Introduction: Navigating the Global Market for 304 stainless machinability

In the competitive landscape of global manufacturing, understanding the machinability of 304 stainless steel is crucial for B2B buyers seeking high-quality components. Sourcing reliable machining solutions can be a daunting task, especially when navigating the complexities of material properties, tooling requirements, and supplier capabilities. This guide aims to simplify that journey by providing a comprehensive overview of 304 stainless machinability, addressing key challenges faced by international buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany.

Throughout this guide, we will delve into the various types of stainless steel, focusing on 304 and its unique characteristics that influence machining processes. You’ll gain insights into optimal tooling options, machining techniques, and best practices to enhance productivity while minimizing costs. We will also cover practical applications of 304 stainless steel across diverse industries, helping you identify suitable suppliers who can meet your specific needs.

By empowering you with actionable knowledge and strategic insights, this guide is designed to facilitate informed purchasing decisions. Whether you are looking to optimize production processes or ensure product quality, understanding the nuances of 304 stainless machinability will be pivotal in achieving your business objectives in the global market.

Understanding 304 stainless machinability Types and Variations

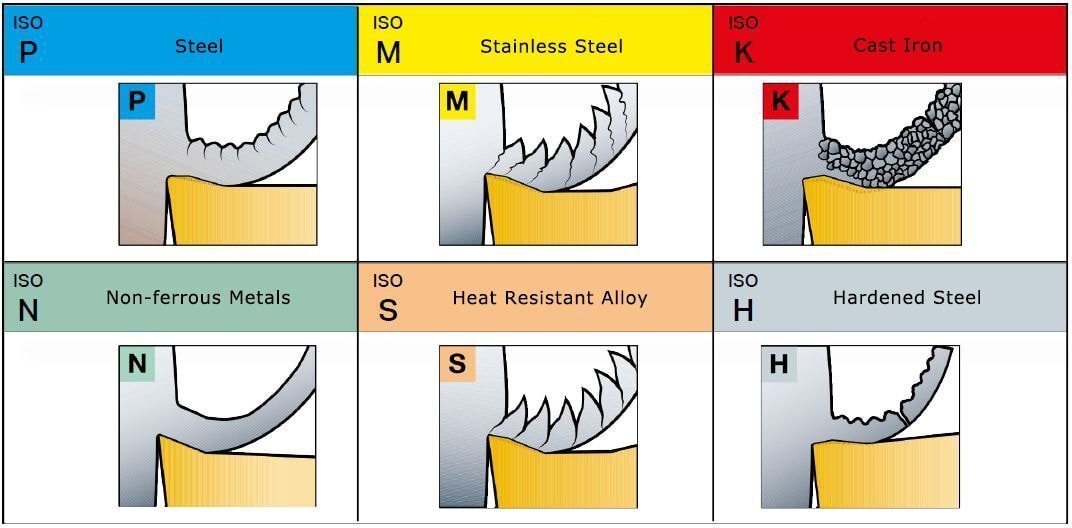

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 304 Stainless | Non-magnetic, excellent corrosion resistance, low work hardening | Food processing, chemical storage, kitchen equipment | Pros: Versatile, widely available. Cons: Lower strength than some alternatives. |

| 304L Stainless | Low carbon content, enhanced weldability | Aerospace, automotive, and marine applications | Pros: Reduced risk of carbide precipitation. Cons: Slightly lower strength than standard 304. |

| 304H Stainless | High carbon content, improved high-temperature strength | Power generation, petrochemical industries | Pros: Better performance under high temperatures. Cons: More expensive than standard 304. |

| 304N Stainless | Nitrogen addition for improved strength and stability | Structural applications, high-stress environments | Pros: Higher yield strength. Cons: Limited availability compared to standard grades. |

| 304Cu Stainless | Copper addition for improved machinability and corrosion resistance | Electrical applications, food and beverage industries | Pros: Enhanced machinability. Cons: May not be suitable for all environments. |

What Are the Key Characteristics of Standard 304 Stainless Machinability?

Standard 304 stainless steel is renowned for its excellent machinability, making it a go-to choice for a variety of industrial applications. Its non-magnetic nature and high corrosion resistance allow it to excel in environments where moisture and chemicals are prevalent. B2B buyers should consider its versatility and availability, though they must also note that it has lower strength compared to some other stainless steel grades, potentially limiting its use in high-stress applications.

How Does 304L Stainless Differ in Machinability and Applications?

304L stainless steel features a lower carbon content, which enhances its weldability and reduces the risk of carbide precipitation during welding. This property makes it particularly suitable for industries like aerospace and automotive, where weld integrity is crucial. Buyers should appreciate its ease of fabrication, although it does come with a trade-off in strength, making it less suitable for high-stress applications compared to standard 304.

What Advantages Does 304H Stainless Offer for High-Temperature Applications?

304H stainless steel is characterized by a higher carbon content, which improves its performance in high-temperature environments. This makes it ideal for power generation and petrochemical applications where thermal stability is essential. B2B buyers should weigh the benefits of enhanced strength at elevated temperatures against the higher cost, as 304H can be more expensive than standard 304.

Why Choose 304N Stainless for Structural Applications?

The addition of nitrogen in 304N stainless steel enhances its yield strength and stability, making it suitable for structural applications and environments that experience high stress. While this variant offers superior performance, it may not be as readily available as standard grades. Buyers should consider the specific requirements of their projects, as the benefits of increased strength may justify the potential sourcing challenges.

What Makes 304Cu Stainless a Good Choice for Machinability?

304Cu stainless steel incorporates copper to improve machinability while maintaining corrosion resistance. This variant is particularly beneficial in electrical applications and the food and beverage industry, where ease of machining is critical. B2B buyers should evaluate the environmental conditions in which this material will be used, as its corrosion resistance may not match that of other grades in extremely harsh settings.

Key Industrial Applications of 304 stainless machinability

| Industry/Sector | Specific Application of 304 stainless machinability | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Manufacturing of processing equipment and storage tanks | Ensures hygiene and corrosion resistance, prolonging equipment life | Compliance with food safety standards, availability of certified suppliers |

| Pharmaceutical | Production of drug manufacturing equipment | High resistance to corrosion and contamination, ensuring product integrity | Need for precision machining and adherence to strict regulatory standards |

| Oil and Gas | Fabrication of pipelines and valves | Durability in harsh environments, reducing maintenance costs | Sourcing from suppliers with experience in high-pressure applications |

| Aerospace | Creation of aircraft components | Lightweight yet strong materials, enhancing fuel efficiency | Quality certifications and adherence to aerospace industry standards |

| Automotive | Production of exhaust systems and structural components | Improved performance and longevity, critical for competitive advantage | Availability of specialized machining services and rapid prototyping capabilities |

How is 304 Stainless Machinability Applied in the Food and Beverage Industry?

In the food and beverage sector, 304 stainless steel is crucial for manufacturing processing equipment such as mixers, tanks, and piping. The material’s excellent corrosion resistance and hygienic properties help maintain food safety standards. B2B buyers must ensure that suppliers can provide equipment that meets local food safety regulations and is capable of precision machining to avoid contamination during production.

What Role Does 304 Stainless Machinability Play in the Pharmaceutical Sector?

The pharmaceutical industry relies on 304 stainless steel for manufacturing equipment like reactors and storage tanks. Its high corrosion resistance is essential for maintaining the integrity of sensitive drugs. International buyers, especially from regions like Africa and South America, should focus on sourcing from manufacturers who can guarantee compliance with stringent regulatory standards and offer advanced machining capabilities for intricate designs.

Why is 304 Stainless Machinability Important in Oil and Gas Applications?

In the oil and gas industry, 304 stainless steel is used to fabricate pipelines, valves, and fittings that must withstand extreme conditions. The alloy’s durability reduces the frequency of maintenance and replacement, leading to significant cost savings. When sourcing, businesses should prioritize suppliers experienced in high-pressure applications and those who can provide certifications for their materials.

How Does 304 Stainless Machinability Benefit the Aerospace Industry?

Aerospace applications require components that are both lightweight and strong, making 304 stainless steel a preferred choice for parts such as brackets and fasteners. The material’s machinability allows for precise manufacturing, which is critical for performance and safety. Buyers in this sector need to ensure their suppliers meet rigorous quality certifications and can handle complex machining tasks.

What is the Importance of 304 Stainless Machinability in Automotive Manufacturing?

In the automotive industry, 304 stainless steel is commonly used in the production of exhaust systems and structural components. Its ability to withstand high temperatures and resist corrosion enhances vehicle performance and longevity. B2B buyers should seek suppliers who offer specialized machining services and rapid prototyping to meet the fast-paced demands of automotive manufacturing.

3 Common User Pain Points for ‘304 stainless machinability’ & Their Solutions

Scenario 1: Difficulty Achieving Precision Cuts with 304 Stainless Steel

The Problem: Many B2B buyers experience significant challenges when machining 304 stainless steel, particularly in achieving precision cuts. The high hardness and tensile strength of 304 stainless can lead to increased tool wear, overheating, and ultimately, compromised part quality. This is especially true for manufacturers in sectors such as automotive or aerospace, where precision is paramount. Buyers may find themselves frustrated by frequent tool failures, increased production costs, and delays in project timelines due to the inability to maintain consistent machining performance.

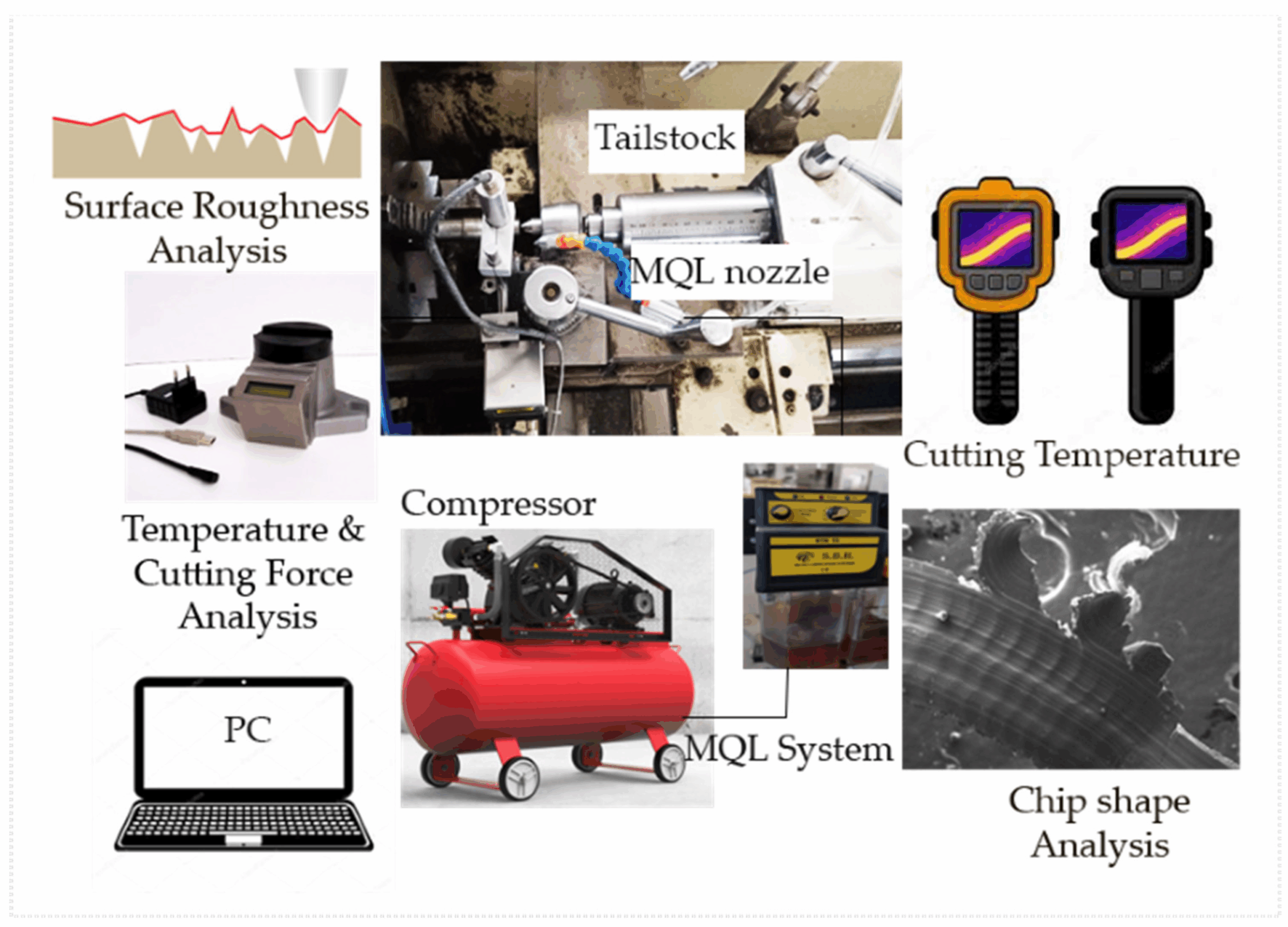

The Solution: To tackle this issue, it is essential to select the right tooling for machining 304 stainless steel. Carbide tools, particularly those with TiAlN (Titanium Aluminum Nitride) coatings, are highly recommended due to their superior hardness and heat resistance. Buyers should also consider optimizing their machining parameters—reducing feed rates and spindle speeds to prevent overheating. For instance, maintaining a surface speed of around 250-300 SFM and a feed rate of 0.0015″-0.002″ per tooth can significantly enhance tool life and precision. Additionally, investing in high-quality coolant systems is crucial; using flood coolant can help manage temperatures and prolong tool durability. Collaborating with suppliers who understand the specific requirements for machining 304 stainless can also provide valuable insights into the best practices tailored to a buyer’s unique production environment.

Scenario 2: Inefficient Machining Processes Leading to Increased Costs

The Problem: B2B buyers often encounter inefficiencies in their machining processes when working with 304 stainless steel, resulting in increased operational costs. Common issues include prolonged cycle times, excessive tool wear, and the need for rework due to poor surface finishes. For companies operating in highly competitive markets, these inefficiencies can erode profit margins and affect overall productivity. Buyers may feel the pressure of balancing cost reduction while maintaining high-quality output, which can be a daunting challenge.

The Solution: Implementing lean manufacturing principles can greatly enhance machining efficiency. Buyers should conduct a thorough analysis of their current machining processes to identify bottlenecks and areas for improvement. Switching to high-performance cutting strategies, such as trochoidal milling, allows for better material removal rates while reducing tool stress. Additionally, utilizing advanced software for simulation and optimization can help in planning tool paths that minimize cycle times. Investing in automation technologies, such as CNC machines with adaptive controls, can further streamline operations and reduce labor costs. Lastly, regular training for machinists on best practices for handling 304 stainless steel will empower the workforce to make real-time adjustments that enhance productivity and reduce waste.

Scenario 3: Struggling with Corrosion Resistance in Machined Parts

The Problem: Another common pain point for B2B buyers is the corrosion resistance of machined parts made from 304 stainless steel. While 304 is generally known for its excellent corrosion resistance, specific environmental conditions—such as exposure to chlorides or acidic substances—can lead to issues like pitting and crevice corrosion. Buyers in industries such as food processing, marine applications, or chemical handling may find themselves facing product failures and costly replacements due to inadequate corrosion protection.

The Solution: To mitigate corrosion risks, it is crucial for buyers to incorporate proper post-machining treatments. One effective method is passivation, which enhances the natural oxide layer on the surface of the stainless steel, improving its corrosion resistance. Buyers should seek suppliers who offer passivation services or invest in training for their teams to perform this process in-house. Additionally, considering alternative grades like 316 stainless steel, which contains molybdenum for improved corrosion resistance, may be beneficial in particularly harsh environments. Regular maintenance and inspections of machined parts can also prevent corrosion-related issues, ensuring longevity and reliability. By taking these proactive measures, buyers can significantly reduce the risk of corrosion and maintain the integrity of their products.

Strategic Material Selection Guide for 304 stainless machinability

What Are the Key Properties of 304 Stainless Steel for Machinability?

304 stainless steel is a widely used alloy known for its excellent machinability, corrosion resistance, and overall durability. Its composition typically includes 18% chromium and 8% nickel, which contribute to its non-magnetic properties and high resistance to oxidation and corrosion. This makes it suitable for various applications, particularly in environments where exposure to moisture and chemicals is common. The material can withstand temperatures up to 870°C (1600°F) in continuous service and has a pressure rating that varies based on thickness and temperature, making it versatile for numerous industrial applications.

What Are the Pros and Cons of Using 304 Stainless Steel?

Pros:

– Durability: 304 stainless steel is highly resistant to corrosion, making it ideal for food processing, pharmaceuticals, and marine applications.

– Weldability: It can be easily welded and formed, which is essential for manufacturing processes.

– Cost-Effectiveness: Compared to other stainless steel grades, 304 offers a good balance of performance and affordability.

Cons:

– Work Hardening: The material can work-harden quickly during machining, which may require frequent tool changes and careful management of cutting speeds and feeds.

– Lower Strength: While it is durable, 304 does not offer the same strength as some other stainless steel grades like 316, which may be a consideration for high-stress applications.

How Does 304 Stainless Steel Impact Application in Various Industries?

The compatibility of 304 stainless steel with specific media is crucial for its application. It is commonly used in food and beverage processing due to its non-reactive nature, ensuring product safety. In the chemical industry, its resistance to a wide range of chemicals allows for its use in storage tanks and piping. However, it is less suitable for environments exposed to chlorides, which can lead to pitting corrosion. Therefore, understanding the specific media and environmental conditions is vital for international buyers when selecting this material.

What Should International B2B Buyers Consider When Sourcing 304 Stainless Steel?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local standards such as ASTM, DIN, and JIS. These standards dictate the quality and performance requirements for stainless steel products. Additionally, buyers should consider the availability of 304 stainless steel in their local markets, potential tariffs, and shipping costs. Engaging with suppliers who understand regional preferences and can provide documentation for compliance will streamline the procurement process.

Summary Table of Material Analysis

| Material | Typical Use Case for 304 stainless machinability | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | Food processing equipment, chemical tanks | Excellent corrosion resistance | Prone to work hardening | Medium |

| 316 Stainless Steel | Marine applications, chemical processing | Superior corrosion resistance | Higher cost compared to 304 | High |

| 430 Stainless Steel | Kitchen appliances, automotive trim | Cost-effective and good corrosion resistance | Lower strength and weldability issues | Low |

| Duplex Stainless Steel | Oil and gas applications, pressure vessels | High strength and corrosion resistance | More complex to machine | High |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to navigate the complexities of sourcing and machining 304 stainless steel, ensuring informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 304 stainless machinability

What Are the Main Stages in Manufacturing 304 Stainless Steel Components?

Manufacturing components from 304 stainless steel involves several key stages that ensure the final product meets the required specifications and quality standards. The main stages are material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is material preparation. This involves sourcing high-quality 304 stainless steel from reputable suppliers. The raw material typically comes in various forms, such as sheets, bars, or coils. Quality assurance begins here, as it is crucial to verify that the material meets the necessary specifications, including chemical composition and mechanical properties. B2B buyers should ensure that suppliers provide certificates of compliance and material test reports to confirm the grade and quality of the stainless steel.

Forming Techniques for 304 Stainless Steel

Once the material is prepared, the next stage is forming. Common forming techniques for 304 stainless steel include:

-

CNC Machining: This method is widely used for precision components. CNC machines can create complex geometries while maintaining tight tolerances, which is essential for many applications in aerospace, automotive, and medical industries.

-

Sheet Metal Fabrication: Techniques such as laser cutting, punching, and bending are employed to shape 304 stainless steel sheets into specific designs. Laser cutting is particularly advantageous due to its precision and ability to cut intricate shapes without compromising the material’s integrity.

-

Welding: 304 stainless steel can be welded using various methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. It is essential to choose the right filler material and welding parameters to maintain the corrosion resistance and strength of the welds.

How Does Assembly Fit into the Manufacturing Process?

After forming, the components may require assembly. This stage involves joining multiple parts to create a final product. Assembly techniques can vary widely depending on the application, but common methods include mechanical fastening, welding, and adhesive bonding. It is crucial to ensure that the assembly process maintains the integrity and performance of the 304 stainless steel components, particularly in high-stress applications.

What Finishing Techniques Are Commonly Used for 304 Stainless Steel?

The finishing stage is critical for enhancing the aesthetic and functional properties of 304 stainless steel components. Common finishing techniques include:

-

Surface Treatment: Methods such as passivation, polishing, or bead blasting can improve corrosion resistance and surface finish. Passivation, for instance, removes free iron and enhances the formation of a protective oxide layer, which is vital for maintaining the stainless steel’s corrosion resistance.

-

Coatings: Depending on the application, components may receive additional coatings for enhanced properties. These could include paint, powder coating, or specialized coatings for increased wear resistance or thermal protection.

What Quality Control Measures Are Essential for 304 Stainless Steel Manufacturing?

Quality control (QC) is paramount in ensuring that 304 stainless steel components meet international standards and customer requirements. Here are some key aspects of QC in this context:

Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of various international standards that govern the quality of stainless steel products. One of the most recognized standards is ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO 9001 indicates that a supplier has established processes for consistent product quality and continuous improvement.

In addition to ISO 9001, industry-specific standards such as CE marking for products sold in Europe or API (American Petroleum Institute) standards for oil and gas applications may be relevant. These standards ensure that products meet regulatory requirements and industry best practices.

What Are the Key QC Checkpoints During Manufacturing?

Quality control should be integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to verify compliance with specifications. Materials should be tested for chemical composition and physical properties to ensure they meet the required standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections should be conducted to monitor processes and identify any deviations from established parameters. This may involve checking dimensions, tolerances, and surface finishes.

-

Final Quality Control (FQC): After the manufacturing process, a thorough inspection of the finished components is essential. This includes dimensional checks, visual inspections, and testing for mechanical properties to ensure that the final product meets specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers have several options to verify the quality control processes of their suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s quality management systems, manufacturing processes, and adherence to standards. This firsthand evaluation can provide valuable insights into the supplier’s capabilities and commitment to quality.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s QC procedures, testing results, and compliance with international standards. These reports should include information on any non-conformances and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an impartial assessment of the supplier’s quality processes and the products being manufactured. This adds an extra layer of assurance for buyers, particularly in regions where local regulations may vary.

What Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several nuances when sourcing 304 stainless steel components:

-

Regulatory Compliance: Different regions may have varying regulations concerning material quality and safety standards. Buyers should ensure that their suppliers are familiar with and compliant with local regulations to avoid any legal issues.

-

Cultural Differences in Quality Expectations: Understanding cultural differences in quality expectations and business practices can facilitate better communication and negotiation with suppliers.

-

Logistics and Supply Chain Considerations: When sourcing internationally, buyers should consider logistics, lead times, and the reliability of shipping methods. Establishing clear communication channels with suppliers can help mitigate potential issues.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing 304 stainless steel components, ensuring that they receive high-quality products that meet their specific requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘304 stainless machinability’

Introduction

This guide serves as a practical checklist for B2B buyers interested in sourcing materials and services related to the machinability of 304 stainless steel. Understanding the intricacies of machining this popular alloy is essential for ensuring product quality and operational efficiency. By following this step-by-step checklist, you can streamline your procurement process and avoid common pitfalls.

Step 1: Define Your Technical Specifications

Clearly outline your machining requirements, including dimensions, tolerances, and surface finishes. This step is crucial because it helps you communicate effectively with suppliers and ensures that the materials you receive meet your production needs. Be specific about:

– Thickness and Form: Specify whether you need sheets, bars, or custom shapes.

– Finish Requirements: Indicate if you require specific surface treatments or finishes.

Step 2: Research Material Properties

Before making a purchase, familiarize yourself with the properties of 304 stainless steel, including its corrosion resistance, ductility, and machinability characteristics. Understanding these properties helps you choose the right machining methods and tools, which can significantly affect production efficiency and product longevity. Focus on:

– Tensile Strength: Know the strength requirements for your application.

– Hardness Levels: Select tooling that matches the hardness of the material.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; look for:

– Certifications: Ensure they have relevant quality and industry certifications (e.g., ISO 9001).

– Reputation: Research reviews and testimonials to gauge their reliability.

Step 4: Inquire About Tooling Options

Ask suppliers about the tooling they recommend for machining 304 stainless steel. Different tools can yield varying results in terms of efficiency and finish quality. Consider:

– Coating Types: Inquire if they recommend TiAlN or TiN coatings for enhanced performance.

– Tool Geometry: Understand the flutes and cutting edge design that best suit your application.

Step 5: Request Samples

Before finalizing your order, ask for samples of the 304 stainless steel and any tooling options they propose. Testing samples allows you to evaluate the machinability and confirm that they meet your specifications. Look for:

– Performance: Assess how well the material machines under your typical conditions.

– Finish Quality: Check if the surface finish aligns with your requirements.

Step 6: Discuss Lead Times and Logistics

Establish clear expectations regarding lead times and logistics to avoid delays in your production schedule. Understanding the supplier’s capacity can help you plan your operations more effectively. Pay attention to:

– Delivery Timeframes: Confirm estimated shipping times.

– Customs and Duties: Be aware of potential import regulations or tariffs that could impact delivery.

Step 7: Negotiate Pricing and Terms

Once you have confirmed your requirements and evaluated suppliers, it’s time to negotiate pricing and terms. Ensure that you get the best value while maintaining quality standards. Focus on:

– Volume Discounts: Inquire about pricing breaks for larger orders.

– Payment Terms: Clarify payment schedules and conditions to ensure mutual understanding.

By following this checklist, you can enhance your sourcing strategy for 304 stainless steel machining, ensuring that you select the right materials and suppliers for your specific needs.

Comprehensive Cost and Pricing Analysis for 304 stainless machinability Sourcing

What Are the Key Cost Components in 304 Stainless Machinability Sourcing?

When sourcing 304 stainless steel for machining, understanding the cost structure is crucial. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of 304 stainless steel fluctuates based on global commodity prices. Buyers should monitor the LME (London Metal Exchange) for real-time pricing. The alloy’s composition—primarily iron, chromium, and nickel—affects its price. As of late 2023, prices can range from $2,000 to $3,000 per metric ton, influenced by market demand and supply chain conditions.

-

Labor: Skilled labor is essential for machining 304 stainless steel due to its hardness and tensile strength. Labor costs vary significantly by region; for instance, skilled machinists in Europe may command higher wages than those in Africa or South America. This cost can account for up to 30% of the total manufacturing expense.

-

Manufacturing Overhead: Overhead costs include utilities, equipment maintenance, and facility expenses. This can typically represent 15% to 25% of the total cost, depending on the operational efficiency of the manufacturing facility.

-

Tooling: High-quality tooling is critical for effective machining of 304 stainless steel. Carbide tools or specialized coatings like TiAlN (Titanium Aluminum Nitride) are often recommended to enhance tool life and performance. Tooling costs can add another 10% to 20% to the total machining cost, particularly if custom tooling is required.

-

Quality Control (QC): Rigorous quality control measures are imperative to ensure that the finished product meets industry standards. QC processes can contribute 5% to 10% of the total cost, factoring in testing, inspections, and certifications.

-

Logistics: Transportation costs can vary greatly depending on the shipping method and the distance from the supplier. International shipping can increase costs significantly, particularly for bulk orders. Buyers must consider both shipping costs and potential tariffs when sourcing materials from abroad.

-

Margin: Suppliers will typically add a margin to cover their risks and ensure profitability. This can range from 10% to 30%, influenced by factors like market competition and demand.

What Influences Pricing for 304 Stainless Machinability?

Several factors can influence the pricing of 304 stainless steel machining:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating minimum order quantities (MOQs) can be beneficial for buyers looking to optimize their budgets.

-

Specifications and Customization: Custom specifications can increase costs due to the need for specialized tooling or processes. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials: The specific grade of stainless steel and any additional alloying elements can affect pricing. For example, 316 stainless steel, with added molybdenum for enhanced corrosion resistance, is generally more expensive than 304.

-

Quality and Certifications: Products that require specific certifications (e.g., ISO, ASME) may carry higher costs due to additional testing and documentation.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The terms of shipping can significantly affect overall costs. Understanding Incoterms can help buyers manage logistics expenses and responsibilities effectively.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Bulk Pricing: Engage suppliers to negotiate bulk pricing, especially for larger orders. Expressing a commitment to long-term partnerships can yield favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but the total cost of ownership, which includes maintenance, tooling, and logistics over the product’s lifecycle.

-

Research Market Trends: Stay informed about market trends and pricing fluctuations. Timing your purchases based on market conditions can lead to significant savings.

-

Explore Alternative Suppliers: Diversifying suppliers can introduce competitive pricing. However, ensure that quality and reliability remain priorities.

-

Understand Regional Differences: Be mindful of the specific economic conditions in your region. For instance, tariffs and local regulations can significantly influence total costs.

In summary, a comprehensive understanding of the cost structure and pricing influencers, combined with strategic negotiation tactics, can empower B2B buyers to optimize their sourcing of 304 stainless steel for machining. Always remember that indicative prices can fluctuate, and staying informed is key to making informed purchasing decisions.

Alternatives Analysis: Comparing 304 stainless machinability With Other Solutions

When considering the machinability of materials in manufacturing processes, exploring alternatives to 304 stainless steel can provide insights into achieving better efficiency, cost-effectiveness, and suitability for specific applications. While 304 stainless steel is renowned for its corrosion resistance and durability, it may not always be the best choice depending on the project’s requirements. Here, we compare 304 stainless machinability with two viable alternatives: aluminum alloys and carbon steel.

| Comparison Aspect | 304 Stainless Machinability | Aluminum Alloys | Carbon Steel |

|---|---|---|---|

| Performance | Good corrosion resistance; requires specialized tooling and techniques for effective machining. | Excellent machinability; lighter weight; good surface finish; may have lower strength in certain grades. | High strength and toughness; generally easier to machine; less corrosion resistance. |

| Cost | Moderate; higher than carbon steel but competitive with some aluminum grades. | Generally lower; varies significantly based on alloy and market conditions. | Low; one of the most economical materials for machining. |

| Ease of Implementation | Requires specific tooling and techniques; may necessitate more downtime for tool changes. | Easier to machine with standard tools; less wear on cutting tools. | Straightforward machining process; fewer complications with tool wear. |

| Maintenance | Requires careful handling to prevent corrosion; regular maintenance of tools needed. | Minimal maintenance; typically resistant to corrosion depending on the alloy. | Generally low maintenance; however, rust prevention is necessary. |

| Best Use Case | Ideal for applications requiring high corrosion resistance, such as food processing and pharmaceuticals. | Best for lightweight applications, such as automotive and aerospace components. | Suitable for structural applications and high-stress environments where strength is essential. |

What are the Advantages and Disadvantages of Aluminum Alloys Compared to 304 Stainless Steel?

Aluminum alloys offer significant benefits in terms of machinability and weight. They are easier to machine, allowing for faster production rates and reduced wear on tooling. However, their strength can vary, and they may not withstand high-temperature applications as effectively as 304 stainless steel. Additionally, aluminum’s susceptibility to corrosion in certain environments can be a concern, although specific alloys can mitigate this issue.

How Does Carbon Steel Measure Up Against 304 Stainless Steel in Machinability?

Carbon steel is known for its exceptional strength and ease of machining. It typically requires less sophisticated tooling compared to 304 stainless steel, leading to lower overall production costs. However, carbon steel’s primary drawback is its vulnerability to corrosion, making it less suitable for applications exposed to harsh environments. While it can be a cost-effective choice for structural applications, it may not meet the needs of industries requiring high corrosion resistance.

Conclusion: How Should B2B Buyers Choose Between 304 Stainless Steel and Its Alternatives?

When selecting the right material for machining, B2B buyers should carefully assess their specific application requirements, including environmental factors, budget constraints, and performance needs. 304 stainless steel is an excellent choice for applications demanding corrosion resistance and durability but may incur higher machining costs and complexities. In contrast, aluminum alloys and carbon steel present viable alternatives with distinct advantages in machinability and cost, depending on the intended use. By evaluating these factors, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for 304 stainless machinability

What Are the Key Technical Properties of 304 Stainless Steel for Machinability?

When considering the machinability of 304 stainless steel, it is crucial to understand its specific properties and how they influence machining processes. Here are some critical specifications:

-

Material Grade: 304 stainless steel is an austenitic alloy primarily composed of iron, chromium (18%), and nickel (8%). This combination provides excellent corrosion resistance and high ductility, making it ideal for various applications in industries such as food processing, pharmaceuticals, and aerospace.

-

Tensile Strength: 304 stainless steel exhibits a tensile strength of around 520 MPa (75,000 psi), which reflects its ability to withstand mechanical stress without failure. For B2B buyers, this property is essential when selecting materials for components that will experience significant loads or pressure.

-

Machinability Rating: The machinability of 304 stainless steel is rated at approximately 70% compared to free-cutting brass. This rating indicates that while it can be machined effectively, it requires specialized tools and techniques to achieve optimal results. Understanding this rating helps manufacturers plan for machining processes and select the appropriate tooling.

-

Hardness: The Rockwell hardness of 304 stainless steel typically ranges between B70 and B90. This hardness level can affect tooling wear rates and the choice of machining parameters. Buyers should factor in hardness when evaluating the lifespan of cutting tools and the overall cost of machining operations.

-

Thermal Conductivity: With a thermal conductivity of about 16 W/m·K, 304 stainless steel has lower heat dissipation capabilities compared to other metals. This characteristic can lead to heat buildup during machining, necessitating the use of coolants to prevent tool damage and workpiece distortion.

What Are Common Trade Terms Related to 304 Stainless Steel Machinability?

Understanding industry jargon can facilitate smoother transactions and communications between B2B buyers and suppliers. Here are some common terms associated with 304 stainless steel machining:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that are sold under another company’s brand. For buyers, identifying OEMs who specialize in machining 304 stainless steel can streamline sourcing efforts.

-

MOQ (Minimum Order Quantity): This term indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B buyers to ensure they meet order requirements without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers to request pricing and terms for specific quantities of materials or services. For buyers, issuing an RFQ can help gather competitive pricing and better assess supplier capabilities.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in the shipping and delivery process. Familiarity with Incoterms is crucial for B2B buyers to understand their obligations regarding shipping costs, risk, and insurance.

-

CNC Machining: Computer Numerical Control (CNC) machining refers to the automated process of controlling machining tools via computer programs. This technology is vital for achieving high precision and consistency when machining 304 stainless steel components.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing and machining 304 stainless steel, ultimately enhancing operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the 304 stainless machinability Sector

What Are the Key Market Drivers Influencing 304 Stainless Machinability?

The global demand for 304 stainless steel is driven by its versatile applications across various industries, including automotive, aerospace, and construction. Its excellent corrosion resistance, high tensile strength, and ease of fabrication make it a preferred choice. Emerging markets in Africa, South America, and the Middle East are increasingly investing in infrastructure, driving demand for durable materials like 304 stainless steel. Additionally, advancements in machining technologies, such as high-speed milling and CNC machining, have significantly enhanced the machinability of this alloy, allowing for more efficient production processes.

Current trends indicate a shift towards automation and digitalization in manufacturing. B2B buyers are increasingly looking for suppliers who can offer smart manufacturing solutions that integrate IoT and AI for optimized machining processes. This trend is particularly significant for international buyers from regions like Germany, where precision engineering is paramount. Moreover, the rise of additive manufacturing is influencing sourcing strategies, as companies explore hybrid production techniques that combine traditional machining with 3D printing.

How Do Sustainability and Ethical Sourcing Impact 304 Stainless Machinability?

Sustainability is becoming a crucial factor in sourcing decisions for 304 stainless steel. The environmental impact of stainless steel production, which includes energy-intensive processes and carbon emissions, is prompting companies to seek greener alternatives. Ethical sourcing practices are gaining traction, with buyers prioritizing suppliers who adhere to sustainable manufacturing processes. This includes the use of recycled materials and certifications that validate eco-friendly practices.

For B2B buyers, understanding the certifications associated with 304 stainless steel is essential. Certifications like ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) can provide assurance that suppliers are committed to sustainability. Furthermore, suppliers that can demonstrate reduced carbon footprints or utilize renewable energy sources in their production processes will have a competitive advantage. This trend not only caters to the growing consumer preference for sustainable products but also aligns with regulatory requirements in many European and Middle Eastern markets.

How Has the 304 Stainless Machinability Sector Evolved Over Time?

The machinability of 304 stainless steel has evolved significantly over the past few decades, driven by technological advancements and increasing demand for high-performance materials. Initially, the machining of stainless steel was fraught with challenges due to its high hardness and tendency to work-harden. However, the development of specialized tooling and cutting strategies, such as the use of carbide and TiAlN-coated tools, has improved machining efficiency and tool life.

Moreover, the introduction of advanced CNC machining technologies has allowed for more precise and efficient machining of 304 stainless steel. These innovations have enabled manufacturers to meet the rising standards for quality and precision in various applications, from aerospace components to medical devices. As global markets continue to expand, the evolution of 304 stainless machinability will be closely tied to ongoing technological advancements and the increasing demand for sustainable practices in manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of 304 stainless machinability

-

How do I solve issues with machining 304 stainless steel?

To effectively solve machining issues with 304 stainless steel, it’s essential to optimize your tooling and settings. Use high-speed steel (HSS) or carbide tools with appropriate coatings such as TiN or TiAlN for better heat resistance. Adjust your feed rates and spindle speeds; for instance, aim for a surface speed of around 250-300 SFM and a feed rate of 0.0015″ to 0.002″ per tooth to enhance tool life. Additionally, ensure adequate cooling with flood coolant to mitigate heat buildup, which can lead to tool failure. -

What is the best tooling for machining 304 stainless steel?

The best tooling for machining 304 stainless steel typically includes carbide end mills or drills, particularly those coated with TiAlN or TiN. These coatings enhance wear resistance and allow for higher cutting speeds. For roughing operations, consider using tools with fewer flutes to improve chip removal. For finishing, a higher flute count can provide better surface finishes. Always select tools that match your specific machining requirements and consider the part geometry and tolerance levels. -

What are the common applications for 304 stainless steel?

304 stainless steel is widely used in various industries due to its excellent corrosion resistance and mechanical properties. Common applications include kitchen equipment, food processing equipment, chemical containers, and architectural elements. Additionally, it is frequently used in the aerospace and automotive sectors for components requiring high strength and durability. Understanding the specific application can help in choosing the right machining processes and tools. -

How can I verify the quality of 304 stainless steel from suppliers?

To ensure the quality of 304 stainless steel, request material certifications, such as the ASTM standards. Conduct visual inspections for surface defects and consistency in finish. If possible, utilize non-destructive testing methods, like ultrasonic testing, to check for internal flaws. Establish a reliable quality assurance process with your supplier, including periodic audits and sampling of materials, to ensure compliance with your specifications. -

What are the typical minimum order quantities (MOQ) for 304 stainless steel?

Minimum order quantities for 304 stainless steel can vary significantly based on the supplier and the form of the material (sheets, bars, etc.). Generally, MOQs range from 500 kg to 1,000 kg for bulk orders. However, many suppliers may offer flexibility for smaller orders, especially for custom machining services. It’s advisable to discuss your specific needs with suppliers to find options that best suit your project requirements. -

What payment terms are commonly offered by suppliers of 304 stainless steel?

Payment terms vary by supplier but typically include options such as net 30, net 60, or payment upon delivery. Some suppliers may require a deposit upfront, especially for custom orders or large quantities. When negotiating terms, consider international factors such as currency conversion and transaction fees. Establishing clear payment terms in your contract helps avoid misunderstandings and ensures a smooth transaction process. -

How do I manage logistics when sourcing 304 stainless steel internationally?

Effective logistics management involves coordinating with freight forwarders to handle shipping and customs clearance. Ensure that your supplier provides the necessary documentation, including invoices and certificates of origin. Familiarize yourself with import regulations in your country, as these can affect delivery times and costs. Consider shipping methods that balance cost and speed, and factor in lead times when planning your project timelines. -

What should I consider when vetting suppliers for 304 stainless steel?

When vetting suppliers for 304 stainless steel, assess their reputation in the industry by reviewing customer testimonials and case studies. Verify their certifications and compliance with international standards. Check their production capabilities and lead times to ensure they can meet your demands. Additionally, consider their communication responsiveness and willingness to provide technical support, as these factors are crucial for a successful long-term partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 304 Stainless Machinability Manufacturers & Suppliers List

1. Reddit – 304 Stainless Steel Machining Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 304 stainless steel is known for its work hardening properties, requiring careful machining with sufficient coolant, sharp tools, and good chip evacuation. It is commonly used in machining but is considered more challenging than other steels like 12L14 or 316 stainless.

2. Practical Machinist – 304 Stainless Steel TIALN Coated Tools

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 304 Stainless Steel, TIALN coated tools, carbide endmills, 7 flute bit, .5″ diameter, FPT .005, 120 IPM, 5400 RPM, 700 SFM, Stepover .025, DOC .5″.

3. Pentaprecision – Stainless Steel 304/304L Machined Parts

Domain: pentaprecision.co.uk

Registered: 2006 (19 years)

Introduction: Product: Stainless Steel 304/304L Machined Parts

Key Attributes:

– Most widely used stainless steel globally

– Excellent corrosion resistance

– Good balance of strength and workability

– Very good value for money

– 304L offers improved resistance to pitting and crevice corrosion in chloride environments

Common Applications:

– Kitchen & food processing equipment

– Buildings & décor

– Tanks & cont…

4. Clinton Aluminum – Key Stainless Steel Grades for Machining

Domain: clintonaluminum.com

Registered: 2000 (25 years)

Introduction: Key stainless steel grades for machining include:

1. **304 Stainless Steel**:

– Composition: 18% chromium, 8% nickel (also known as 18/8 stainless steel)

– Machinability rating: 48%

– Widely used but not well-suited for machining.

2. **303 Stainless Steel**:

– Enhanced with sulfur for improved machinability.

– Machinability rating: 75%

– Known as “free-machining” stainless ste…

5. Hobby Machinist – Stainless Steel Machining Guide

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Machining stainless steel 304 vs 316: 304 is harder and work-hardens more quickly if heat is not controlled. 316 is preferred for better anti-corrosion properties, especially in marine applications. Machinability ratings: 316 (60), 304 (70). 303 stainless is more machining-friendly but not ideal for welding due to sulfur content. For internal M12 threads, a sharp HSS tap is recommended. 308L weldi…

Strategic Sourcing Conclusion and Outlook for 304 stainless machinability

In conclusion, understanding the machinability of 304 stainless steel is crucial for international B2B buyers seeking reliable and efficient sourcing solutions. The unique properties of 304 stainless steel, including its excellent corrosion resistance and high strength, make it a preferred choice across various industries. However, successful machining of this material requires an informed approach—utilizing the right tooling, optimal cutting speeds, and appropriate coolant strategies is essential to avoid common pitfalls such as tool wear and overheating.

Strategic sourcing not only ensures access to high-quality materials but also fosters partnerships with suppliers who can provide valuable insights and support throughout the machining process. As global markets continue to evolve, staying ahead of trends in stainless steel machining can provide a competitive advantage, particularly for businesses in Africa, South America, the Middle East, and Europe.

Moving forward, it is imperative for buyers to engage with experienced suppliers who can navigate the complexities of 304 stainless steel machining. By investing in strategic partnerships and leveraging best practices, companies can enhance their operational efficiency and product quality. Embrace this opportunity to refine your sourcing strategy and connect with industry leaders who can help propel your business to new heights.