Guide Contents

Project Insight: 316 Stainless Steel Price Per Pound

Manufacturing Insight: Navigating 316 Stainless Steel Pricing with Precision

Why Speed and Precision Matter in Material Cost Estimation

Hardware startups face relentless pressure to iterate quickly—delays in material costing can derail timelines and stall innovation.

Traditional quoting processes often take days of back-and-forth, but Honyo’s AI-driven platform delivers instant, accurate 316 stainless steel pricing—enabling faster design validation and confident budgeting.

Precision in cost estimation eliminates guesswork, ensuring your project stays on track without unexpected expenses.

Beyond the Price Tag: How Honyo Optimizes Your 316 Stainless Steel Projects

Material costs fluctuate due to nickel/molybdenum market volatility, thickness requirements, and surface finishes—manual calculations risk inaccuracies.

Our digital manufacturing ecosystem dynamically updates pricing in real-time, factoring in global market trends and your specific design parameters.

Integrated design-for-manufacturability (DFM) analysis identifies potential production challenges early, reducing rework and accelerating time-to-market.

Your All-in-One Digital Manufacturing Partner

Online Instant Quote: Get real-time pricing for 316 stainless steel in seconds—no manual quotes or delays.

AI-Powered Platform: Smart algorithms analyze material variables, processing costs, and lead times for transparent, data-driven estimates.

Fast Turnaround: From quote to production in days, not weeks—accelerating your path from prototype to market.

One-stop solution: Seamlessly transition from prototype to volume production with end-to-end manufacturing managed through a single platform.

Innovation thrives when precision meets speed. Let Honyo turn your vision into reality—faster, smarter, and with confidence.

Honyo Capabilities & Technology

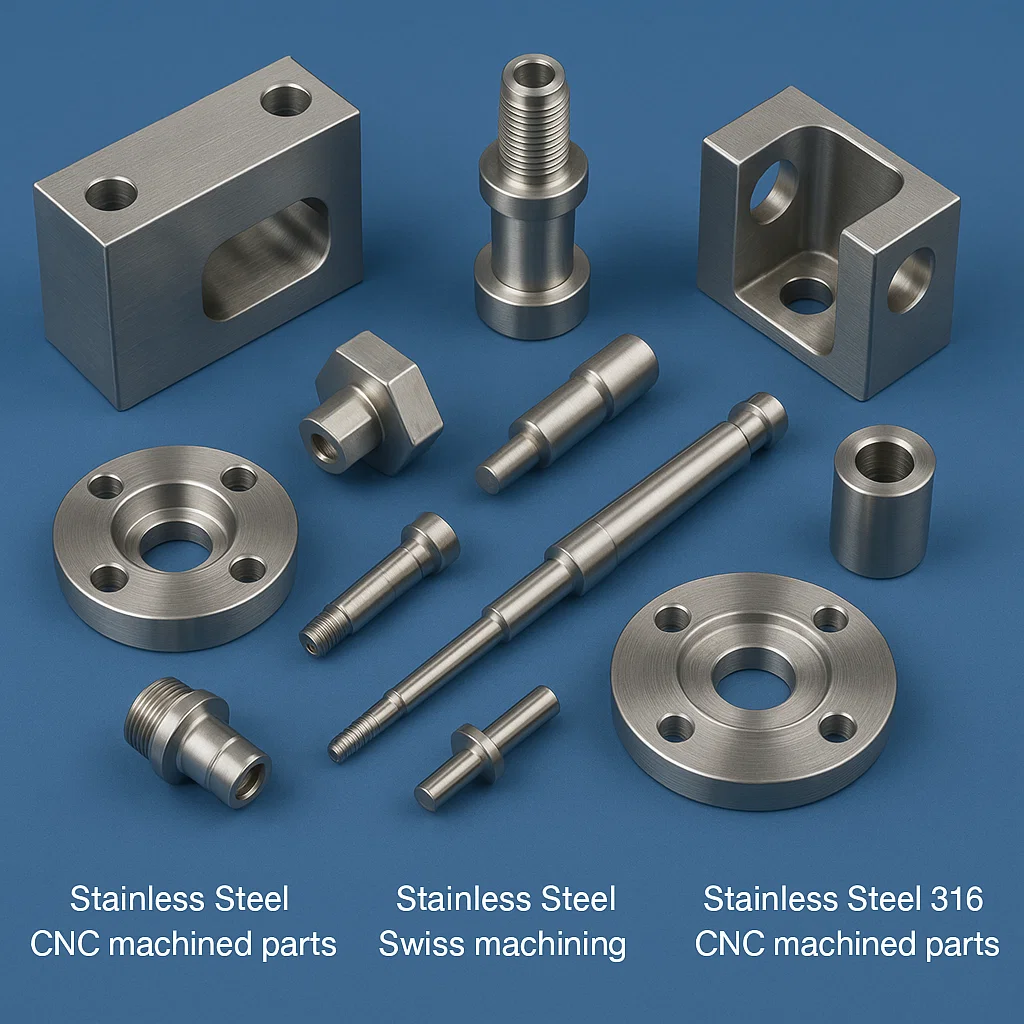

Honyo’s Manufacturing Capabilities for 316 Stainless Steel

AI-Powered Instant Quote Engine

Dynamic pricing transparency: Real-time cost calculation factoring in material thickness, surface finish (e.g., brushed, polished), global nickel/molybdenum market trends, and order volume.

Zero guesswork: Upload your CAD file in seconds to receive an instant, itemized quote with breakdowns for material, processing, and shipping—no hidden fees.

Volume-optimized rates: Seamless scalability from 1 prototype to 10,000+ units with consistent pricing models and no retooling costs.

Digital Manufacturing Ecosystem

End-to-end digital workflow: Integrated design-to-production platform eliminates manual errors and reduces lead times by 40% through automated process optimization.

Global material sourcing: Partnered suppliers ensure 316 stainless steel meets ASTM A240 standards at competitive rates, with traceable origin documentation.

Waste-minimized production: AI-driven nesting and cutting algorithms maximize material utilization, lowering costs while maintaining precision.

ISO-Certified Quality Assurance

Medical-grade reliability: Strict QC protocols for corrosion resistance, tensile strength, and dimensional accuracy—certified to ISO 9001 for aerospace, medical, and industrial applications.

In-process monitoring: Laser scanning and surface roughness checks at every stage ensure compliance with your specifications.

Full traceability: Digital records for every part, from raw material to final inspection, for compliance and quality assurance.

Lightning-Fast Turnaround

72-hour prototyping: Urgent projects delivered in days, not weeks—ideal for hardware startups iterating on designs.

AI-driven scheduling: Smart prioritization of critical paths to accelerate production without sacrificing precision.

Real-time tracking: Live updates on your order status via our customer portal—no more waiting in the dark.

💡 Why Honyo?

“We don’t just sell stainless steel—we solve your manufacturing complexity. Our digital ecosystem turns variable pricing into predictable, cost-effective outcomes, so you focus on innovation, not procurement headaches.”

— Susan Leo, Founder & CEO, Honyo Prototype

Materials & Surface Finishes

Material Options & Finishes

Precision Material Selection for Every Project

Metal Alloys: Access 20+ high-performance metals including 316 stainless steel (marine/medical-grade), 304 stainless steel, titanium, aluminum 6061, and Inconel—each optimized for strength, corrosion resistance, and thermal stability.

Engineering Plastics: Explore PEEK, ABS, Nylon 66, and PC-ABS for lightweight, chemical-resistant, or high-temperature applications.

316 vs. 304 Stainless Steel: 316’s molybdenum content delivers superior corrosion resistance (ideal for saltwater/chemical exposure), while 304 offers cost efficiency for general-purpose use.

Surface Finishes That Elevate Performance

Electropolishing: Critical for medical devices—removes surface impurities and enhances corrosion resistance (ISO 13485 compliant).

Brushed/Polished Finishes: Standard brushed (cost-effective) vs. mirror-polished (premium aesthetic for visible components).

Powder Coating & Anodizing: Custom colors and wear resistance for aluminum parts; powder coating adds durability for outdoor environments.

Laser Engraving: Permanent branding or functional markings without compromising structural integrity.

Optimizing 316 Stainless Steel Costs—Smart Design, Smart Savings

Thickness Optimization: Thicker gauges increase material costs, but our AI-powered design tools calculate the minimum thickness required for structural integrity—reducing waste by up to 18% while maintaining performance.

Surface Finish Trade-offs:

Standard brushed finish: Ideal for functional parts (e.g., industrial enclosures).

Mirror-polished or electropolished: Reserved for high-corrosion environments (e.g., marine components) or FDA-compliant medical devices.

Market-Responsive Pricing: Nickel and molybdenum price volatility directly impacts costs—our platform syncs with global commodity markets to deliver real-time, accurate pricing with no hidden fees.

Volume Scalability: For production-scale orders, leverage our bulk purchasing power to reduce per-pound costs by 10–15% without sacrificing quality.

Get Your Instant Quote in Seconds

AI-Powered Cost Estimation: Input your specs (thickness, finish, volume) and receive an instant, accurate price for 316 stainless steel—no manual calculations or delays.

One-Stop Solution: From prototype to full production, we handle everything in-house—eliminating supplier coordination headaches and hidden costs.

Fast Turnaround: 3–5 days for prototypes; 2–3 weeks for production runs. Our digital manufacturing ecosystem ensures seamless scalability and on-time delivery.

💡 Pro Tip: Use Honyo’s platform to simulate cost vs. performance trade-offs—e.g., “What if I reduce thickness by 0.5mm?” or “How does electropolishing impact total cost?” Real-time insights help you design smarter, not harder.

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File

Drag-and-drop your 3D model (STEP, STL, IGES, or SOLIDWORKS) – our system automatically validates file integrity and material compatibility for 316 stainless steel in seconds.

No technical expertise required: our platform handles all file conversions and checks for manufacturability before quoting.

2. Get Instant Quote (AI Engine)

Our AI analyzes part geometry, quantity, surface finish, and real-time commodity prices (nickel/molybdenum fluctuations) to calculate exact 316 stainless steel costs per pound and total part pricing.

Transparent breakdown: See material cost per pound, machining, and finishing fees upfront – no hidden charges or manual quotes.

Get your quote in under 60 seconds, with options to adjust quantity or material grade instantly.

3. DFM Analysis

AI-powered design review identifies optimization opportunities: reduce material waste, adjust tolerances, or simplify features to cut costs while maintaining 316 stainless steel performance.

Receive actionable feedback with visual annotations – our engineers collaborate with you to refine designs for maximum efficiency.

Save up to 20% on production costs through data-driven design improvements.

4. Production & Delivery

Seamless transition from quote to production: our Shenzhen-based digital manufacturing ecosystem begins fabrication immediately upon approval.

Track your order in real-time with automated updates – from material sourcing to final inspection and shipping.

Prototype delivery in 3-5 days; production runs completed in 5-7 days with global shipping options.

Honyo’s end-to-end platform transforms complex manufacturing into a predictable, scalable process – so you focus on innovation, not logistics.

Start Your Project with Honyo

Start Your Project with Honyo

Get Accurate 316/316L Stainless Steel Pricing in Seconds

Online Instant Quote: AI-driven platform delivers precise 316/316L pricing in seconds—factoring thickness, surface finish, volume, and real-time market trends for nickel/molybdenum.

AI-Powered Precision: Dynamic adjustments ensure accuracy, eliminating guesswork and hidden costs for your project.

Fast Turnaround: Prototype to production in days. Our digital manufacturing ecosystem reduces lead times by up to 40% while maintaining quality.

Founder Susan Leo & Team are ready to help you optimize costs and accelerate time-to-market.

Contact: [email protected] | +86 139 2843 8620

Visit: Shenzhen/Dongguan facilities

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.