my order for 36 gauge copper sheets in terms of size and finish?

Many suppliers offer customization options for copper sheets, including variations in size, finish, and even thickness. It’s essential to discuss your specific requirements with your supplier to determine their capabilities. Custom orders may have different lead times, so plan accordingly. Always confirm the final specifications in writing to avoid any discrepancies during production or delivery.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 36 Gauge Copper Sheet Manufacturers & Suppliers List

1. Basic Copper – 5 Mil Copper Sheet

Domain: basiccopper.com

Registered: 2006 (19 years)

Introduction: Product Name: 5 Mil/36 Ga. Copper Sheet

Thickness: 5 Mil (0.005 inches)

Gauge: 36

Material: Copper Alloy 110 (99.9% pure copper)

Finish: Smooth Commercial Finish/Annealed (Soft and Very Malleable)

Manufactured to: ASTM-B152 specifications

Applications: Embossing, repousse, home improvement projects, arts and crafts, manufacturing, electrical applications (including RF shielding), research and deve…

2. Basic Copper, Inc. – Copper Sheet/Plate 0.005 inches

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“Thickness”:”0.005 inches (5 Mil, 36 gauge)”,”Width”:”12 inches”,”Weight”:”4 oz.”,”Material”:”Copper”,”Alloy”:”110″,”Temper”:”Annealed”,”Shape”:”Sheet/Plate”,”MTR Availability”:”No”,”Brand”:”Basic Copper, Inc.”,”Weight/Lineal Foot”:”0.23 pounds”,”Mechanical Properties”:{“Brinell Hardness”:”57″,”Density”:”9 g/cm^3″,”Rockwell Hardness”:”10 B Scale”,”Ultimate Tensile Strength”:”32 KSI”,”Yield Tensil…

3. MetalsDepot® – Copper Sheet & Plate

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Copper Sheet & Plate Online! Copper Sheet & Plate 110 Copper Sheet & Plate is widely known for its architectural applications. Copper sheets and plates have excellent hot or cold workability, are ductile when heated, and are noted for their high electrical and thermal conductivity, and good corrosion resistance. Available in many sizes, sold only in unpolished industrial mill fi…

4. Copper – 32 oz, 19-Gauge Sheet

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “32 oz, 19-Gauge Copper Sheet”, “Dimensions”: “36” x 96″ (3′ x 8′)”, “Purity”: “99.999% PURE”, “Condition”: “New”, “Price”: “$599.00/ea”, “Bulk Pricing”: [{“Quantity”: 1, “Price”: “$599.00”}, {“Quantity”: 2, “Price”: “$581.03/ea”}, {“Quantity”: 3, “Price”: “$569.05/ea”}, {“Quantity”: 4, “Price”: “$557.07/ea”}], “Shipping”: “$104.04 UPS Ground”, “Returns”: “14 days returns, buyer p…

5. Cut2Size Metals – Copper 110 Sheets

Domain: cut2sizemetals.com

Registered: 2009 (16 years)

Introduction: Cut2Size Metals offers 110 copper sheet in various thicknesses. Copper 110, also known as Electrolytic Tough Pitch (ETP) copper, is 99.9% pure and is the most common form of copper due to its versatility. It features excellent electrical conductivity, high corrosion resistance, great thermal conductivity, and solid forgeability. Common applications include electromagnets, motors, flashing, roofing…

6. Best Materials – Copper Roofing Sheet

Domain: bestmaterials.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “Copper Roofing Sheet”, “Dimensions”: “36 x 120 inch”, “Weight”: “30 Lb”, “Thickness”: “0.020 inch”, “Material”: “Pure Copper”, “Finish”: “Mill Finish”, “Price”: “$559.99”, “Original Price”: “$975.00”, “Savings”: “$415.01”, “Shipping Leadtime”: “1-2 business days”, “Order Options”: “Price/Each”, “Features”: [“Solid copper sheet”, “1-lb square foot”, “Roofing/Architectural Finish”,…

7. Reddit – Copper Sheet Cutting Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Copper Sheet Cutting Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for 36 gauge copper sheet

How Can Strategic Sourcing Enhance Your Procurement of 36 Gauge Copper Sheet?

In conclusion, the strategic sourcing of 36 gauge copper sheets presents an exceptional opportunity for international B2B buyers to enhance their supply chain efficiency and product quality. By prioritizing suppliers who offer high-purity copper, such as Alloy 110, companies can ensure they receive materials that meet stringent industry standards for various applications, from manufacturing to art projects. Additionally, leveraging the versatility of 36 gauge copper sheets allows for creative solutions in diverse sectors, enhancing product offerings and customer satisfaction.

For buyers in Africa, South America, the Middle East, and Europe, establishing relationships with reliable suppliers can lead to cost savings and improved service levels. It is crucial to consider factors such as material integrity, supplier responsiveness, and logistical capabilities when selecting a vendor.

Looking ahead, the demand for high-quality copper materials is expected to grow, driven by advancements in technology and sustainability initiatives. Engage with trusted suppliers today to secure your copper needs and stay ahead in a competitive market. Your proactive approach to sourcing will not only optimize your operations but also position your business for future success.