Introduction: Navigating the Global Market for 316 stainless steel price per pound

In the competitive landscape of international manufacturing, understanding the 316 stainless steel price per pound can pose significant challenges for B2B buyers. Fluctuating prices, varying quality standards, and sourcing complexities can complicate procurement processes, particularly for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe. This guide is designed to demystify the pricing landscape of 316 stainless steel, providing you with the insights needed to make informed purchasing decisions.

Throughout this comprehensive guide, we will explore various aspects of 316 stainless steel, including its types, applications, and the factors influencing pricing. We will also delve into effective supplier vetting strategies, enabling you to identify reliable partners and mitigate risks associated with international transactions. Moreover, we will offer actionable insights on negotiating favorable terms and understanding the total cost of ownership, ensuring you maximize value in your investments.

By equipping international B2B buyers with critical knowledge and tools, this guide empowers you to navigate the complexities of sourcing 316 stainless steel with confidence. Whether you are in Nigeria, Vietnam, or elsewhere, you will be better positioned to secure the best materials at competitive prices, ultimately driving your business forward in a global market.

Understanding 316 stainless steel price per pound Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 316 Stainless Steel Sheet | Thin, flat pieces available in various thicknesses | Marine, chemical processing, food industry | Pros: Versatile and easy to fabricate. Cons: Prone to scratching. |

| 316 Stainless Steel Plate | Thick, durable material ideal for heavy-duty applications | Construction, manufacturing, aerospace | Pros: High strength and corrosion resistance. Cons: Heavier and more expensive. |

| 316 Stainless Steel Bar | Solid, long lengths used for structural support | Construction, automotive, machinery | Pros: Excellent tensile strength. Cons: Limited shape options. |

| 316 Stainless Steel Pipe | Tubular form, suitable for transporting fluids | Oil & gas, water treatment, HVAC systems | Pros: High pressure tolerance. Cons: Installation can be complex. |

| 316 Stainless Steel Wire | Thin strands used for various applications | Electrical, construction, decorative uses | Pros: Flexibility and corrosion resistance. Cons: Less structural integrity compared to bars. |

What Are the Key Characteristics of 316 Stainless Steel Sheet?

316 stainless steel sheets are thin, flat pieces that come in various thicknesses, making them ideal for applications requiring flexibility and ease of fabrication. They are particularly useful in marine environments, chemical processing, and the food industry due to their excellent corrosion resistance. When purchasing, buyers should consider the thickness required for their specific applications, as well as the potential for scratching during handling and installation.

How Does 316 Stainless Steel Plate Differ in Application?

316 stainless steel plates are thicker and more durable than sheets, making them suitable for heavy-duty applications such as construction, manufacturing, and aerospace. Their high strength and resistance to corrosion make them a preferred choice in environments exposed to harsh chemicals or extreme conditions. Buyers should evaluate the weight and cost implications, as these plates can be heavier and more expensive than other options.

What Role Does 316 Stainless Steel Bar Play in Structural Support?

316 stainless steel bars are solid lengths used primarily for structural support in construction, automotive, and machinery applications. They offer excellent tensile strength, which is critical for load-bearing applications. However, buyers should note that while bars provide superior strength, they come with limited shape options compared to other forms, which may restrict design flexibility.

Why Choose 316 Stainless Steel Pipe for Fluid Transport?

316 stainless steel pipes are tubular and designed for transporting fluids in industries such as oil & gas, water treatment, and HVAC systems. Their high pressure tolerance is a key feature, ensuring safety and reliability in fluid transport. Buyers must consider installation complexities, as piping systems often require specialized fittings and techniques, which can add to overall project costs.

What Are the Benefits of 316 Stainless Steel Wire in Various Applications?

316 stainless steel wire is characterized by its thin strands, making it suitable for a wide range of applications, including electrical, construction, and decorative uses. Its flexibility and corrosion resistance are significant advantages, especially in outdoor or humid environments. However, buyers should be aware that while wire is versatile, it may lack the structural integrity required for certain heavy-duty applications, limiting its use in load-bearing scenarios.

Key Industrial Applications of 316 stainless steel price per pound

| Industry/Sector | Specific Application of 316 stainless steel price per pound | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine and Offshore | Fabrication of marine hardware and components | Corrosion resistance in saltwater environments | Compliance with maritime standards and certifications |

| Chemical Processing | Construction of storage tanks and piping systems | Enhanced resistance to harsh chemicals and heat | Material certifications and compatibility assessments |

| Food and Beverage | Manufacturing of food processing equipment | Hygiene and ease of cleaning to meet health standards | Certifications for food safety and quality control |

| Pharmaceutical Industry | Production of equipment for drug manufacturing | Non-reactive properties ensuring product integrity | Regulatory compliance and traceability of materials |

| Construction and Architecture | Use in architectural features and structural supports | Aesthetic appeal combined with durability | Design specifications and local building codes |

In the Marine and Offshore industry, 316 stainless steel is critical for fabricating marine hardware and components such as boat fittings, deck equipment, and railings. Its exceptional corrosion resistance in saltwater environments significantly extends the lifespan of these components, reducing maintenance costs for operators. International buyers, particularly in regions like Africa and the Middle East, should ensure their suppliers comply with maritime standards and certifications to guarantee quality and reliability.

Within the Chemical Processing sector, 316 stainless steel is extensively used in constructing storage tanks, piping systems, and reactors. Its enhanced resistance to corrosive chemicals and high temperatures makes it ideal for handling aggressive substances without compromising safety or structural integrity. Buyers must consider the need for material certifications and compatibility assessments to ensure that the steel meets their specific processing requirements.

In the Food and Beverage industry, 316 stainless steel is vital for manufacturing equipment such as mixers, conveyors, and storage tanks. The material’s non-reactive properties ensure that it does not contaminate food products, while its ease of cleaning meets stringent health and safety standards. B2B buyers must prioritize suppliers that provide certifications for food safety and quality control to maintain compliance with industry regulations.

The Pharmaceutical Industry relies on 316 stainless steel for producing equipment used in drug manufacturing, including reactors and storage containers. Its non-reactive nature ensures that the integrity of sensitive pharmaceutical products is maintained throughout the manufacturing process. Buyers should focus on regulatory compliance and traceability of materials to guarantee that their sourcing meets industry standards and avoids contamination risks.

Lastly, in Construction and Architecture, 316 stainless steel is utilized for architectural features and structural supports due to its aesthetic appeal and durability. Its ability to withstand environmental stressors makes it a preferred choice for modern designs. When sourcing, it is essential for buyers to adhere to local building codes and design specifications to ensure compliance and safety in construction projects.

3 Common User Pain Points for ‘316 stainless steel price per pound’ & Their Solutions

Scenario 1: Fluctuating Prices Affecting Budget Forecasts

The Problem: B2B buyers often struggle with the volatility of 316 stainless steel prices. When purchasing in bulk for large projects, sudden price hikes can disrupt budget forecasts and lead to potential losses. For buyers in regions like Africa and South America, where economic conditions can fluctuate rapidly, the inability to predict future costs can severely impact project timelines and overall profitability.

The Solution: To mitigate the impact of price fluctuations, buyers should consider establishing long-term contracts with suppliers that allow for fixed pricing or capped price agreements. This strategy not only provides price stability but also fosters a more reliable supplier relationship. Additionally, buyers can engage in market analysis to track price trends and forecast potential increases. Utilizing tools such as price alerts from reputable suppliers can also help buyers make informed purchasing decisions before prices rise. Finally, diversifying suppliers can provide a safety net; if one supplier raises prices, buyers can pivot to others that offer competitive rates.

Scenario 2: Difficulty in Sourcing Quality Materials

The Problem: International buyers often face challenges in sourcing high-quality 316 stainless steel due to varying standards and specifications across suppliers. In regions such as the Middle East and Europe, the lack of clarity on material grades can lead to the procurement of subpar products, which can jeopardize project integrity and safety.

The Solution: To ensure the procurement of quality materials, buyers should prioritize suppliers who provide detailed material certifications, including mill test reports (MTRs) that verify the chemical and physical properties of the steel. Buyers should also invest time in building relationships with suppliers who have established reputations for quality and compliance with international standards, such as ASTM or ISO. It is beneficial to conduct site visits or audits when possible to assess the supplier’s operations and quality control processes. Additionally, leveraging industry networks and trade associations can help buyers identify trustworthy suppliers and share experiences regarding material quality.

Scenario 3: Understanding Total Cost of Ownership (TCO)

The Problem: Many B2B buyers focus solely on the price per pound of 316 stainless steel without considering the total cost of ownership (TCO). This oversight can lead to unexpected expenses related to maintenance, processing, and even shipping, particularly for buyers in remote locations such as Nigeria or Vietnam where logistics can add significant costs.

The Solution: To gain a comprehensive understanding of TCO, buyers should evaluate all associated costs beyond the initial purchase price. This includes shipping fees, import duties, and potential tariffs that may apply when sourcing materials internationally. Buyers should also consider the longevity and maintenance requirements of 316 stainless steel, as its corrosion resistance can lead to lower maintenance costs over time compared to lower-grade alternatives. Conducting a cost-benefit analysis that factors in these variables can help buyers make more informed purchasing decisions. Moreover, collaborating with logistics experts can streamline the supply chain process, ensuring that all costs are accounted for and that the materials arrive on time and in optimal condition.

Strategic Material Selection Guide for 316 stainless steel price per pound

When selecting materials for applications requiring 316 stainless steel, it’s essential to consider various alternatives based on specific performance needs, cost implications, and international compliance standards. Below, we analyze three common materials that are often compared with 316 stainless steel in terms of price per pound and application suitability.

What are the Key Properties of 316 Stainless Steel?

316 stainless steel is renowned for its excellent corrosion resistance, particularly in chloride environments, making it suitable for marine applications. It has a temperature rating of up to 1,600°F (870°C) and can withstand high pressures, which is critical in industrial settings. The addition of molybdenum enhances its resistance to pitting and crevice corrosion, making it a preferred choice for chemical processing and food industries.

What are the Pros and Cons of Using 316 Stainless Steel?

Pros:

– Durability: 316 stainless steel is highly durable and can withstand harsh environments, making it ideal for long-term applications.

– Corrosion Resistance: Its resistance to corrosion, especially in saline and acidic conditions, is superior to many other materials.

– Versatility: It can be fabricated into various forms, including sheets, plates, and tubes, allowing for diverse applications.

Cons:

– Cost: 316 stainless steel is generally more expensive than alternatives like 304 stainless steel or carbon steel.

– Manufacturing Complexity: The fabrication process can be more complex due to its toughness, potentially increasing production costs.

How Does 316 Stainless Steel Impact Application Performance?

In applications involving exposure to seawater, chemicals, or high temperatures, 316 stainless steel significantly enhances product longevity and reliability. Its compatibility with various media, including acids and chlorides, ensures that it maintains structural integrity over time. For international buyers, understanding the specific media compatibility is crucial for ensuring the material meets operational requirements.

What Should International B2B Buyers Consider When Selecting 316 Stainless Steel?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various compliance and standards. Common standards include ASTM for the U.S., DIN for Germany, and JIS for Japan. Buyers should also consider local regulations regarding material sourcing and environmental impact. Additionally, understanding the logistics and potential tariffs associated with importing stainless steel can influence overall costs.

Comparative Analysis of Alternative Materials

-

304 Stainless Steel

– Key Properties: Good corrosion resistance, lower cost than 316.

– Pros: Cost-effective, widely available, easy to fabricate.

– Cons: Less corrosion-resistant than 316, not suitable for chloride environments. -

Carbon Steel

– Key Properties: Strong and durable, but prone to rust.

– Pros: Low cost, high strength.

– Cons: Poor corrosion resistance, requires protective coatings. -

Aluminum

– Key Properties: Lightweight, good corrosion resistance.

– Pros: Lightweight, easy to machine, cost-effective.

– Cons: Lower strength compared to stainless steel, not suitable for high-temperature applications.

Summary Table

| Material | Typical Use Case for 316 stainless steel price per pound | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 316 Stainless Steel | Marine applications, chemical processing equipment | Excellent corrosion resistance | Higher cost compared to alternatives | High |

| 304 Stainless Steel | Food processing, kitchen equipment | Cost-effective and widely available | Less corrosion-resistant in saline | Medium |

| Carbon Steel | Structural applications, automotive parts | Low cost and high strength | Prone to rust, requires coatings | Low |

| Aluminum | Aerospace, packaging, automotive parts | Lightweight and easy to machine | Lower strength, not for high temps | Medium |

This comparative analysis provides B2B buyers with critical insights into material selection, enabling informed decisions based on application requirements and budget considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 316 stainless steel price per pound

What Are the Key Stages in the Manufacturing Process of 316 Stainless Steel?

The manufacturing process of 316 stainless steel involves several critical stages that ensure the material meets the specifications required for various industrial applications. Understanding these stages is essential for B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe.

Material Preparation

The first step in manufacturing 316 stainless steel is material preparation. This involves sourcing high-quality raw materials, primarily iron, chromium, nickel, and molybdenum. The purity of these materials directly affects the final product’s quality. Suppliers often conduct preliminary tests to confirm the chemical composition before proceeding to the melting stage.

Melting and Alloying

Once the raw materials are verified, they are melted in an electric arc furnace (EAF) or a vacuum induction furnace (VIF). This process allows for precise control over the temperature and composition, ensuring that the desired alloy properties are achieved. During this phase, the materials are mixed to create the specific 316 stainless steel alloy, which contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.

Forming and Shaping

The molten alloy is then cast into ingots or slabs, which are subsequently cooled and solidified. The next stage involves forming and shaping the steel into various products, such as sheets, plates, and pipes. Techniques like hot rolling and cold working are commonly employed to achieve the desired thickness and dimensions. Hot rolling is particularly effective for large-scale production, while cold working enhances the material’s strength and finish.

Finishing Processes

Finishing processes include annealing, pickling, and passivation. Annealing involves heating the steel to relieve internal stresses and improve ductility. Pickling removes surface impurities and oxides, while passivation enhances corrosion resistance by forming a protective oxide layer. These processes are crucial for ensuring that the final product meets industry-specific requirements and is ready for use in demanding environments.

How Is Quality Assurance Implemented in 316 Stainless Steel Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for 316 stainless steel. It ensures that the products meet international standards and customer specifications.

What Are the Relevant International Standards?

B2B buyers should be aware of various international standards that govern the quality of stainless steel. ISO 9001 is a widely recognized standard for quality management systems, ensuring consistency in production and service delivery. Additionally, industry-specific certifications such as CE marking and API (American Petroleum Institute) standards are crucial for certain applications, particularly in construction and oil and gas.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically conducted at several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified chemical and physical properties.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is performed to detect any deviations from standards. This includes checking dimensions, mechanical properties, and surface quality.

-

Final Quality Control (FQC): Once production is complete, the final products undergo comprehensive testing, including dimensional checks, mechanical property tests, and corrosion resistance evaluations.

What Common Testing Methods Are Used in 316 Stainless Steel Production?

Several testing methods are employed to ensure the quality of 316 stainless steel:

-

Chemical Analysis: This includes spectrometry and titration methods to verify the alloy’s composition.

-

Mechanical Testing: Tensile tests, hardness tests, and impact tests assess the material’s strength and ductility.

-

Corrosion Testing: Tests such as salt spray tests and electrochemical testing evaluate the corrosion resistance of the stainless steel.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from emerging markets, verifying supplier quality control is essential. Here are several strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality management systems. This includes reviewing their certifications, quality control protocols, and production capabilities.

-

Quality Reports: Requesting detailed quality reports and certificates of conformity can help verify that the products meet required standards. Suppliers should provide documentation for all testing and inspections performed.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. This is particularly beneficial for large orders or critical applications.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the quality control landscape can be complex for international buyers. Factors such as regional standards, language barriers, and varying levels of supplier expertise can complicate the purchasing process.

-

Understanding Regional Standards: Buyers should familiarize themselves with both international and local standards applicable to their industries. This knowledge is crucial for assessing supplier capabilities.

-

Communication: Clear communication with suppliers regarding quality expectations and standards is vital. Misunderstandings can lead to discrepancies in product quality.

-

Building Relationships: Establishing strong relationships with suppliers can facilitate better quality assurance practices. Regular communication and feedback can help ensure that quality remains a priority throughout the production process.

Conclusion

An in-depth understanding of the manufacturing processes and quality assurance measures for 316 stainless steel is essential for B2B buyers. By being informed about the stages of production, relevant quality standards, and effective verification methods, international buyers can make educated decisions that align with their specific needs. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘316 stainless steel price per pound’

This guide provides a structured approach for B2B buyers looking to procure 316 stainless steel, focusing specifically on understanding its price per pound. By following these steps, you can ensure you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for 316 stainless steel. This includes specifying dimensions, thickness, and form (sheet, plate, bar, etc.). Having precise specifications helps suppliers provide accurate quotes and ensures that the material meets your project’s standards.

Step 2: Research Market Prices

Conduct thorough research on current market prices for 316 stainless steel per pound. Utilize online resources, industry reports, and local suppliers to gather data. Understanding the price range will empower you to negotiate better and avoid overpaying.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Evaluate their production capabilities, delivery timelines, and customer service reputation to ensure they can meet your requirements.

- Check for Certifications: Look for suppliers with relevant industry certifications, such as ISO or ASTM standards, which demonstrate their commitment to quality.

Step 4: Request Quotes and Compare Offers

Once you have a shortlist of suppliers, request detailed quotes that include pricing per pound, shipping costs, and payment terms. Comparing multiple offers allows you to identify the best value while ensuring you understand the total cost of procurement.

- Consider Bulk Discounts: Inquire if the supplier offers discounts for larger orders, as this can significantly lower your overall costs.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with your selected suppliers to finalize terms and conditions. This should include payment terms, delivery schedules, and return policies. Effective negotiation can lead to cost savings and more favorable terms for your business.

- Clarify Quality Assurance: Ensure that the supplier has a clear quality assurance process in place, which includes inspections and testing of the material before shipping.

Step 6: Confirm Delivery and Logistics Arrangements

Once you have agreed on terms, confirm the logistics arrangements for delivery. Discuss shipping options, estimated delivery times, and any customs requirements, especially if you’re sourcing internationally. Proper planning will help prevent delays in your production schedule.

Step 7: Monitor Market Trends and Supplier Performance

After your procurement, continuously monitor market trends related to 316 stainless steel prices and assess your supplier’s performance. Keeping abreast of industry developments can inform future purchases and help maintain strong supplier relationships.

By following this checklist, B2B buyers can effectively navigate the procurement process for 316 stainless steel, ensuring they achieve optimal pricing and quality for their projects.

Comprehensive Cost and Pricing Analysis for 316 stainless steel price per pound Sourcing

What Are the Key Cost Components in Sourcing 316 Stainless Steel?

When sourcing 316 stainless steel, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The price of raw 316 stainless steel is influenced by market fluctuations and the global demand for nickel and chromium, which are key alloying elements. Prices can vary significantly based on supplier relationships and regional availability.

-

Labor: Labor costs encompass the wages of skilled workers involved in production, fabrication, and quality assurance. These costs can differ widely depending on the region, with labor-intensive processes potentially increasing overall expenses.

-

Manufacturing Overhead: This includes the indirect costs associated with production facilities, machinery maintenance, utilities, and administrative expenses. Buyers should factor in these costs when evaluating supplier pricing.

-

Tooling: Customization of products, such as unique dimensions or finishes, may require specific tooling investments. This can lead to additional charges, especially for low-volume orders.

-

Quality Control (QC): Ensuring compliance with industry standards and certifications can incur costs related to testing, inspections, and certifications. Buyers should inquire about QC practices to understand their impact on pricing.

-

Logistics: Transportation costs, including freight, handling, and storage, are significant, particularly for international shipments. Incoterms play a critical role in determining who bears these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the competitive landscape can help buyers gauge the reasonableness of supplier quotes.

How Do Volume and Specifications Influence Pricing?

The price of 316 stainless steel is often influenced by purchase volume and specific requirements:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally lead to lower per-pound costs due to economies of scale. Suppliers may offer significant discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Unique specifications, such as thickness, finish, or certification requirements, can increase costs. Custom solutions often require additional tooling and processing, which should be factored into the overall budget.

-

Quality and Certifications: Higher-grade materials with specific certifications (e.g., ASTM, ISO) tend to command a premium price. Buyers should assess their quality requirements against budget constraints to find the right balance.

What Buyer Tips Can Enhance Cost-Efficiency?

To navigate the complexities of sourcing 316 stainless steel, B2B buyers should consider the following strategies:

-

Negotiation: Establish strong relationships with suppliers to negotiate better terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Total Cost of Ownership (TCO): Evaluate not only the price per pound but also associated costs such as shipping, handling, and potential waste. A lower initial price may not result in overall savings if additional costs arise.

-

Pricing Nuances for International Buyers: For buyers from regions like Africa, South America, the Middle East, and Europe, currency fluctuations and import tariffs can significantly affect total costs. Awareness of these factors is crucial when budgeting for purchases.

-

Supplier Factors: Assessing supplier reliability, lead times, and after-sales support can influence long-term costs. A dependable supplier may justify a higher price point through consistent quality and service.

What Should Buyers Know About Indicative Prices?

It’s important to note that the prices for 316 stainless steel can fluctuate based on market conditions. Therefore, while indicative prices may provide a general idea, buyers should seek quotes from multiple suppliers to obtain the most accurate and competitive pricing. Additionally, staying informed about market trends and material costs can empower buyers to make informed purchasing decisions.

Alternatives Analysis: Comparing 316 stainless steel price per pound With Other Solutions

Introduction: Understanding Alternatives to 316 Stainless Steel

In the competitive landscape of industrial materials, 316 stainless steel is often favored for its corrosion resistance and durability. However, B2B buyers must consider alternatives that may meet their specific needs while offering different performance characteristics and cost structures. This analysis compares 316 stainless steel against two viable alternatives: 304 stainless steel and aluminum alloys, providing insights into their respective advantages and limitations.

Comparison Table

| Comparison Aspect | 316 Stainless Steel Price Per Pound | 304 Stainless Steel | Aluminum Alloys |

|---|---|---|---|

| Performance | Excellent corrosion resistance | Good corrosion resistance, less than 316 | Moderate corrosion resistance, varies by alloy |

| Cost | $2.50 – $3.00 per pound | $1.50 – $2.00 per pound | $1.00 – $2.50 per pound |

| Ease of Implementation | Moderate; requires specialized tools | Easy; common fabrication practices | Easy; lightweight, easy to work with |

| Maintenance | Low; resistant to rust and staining | Low; susceptible to pitting in saline environments | Moderate; may require protective coatings |

| Best Use Case | Marine applications, chemical processing | Food and beverage industry, general fabrication | Automotive, aerospace, and construction applications |

Detailed Breakdown of Alternatives

304 Stainless Steel: A Cost-Effective Solution

304 stainless steel is often considered a cost-effective alternative to 316 stainless steel. While it offers good corrosion resistance, particularly in food processing environments, it is not as resistant to chlorides, making it less suitable for marine applications. The cost savings can be significant, with prices generally ranging from $1.50 to $2.00 per pound. However, buyers should be cautious of its limitations in highly corrosive environments, as it may require more frequent replacements or maintenance.

Aluminum Alloys: Lightweight and Versatile

Aluminum alloys provide a lightweight alternative, making them particularly advantageous for industries such as automotive and aerospace. With prices typically between $1.00 and $2.50 per pound, they present a budget-friendly option. However, the corrosion resistance of aluminum varies significantly depending on the alloy, with some types requiring protective coatings to enhance durability. Their ease of fabrication and lower weight can lead to reduced shipping and installation costs, making them an attractive choice for many applications.

Conclusion: Choosing the Right Material for Your Needs

When selecting between 316 stainless steel and its alternatives, B2B buyers should assess their specific application requirements, including environmental conditions, budget constraints, and long-term maintenance considerations. While 316 stainless steel excels in corrosive environments, alternatives like 304 stainless steel and aluminum alloys can offer significant cost and weight advantages in less demanding applications. Ultimately, the decision should align with the operational goals and the specific challenges faced by the business in its respective industry.

Essential Technical Properties and Trade Terminology for 316 stainless steel price per pound

What Are the Key Technical Properties of 316 Stainless Steel?

Understanding the essential technical properties of 316 stainless steel is crucial for B2B buyers looking to make informed purchasing decisions. Here are some of the most important specifications:

-

Material Grade

316 stainless steel is classified as an austenitic stainless steel, which includes molybdenum, enhancing its resistance to corrosion, particularly in chloride environments. This property makes it ideal for marine applications and chemical processing. Buyers should evaluate the grade to ensure it meets the specific requirements of their projects. -

Thickness and Tolerance

The thickness of 316 stainless steel products can vary, often ranging from 0.016 inches to several inches. Tolerance indicates how much the actual dimensions can deviate from specified measurements. Accurate thickness and tolerance are vital for ensuring proper fit and function in applications, reducing the likelihood of costly rework. -

Mechanical Properties

Key mechanical properties of 316 stainless steel include yield strength, tensile strength, and elongation. For instance, the yield strength typically hovers around 30,000 psi, while tensile strength is about 70,000 psi. Understanding these properties helps B2B buyers assess whether the material can withstand the stresses of their intended applications. -

Corrosion Resistance

One of the standout features of 316 stainless steel is its excellent corrosion resistance, particularly in acidic and saline environments. This property is essential for industries like oil and gas, pharmaceuticals, and food processing, where material integrity is crucial for safety and compliance. -

Finish Types

Stainless steel can come in various finishes, such as brushed, polished, or matte. The finish not only affects aesthetics but also influences corrosion resistance and ease of cleaning. Buyers should consider the finish type that aligns with their application needs. -

Weldability

The weldability of 316 stainless steel is another important property. It can be easily welded using various methods, making it versatile for construction and manufacturing processes. However, post-welding treatments may be necessary to maintain corrosion resistance.

Which Trade Terms Should B2B Buyers Understand When Purchasing 316 Stainless Steel?

Navigating the terminology of stainless steel procurement can be challenging. Here are some common trade terms that B2B buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is essential for ensuring compatibility and quality in your supply chain. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage their inventory and budget effectively, ensuring they do not overcommit financially. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This is a critical step in the procurement process, allowing buyers to compare options and negotiate better deals. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms can help mitigate risks and avoid misunderstandings in cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. It is crucial for supply chain planning, as longer lead times can affect project timelines and inventory management. -

Certification

Certifications, such as ASTM or ISO standards, validate the quality and compliance of materials. Buyers should always check for relevant certifications to ensure they meet industry standards and regulations.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing 316 stainless steel, ultimately leading to better procurement outcomes.

Navigating Market Dynamics and Sourcing Trends in the 316 stainless steel price per pound Sector

What are the Current Market Dynamics Influencing the 316 Stainless Steel Price per Pound?

The global market for 316 stainless steel is characterized by dynamic shifts influenced by various economic and environmental factors. One of the primary drivers is the increasing demand from industries such as construction, automotive, and food processing, particularly in regions like Africa, South America, the Middle East, and Europe. For instance, the rise in infrastructure projects across Africa and the growing manufacturing sector in South America have amplified the demand for durable and corrosion-resistant materials like 316 stainless steel.

Additionally, the ongoing transition to Industry 4.0 is reshaping sourcing strategies. Businesses are increasingly adopting digital platforms to streamline procurement processes, allowing for better price transparency and supplier comparisons. Technologies such as AI and machine learning are also enhancing predictive analytics, helping buyers anticipate price fluctuations and optimize inventory management. Emerging trends like just-in-time inventory systems are becoming more prevalent, enabling companies to reduce holding costs while maintaining flexibility in sourcing.

Moreover, geopolitical factors, including trade policies and tariffs, significantly impact pricing. For example, restrictions on imports from certain countries can lead to increased prices in regions reliant on foreign supply. Understanding these market dynamics is crucial for international B2B buyers looking to make informed purchasing decisions regarding 316 stainless steel.

How is Sustainability Impacting the Sourcing of 316 Stainless Steel?

Sustainability is increasingly becoming a focal point for B2B buyers in the 316 stainless steel sector. The environmental impact of steel production is substantial, contributing to greenhouse gas emissions and resource depletion. As a response, many companies are prioritizing ethical sourcing and sustainability in their supply chains. Buyers are now more inclined to partner with suppliers that demonstrate a commitment to reducing their carbon footprint and employing sustainable practices.

The significance of ethical supply chains is underscored by the growing consumer demand for products that are environmentally friendly. Certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming essential criteria for B2B buyers. Furthermore, the circular economy model is gaining traction, where stainless steel products are designed for reuse and recycling, thus minimizing waste.

Incorporating sustainability into sourcing strategies not only meets regulatory requirements but also enhances brand reputation and can lead to cost savings over time. For B2B buyers in regions like Europe and the Middle East, where environmental regulations are stringent, ensuring that suppliers adhere to sustainable practices is critical for long-term competitiveness.

What is the Historical Context of 316 Stainless Steel Pricing?

The evolution of 316 stainless steel pricing has been shaped by various historical and economic factors. Initially developed in the early 20th century, 316 stainless steel gained prominence due to its superior resistance to corrosion and heat compared to other alloys. Its unique properties made it a preferred choice in marine applications and chemical processing industries.

Over the decades, fluctuations in raw material costs, particularly nickel and molybdenum, have significantly influenced pricing. The rise of global demand, especially in emerging markets, has also contributed to price volatility. As supply chains became more interconnected, events such as natural disasters or geopolitical tensions have had an immediate impact on availability and pricing.

In recent years, the push towards sustainability and ethical sourcing has led to a shift in how prices are determined. Buyers are now more informed and willing to pay a premium for sustainably sourced materials, reflecting a broader trend of integrating environmental and social governance (ESG) criteria into procurement processes. Understanding this historical context provides valuable insights for B2B buyers navigating the complexities of the current 316 stainless steel market.

Frequently Asked Questions (FAQs) for B2B Buyers of 316 stainless steel price per pound

-

How do I determine the current price of 316 stainless steel per pound?

To find the current price of 316 stainless steel per pound, consider monitoring various metal market reports and industry publications that provide daily pricing updates. Additionally, engaging with suppliers who specialize in stainless steel can yield real-time quotes based on your specific needs. Online platforms and marketplaces can also offer comparative pricing, but ensure you account for any regional factors that may influence costs, such as tariffs or shipping fees. -

What factors influence the price of 316 stainless steel?

The price of 316 stainless steel is influenced by several factors, including raw material costs, manufacturing processes, demand and supply dynamics, and global market conditions. Additionally, geographical location plays a crucial role, as shipping costs and tariffs can add to the final price. Fluctuations in nickel and molybdenum prices, essential components in 316 stainless steel, can also directly impact pricing. -

What are the typical minimum order quantities (MOQ) for 316 stainless steel?

Minimum order quantities for 316 stainless steel can vary significantly depending on the supplier and the form of steel (sheet, plate, bar, etc.). Generally, MOQs can range from 500 pounds to several tons. It’s advisable to discuss your specific requirements with suppliers to negotiate favorable terms, especially if you’re testing new applications or looking for customized solutions. -

How can I vet suppliers of 316 stainless steel?

Vetting suppliers requires a comprehensive approach. Start by checking their industry certifications, such as ISO standards, to ensure quality assurance. Request references and reviews from other clients, and assess their responsiveness and customer service. Additionally, evaluate their production capabilities and lead times, and consider visiting their facilities if possible. Establishing clear communication regarding your specifications and expectations is also crucial. -

What payment terms should I expect when purchasing 316 stainless steel?

Payment terms can vary by supplier but typically include options such as upfront deposits, net 30/60/90 days, or letters of credit for larger orders. It’s crucial to clarify these terms before finalizing any agreements. Establishing a solid relationship with your supplier may provide leverage for better payment conditions. Always ensure that payment methods are secure, especially in international transactions. -

How can I customize my order of 316 stainless steel?

Many suppliers offer customization options for 316 stainless steel, such as specific dimensions, thicknesses, and finishes. When placing an order, clearly communicate your requirements regarding size, shape, and any treatments (like annealing or pickling). Some suppliers may also provide machining or fabrication services, enabling you to receive materials ready for immediate use in your applications. -

What quality assurance processes should I look for in 316 stainless steel suppliers?

Quality assurance processes are essential to ensure that the 316 stainless steel you receive meets industry standards. Look for suppliers who conduct regular inspections and tests, such as tensile strength tests, corrosion resistance evaluations, and certifications from recognized standards organizations. Inquire about their traceability systems for raw materials, which can help track the quality of the steel throughout the supply chain. -

What logistics considerations are important for importing 316 stainless steel?

When importing 316 stainless steel, consider factors like shipping methods, delivery timelines, and customs clearance procedures. Collaborate with logistics providers experienced in handling metal imports to navigate tariffs, duties, and documentation requirements effectively. It’s also wise to plan for potential delays due to international shipping challenges and ensure that your supplier can accommodate your delivery schedule to avoid production disruptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 316 Stainless Steel Price Per Pound Manufacturers & Suppliers List

1. Metals Depot – Stainless Sheet Type 316

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “Stainless Sheet Type 316”, “Material Type”: “316/316L Stainless Steel Sheet”, “Corrosion Resistance”: “Superior”, “Finish Options”: [“2B Mill Finish”, “#4 Brushed Polish”], “Use Cases”: [“Marine environments”, “Highly acidic environments”, “Underwater equipment”, “Surgical tools”, “Food applications”, “Pharmaceutical applications”], “Mechanical Properties”: {“Tensile Strength”: “…

2. SGT Scrap – Stainless Steel Pricing

Domain: sgt-scrap.com

Registered: 2013 (12 years)

Introduction: This company, SGT Scrap – Stainless Steel Pricing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Speedy Metals – 1/4 316 Stainless Steel Plate

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “1/4″ 316 Stainless Steel Plate”, “Material”: “Stainless Steel”, “Grade”: “316”, “Shape”: “Plate”, “Dimensions”: [{“Length”: “12” , “Width”: “12”, “Weight”: “11.1600 lbs”, “Price”: “$144.68”}, {“Length”: “12”, “Width”: “18”, “Weight”: “16.7400 lbs”, “Price”: “$189.89”}, {“Length”: “12”, “Width”: “24”, “Weight”: “22.3200 lbs”, “Price”: “$231.49”}], “Cutting Tolerance”: “+/- 1/4”, “…

4. Midwest Steel Supply – 316 Stainless Steel Round Bar

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: {“Product Name”: “316 Stainless Steel Round Bar”, “Sizes Available”: [“1/8”, “1/4”, “5/16”, “3/8”, “7/16”, “1/2”, “9/16”, “5/8”, “3/4”, “7/8”, “1”, “1-1/8”, “1-1/4”, “1-3/8”, “1-1/2”, “1-5/8”, “1-3/4”, “1-7/8”, “2”, “2-1/8”, “2-1/4”, “2-3/8”, “2-1/2”, “2-5/8”, “2-3/4”, “2-7/8”, “3”, “3-1/8”, “3-1/4”, “3-1/2”, “3-5/8”, “3-3/4”, “3-7/8”, “4”, “4-1/4”, “4-1/2”, “4-3/4”, “5”, “5-1/4”, “5-1/2”, “5-3/4″…

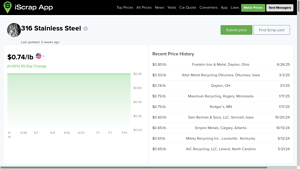

5. iScrap App – 316 Stainless Steel Scrap Price

Domain: iscrapapp.com

Registered: 2010 (15 years)

Introduction: 316 Stainless Steel Scrap Price: $0.74/lb (0.00% change) as of July 17, 2025. Price history includes: $0.80/lb in Dayton, OH (6/26/25), $0.53/lb in Ottumwa, IA (3/3/25), $0.74/lb in Dayton, OH (3/1/25), $0.75/lb in Rogers, MN (1/17/25), $0.60/lb in Grinnell, IA (10/20/24), $0.65/lb in Calgary, AB (10/13/24), $0.61/lb in Louisville, KY (6/12/24), $0.65/lb in Leland, NC (5/21/24). 316 Stainless Stee…

6. ScrapWorks – Stainless Steel Scrap Pricing

Domain: scrapworks.com

Registered: 2002 (23 years)

Introduction: 304 Stainless Steel Scrap Price Per Pound: Competitive prices based on market conditions and demand. 316 Stainless Steel Scrap Price Per Pound: Fair and competitive prices considering specific qualities of 316 stainless steel. Prices are for material delivered to the yard and are subject to change without notice due to volatile market conditions.

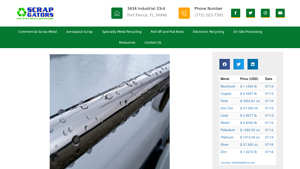

7. ScrapGators – Stainless Steel Prices

Domain: scrapgators.com

Registered: 2018 (7 years)

Introduction: Stainless Steel Prices Per Pound: $0.64 (as of late January 2022). Different categories of stainless steel include: 1. Austenitic Stainless Steel: 304 stainless steel ($0.66), 316 stainless steel ($0.86). 2. Ferritic Stainless Steel: 430 stainless steel ($0.16), 434 stainless steel ($0.25). 3. Martensitic Stainless Steel: 420 stainless steel (not priced). Other prices include: 300 series stainless…

8. Scrap Metal Buyers – Current Copper & Brass Prices

Domain: scrapmetalbuyers.com

Registered: 2018 (7 years)

Introduction: Current Prices for Scrap Metal Recycling:

1. **Copper & Brass**:

– #1 Bare Bright Wire: $2.40/lb

– #1 Copper Tubing / Flashing: $2.10/lb

– #2 Copper Tubing / Bus Bar: $1.90/lb

– #3 Roofing Copper: $1.80/lb

– Brass: $1.25/lb

– Brass (Plumbing, Pipe): $1.37/lb

– Bronze: $1.55/lb

– Brass Shells: $1.22/lb

– Brass Water Meter: $0.75-$1.50/lb

– Dirty Brass Faucets: $0.40/l…

9. Reddit – Stainless Steel Scrap Pricing

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 316 stainless steel, scrap price range of $0.50-$0.70 per pound observed online; offered $0.33 per pound at a scrapyard; commonly misidentified as 304 stainless steel by scrap yards.

Strategic Sourcing Conclusion and Outlook for 316 stainless steel price per pound

In navigating the complex landscape of 316 stainless steel pricing, strategic sourcing emerges as a crucial component for B2B buyers. Understanding the factors influencing prices—such as global demand, material availability, and scrap metal fluctuations—enables companies to make informed purchasing decisions. By establishing strong relationships with suppliers and leveraging market insights, businesses can mitigate risks associated with price volatility.

For international buyers from regions like Africa, South America, the Middle East, and Europe, the importance of a proactive sourcing strategy cannot be overstated. Engaging with multiple suppliers and exploring diverse procurement channels can enhance negotiating power and ensure access to competitive pricing. Additionally, staying abreast of market trends and technological advancements in steel production can provide a significant edge.

As we look to the future, it is essential for B2B buyers to adopt a forward-thinking approach. Emphasizing collaboration and continuous evaluation of sourcing strategies will not only optimize costs but also improve supply chain resilience. Embrace these insights to secure your competitive advantage in the global market for 316 stainless steel.